The Treehouse Shop

Europe's #1 specialist shop for treehouse builders – professional fastenings, practical accessories and genuine know-how!

Filters

Filters

55 products

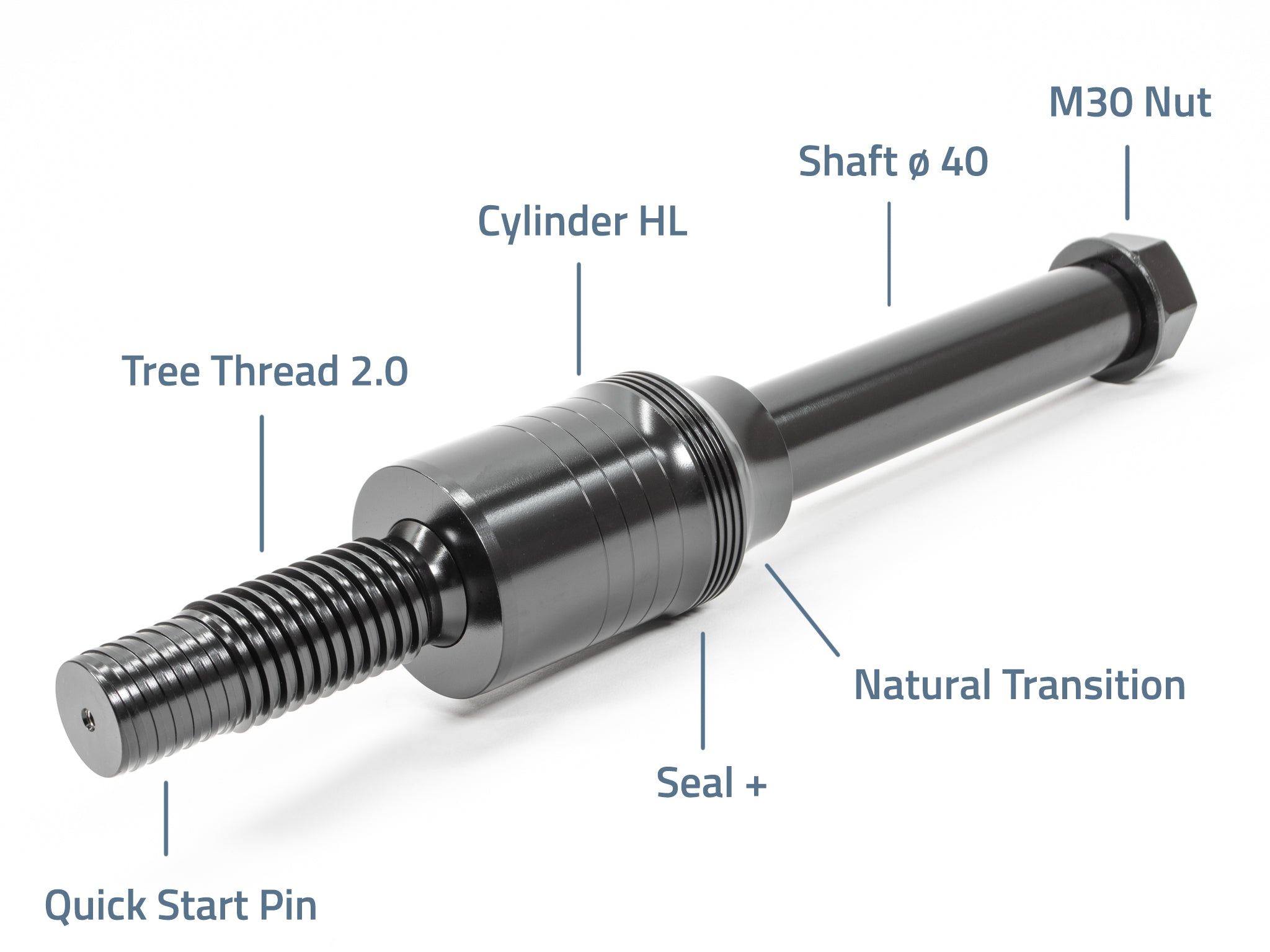

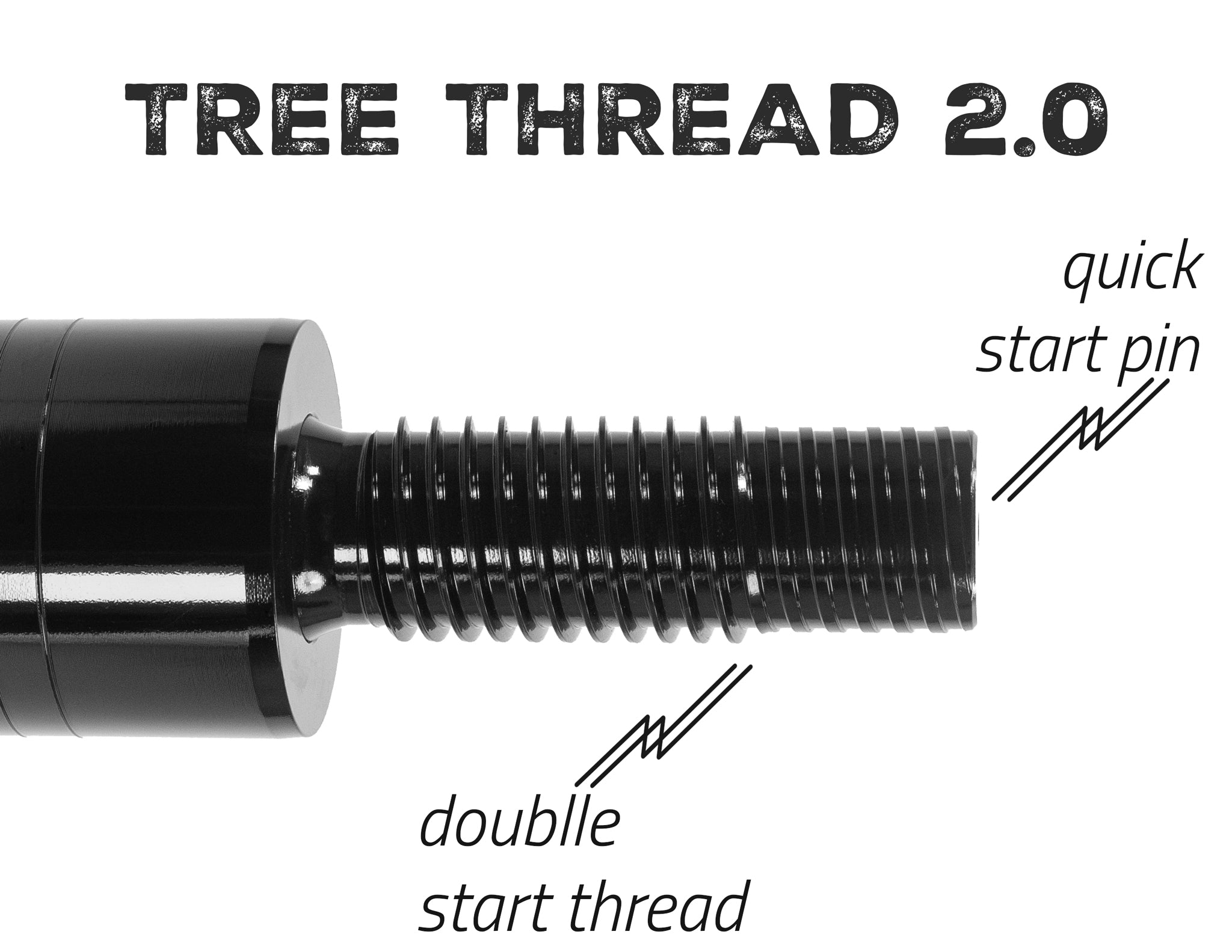

