Step 4: Calculate treehouse size & weight

Building a safe treehouse – it's not that hard:

✔ Healthy trees with a trunk diameter of 30 cm or more are suitable for treehouses

✔ Crucial: the load capacity of the fastenings on the tree

✔ Simple rules of thumb for estimating the weight of a treehouse

✔ Real-life examples & professional tips included!

1. Can the tree support a treehouse?

A healthy, well-rooted tree with a diameter of 30 cm (11.8 in) or more can easily support the weight of a treehouse. The actual factors that limit the maximum size and weight of a treehouse are:

- the fastening technology and its maximum load capacity

- the tree species, i.e. the strength of the wood at the fastening points (hardwood or softwood)

- the trunk diameter, which determines how many fastenings are possible

‘Living wood’ has an average compressive strength in the grain direction of approx. 2.0 kN/cm² or 200 kg/cm² with deviations of up to approx. 0.50%; properties of fresh wood. A round, straight tree trunk with a diameter of 30 cm (11.8 in) can theoretically bear a load of 707 cm² × 200 kg = 141 tonnes.

Even in practical structural analysis calculations (e.g. according to Eurocode, C16 for outdoor use), a wooden post 3 m long and with a cross-section of 30 × 30 cm can still bear approx. 7 tonnes – with large safety factors.

The load capacity of the trunk is therefore more than sufficient, regardless of the tree species and any deviations.

Trees can bear enormous loads via their trunks and roots – a treehouse weighing a few tonnes is no problem. The load capacity of the individual attachment points is crucial.

2. What is the weight of a treehouse?

In order to know how much weight each fastening will have to bear, we first need to calculate the weight of the treehouse.

The maximum total load of the treehouse The maximum total load simulates the very unlikely, absolute extreme case! is made up of:

- Dead load (platform + treehouse)

- Live load (people and furniture)

- Snow & wind load

net weight

Total of all permanently installed elements: Treehouse + platform + support structure + windows + screws, ...

Maximum traffic load

Total number of movable items: people + animals + furniture

snow load

Snow load in the region where the treehouse is located.

wind load

Should be on your radar, but is not included in this rule of thumb.

FASTENING TO THE TREE

The fastenings must safely transfer the total load to the tree trunk.

