Step 8: German Treehouse Screw GTS

GTS Tree Bolts – Professional-grade fasteners:

✔ Special screw for anchoring heavy constructions to living trees

✔ Extremely high load capacity – up to 4 tonnes

✔ Keeps beams at a distance – trees have room to grow

✔ Ideal for long-term projects over 3 years

✔ More tree-friendly in the long term than conventional fastenings

✔ Proven technology for over 30 years

1. Advantages & application of GTS tree bolts

Especially for living trees

Tree Bolts – also known as TAB, Garnier Limb or Tree Fastener – are the most advanced fastening technology for heavy loads on living trees:

✔ Extremely resilient & safe

✔ Creates distance between tree & support structure

✔ Tree can grow freely in width

✔ Sustainable and tree-friendly

✔ For long-term fastenings (> 3 years)

Recommended by professionals and DIY enthusiasts

The first tree bolts – TAB & Garnier Limb – were developed in the USA over 30 years ago. Since then, thousands of treehouses have been built with them worldwide:

✔ Top quality – 100% made in Germany

✔ Proven technology with decades of experience

✔ Tested, inspected & tried and tested

✔ Suitable for professionals & DIY enthusiasts

Wide range of applications

Depending on the size of the project, there is the right GTS model with matching accessories for every application. This makes the fastening system ideal for all types of construction projects:

✔ Treehouses

✔ Platforms

✔ Climbing forest fastenings

✔ Tree top paths

✔ Adventure courses in the forest

✔ Hunting seats

Buy GTS Treehouse Hardware!Tree bolts are the most popular technique worldwide for permanently anchoring treehouses and platforms to trees.

2. Highest quality – 100% made in Germany

Without Treehouse Screws, modern treehouse construction would not exist. This technology was developed around 30 years ago by American treehouse pioneers Charles Greenwood, Michael Garnier (Garnier Limb – ‘GL’) and Pete Nelson (Treehouse Attachment Bolt – ‘TAB’).

Based on these American treehouse bolts, we have further optimised our GTS Tree Bolts and adapted them to the European market – may we present:

GTS Allstar 2.0

✔ Maximum Load Capacity

✔ Recommended for all tree trunks ø > 35 cm (13.8 in)

GTS Top

✔ Medium load capacity

✔ Recommended for thin, straight tree trunks ø 25 - 35 cm (13,8 in)

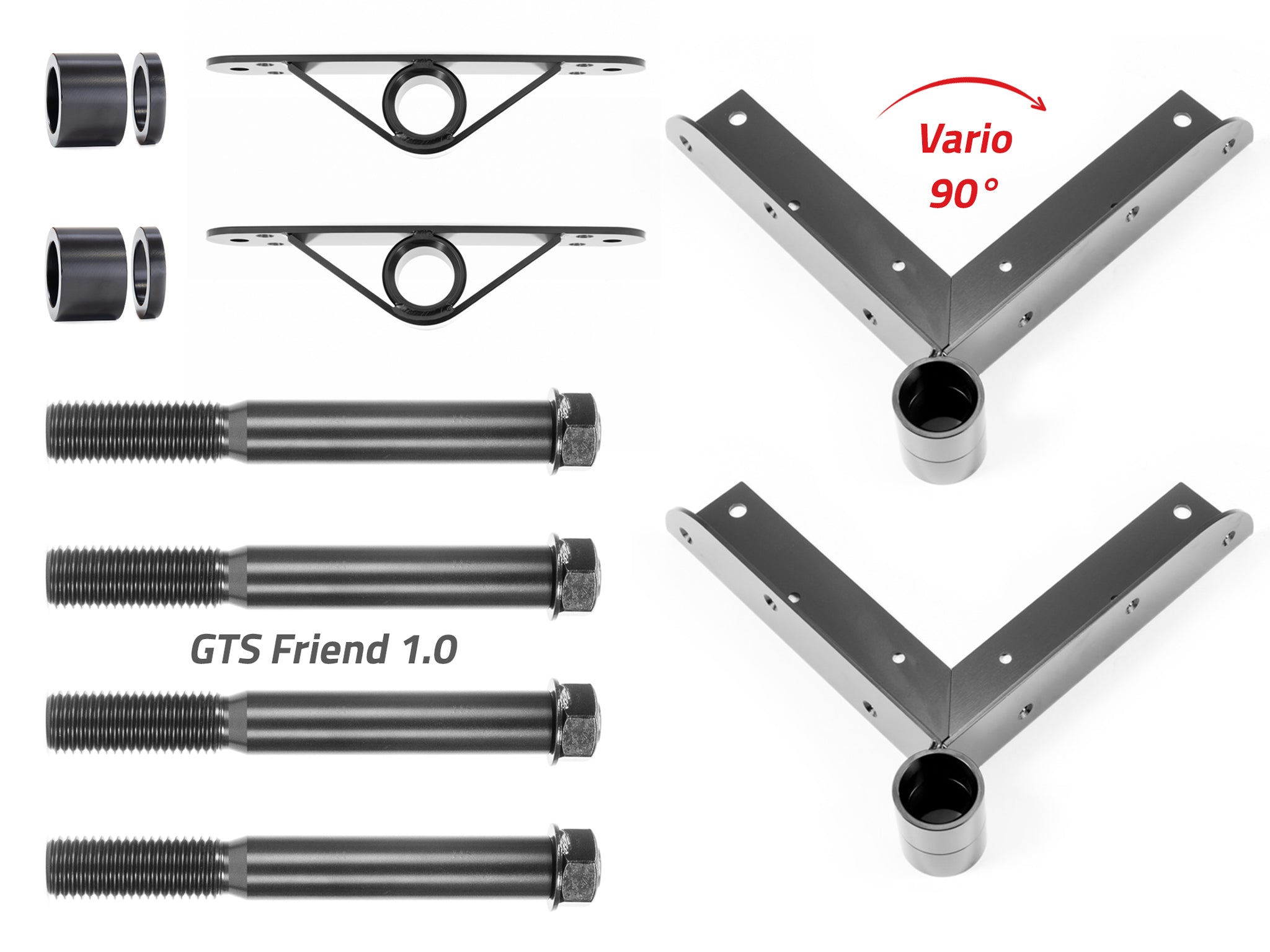

GTS Friend 2.0

✔ Low load capacity

✔ Auxiliary screw for thin tree trunks from ø > 25 cm (9.8 in)

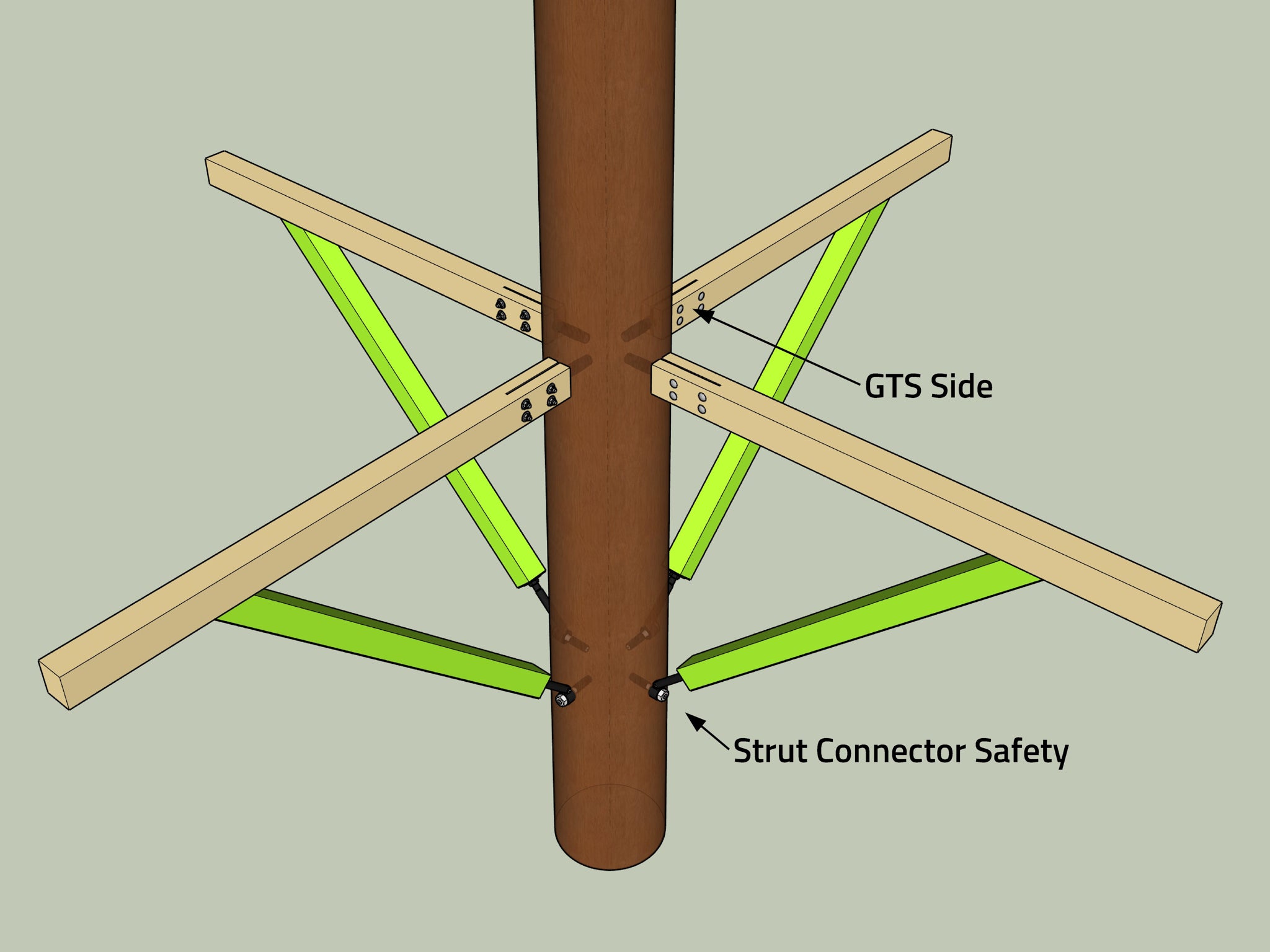

GTS Side

✔ For beams protruding from the side

✔ For tree trunks with a diameter of > 25 cm (9.8 in)

GTS Free 2.0

✔ Affordable solution for kids treehouses

✔ For tree trunks with a diameter of > 25 cm (9.8 in)

Our flagship – the GTS Allstar 2.0

✔ Extremely safe and reliable

✔ Maximum load capacity (up to 3,800 kg per screw)

✔ Withstands vertical and lateral loads

✔ Long shaft – trees can grow undisturbed

✔ Easy installation & very low maintenance

Buy GTS Allstar 2.0!

