TREEHOUSE SCREW – GTS TOP

Big dreams in small trees

You want to build a treehouse for you and your children, but there are only small trees in your garden? No problem with our GTS TOP!

For straight trees ø 25 – 35 cm and mainly vertical load.

229,00 €

incl. VAT plus shipping

In stock

In stock

| ✓ Made in Germany | ✓ 50 Years Warranty | ✓ 30 Days Return |

The solution for small trees and thin trunks

Often there is no other way, you want to build a real treehouse, but the tree or one of the trees has a very thin trunk ø < 35 cm. Normally we always recommend the GTS Allstar, but the large hole for the cylinder would destroy too much tissue on such young trees. That's why we developed the GTS Top: instead of the thick cylinder, it has a narrow support plate that safely transfers even large vertical loads into the trunk.

Tree-Friendly

For thin trees

With the GTS Top, you can build a decent treehouse even in very young trees. Due to the additional steel plate, the Screw carries much more vertically than the smaller models GTS Friend and GTS Free. The trunk must have a diameter of ø > 25 cm (10 in) at the installation point.

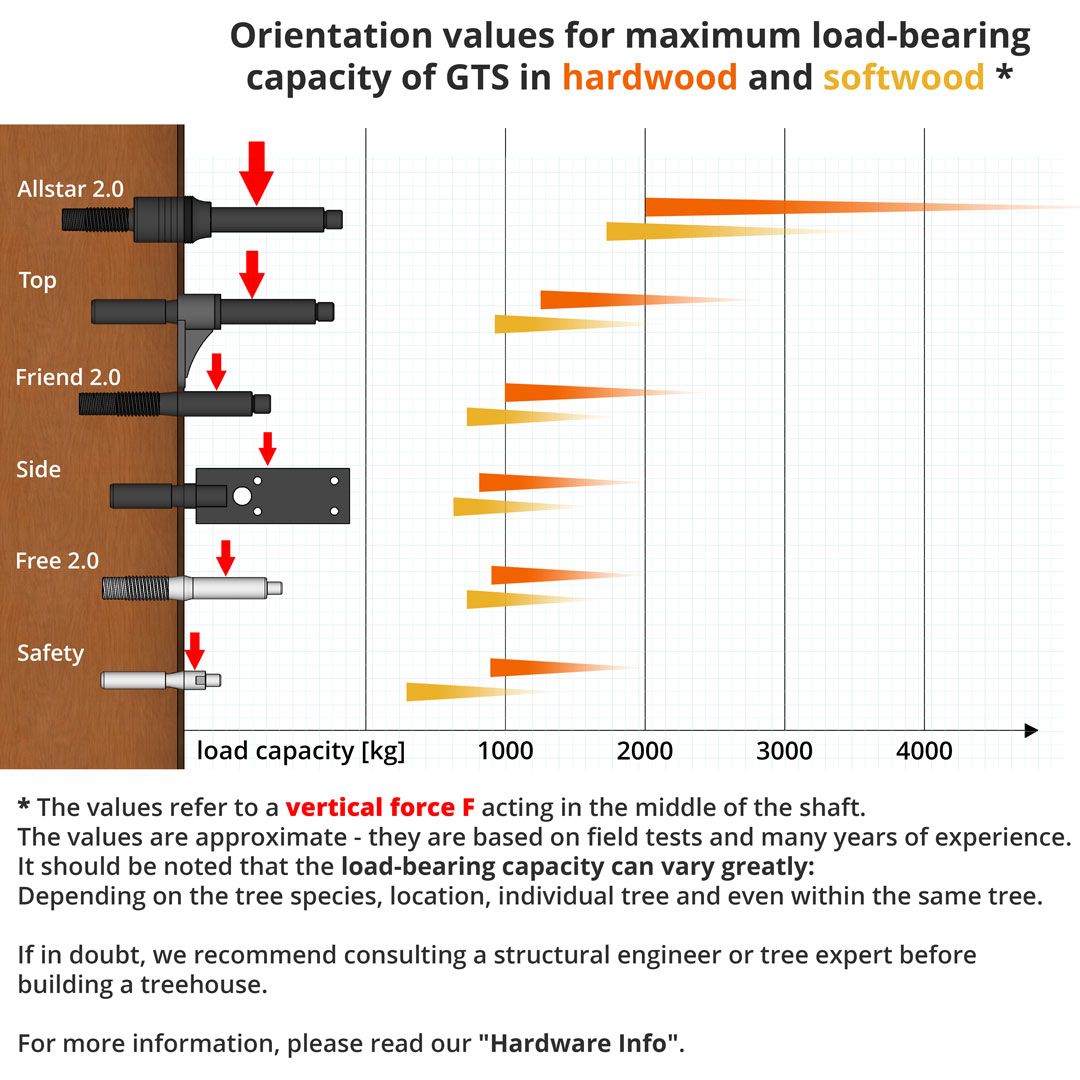

Load Capacity

For vertical loads

The GTS Top works particularly well in hardwood and with predominantly vertical loads.

Caution: In softwood (spruce, fir, pine) and with horizontal loads (lateral pulling and jerking), the load-bearing capacity is significantly lower! Here, as with all other GTS Screws, an additional reinforcement, e.g. the Cable Suspension, can be fitted.

Assembly

Smooth and Straight

To ensure that the steel plate fits neatly, the mounting surface must be smooth and straight! The bark is carefully removed with a chisel without damaging the cambium underneath. This allows the tree to grow over the Screw and integrate it like an artificial branch.

Click here for the installation video of the GTS Top.

What is delivered?

1 × GTS Top (incl. nut greased)

Product Details

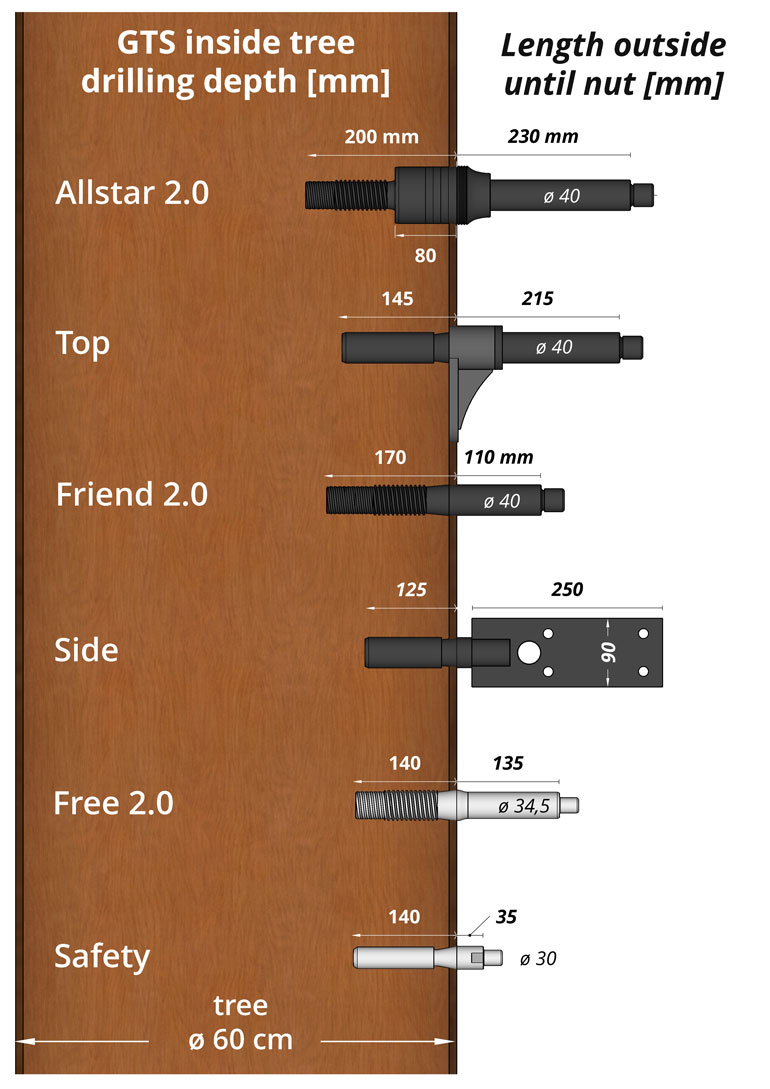

- Tree Thread ø40: Specially developed coarse thread for the tree guarantees high pull-out resistance (500 – 1000 kg = 1100 – 2200 lbs) & optimal force flow.