Practical example: treehouse – the sum of all loads

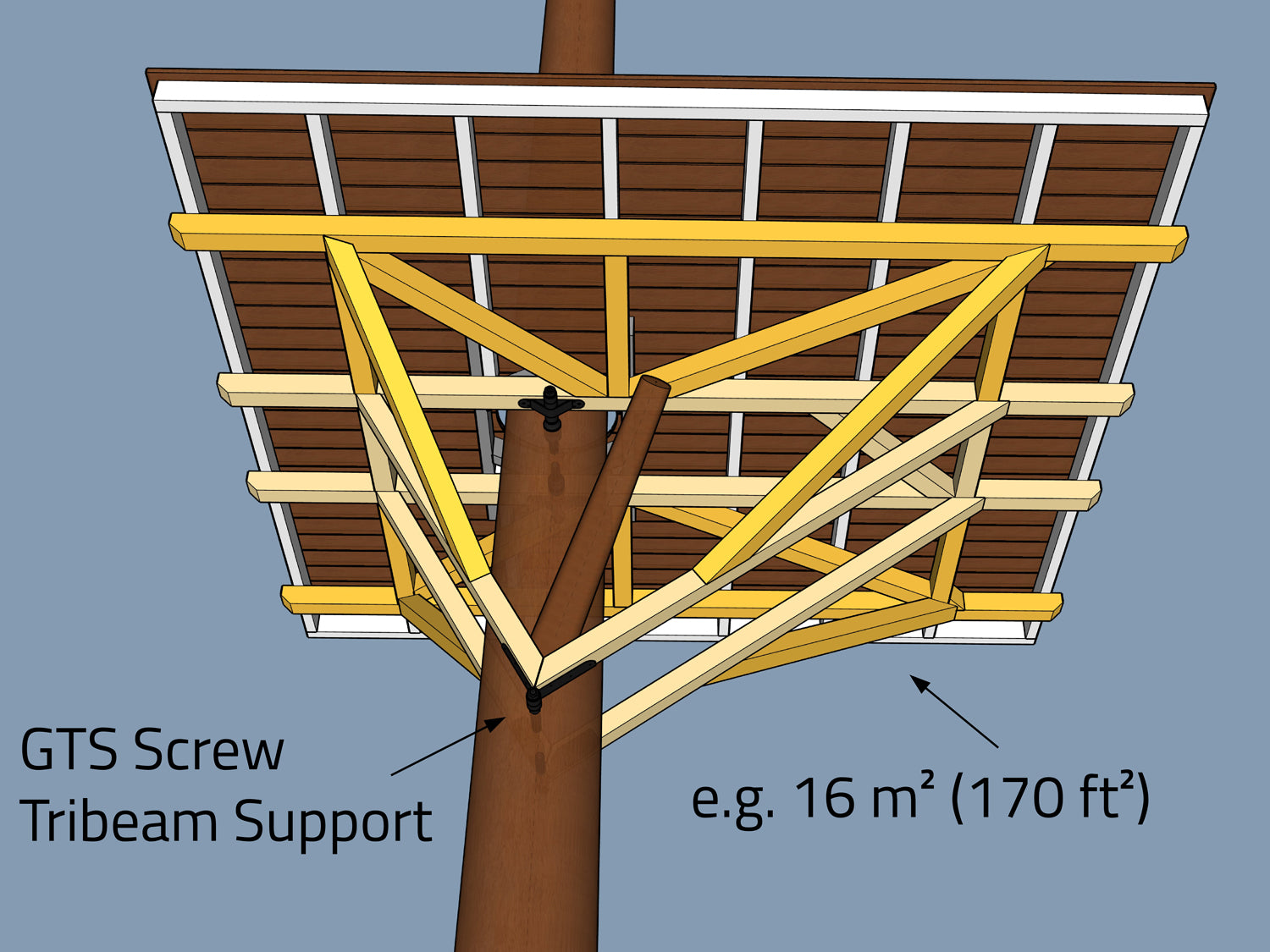

All loads (dead weight, live load, snow load and wind load) together make up the maximum total weight of the treehouse. This weight must be distributed as evenly as possible across the individual fastening points (e.g. GTS Tree Bolts).

For example, the treehouse shown here has a maximum weight of 8,000 kg, which is distributed across 4 GTS Tree Bolts. Roughly speaking, each GTS Tree Bolt must therefore have a load capacity of 8,000 kg / 4 = 2,000 kg per GTS in extreme cases!

Self-weight – total weight of materials

The self-weight is the total weight of the materials used to build the platform and treehouse: timber, windows, doors, insulation, screws, etc.

👉 Self-weight = (platform load × platform area [m²] ) + (treehouse load × treehouse area [m²] )

Here are a few examples with guidelines for a platform + single-storey treehouse:

platform

✔ Support Structure

✔ Floor Joists

✔ Decking Boards

✔ Railings

Approx. 30 kg / m²

Simple children's playhouse

✔ Floor plan < 10 m² (107,6 ft²)

✔ Very lightweight construction

✔ Uninsulated

✔ For playing in summer

Approx.80 kg/m²

Habitable treehouse

✔ Floor plan House 10 - 25 m² (269 ft²)

✔ Stable construction

✔ High-quality roofing

✔ Double glazing

Approx. 130 kg / m²

luxury treehouse

✔ Floor plan House 20 - 40 m² (430 ft²)

✔ Solid construction

✔ Large windows

✔ High-quality interior finish

Approx. 150 kg / m²

Traffic load – additional weight due to use

The live load (payload) is calculated from the maximum number of people plus furniture – and it has a major impact on the total load!

Imagine it's a birthday party and all the guests are crowding onto one side of the treehouse for a photo: ‘On the count of three, everyone jump!’

It rarely happens, but we calculate for maximum loads. So: It is better to calculate generously!

Simple children's playhouse

✔ Mainly for small children

✔ Small, lightweight furniture

Approx. 50 kg/m²

Habitable treehouse

✔ Suitable for many adults

✔ Lightweight furniture

Approx. 100 kg/m²

luxury treehouse

✔ Suitable for many adults

✔ Solid interior construction

Approx. 120 kg/m²

Snow load – weight of wet snow

Where is your treehouse located – and how high is the snow load there? You can find this out at your local building authority or online using your postcode... If your garden regularly has more than 10 cm of wet snow, you should definitely take this into account.

Wind load – Extreme weather & squalls

If the treehouse is located in a stormy or exposed area, this must be taken into account. The walls of the treehouse are like a sail in the wind:

✔ Pay attention to the prevailing wind direction and make sure that the treehouse offers as little surface area as possible for the wind to catch.

✔ The closer the treehouse is to the ground, the lower the wind load.

✔ The treehouse must not protrude too asymmetrically. It must not be able to turn in the wind.

✔ Avoid lever arms and do not build in crooked trees.

3. Examples – calculations using the rule of thumb

Total load = self-weight + payload + snow load

✅ With our guidelines calculated above, this total value is 100% accurate for all normal DIY treehouse projects.

Rule of thumb + extra safety factors

Total load = 1.35 x dead load + 1.5 x live load + snow load

For unusual constructions with high loads or special requirements, use the rule of thumb with extra safety factors!

✅ Public projects where large crowds are expected

✅ Very large & heavy constructions (> 40 m²)

✅ Highly asymmetrical designs that create uneven loads

✅ Extreme weather conditions (e.g. earthquakes, hurricanes, snow depths > 1 m)

Safety first – if in doubt, always consult a structural engineer and tree expert!

load distribution

Not all fastenings are always subjected to the same load!

In the event of uneven load distribution (e.g. if the platform protrudes further on one side), you should distribute the total load realistically.

An example:

- 40% of the load on the ‘lighter, green side’

- 60% of the load on the ‘heavier, yellow side’

This ensures that each fastening bears the correct load and your treehouse remains stable.

Important note!

These formulas are not guaranteed and are only intended for rough planning and initial assessment. For large or public projects with liability risks, we strongly recommend consulting a structural engineer and tree expert!

TheTreehouse.Shop and Vitus Wahlländer accept no liability for the accuracy of the information provided.