Buy GTS Allstar 2.0!

GTS hardware – by professionals for DIY!

✔ We sell 6 different screw models – there is a suitable tree bolt for every situation.

✔ Few tools required thanks to perfectly coordinated products.

✔ Cordless working: We have our tools. You can move safely and freely in the tree!

✔ European market: Screws and accessories have been developed for the European market, i.e. metric dimensions, time-saving tool and spare parts procurement, no expensive special tools.

✔ Shipping from Germany to the EU: fast delivery, no customs duties, no import taxes.

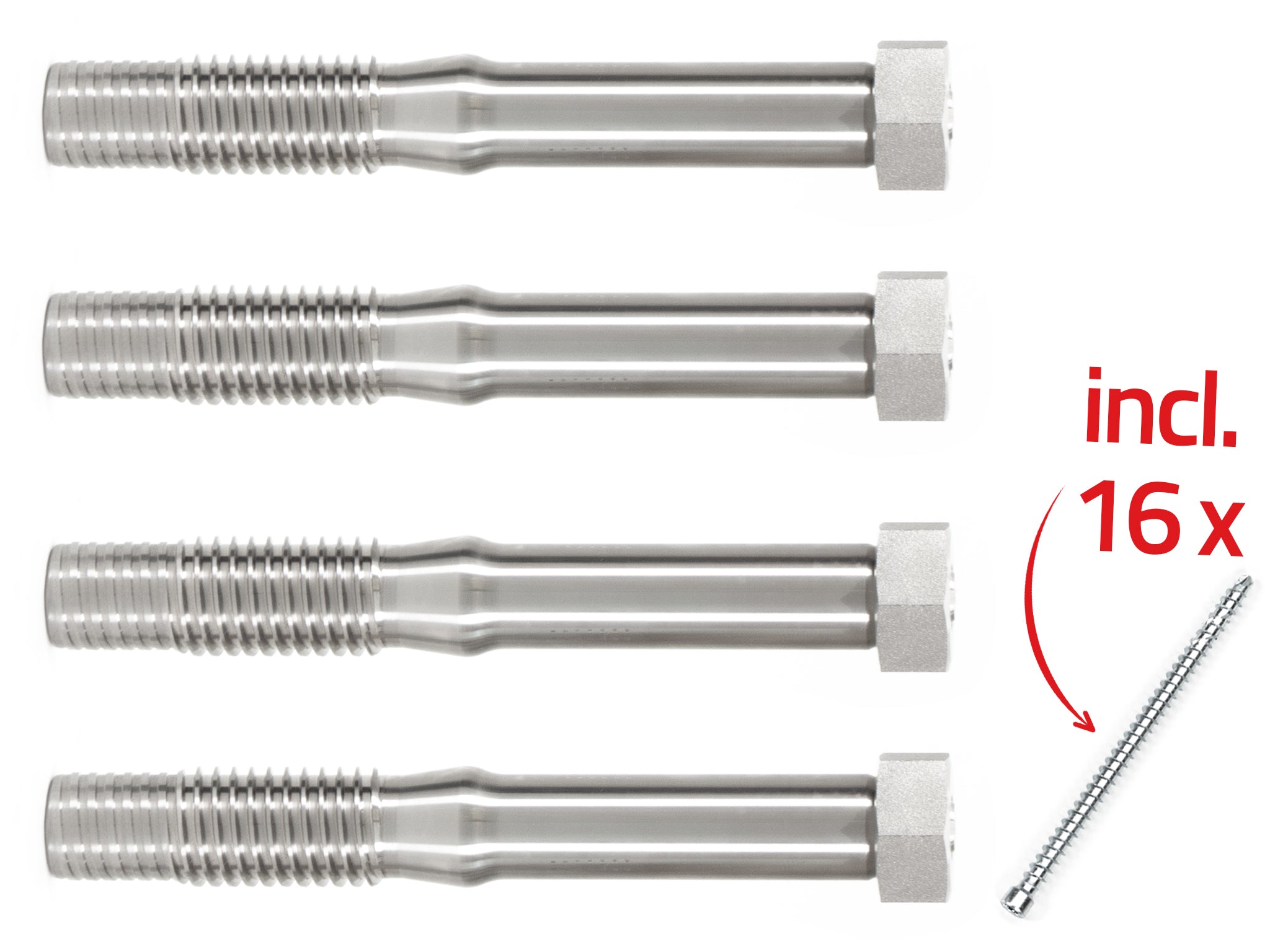

Technical details – NEW VERSION 2.0

- NEW – Tree Thread 2.0: The two-start coarse thread was specially developed for living trees. The optimised thread shape has even higher load transfer and saves a lot of energy and time during installation.

- NEW – Quick Start Pin: The smoothed pin at the start of the screw can be inserted directly into the drill hole – this makes installation in the tree much easier!

- NEW – Cylinder HL: The solid ‘Heavy Load’ cylinder (ø 74 mm) transfers even the heaviest loads safely into the trunk. Four fine grooves mark the installation depth.

- NEW – Seal +: The flared cylinder seals the drill hole, ensuring that the screw fits snugly and securely. The deep grooves make it easier for the tree to close the wound as it grows in width.

- Natural Transition: Over the years, the tree grows over the screw. This process is facilitated by the parabolic transition. The smooth transition makes the overall appearance more aesthetic – like a natural branch.

- Shaft ø40: With a diameter of ø 40 mm, the shaft can withstand even the highest alternating loads – a peaceful night's sleep is guaranteed.

- Seamless: We do not use weld seams in our screws – our new steel alloy makes GTS Screws indestructible!

- Black KTL Coating: The environmentally friendly coating process ensures optimum corrosion protection and excellent sliding properties. The black finish allows the screw to blend inconspicuously into the tree.

Video: Production at TheTreehouse.Shop

A brief insight into the production of our Treehouse Hardware (from 2022) – our warehouse has since moved, but the team remains the same :)

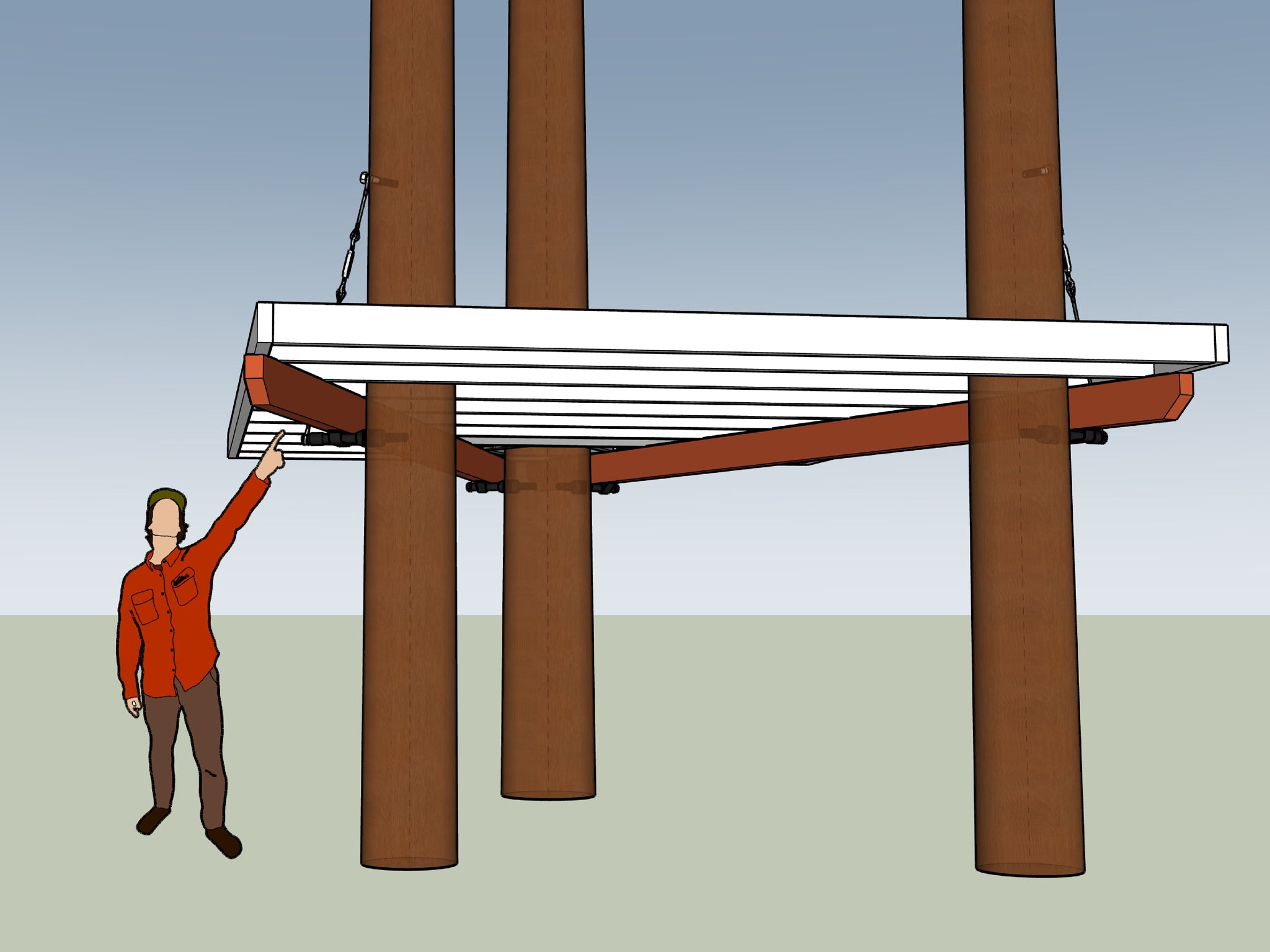

3. Mounting the GTS Screws on the tree

Pre-drill – screw in – build your treehouse!

Installing GTS Screws is simple and so far, all of our customers have mastered it.