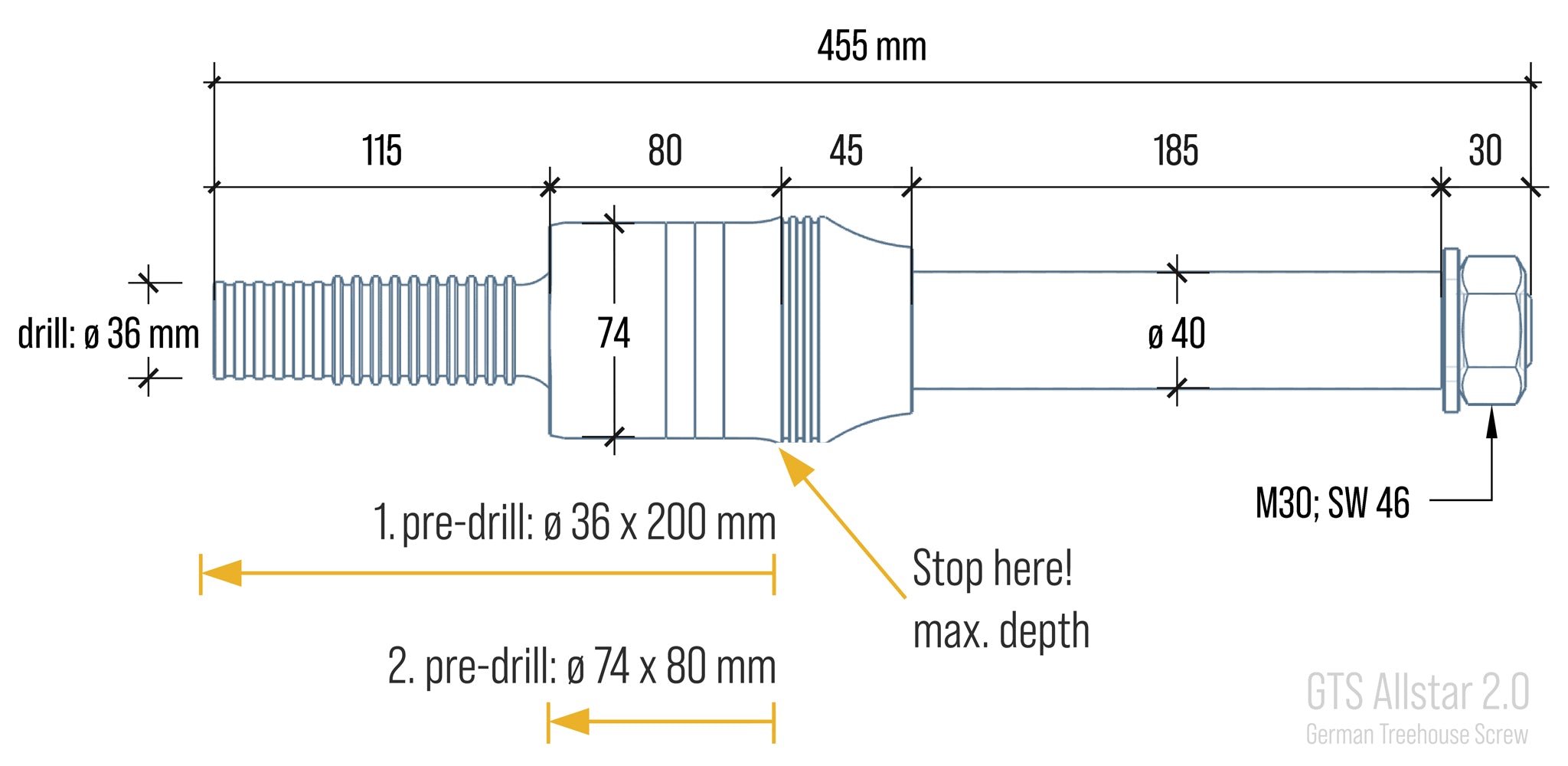

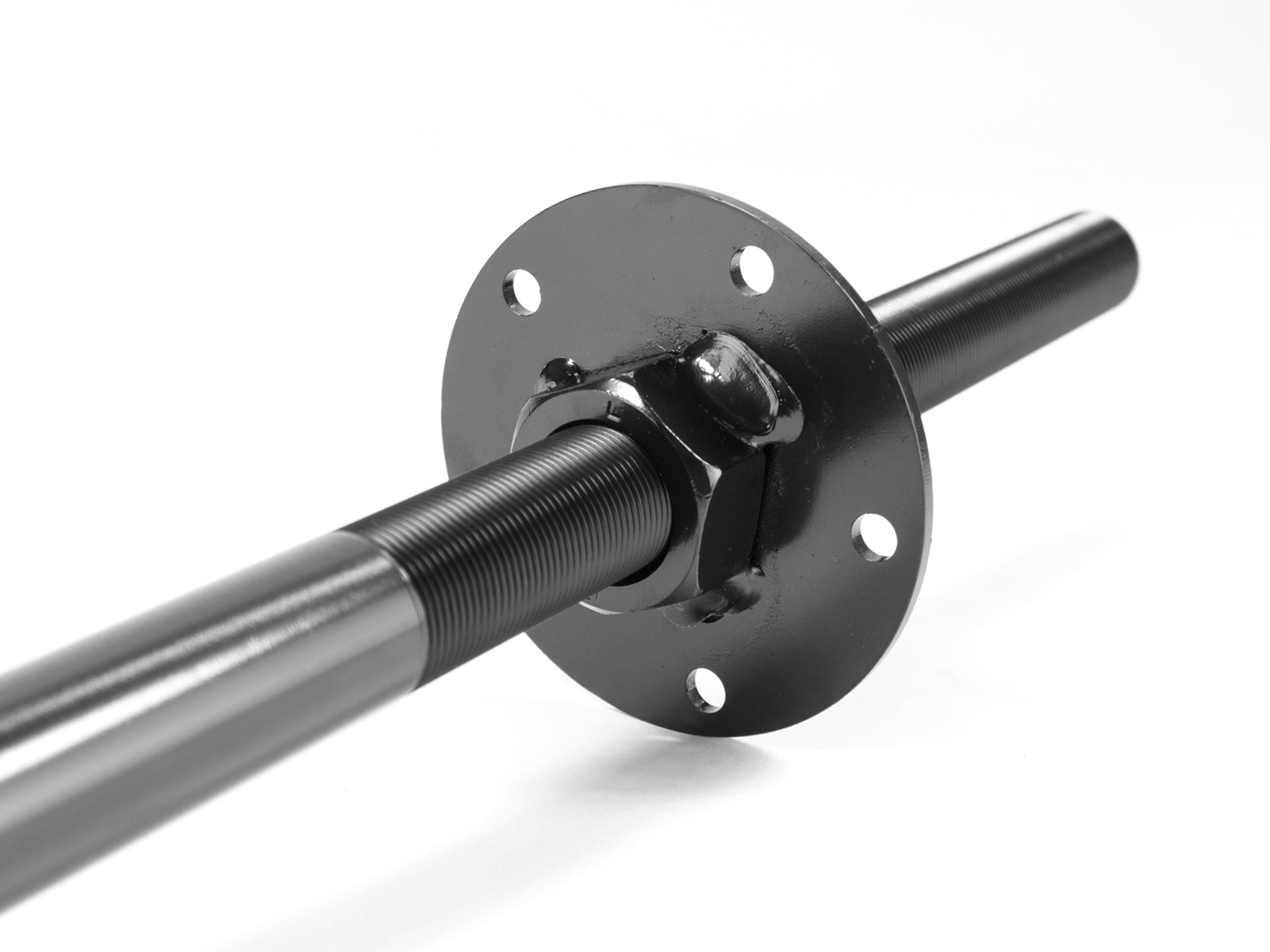

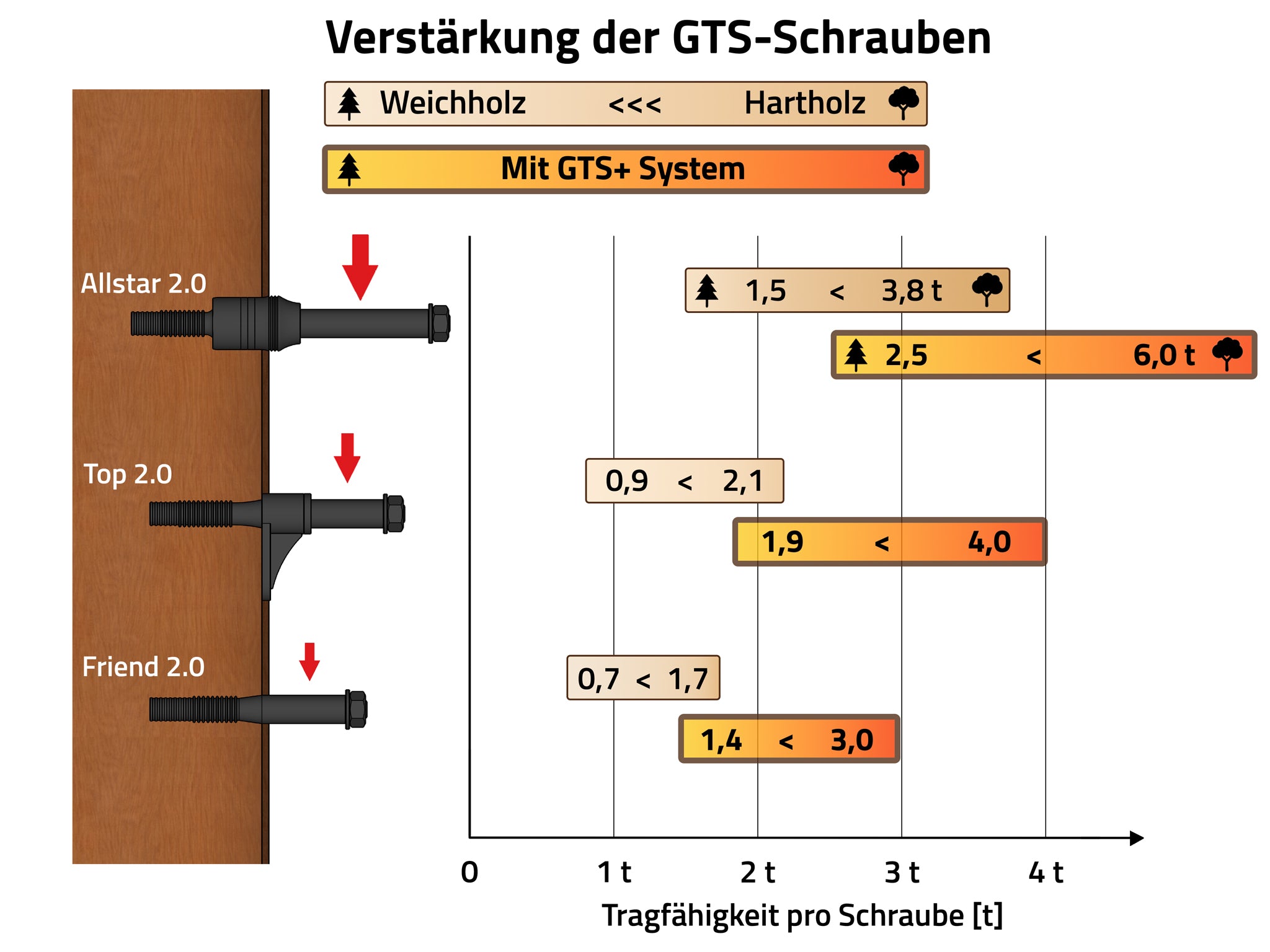