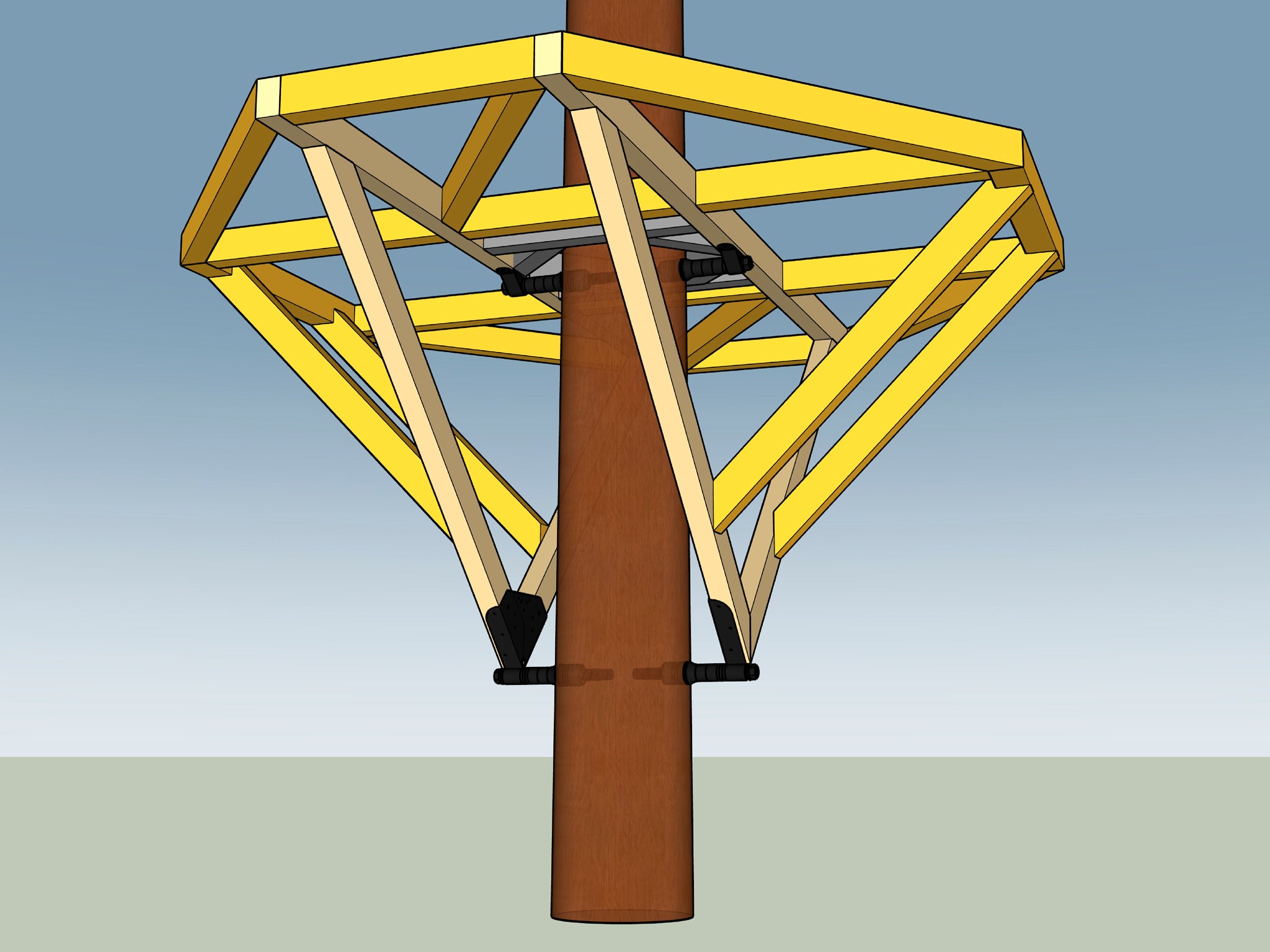

Practical examples from our customers – The right treehouse fastening

Click on the coloured dots in the images to see the individual loads.

Our goal: to understand how the calculated total load affects the treehouse fastenings. This will help us determine how many tree bolts are needed and which GTS model is right for your project!

Example 1: Platform without house

Platform dead weight 12 m²

12 m² x 30 kg/m² = 360 kg

Maximum traffic load

Adults (without furniture): 80 kg/m²

12 m² x 80 kg/m² = 960 kg

snow load

Maximum 20 cm (7.9 in) wet snow: 2 x 40 kg/m²

12 m² (131 ft²) x 80 kg/m² = 960 kg

Load per fastening (4 GTS Screws)