Here we use the GTS Allstar as an example to show how a tree bolt is installed and how it transfers loads into the tree trunk.

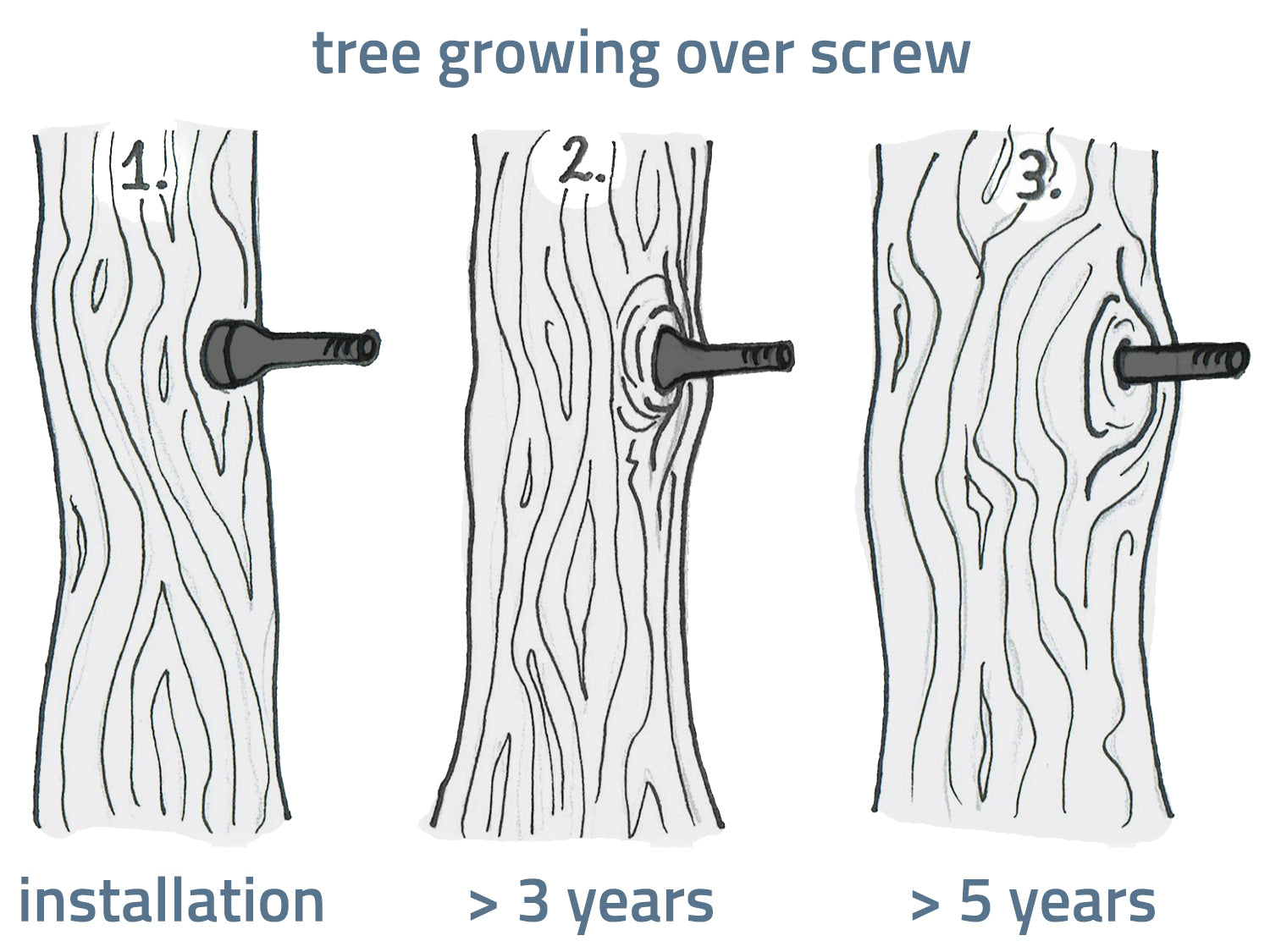

The tree continues to grow wider every year (annual ring width 3–15 mm) and will firmly enclose and integrate the screw.

The more undisturbed the tree can grow in width, the better.

3. Mounting the GTS Screws on the tree

Pre-drill – screw in – build your treehouse!

Installing GTS Screws is simple and so far, all of our customers have mastered it.

Here we use the GTS Allstar as an example to show how a tree bolt is installed and how it transfers loads into the tree trunk.

The tree continues to grow wider every year (annual ring width 3–15 mm) and will firmly enclose and integrate the screw.

The more undisturbed the tree can grow in width, the better.

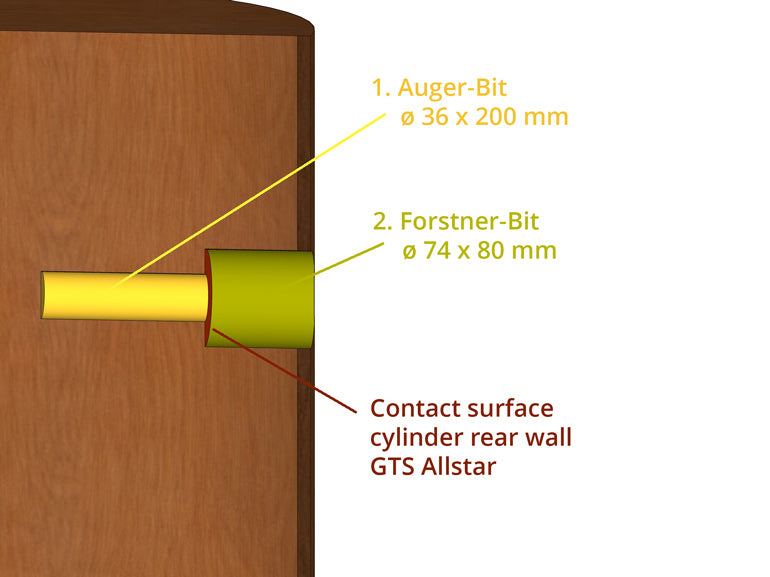

German Treehouse Screw – GTS Allstar 2.0

Assembly & function under vertical load

1. Pre-drill hole for GTS

✔ Pre-drill coarse thread ø 36 mm (yellow)

✔ Pre-drill cylinder ø 74 mm (green)

✔ This creates the ‘contact surface’ (red)

The screw is screwed into the hole until the cylinder is firmly against the contact surface.

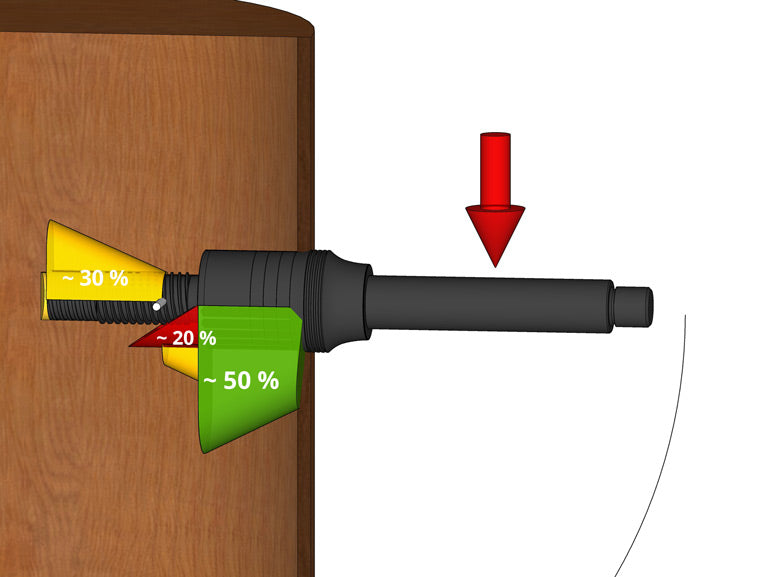

2. Vertical load on the GTS in the tree

The screw transfers the load from the treehouse (red arrow) into the trunk. The wooden beams are fastened to the shaft using accessories. If necessary, the load capacity of the screws can be almost doubled with the GTS+ system.

Assembly videos on YouTube

4. Load Capacity of GTS Screws

Tree bolts are primarily designed for high vertical loads. Unlike normal wood screws or threaded rods from DIY stores, they can also withstand dynamic loads (during storms) permanently and safely!

Depending on the application, we offer 6 GTS models with different load capacities: from simple rope fastenings (GTS Safety up to 1,100 kg) to huge support structures (GTS Allstar up to 3,800 kg).

The load capacity of the individual GTS Screws depends largely on the following factors:

A) Wood strength and wound healing of the tree

B) Lever arm and type of load

4. Load Capacity of GTS Screws

Tree bolts are primarily designed for high vertical loads. Unlike normal wood screws or threaded rods from DIY stores, they can also withstand dynamic loads (during storms) permanently and safely!

Depending on the application, we offer 6 GTS models with different load capacities: from simple rope fastenings (GTS Safety up to 1,100 kg) to huge support structures (GTS Allstar up to 3,800 kg).