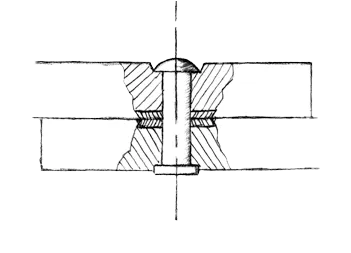

GTS Allstar – Tree bolt up to 3,800 kg load

Sale price€221,00

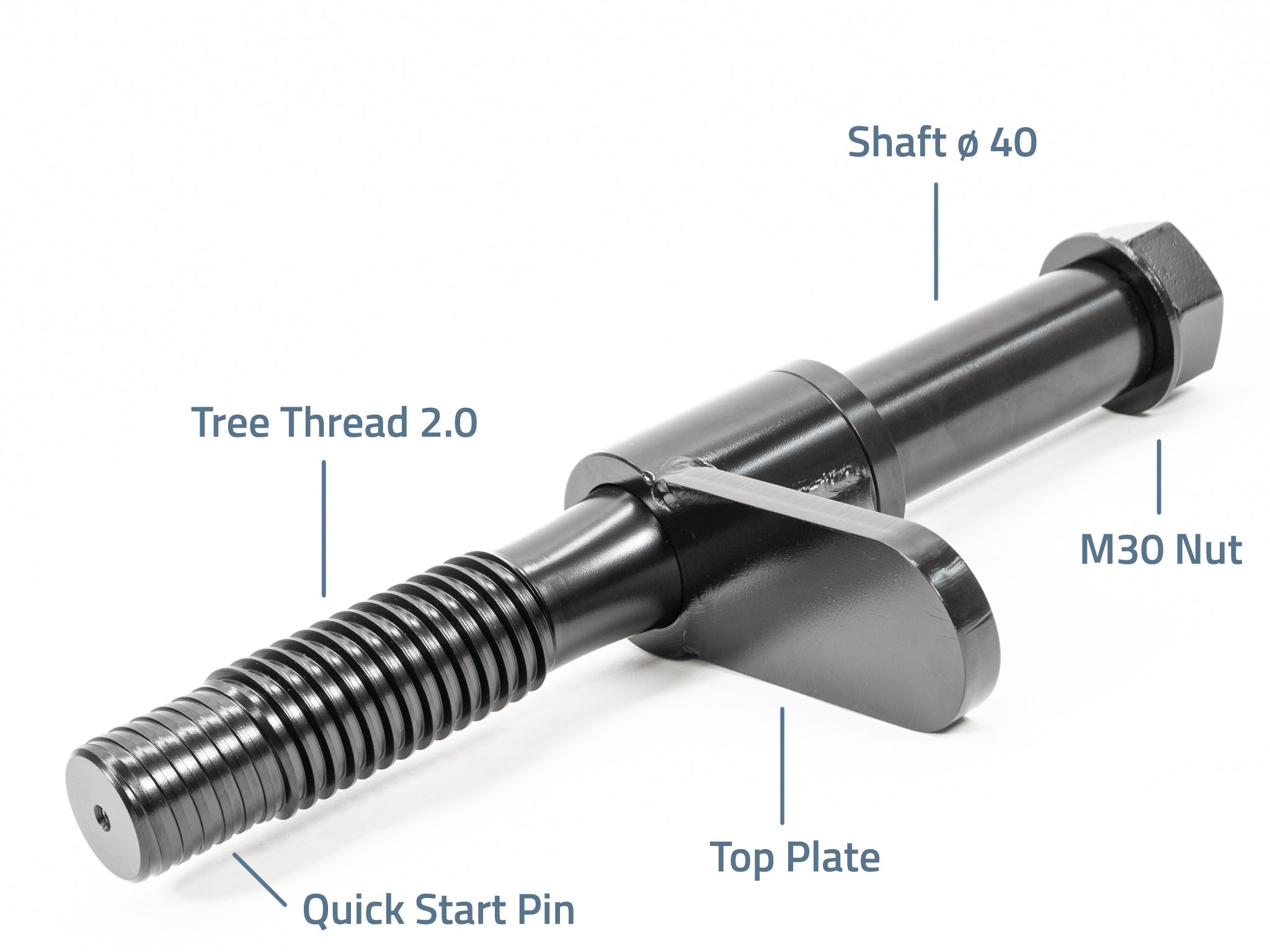