✅ 2280 kg x 4 = 570 kg / GTS

Example 1: Small 12 m² platform without treehouse in solid oak

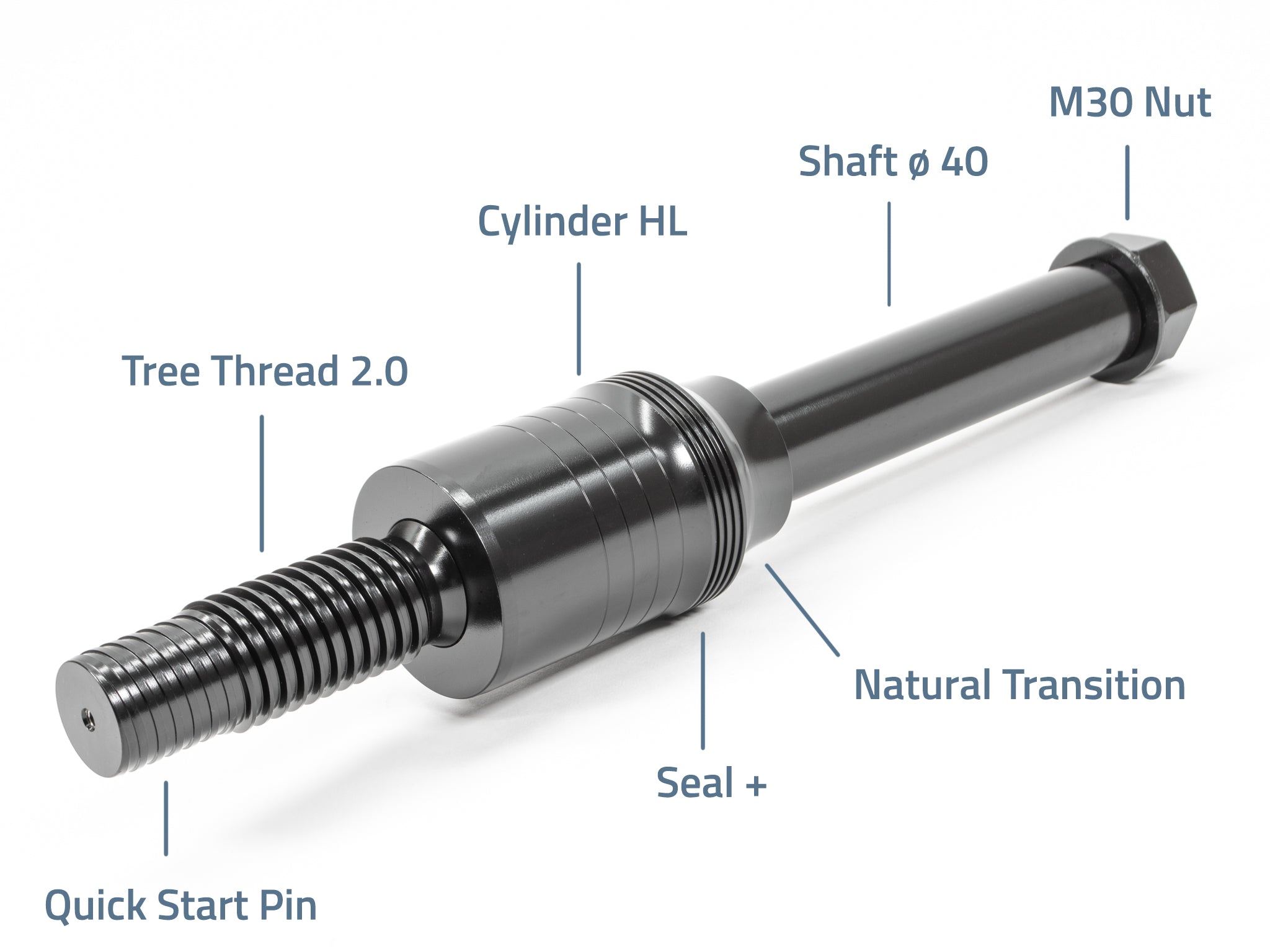

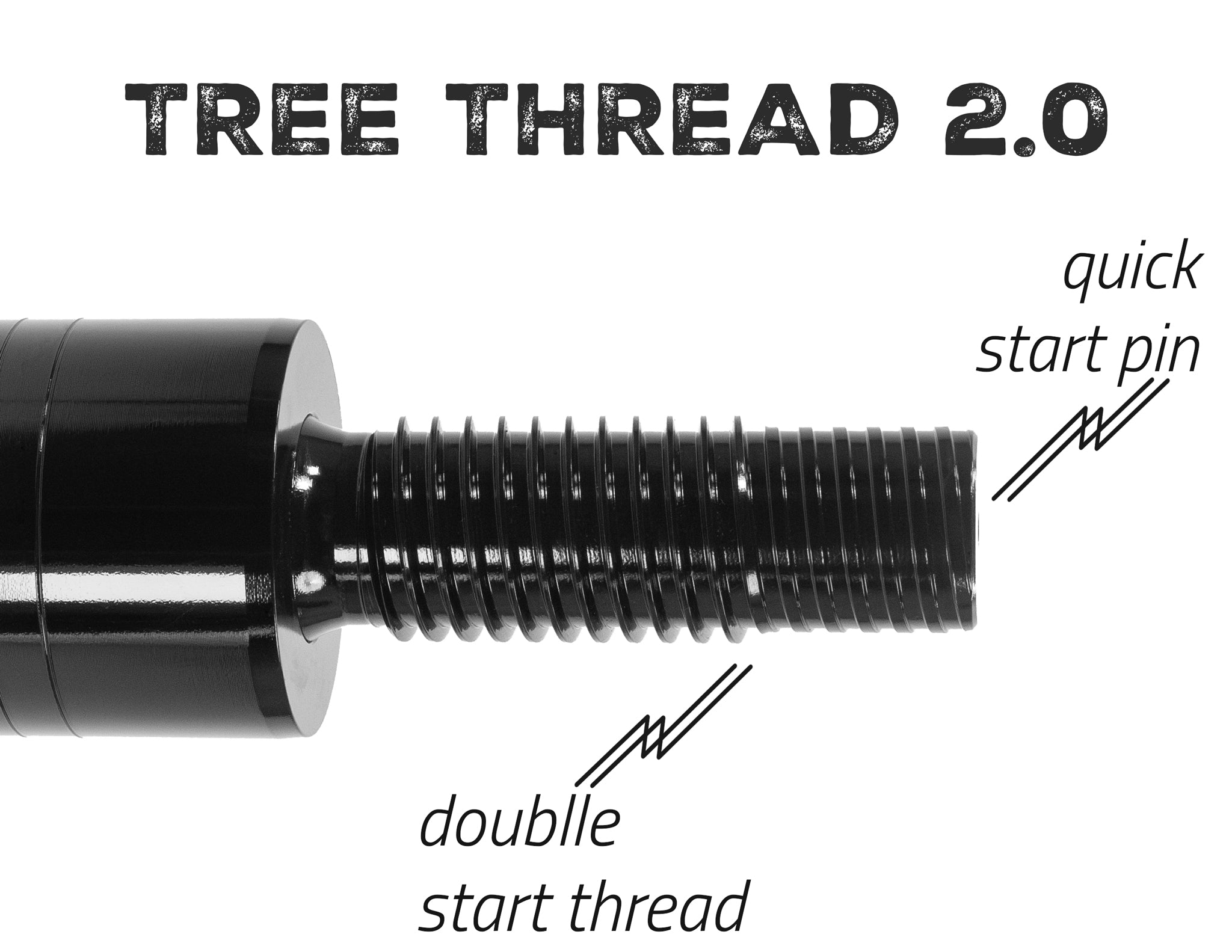

Although 4 GTS Friends would be sufficient for a load of 570 kg / GTS, the GTS Allstar is clearly the better choice here.

That's why we recommend the XL kit:

✔ For tree trunks > 35 cm, we always recommend the GTS Allstar.

✔ The longer shaft allows the wooden beams to be mounted further apart, allowing the tree to continue growing undisturbed.