The load capacity of the individual GTS Screws depends largely on the following factors:

A) Wood strength and wound healing of the tree

B) Lever arm and type of load

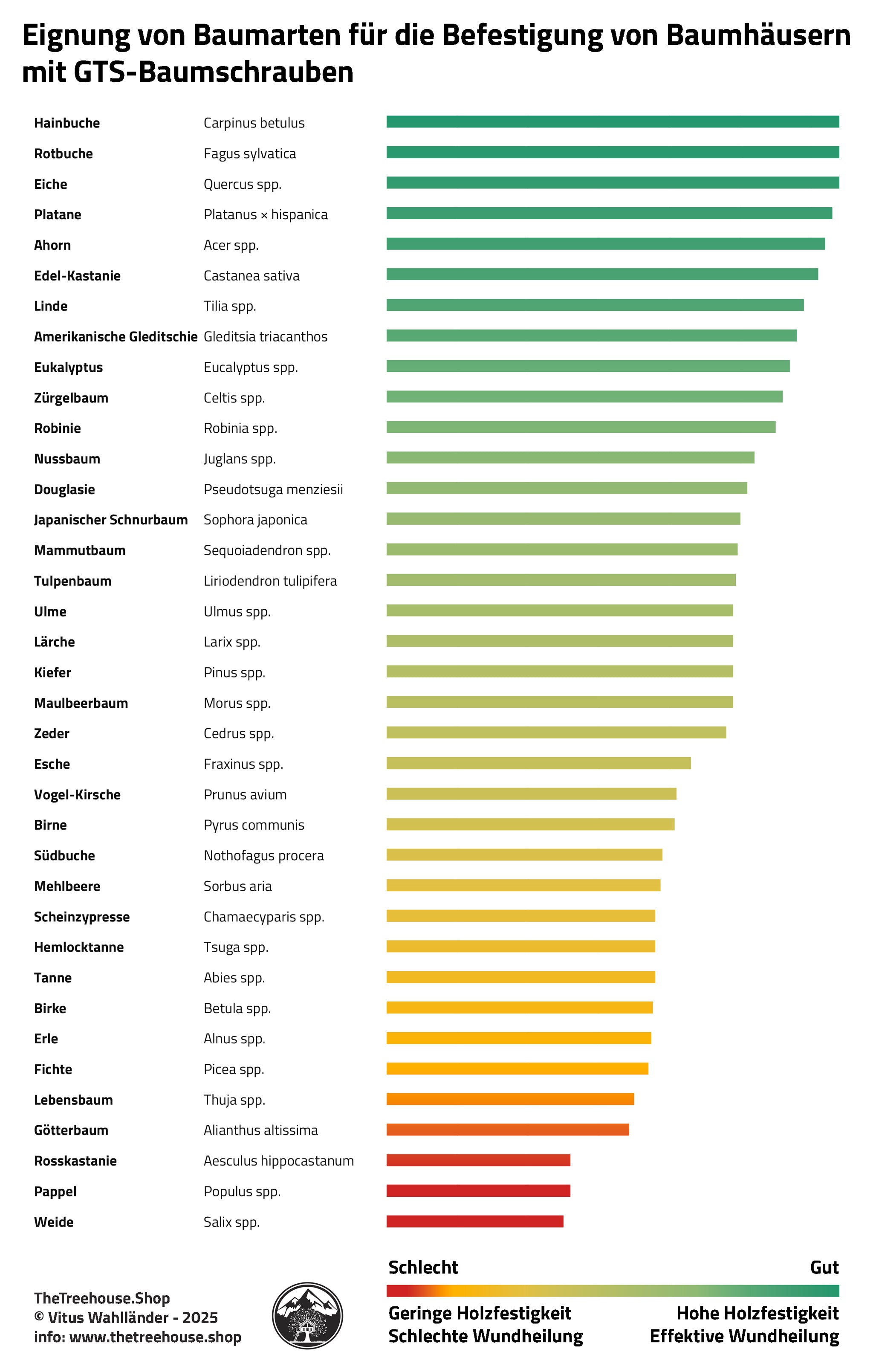

A) Wood strength + wound healing = good treehouse tree

Fastening techniques such as tree bolts, TABs and Garnier Limb penetrate deep into the tree.

In addition to the wood strength of the tree, the wound healing capacity must also be taken into account, i.e. the ability of the tree to respond to major injuries and protect itself from rot.

We have investigated these properties in 37 tree species and compiled a kind of ‘best list of treehouse trees’:

Very high wood strength: > 2.3 kN/cm²

GTS Screws achieve their maximum load capacity in these woods (e.g. GTS Allstar 3.8 t). Large tree house projects can be realised without hesitation:

- American honey locust (Gleditsia triacanthos)

- Oak (Quercus spp.)

- Ash (Fraxinus spp.)

- Eucalyptus (Eucalyptus spp.)

- Hornbeam (Carpinus betulus)

- Sycamore (Platanus×hispanica)

- Black locust (Robinia spp.)

- European beech (Fagus sylvatica)

- European hackberry (Celtis spp.)

High wood strength: 2.0 - 2.2 kN/cm²

These trees are also ideal for large and heavy treehouses due to their strength:

- Maple (Acer spp.)

- Birch (Betula spp.)

- Pear (Pyrus communis)

- Douglas fir (Pseudotsuga

- menziesii)

- Sweet chestnut (Castanea sativa)

- Japanese string tree (Sophora japonica)

- Whitebeam (Sorbus aria)

- Walnut (Juglans spp.)

- Bird cherry (Prunus avium)

Average strength: 1.8 - 1.9 kN/cm²

These trees are also suitable for building treehouses, but for very high loads, the GTS Screws should be reinforced or additional struts or stilts should be installed.

- Alder (Alnus spp.)

- Hemlock (Tsuga spp.)

- Pine (Pinus spp.)

- Larch (Larix spp.)

- Linden (Tilia spp.)

- Giant sequoia (Sequoiadendron spp.)

- Mulberry (Morus spp.)

- False cypress (Chamaecyparis spp.)

- Southern beech (Nothofagus procera)

- Fir (Abies spp.)

- Elm (Ulmus spp.)

- Cedar (Cedrus spp.)

Low wood strength: 1.5 - 1.7 kN/cm²

Despite their relatively low strength, treehouses can still be anchored in these trees, but the load must be kept correspondingly low. The trees mark the lower load-bearing values of the GTS Screws (e.g. GTS Allstar 1.5 t).

- Spruce (Picea spp.)

- Sassafras (Alianthus altissima)

- Arborvitae (Thuja spp.)

- Poplar (Populus spp.) ❌

- Horse chestnut (Aesculus hippocastanum) ❌

- Tulip tree (Liriodendron tulipifera)

- Willow (Salix spp.) ❌

Explanation of the table and values

- Important note: These values are guidelines – in practice, the values may vary, so each tree must be considered individually.

- The wood quality directly at the installation site is decisive for the load capacity of tree bolts.

- 1 kN/cm² ≈ 100 kg/cm

- Tree species that are unsuitable for drilling due to poor wound healing are marked with ❌.

- More on this in step 5: The right tree for your treehouse.

- More detailed data on the strength and wound healing of individual tree species – including sources – can be found here: ‘PDF – Wood strength and wound healing of different tree species.’

