V-BRACKET 45°

V-Bracket with 45°

This model is identical to the normal V-Bracket, except that the closed angle is 45° instead of 60°. So if you don’t want to build an pointed triangle, grab it and save money!

213,00 € Original price was: 213,00 €.149,00 €Current price is: 149,00 €.

incl. VAT plus shipping

In stock

In stock

| ✓ Made in Germany | ✓ 5 Years Warranty | ✓ 30 Days Return |

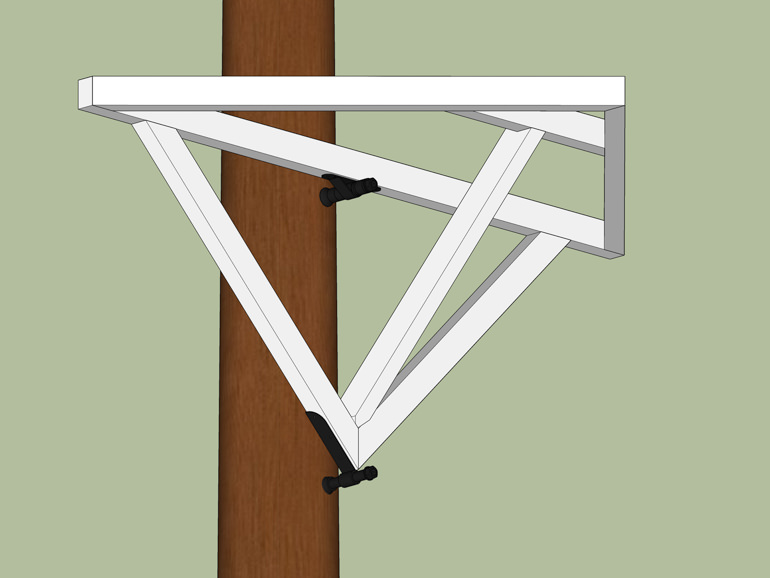

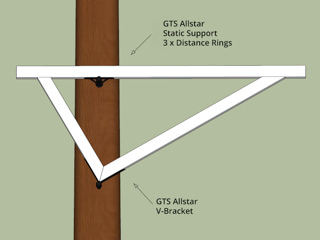

Support your platform safely on triangles

The field of application of the V-Bracket 45° is small to medium-sized platforms. Depending on the GTS used (GTS Allstar, Top or Friend), large triangles can also be built and very large loads can be safely supported. The advantage of the V-Bracket over the rigid Diamond-Bracket is that you can also build platforms that cantilever on one side. In addition, you are more flexible if branches are in the way or you want to build very close to the ground. You can also build 3D struts with the V-Bracket, but the Diamond-Bracket with its rigid back is even more stable.

V-Bracked Closed

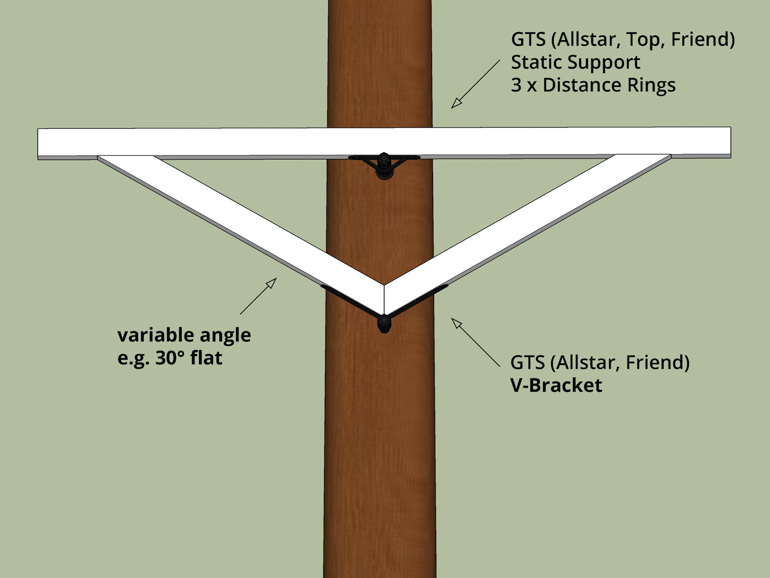

45° Universal

The classic angle for triangular braces is 45°, here the loads are evenly distributed and the angle cuts are simple.

V-Bracket Opened

The flat triangle

You need flat angles either to avoid branches or if your triangle is built just above the ground and you have no other space. But beware, with very shallow angles, the lower GTS Screw is heavily loaded laterally and the load capacity is lower.