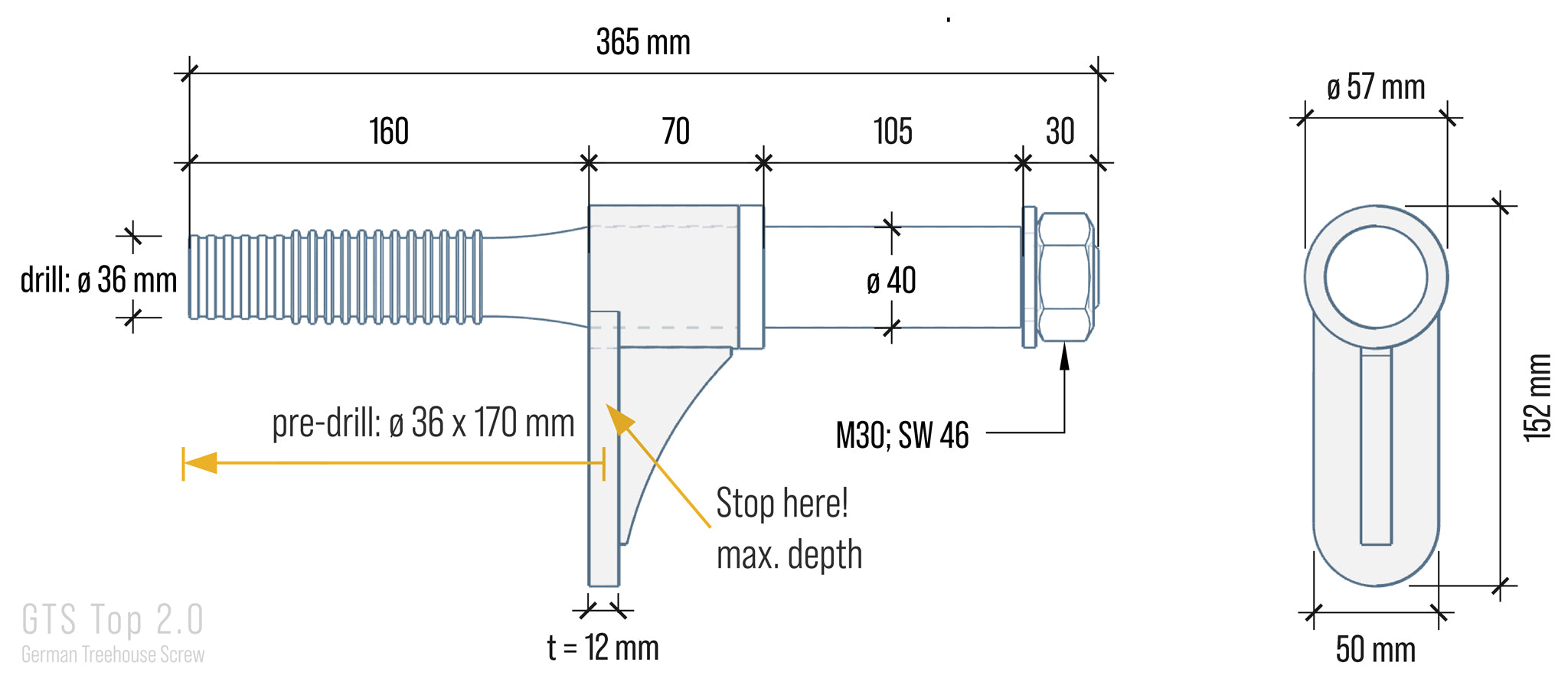

GTS Top – Tree bolt up to 2,100 kg load

Sale priceFrom €204,00