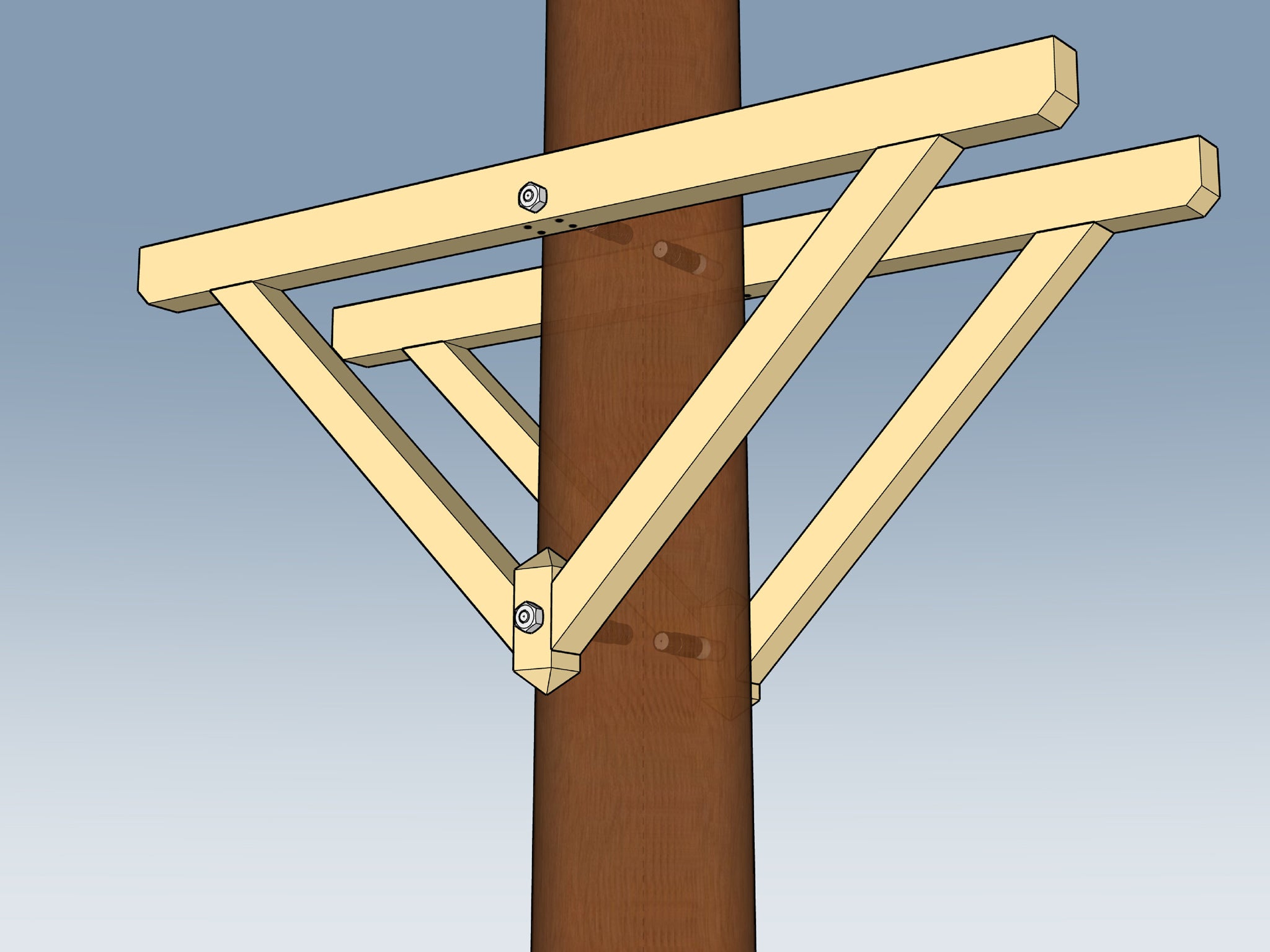

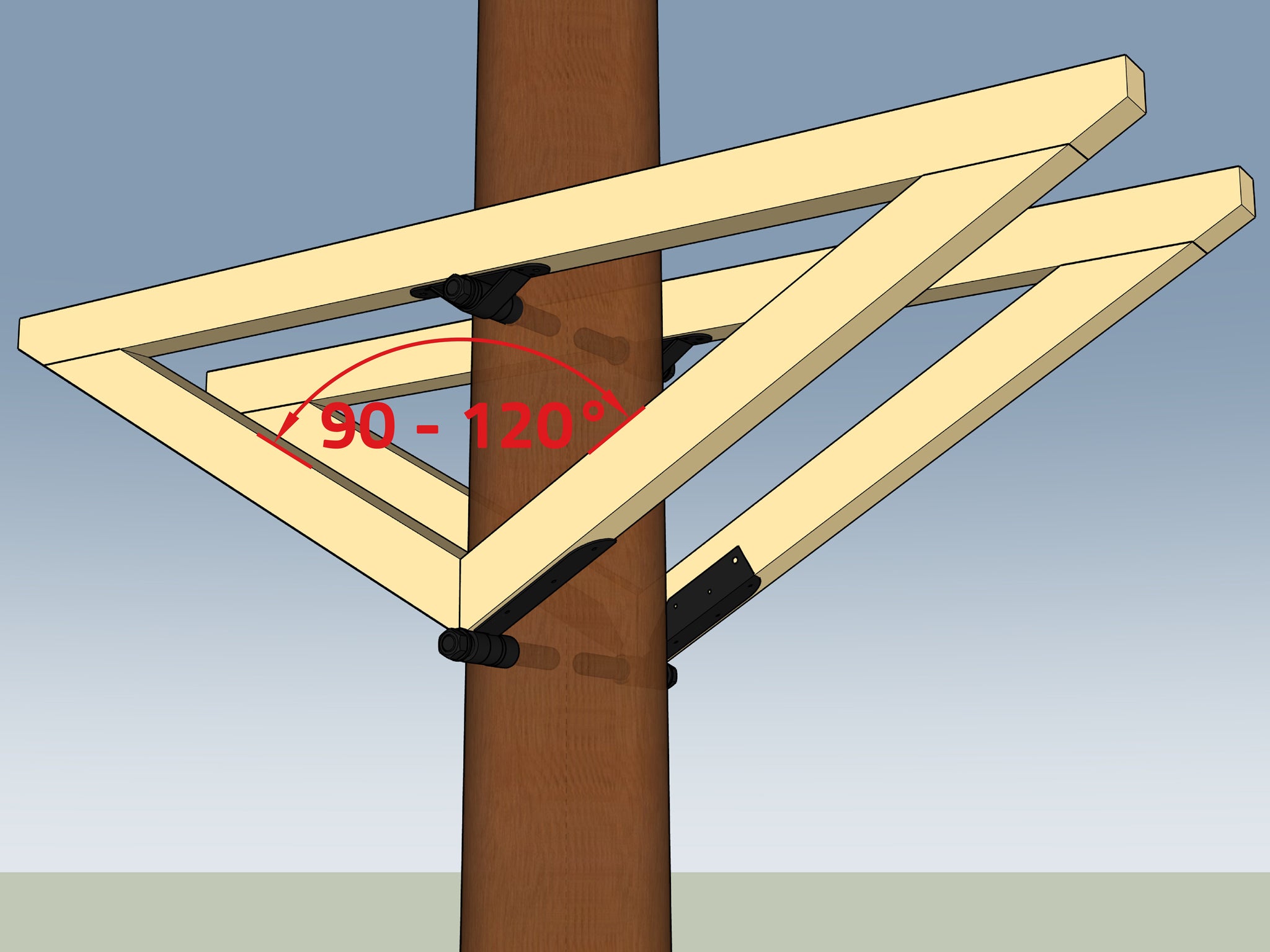

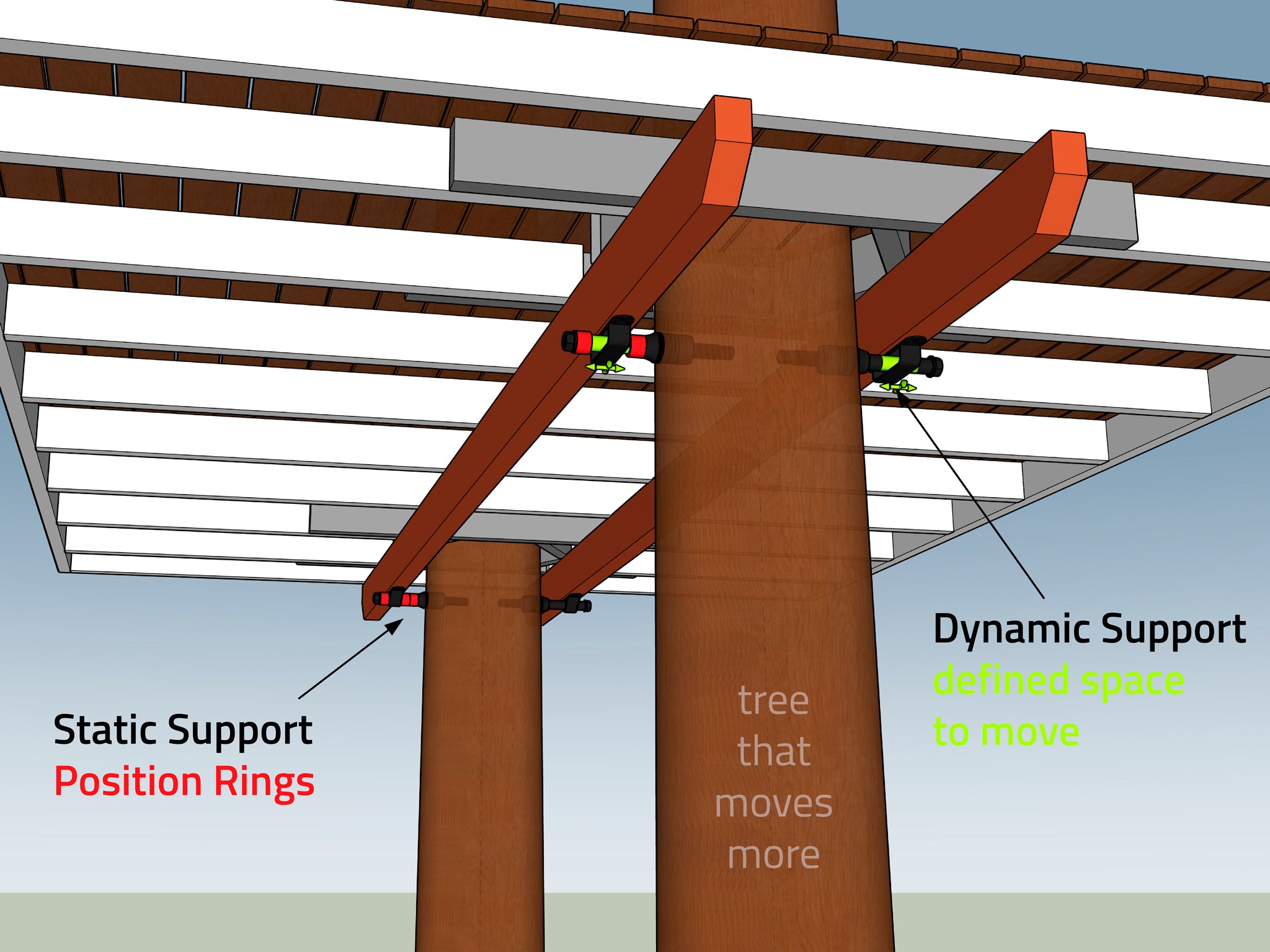

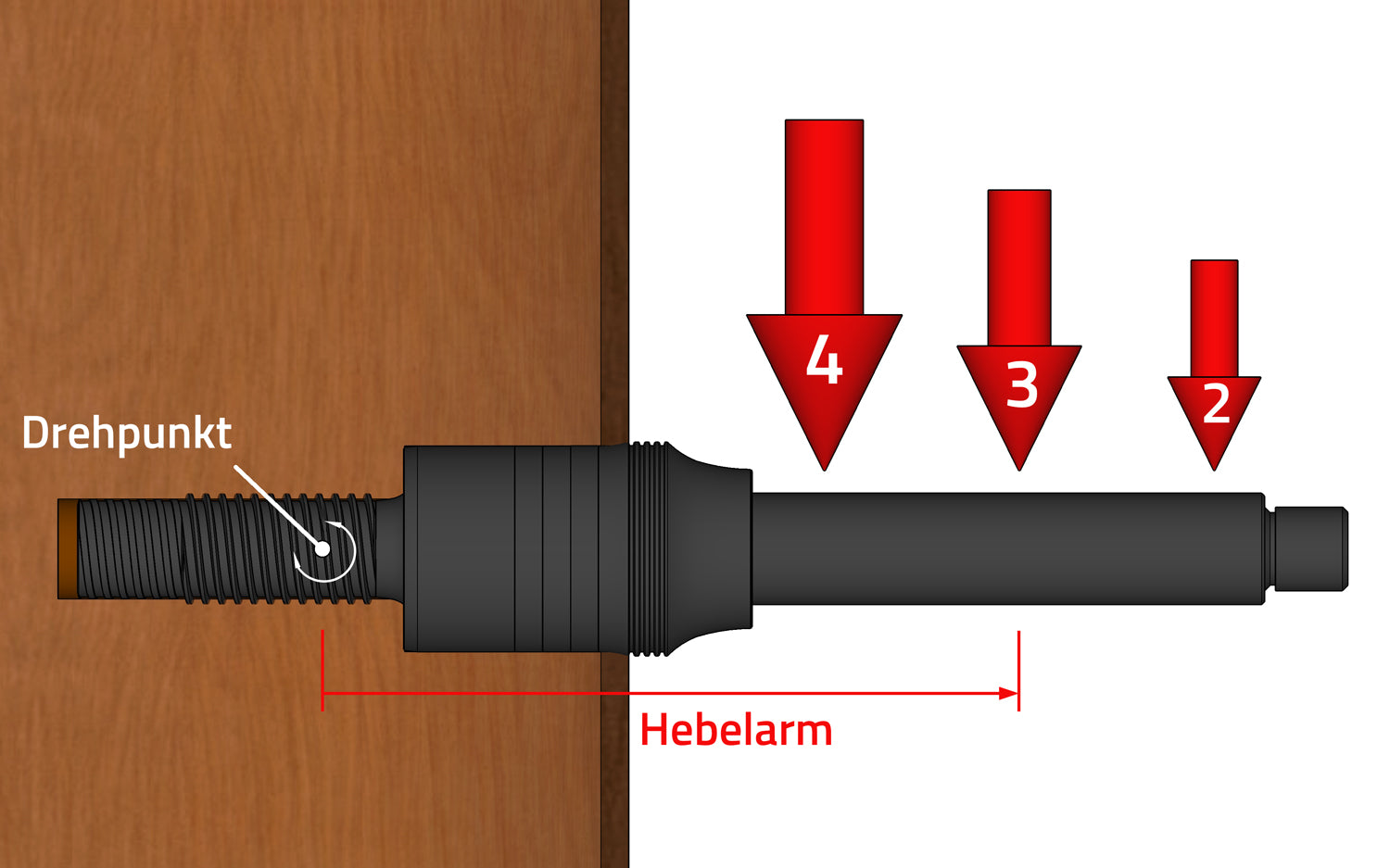

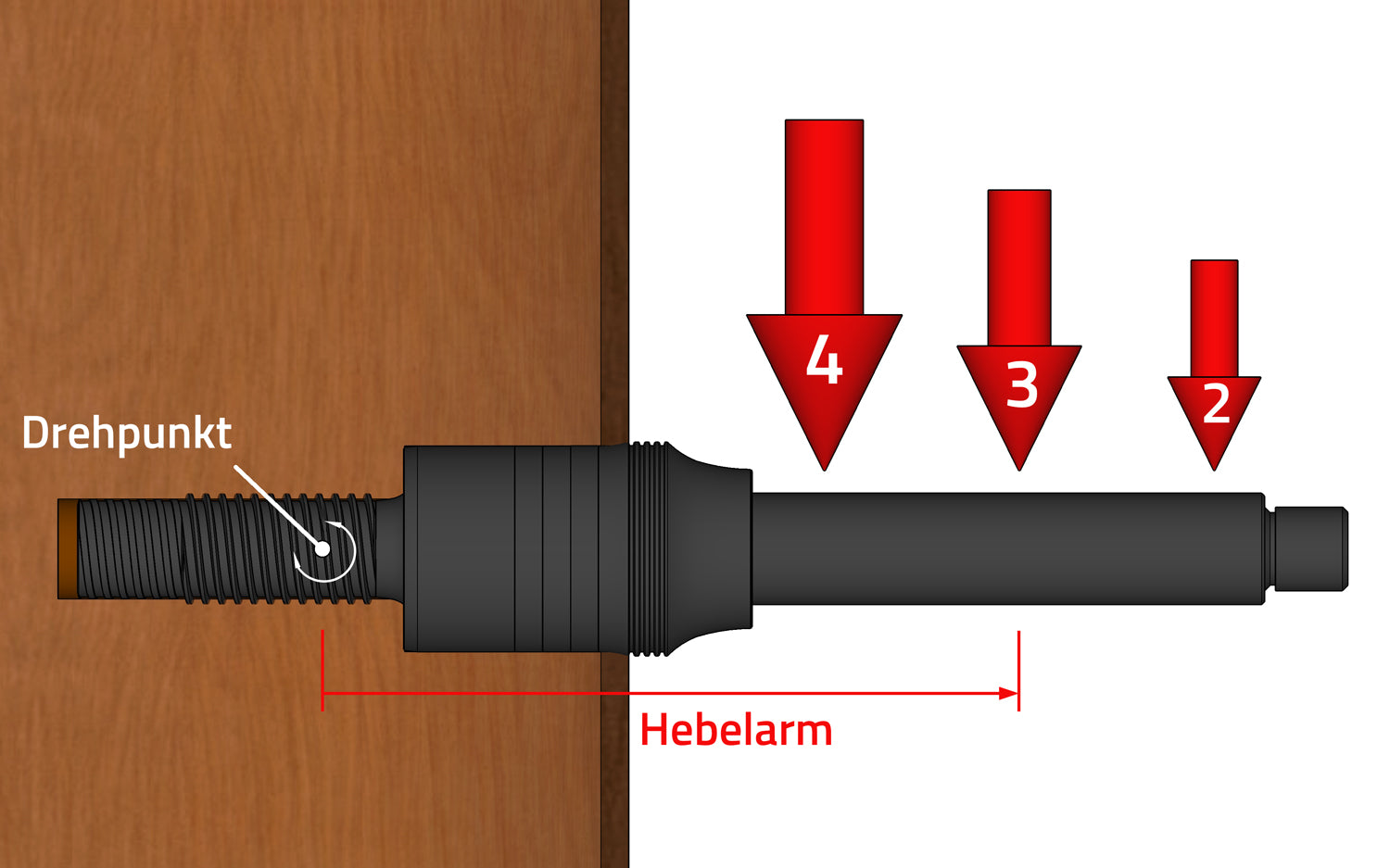

B) Lever arm & type of load

Unfortunately, you cannot change the strength of the wood – but you can change the lever arm and the direction of the load. Both have a major influence on the load capacity of the tree bolt and can be taken into account during planning:

Lever arm – has a major influence!

The load capacity also depends significantly on the lever arm:

The closer the construction is to the tree, the higher the load capacity!