Overhanging on one side

Cantilevered platforms

You can also open the triangle on one side to build cantilevered platforms. Again, make sure that the leverage is not too great, build lightly and avoid twisting around the trunk.

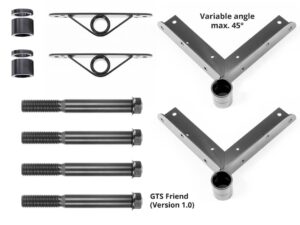

What is delivered?

1 × V-Bracket 45° (consists of 2 parts)

Product Details

- Variable angle (max. 45° closed) gives freedom in designing the triangle

- Chamfered screw holes guarantee optimum fastening of the wooden beams:

- 5 x ø 8.5 mm for wood screws

- 1 x ø 13.5 mm for hexagonal or carriage bolt screw

Compatible with:

Technical Data

-

- Certified DIN quality steel

- Black KTL coating

- Weight: 2930 g (6,46 lbs)

- Sheet thickness: 4 mm (0,04 in)

- Outer dimensions single part: l= 355 mm; b=70 mm; h=70 mm

- Height triangle over axis of GTS: 29 mm

- Article-No.: TTS2004-45

- HS-Code (Customs): 73089059

Dimensions:

-

- lring = 70 mm (2,76 in)

- wsheet= 70 × 70 mm

- lsheet = 300 mm (11,8 in; outer edge to ring)

- øsmall holes = 8,5 mm (3,35 in)

- ølarge holes = 13,5 mm (5,31 in)

Assembly

Attention: The 2 parts of the V-bracket must always be used together. NEVER fix individual struts with the individual parts, otherwise the steel sheet may break!

This is how it works:

- Two GTS bolts are installed on top of each other, with a distance of 1.3 to 2.5 m (4 – 8 ft). The cross beam is fixed to the upper one by Static Support

- To prevent it from tipping, the cross beam is braced with the underlying GTS and the V-Bracket – a stable triangular construction.

Installation Instruction

Assembly Video

YouTube Tutorial

Shipping Service

Hardware Info

Frequently Asked Questions

When to use V-Bracket and when to use 45°-Diamond-Bracket?

The V-Bracket is more suitable for light and medium-weight treehouses that cantilever out to the side.

In contrast to the 45°-Diamond-Bracket, the angle of the V-bracket is freely adjustable: from 60° acute to completely open. This has the advantage that you can avoid interfering branches and have more leeway in the design of the platform (eccentric platforms).

The V-Bracket can also be used to build heavy 3D triangular constructions, but these are somewhat more difficult and unstable due to the lack of a continuous back wall.

Working with different angles makes the dimensioning and cutting of the timbers somewhat more challenging.

How do the triangles remain movable with 2 trees?

Both the supports on the GTS shaft and the triangle and the platform connected to it have a certain amount of play by nature and can easily buffer slight movements.

Ideally, both trees have a trunk diameter ø > 45 cm (18 in) at the height of the platform and hardly move, then no further measures are necessary.

If the trees are somewhat thinner and move only slightly during storms, one of the triangles can be mounted without spacer rings to have a little more leeway.

If it is to be expected that the trees will sway strongly, the triangles must be decoupled to avoid damage to the construction! Above all, it is important that the tree bolts are not jerked back and forth. Decoupling is done constructively by slidingly supporting the platform beams on the triangle, e.g. with our Sliding Plates.

Which GTS are best to use?

Depending on the load situation, the GTS Allstar, Top or Friend can be installed. The top bolt with the Static Support is usually the larger one, as it takes more load. The lower GTS also takes a lot of load, but is mainly important for lateral stabilisation.

If the log is ø >35 cm (14 in) at the height of the platform, at least one GTS Allstar should always be used. The long rod of the Allstar gives leeway if the tree is tilted forward or backward.

How thick do the wooden beams and struts have to be?

- Always use beams made of solid structural timber (larch, Douglas fir, cedar, …) in outdoor areas.

- Width of the beams: 6 – 12 cm (2,4 – 4,7 in)

- Height of the beams: 8 – 20 cm (3,1 – 7,9 in)

- The beams are installed upright / on edge.

- Make sure that there are no large knotholes or cracks in the beam.

The exact dimensions of the beams depend on the:

- Load (light children’s playhouse or heavy insulated tree hotel?).

- The greater the load, the thicker the wooden beams must be.

- The larger the triangle, the thicker the beams must be.

You can find out more about building the triangle in our Assembly Instructions.