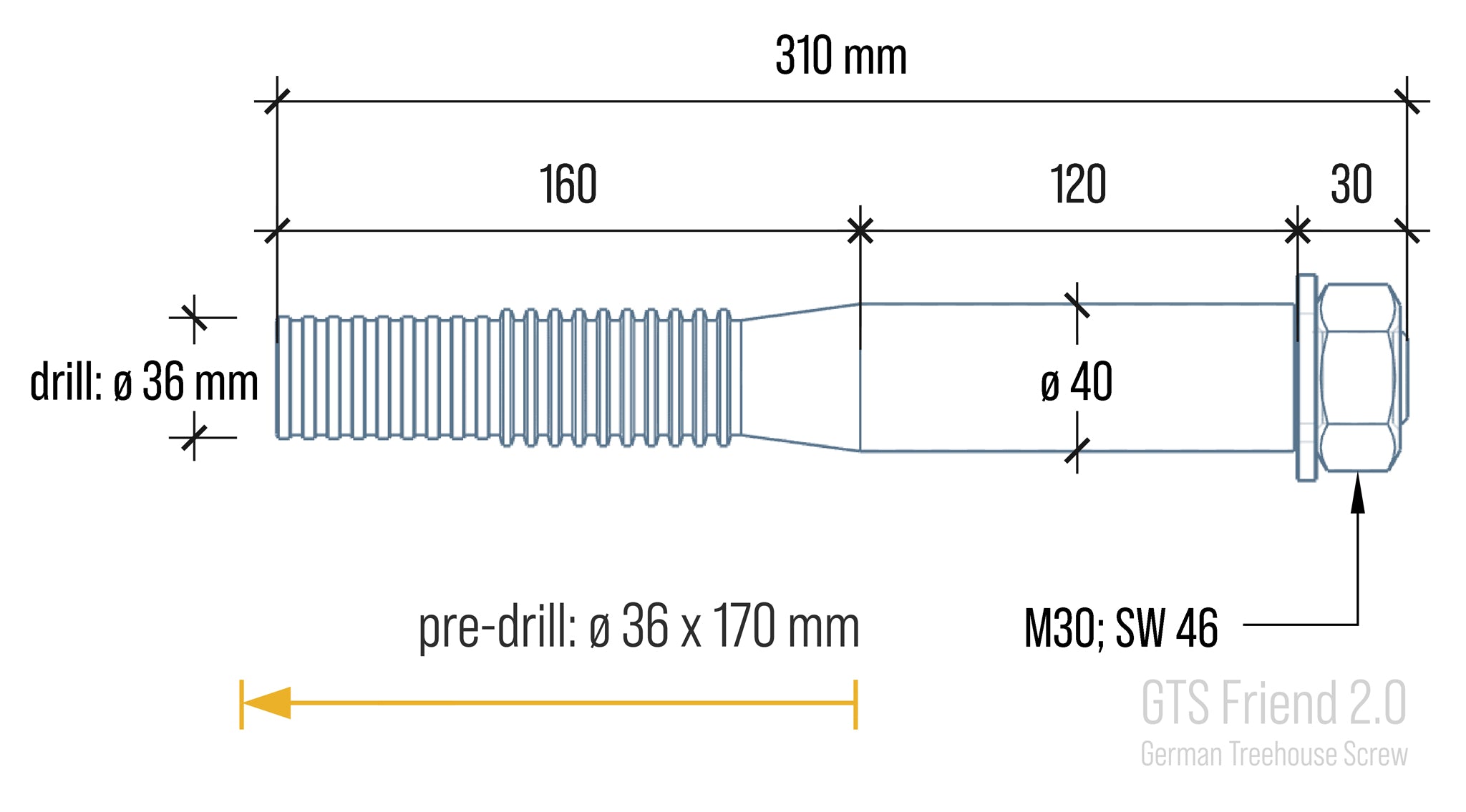

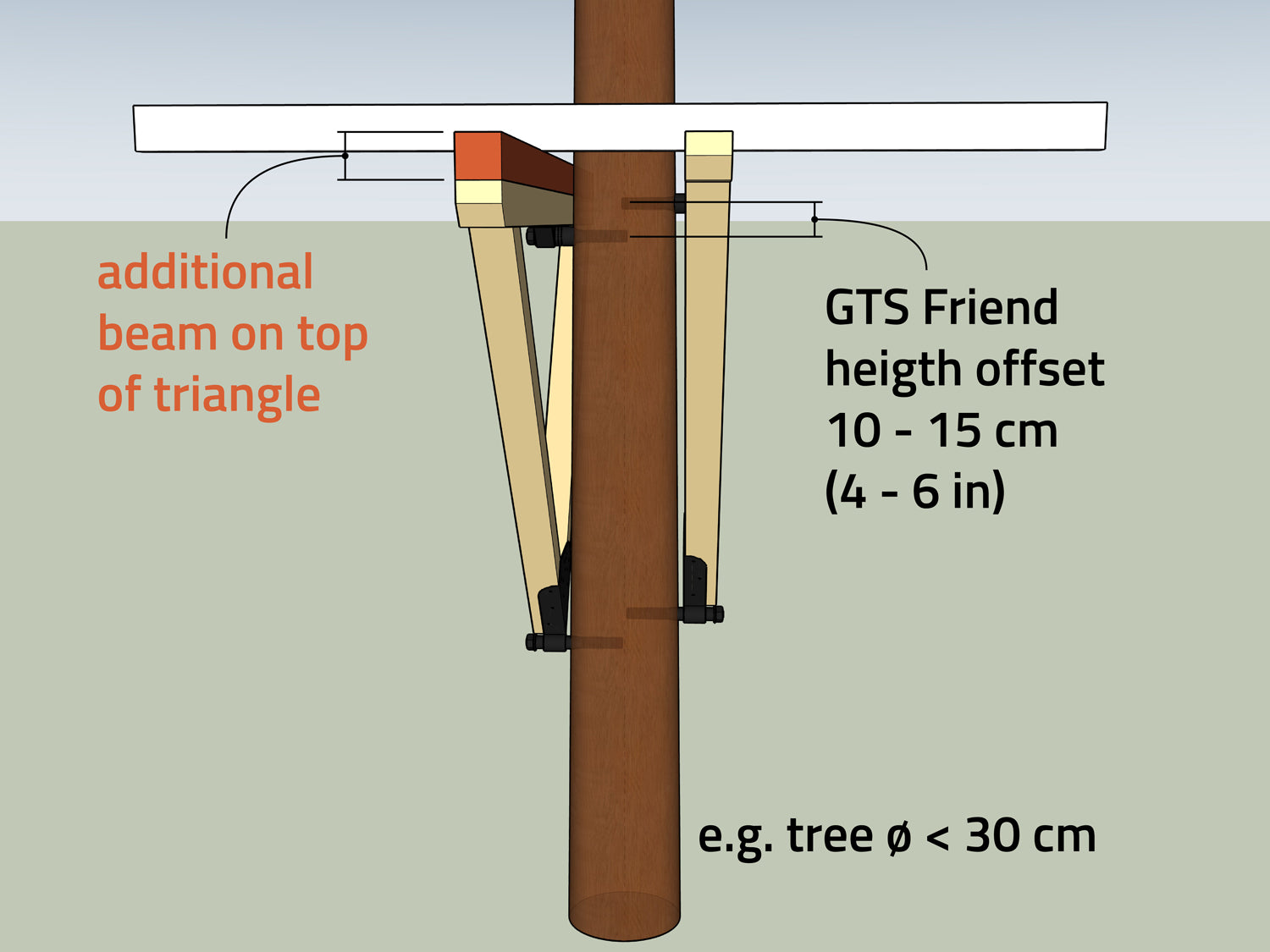

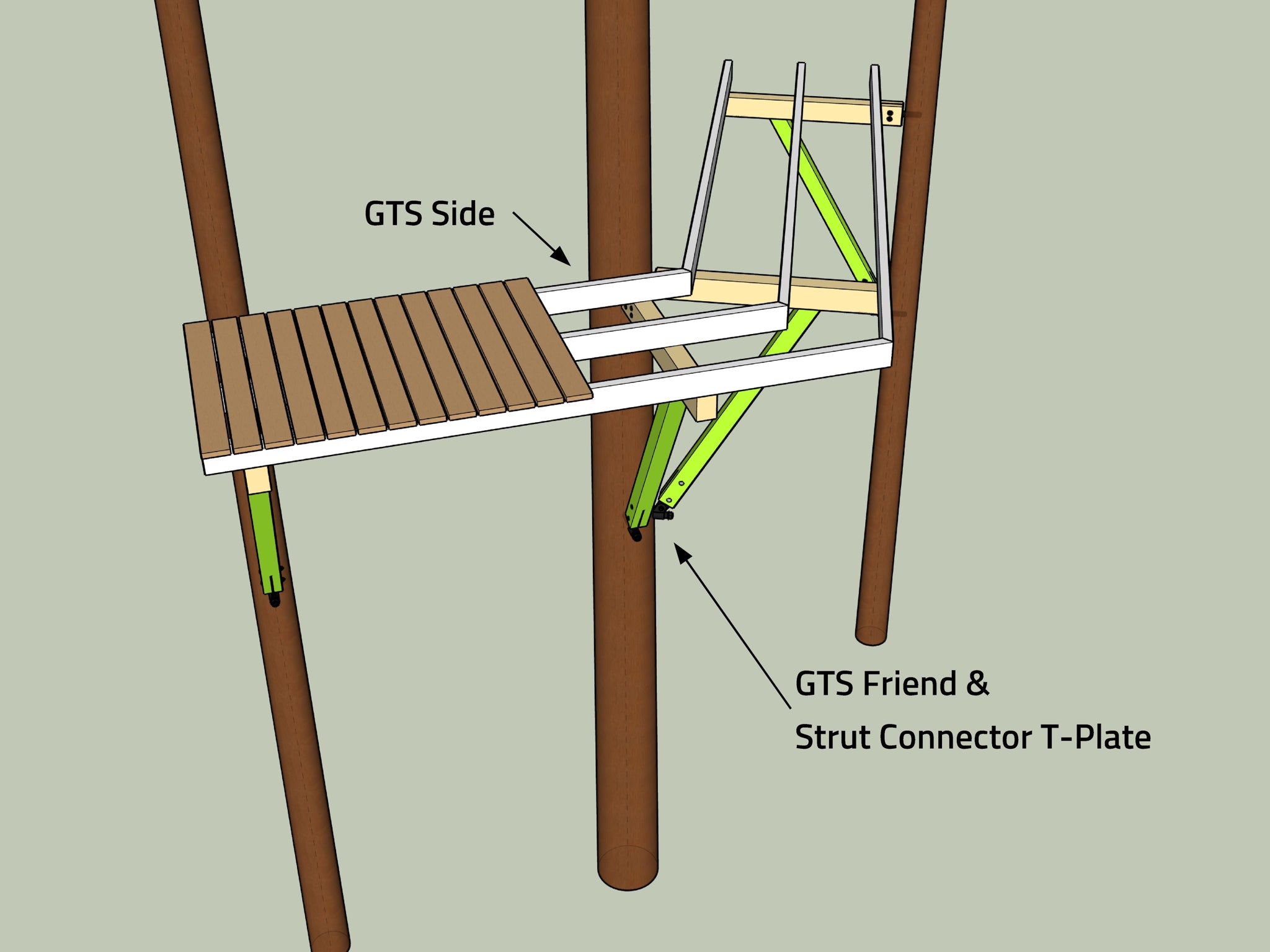