For very heavy loads or very soft wood, the support beam should therefore be positioned closer to the tree.

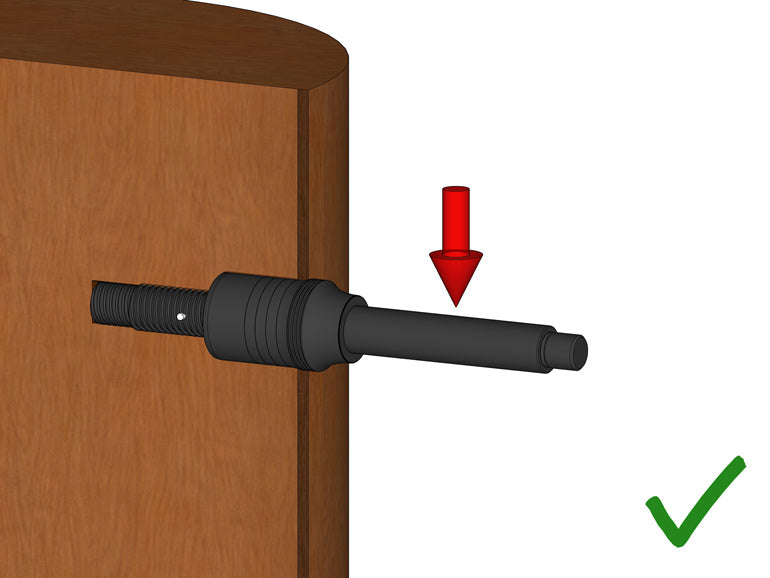

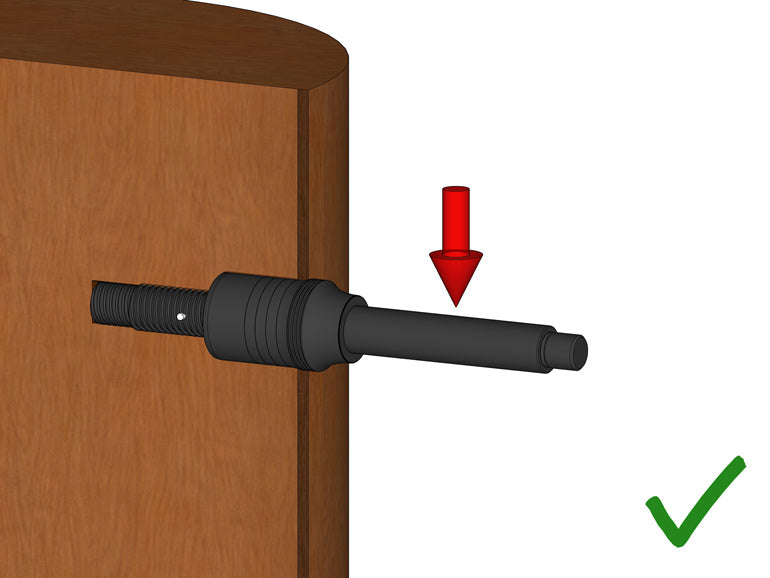

GOOD: Centrally balanced!

The GTS is loaded vertically in the centre of the shaft. Under normal loads, we recommend the central position on the shaft, as this offers the best compromise between load capacity and sufficient space for the boom to grow in width.

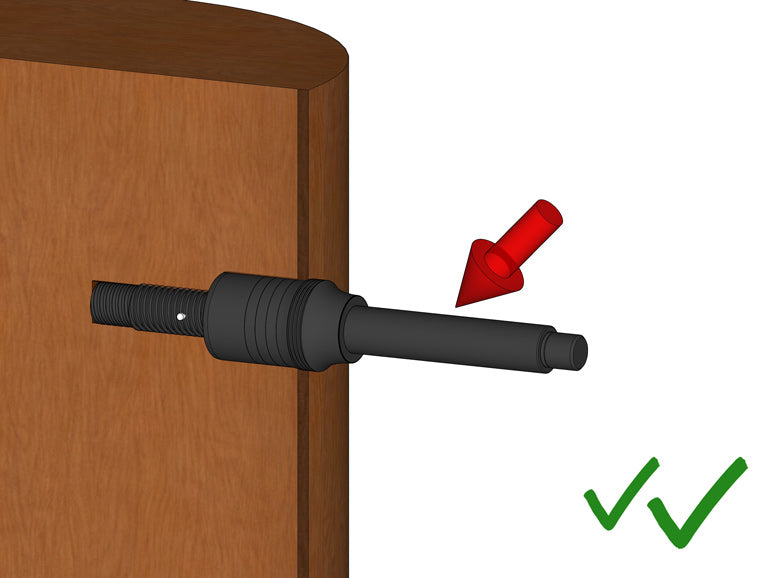

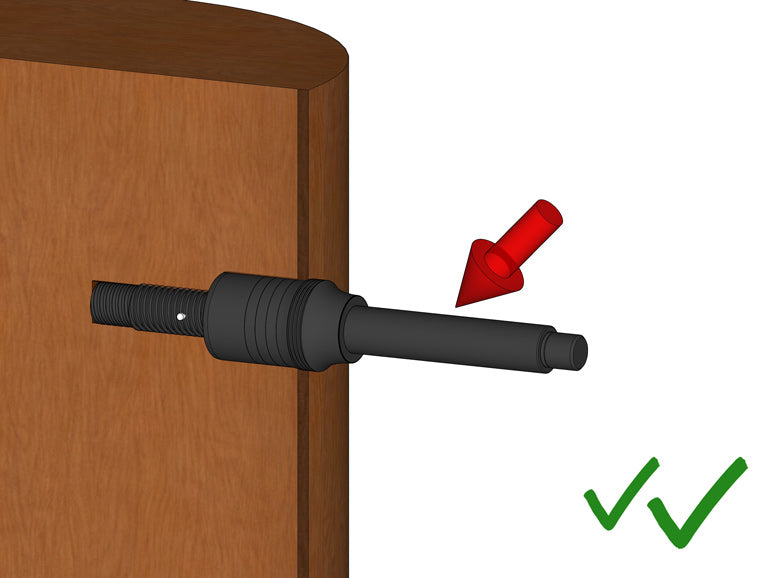

VERY GOOD: Pressure load in the direction of the trunk

If the vertical load acts in the direction of the tree, the load capacity of the tree bolts increases significantly.