- Top-Plate: Additional support plate for higher vertical loads.

- Shaft 40: With a diameter of ø 40 mm, the shaft withstands even the highest alternating loads – peaceful sleep is guaranteed.

- Seamless: The shaft has no welds – the new steel alloy makes the screws indestructible!

- Black KTL Coating: The environmentally friendly coating process ensures optimum corrosion protection and excellent sliding properties. Due to the black appearance, the screw disappears inconspicuously in the tree.

Technical Data

- Certified DIN quality steel

- Special steel alloy (shaft not weldable)

- Shaft dimensions:

- ltotal = 395 mm (15,55 in)

- lthread = 140 mm (5,5 in)

- lshaft = 155 mm (6,1 in)

- øshaft = 40 mm (1,57 in)

- Dimensions steel plate:

- bplatte = 50 mm (1,97 in)

- hplatte = 152 mm (5,98 in)

- tBlech = 12 mm (0,47 in)

- øring = 57 mm (2,24 in)

- Weight: 4860 g (incl. nut)

- Article-No.: TTS1002

- HS-Code (Customs): 73181542

Assembly

- Pre-Drill (Auger-Bit ø 36 mm)

- Prepare Steel Plate (Cutter and chisel)

- Screw in GTS (Ratchet 1“ for Nut M30, SW46)