✔ 100% safety and design freedom for your treehouse project.

XL Treehouse Hardware Kit for 1-2 Trees, Tribeam D90

Tax included. Shipping calculated at checkout

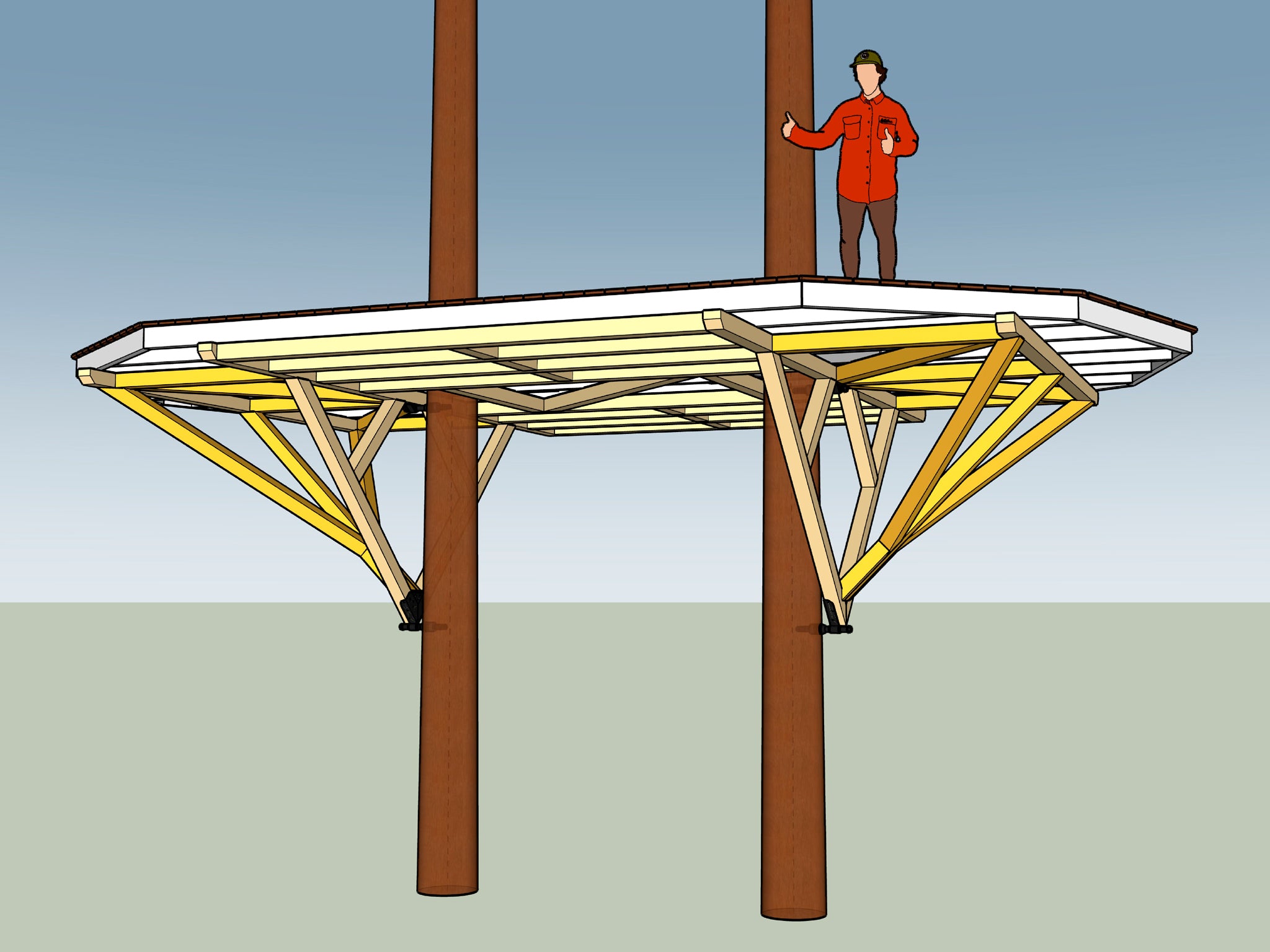

Example 2: Habitable house

Dead weight platform 20 m²

20 m² x 30 kg/m² = 600 kg

Dead weight treehouse 12 m²

Habitable treehouse: 12 x 130 kg/m²

12 m² x 130 kg/m² = 1560 kg

Maximum traffic load

Many adults: 100 kg/m²

20 m² x 100 kg/m² = 2000 kg

Load per fastening (4 GTS Screws)