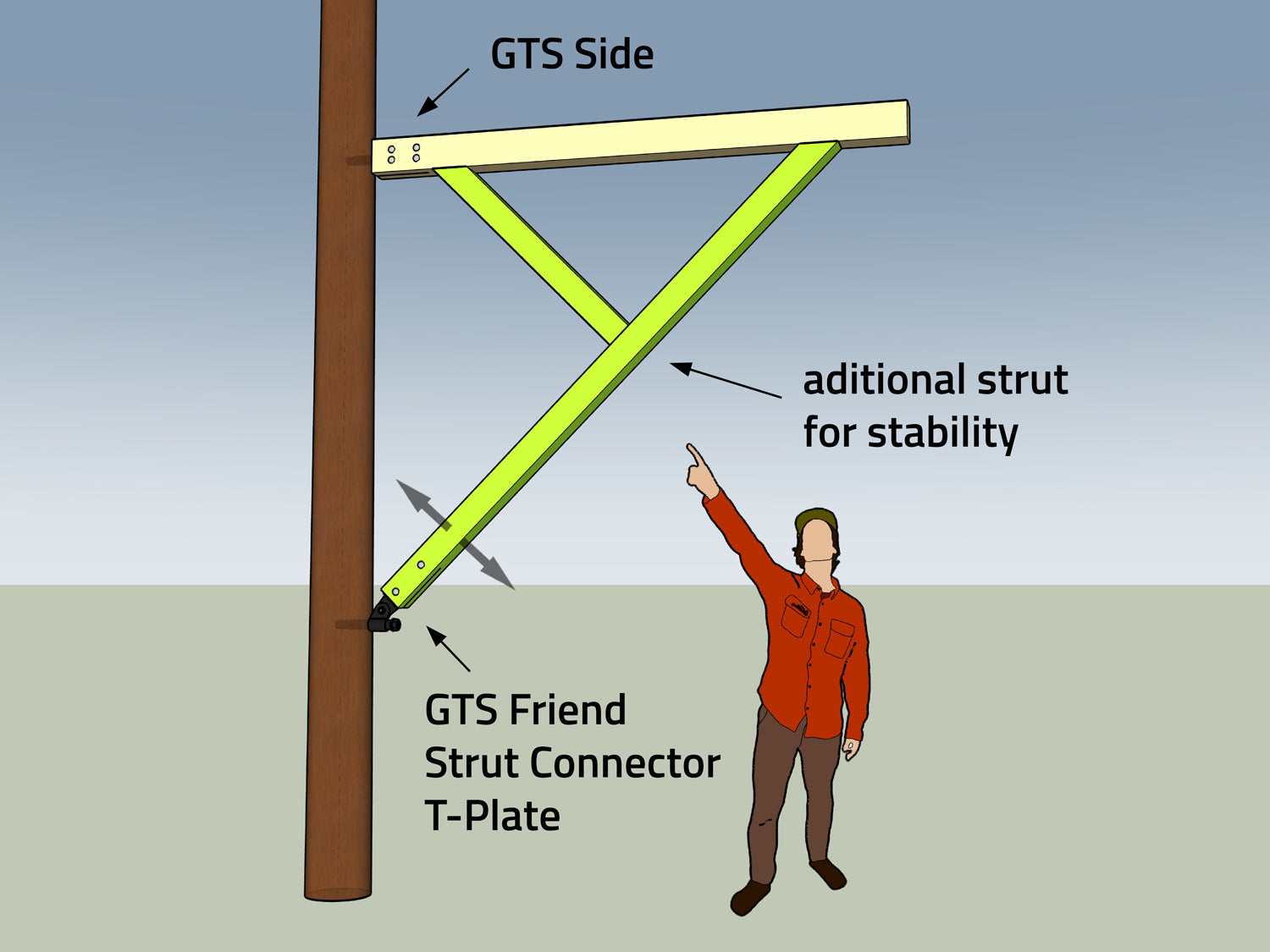

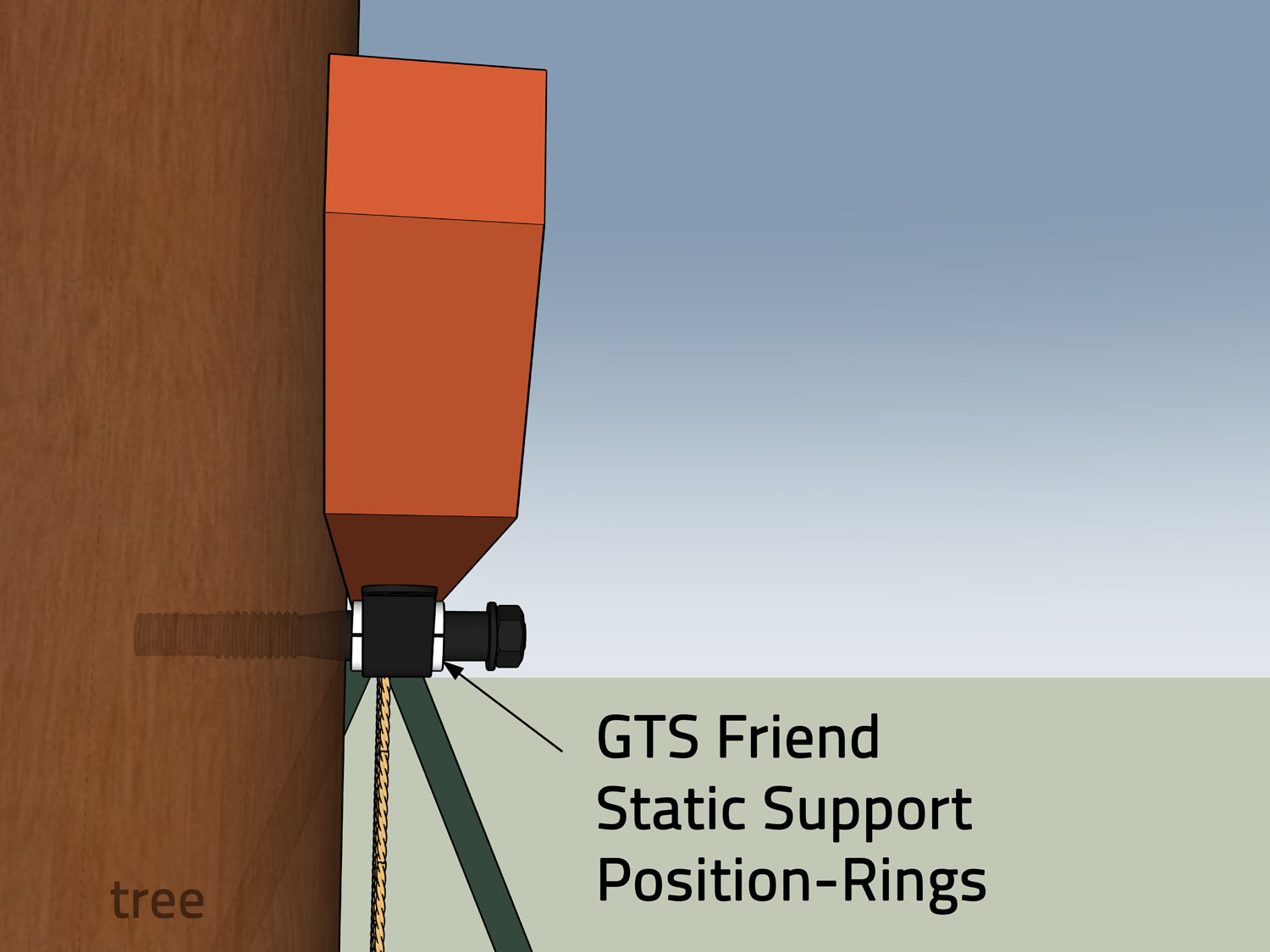

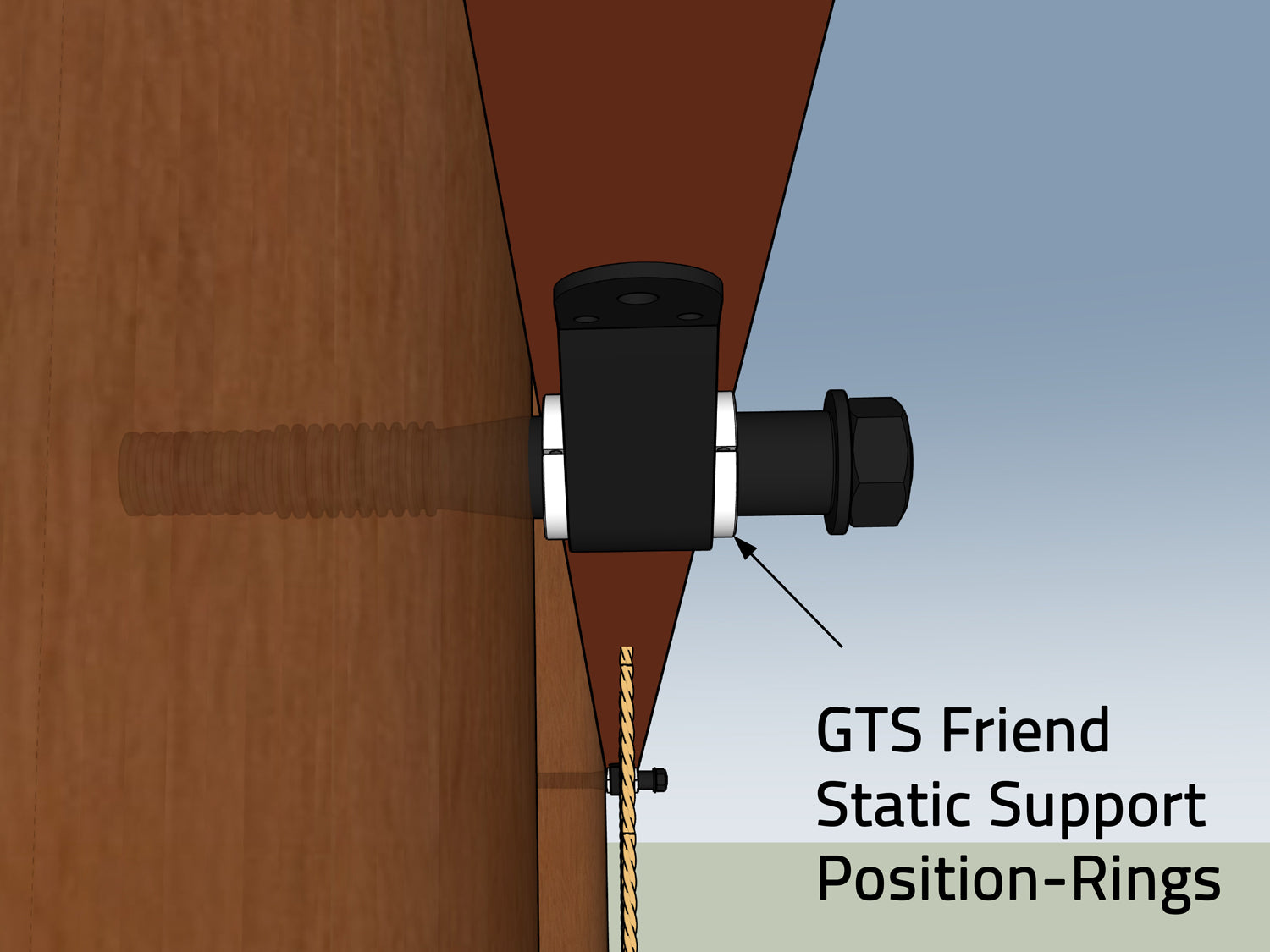