Installation Instruction

Asselbly Video

Shipping Service

Hardware Info

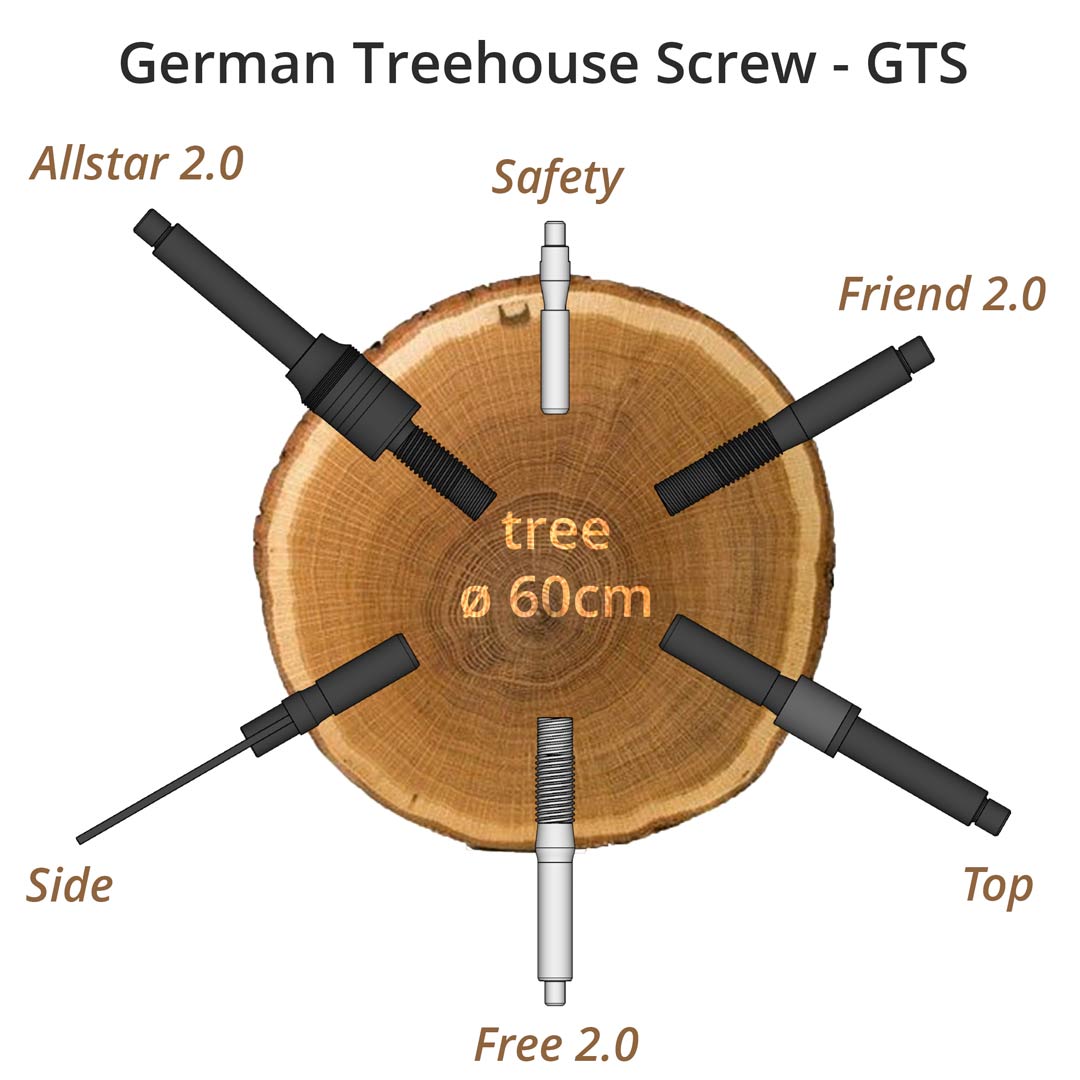

6 Treehouse Screws

Find the right Screw

Normally, we always recommend our GTS Allstar for large loads, as it has a strong vertical and horizontal load capacity thanks to the thick cylinder – this is particularly noticeable in softwood!

The GTS Allstar is therefore the first choice for all projects! Only if you have a log diameter of < 35 cm (14 in) or are building a very small platform, it makes sense to use one of the smaller GTS. Our product guide will help you!

Frequently Asked Questions

How to mount the GTS in the tree?

- Pre-drill the hole in the tree (Auger or Forstner bit).

- Screw in the screw (large ratchet).

- Push on the Support with the wooden beam.

- Done!

The tools are all available in our online shop. You can find detailed assembly videos on our YouTube channel.

Will my treehouse grow up with the tree?

Don’t worry, you don’t have to extend your ladder every year. Trees only sprout at the branch tips. The rest of the tree then only grows in width (thickness growth, annual rings). You can easily observe this by looking at the carvings on the trunk, they remain at the same height for the rest of the tree’s life – just like your treehouse.

Is my tree hardwood or softwood?

The decisive factor for anchoring the treehouse with Treehouse Screws is the compressive strength along the wood grain.

Hardwood (> 2.5 KN/cm²) – very suitable for Treehouse Bolts:

- Hardwoods: maple, beech, oak, ash, walnut, sycamore, robinia.

Medium hardwood (2 – 2.5 KN/cm²) – well suited for Treehouse Bolts:

- Hardwoods: birch, sweet chestnut, alder, cherry tree, lime tree

- Softwoods: Douglas fir, pine, larch, spruce, fir

Softwood (< 2 KN/cm²) – moderately suitable for high loads on Treehouse Bolts:

- Hardwoods: aspen, poplar, pear, horse chestnut, elm, willow

- Coniferous woods: cedar

IMPORTANT: These are only rough guide values – wood strength varies from tree to tree, from place to place and even within a tree! Wound healing and compartmentalisation also play an important role. You can find out how to analyse your treehouse-tree on this page: Which tree is suitable?

What is the difference between German Treehouse Screw, Garnier Limb & TAB?

Treehouse Screws or Treehouse Bolts are available from different manufacturers with different names:

- Garnier Limb GL (Michael Garnier, USA)

- Treehouse Attachment Bolt TAB (Pete Nelson, USA)

- German Treehouse Screw GTS (TheTreehouse.Shop, Germany)

All Treehouse Screws/Bolts function according to the same principle, differences exist in the manufacturing quality, the service (know-how, advice) and the associated price. The components of the different manufacturers cannot be combined with each other! The original treehouse bolts were developed over 20 years ago in the USA by treehouse pioneers Michael Garnier, Charles Greenwood and later Pete Nelson (TV series). TheTreehouse.Shop is the only manufacturer in Europe that works with metric measurements [mm]!

Our German Treehouse Screw (GTS) is the latest generation of treehouse screws. Our GTS are manufactured with the highest quality standards in Germany (near Munich) and shipped worldwide. Based on American models, our engineers have further perfected the Screw – our goal is to make treehouse construction even safer and assembly as easy as possible!