✅ 4160 kg / 4 = 1040 kg / GTS

Example 2: Standard treehouse on a 20 m² platform in oak

Here, the treehouse is not centred, but protrudes to the side. This means that the loads are uneven and exert greater force on the tree bolts at the sides.

That is why we use 4 x GTS Allstar tree bolts:

✔ For loads over 500 kg / GTS, the GTS Allstar is the only option – not the GTS Friend!

✔ Only the GTS Allstar can safely absorb lateral loads thanks to its thick cylinder.

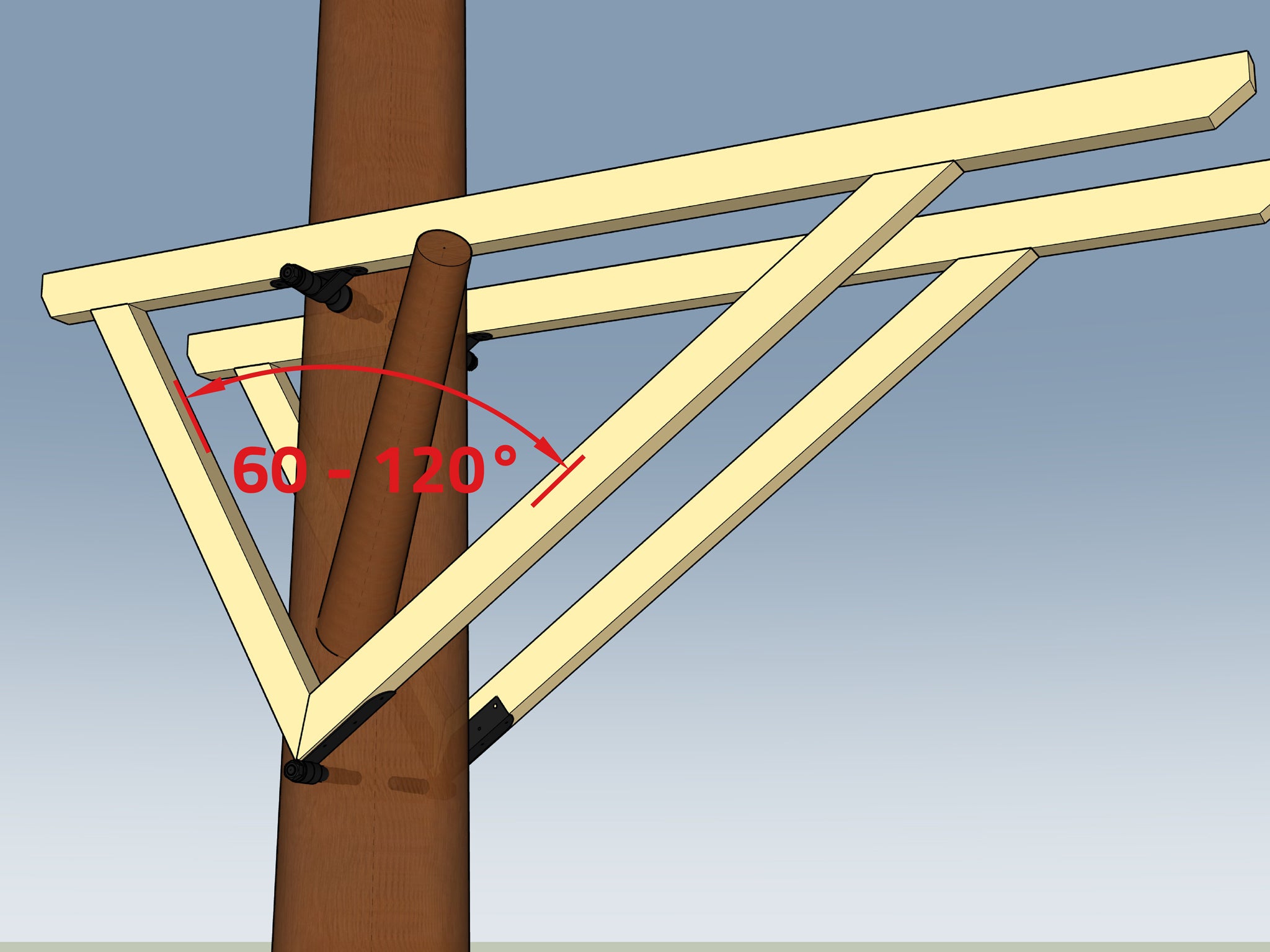

✔ A Tribeam Bracket with variable angle is used here – this allows thick branches to be elegantly bypassed.