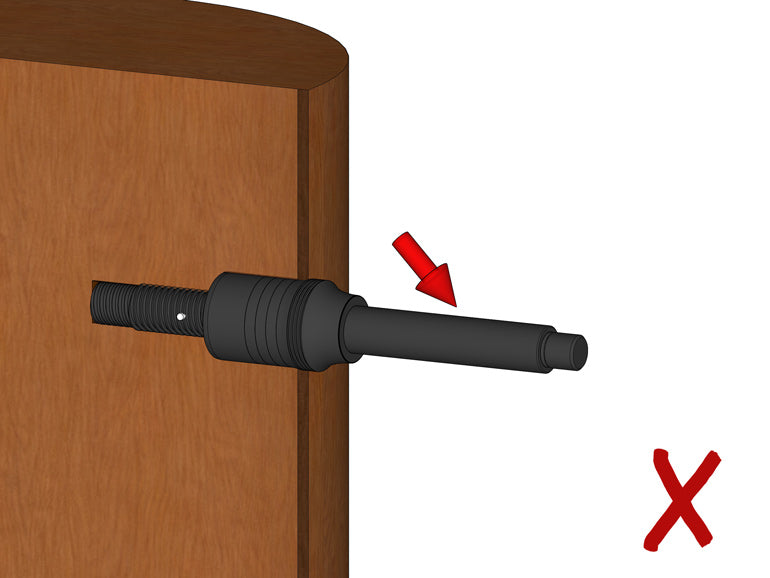

OK: Load pulls away from the tree

If, on the other hand, a load pulls the screw out of the tree, the load capacity is reduced, which should be avoided (e.g. tilting triangular construction).

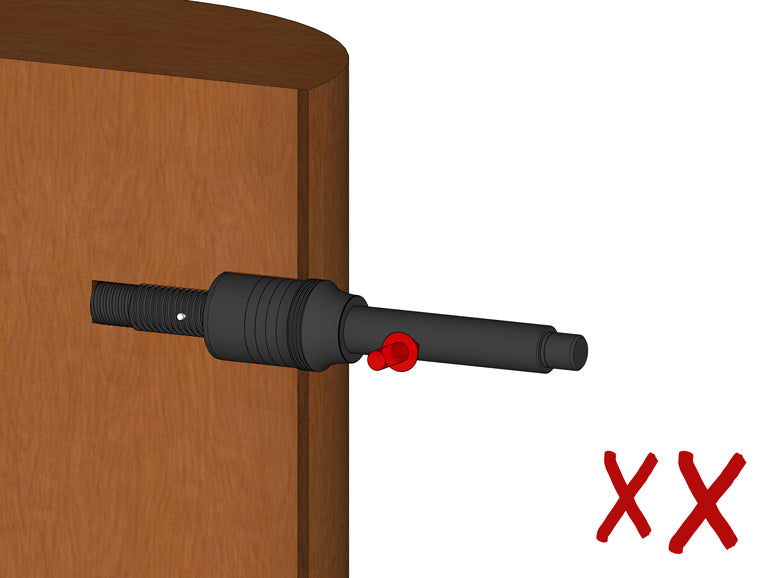

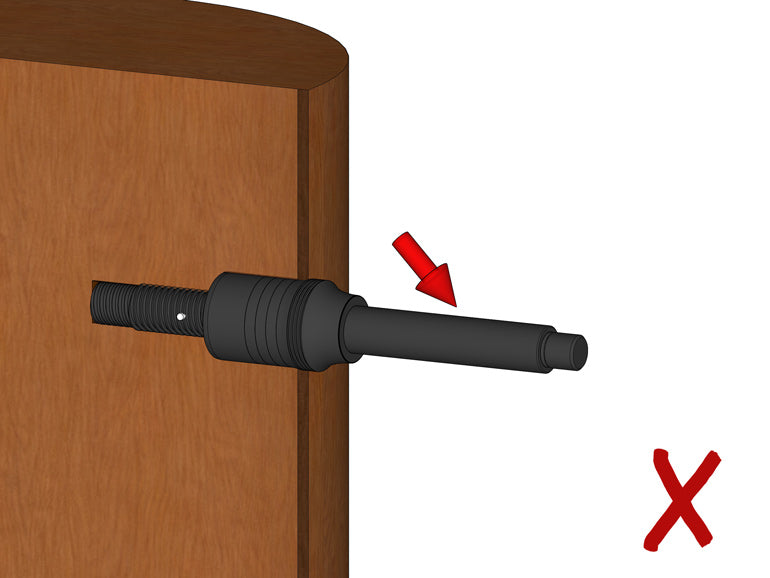

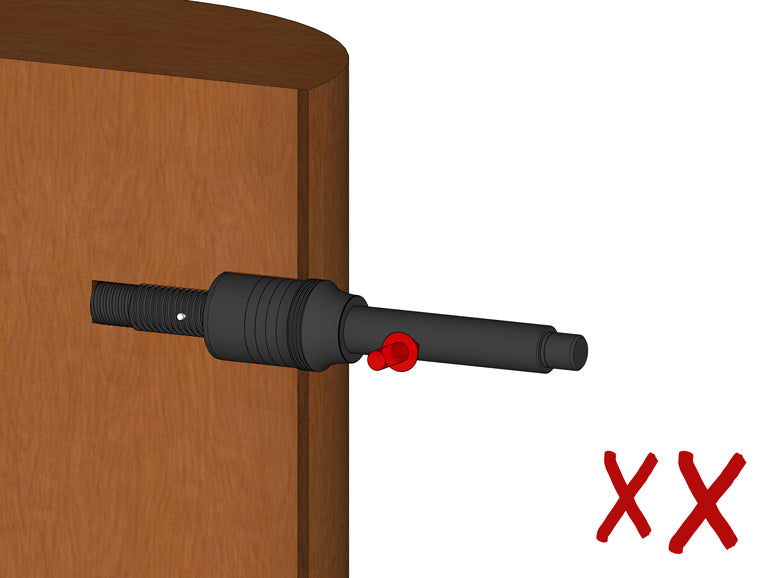

AVOID: Heavy horizontal loads

Lateral, horizontal loads should be avoided, as the load capacity is only about 1/3 compared to the longitudinal direction of the fibre (e.g. single strut pressing sideways on the screw or triangular construction with heavy one-sided load).

Lever arm – has a major influence!

The load capacity also depends significantly on the lever arm:

The closer the construction is to the tree, the higher the load capacity!

For very heavy loads or very soft wood, the support beam should therefore be positioned closer to the tree.

GOOD: Centrally balanced!

The GTS is loaded vertically in the centre of the shaft. Under normal loads, we recommend the central position on the shaft, as this offers the best compromise between load capacity and sufficient space for the boom to grow in width.

VERY GOOD: Pressure load in the direction of the trunk

If the vertical load acts in the direction of the tree, the load capacity of the tree bolts increases significantly.

OK: Load pulls away from the tree

If, on the other hand, a load pulls the screw out of the tree, the load capacity is reduced, which should be avoided (e.g. tilting triangular construction).

AVOID: Heavy horizontal loads

Lateral, horizontal loads should be avoided, as the load capacity is only about 1/3 compared to the longitudinal direction of the fibre (e.g. single strut pressing sideways on the screw or triangular construction with heavy one-sided load).