L Treehouse Hardware Kit for 1-2 Trees, Tribeam V60

Tax included. Shipping calculated at checkout

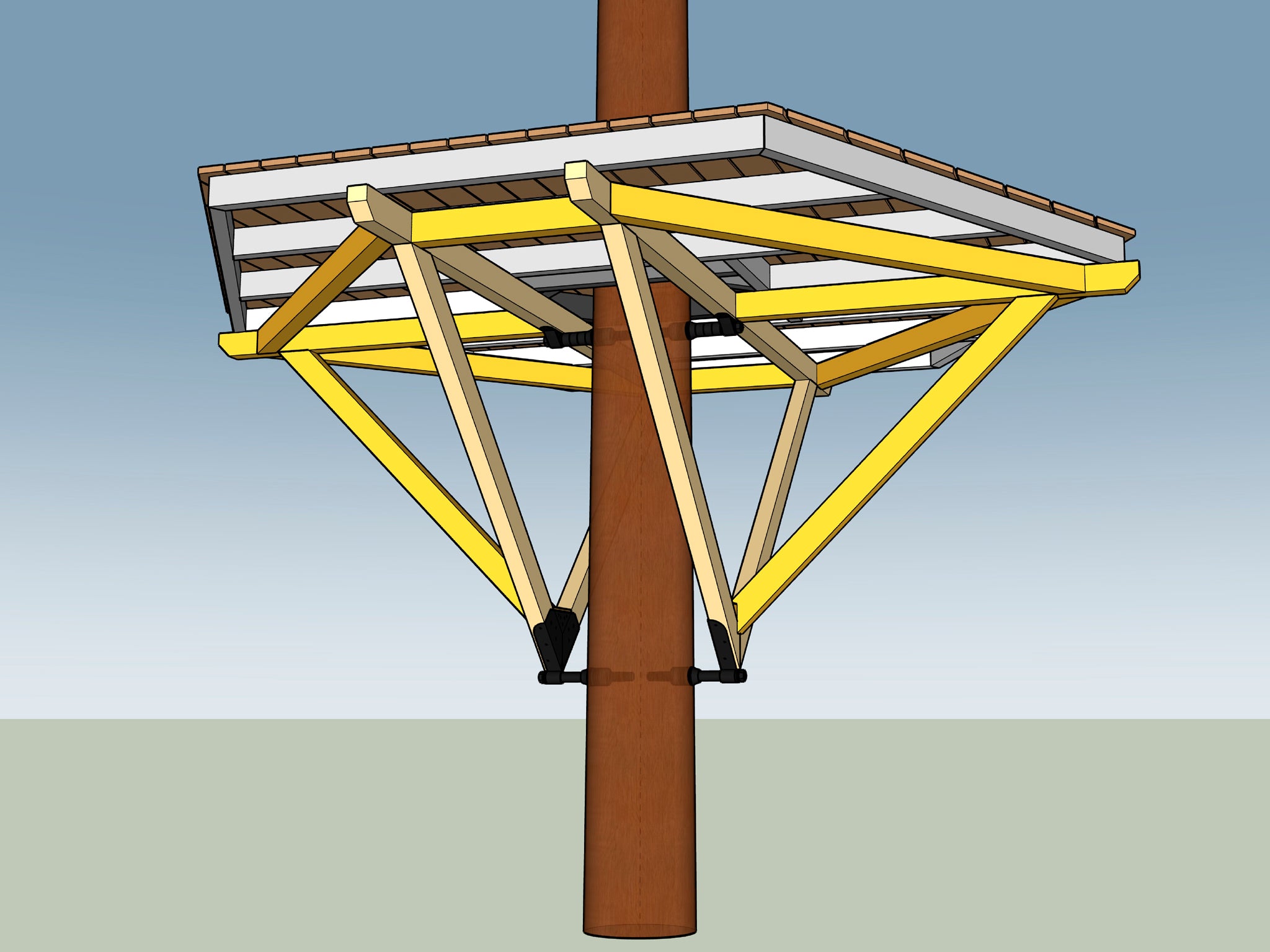

Example 3: Heavy luxury treehouse

Dead weight platform 40 m² (430 ft²)

40 m² x 30 kg/m² = 1200 kg

Dead weight treehouse 40 m² (430 ft²)

Luxury treehouse: 40 x 150 kg/m²

40 m² x 150 kg/m² = 6000 kg

Maximum traffic load

Many adults: 120 kg/m²

40 m² (430 ft²) x 120 kg/m² = 4800 kg

Load per fastening (6 GTS Screws)

✅ 12000 kg / 6 = 2000 kg / GTS

Example 3: Heavy luxury treehouse with a 40 m² (430 ft²) platform in a crooked oak tree

This treehouse is the maximum that this oak tree should bear. The solid construction, luxurious interior fittings (shower, toilet, sofa, etc.) and large number of people in the treehouse hotel result in a total load of 12,000 kg.

Maximum treehouse weight – still securely fastened:

✔ To safely support these extreme loads, 6 x GTS Allstar are required – each with a load capacity of 2,000 kg.

✔ In hard oak wood, the GTS Allstar can reliably hold this load.

✔ Better safe than sorry: Despite stable fastening, the traffic load and number of people in the treehouse should be limited to 10 people to avoid overload.

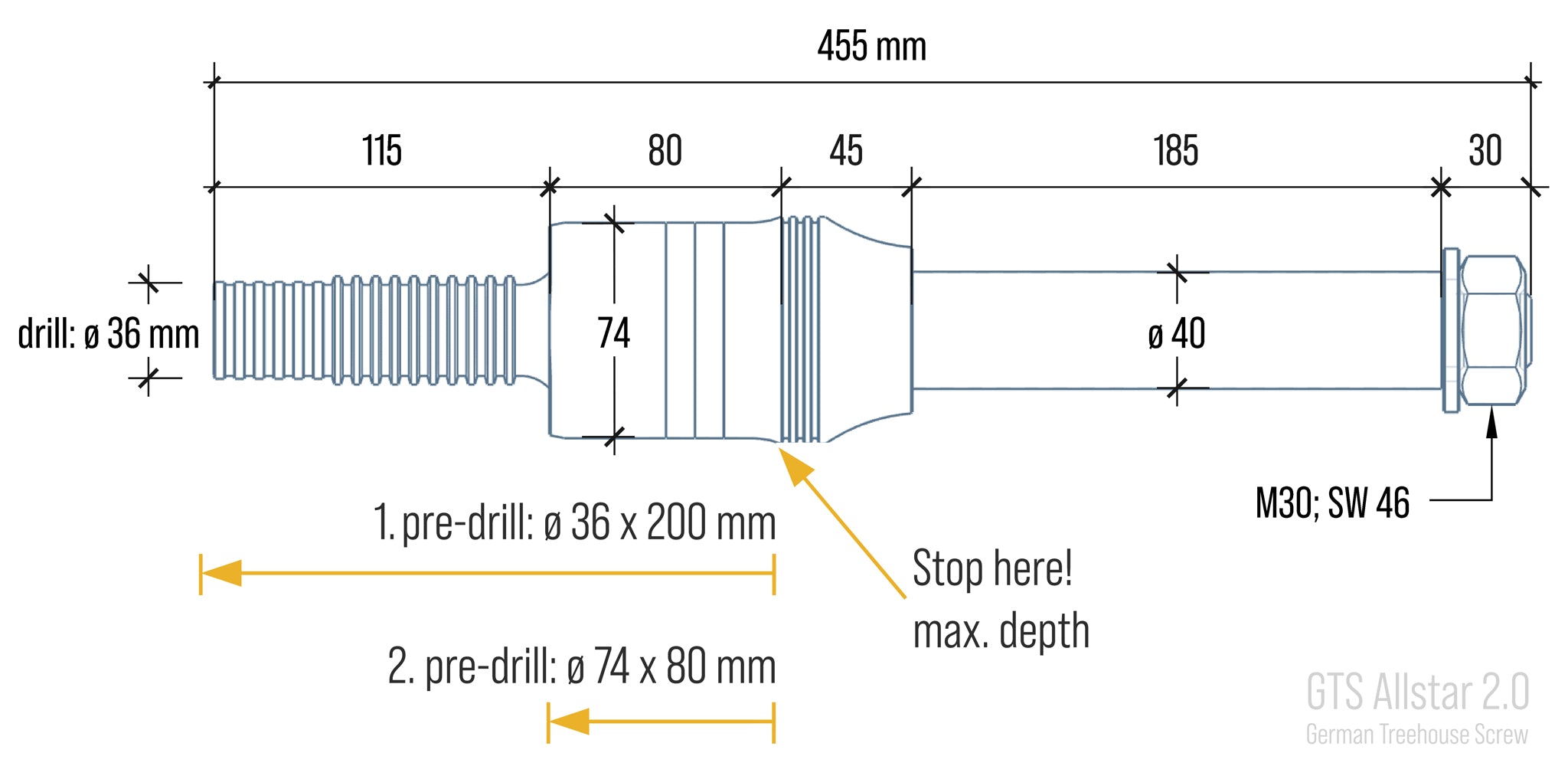

GTS Allstar – Tree bolt up to 3,800 kg load

4. Practical tips & solutions for maximum load

Example 3 - The luxury treehouse at the Bockhop Treehouse Hostel is a prime example of the maximum dimensions of a treehouse:

- Even from a purely visual perspective, the treehouse appears to be borderline too large for the tree.

- The calculated load per GTS Allstar is quite high at 2 tonnes.

- This is a publicly accessible building that is rented out as a tree house hotel, which means that nothing can go wrong here due to liability for personal injury.

4. Practical tips & solutions for maximum load

Example 3 - The luxury treehouse at the Bockhop Treehouse Hostel is a prime example of the maximum dimensions of a treehouse:

- Even from a purely visual perspective, the treehouse appears to be borderline too large for the tree.

- The calculated load per GTS Allstar is quite high at 2 tonnes.

- This is a publicly accessible building that is rented out as a tree house hotel, which means that nothing can go wrong here due to liability for personal injury.

In the upper load range of our GTS Screws, we recommend a more detailed check. The extreme load values from the formula mainly result from maximum traffic or snow loads – these are easy to manage in practice!

4 practical solutions for maximum loads

The calculations clearly show that the dead weight of the platform and treehouse is negligible compared to the live load and snow load – which is good, as we can easily handle both of these extreme loads:

Limit maximum number of persons

The traffic load of treehouses can be easily controlled – simply hang a sign at the entrance: ‘Maximum 10 people at a time!’

Be careful in extreme weather conditions

The risk of personal injury during storms and severe weather can also be easily avoided – for example, with signs such as: ‘No entry during storms and snow!’

Large amounts of snow

The snow load can be significantly reduced: in the event of heavy snowfall, simply shovel off the treehouse and nothing will come between you and romantic winter nights.

Reinforce Support Structure

For maximum safety, individual GTS Screws can be reinforced. Alternatively, heavily stressed parts can be relieved by adding struts or concreting in supports.