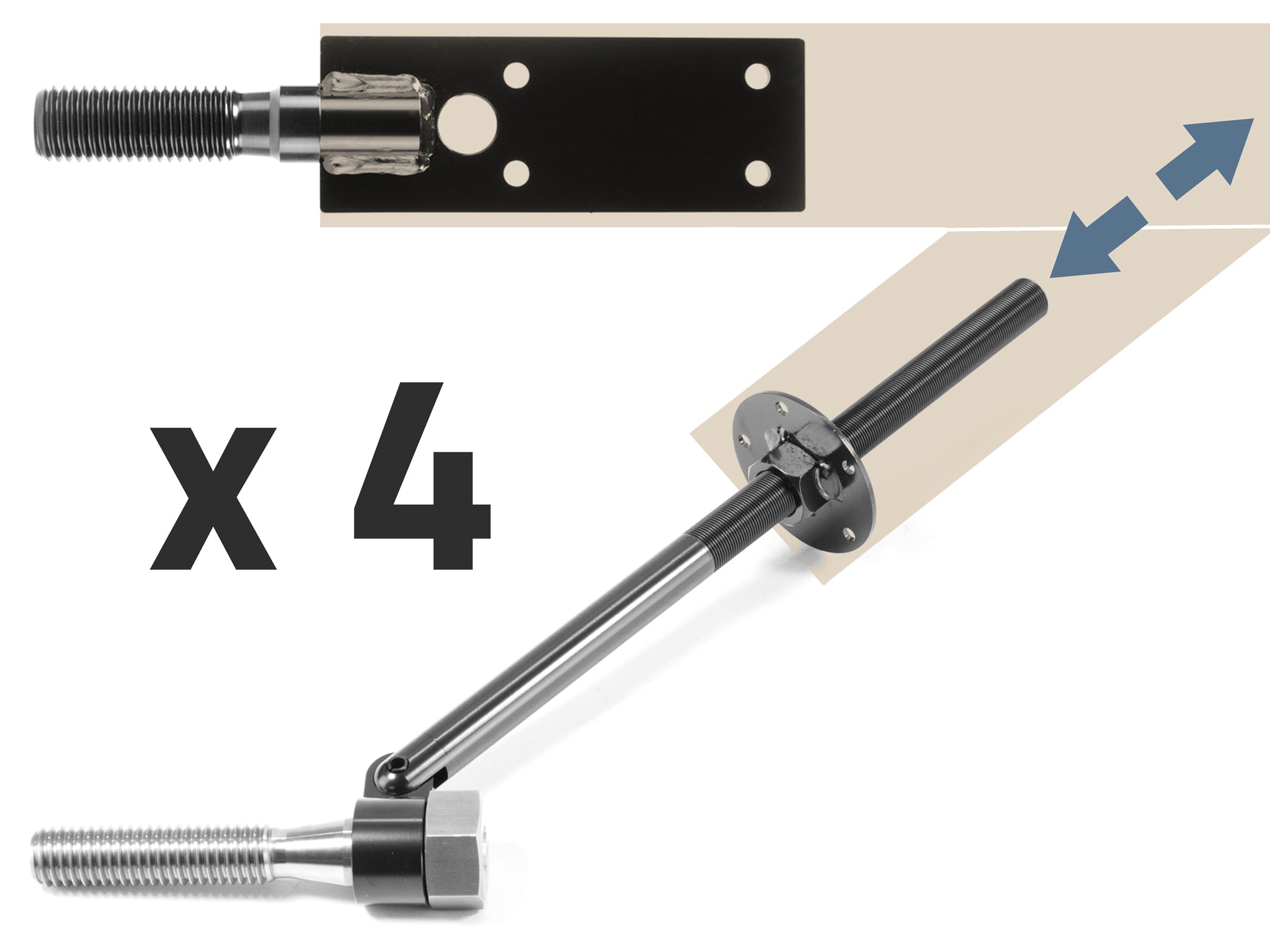

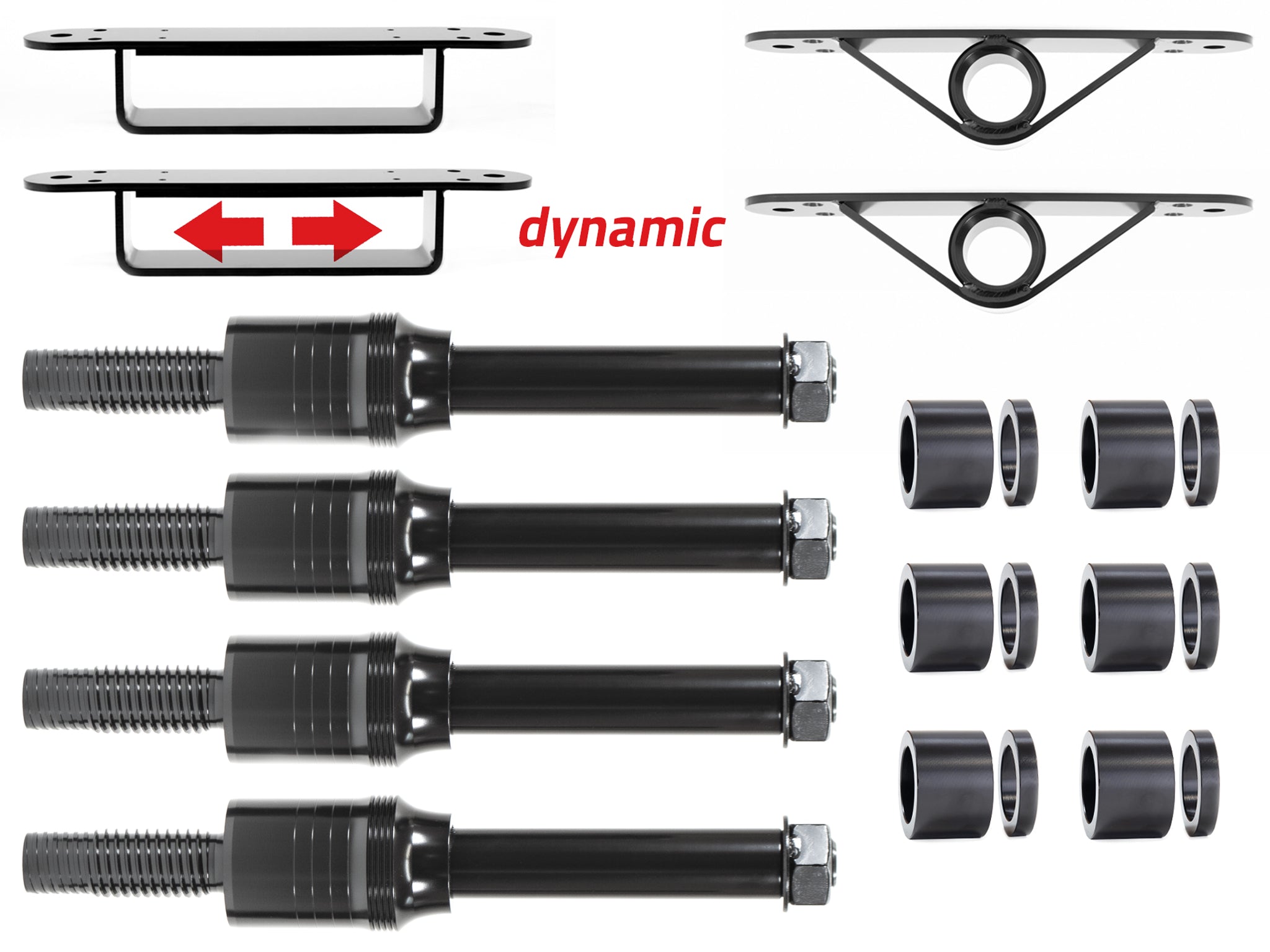

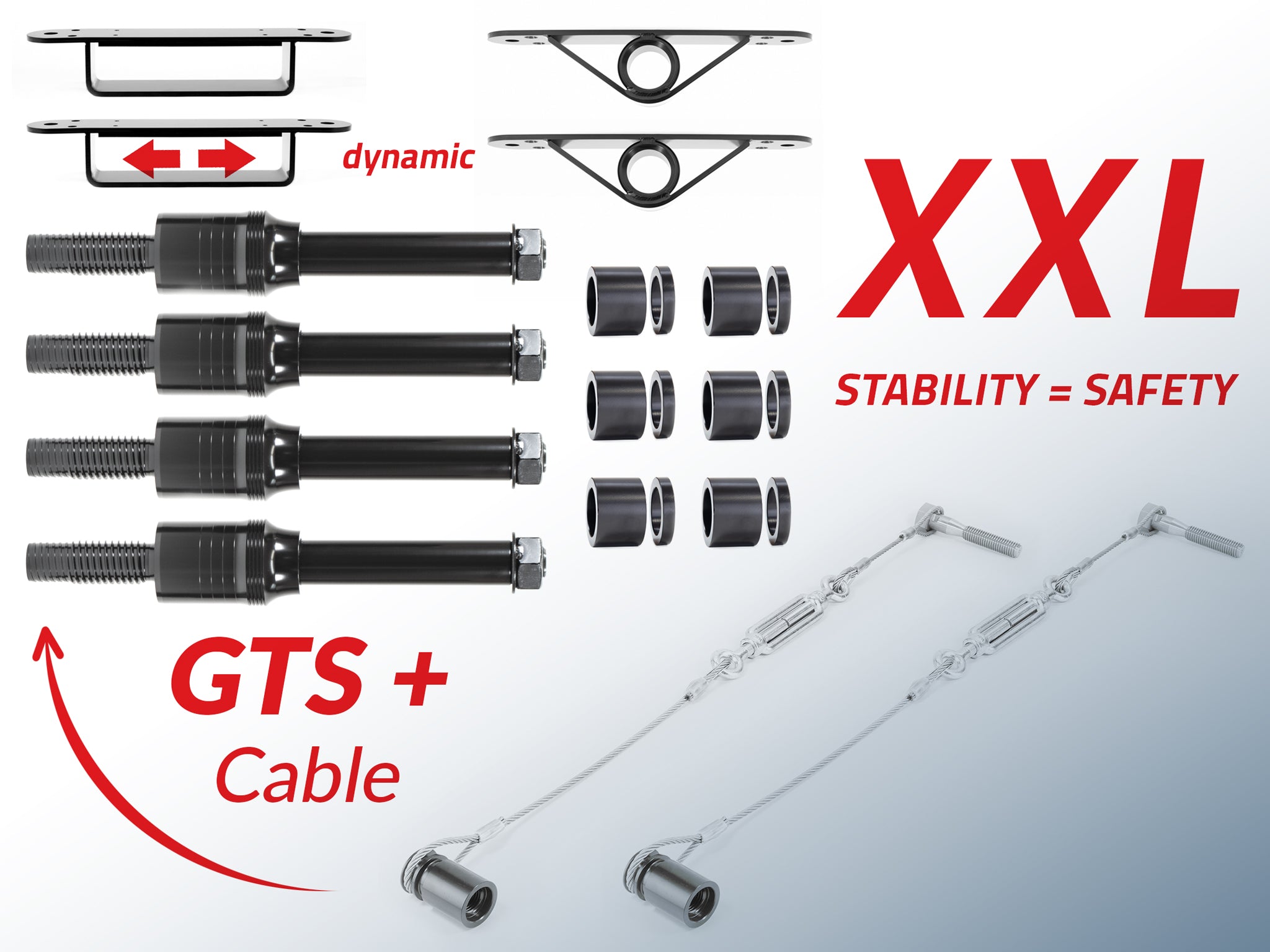

5. Complete hardware kits for building treehouses

To build a treehouse, you usually need several tree bolts and the appropriate accessories to attach the wooden beams to the bolt.

For the most common treehouse projects, we have already put together ready-made Treehouse Hardware Kits in our shop – so you can get started right away!

5. Complete hardware kits for building treehouses

To build a treehouse, you usually need several tree bolts and the appropriate accessories to attach the wooden beams to the bolt.

For the most common treehouse projects, we have already put together ready-made Treehouse Hardware Kits in our shop – so you can get started right away!

Ready-made GTS Treehouse Hardware Kits

Many thanks to Vitus and his team for the excellent products and advice. The Treehouse Screws are amazing and have made our summer project a reality.

Really good products and professional service. You can tell they have a lot of experience and know all the pitfalls. Highly recommended.