GTS Friend – Tree bolt up to 1,700 kg load

Sale price€132,00

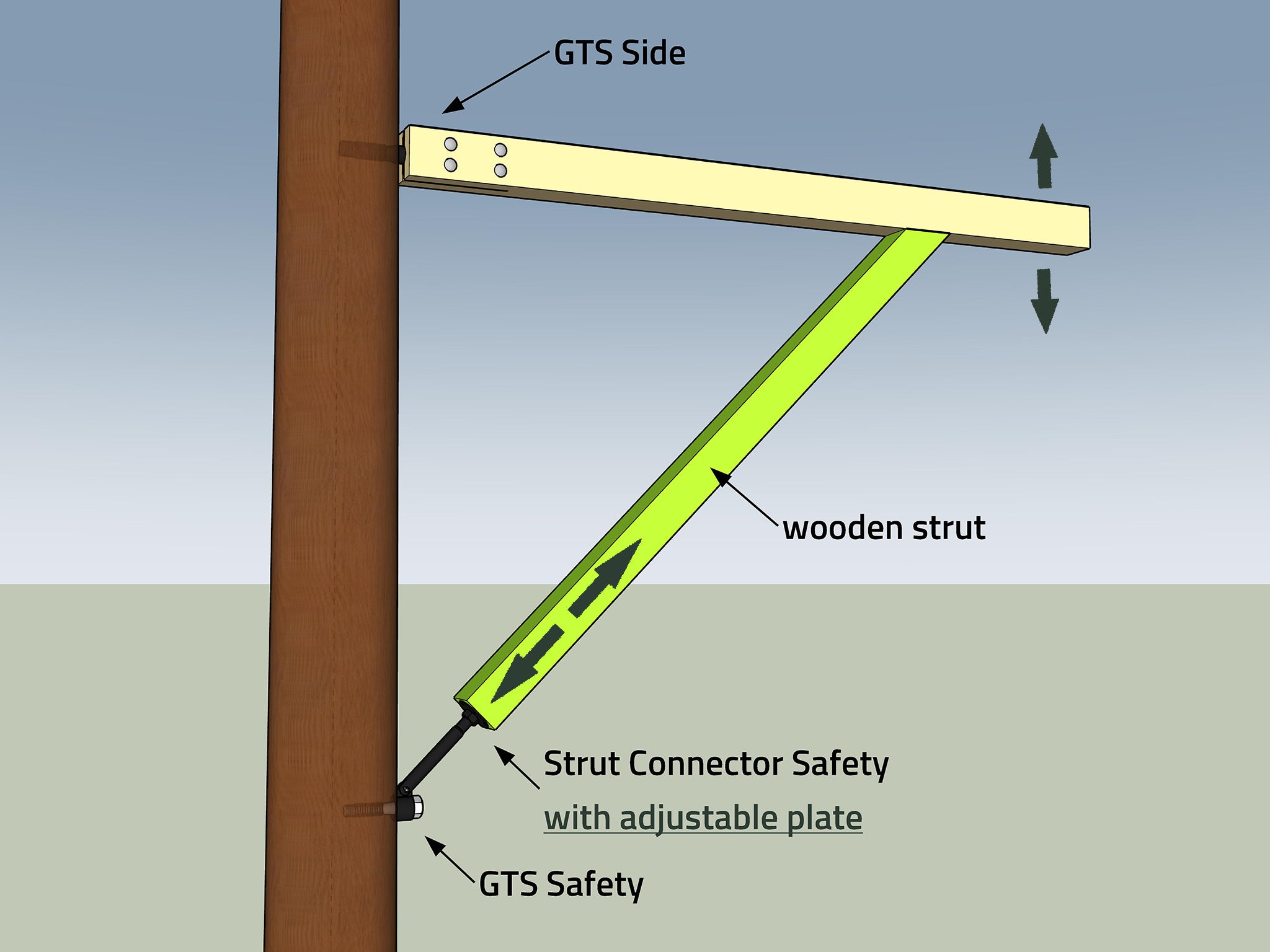

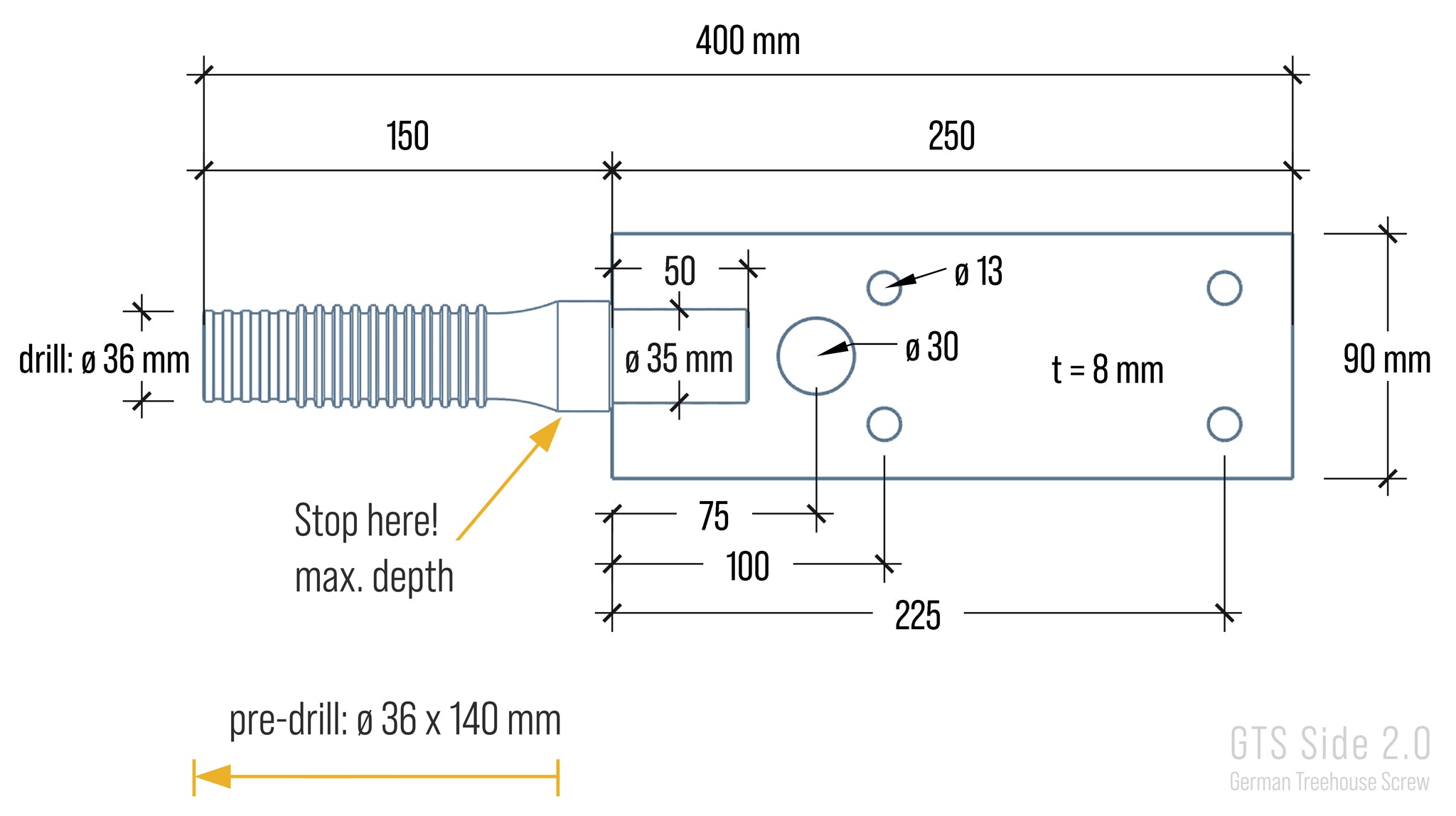

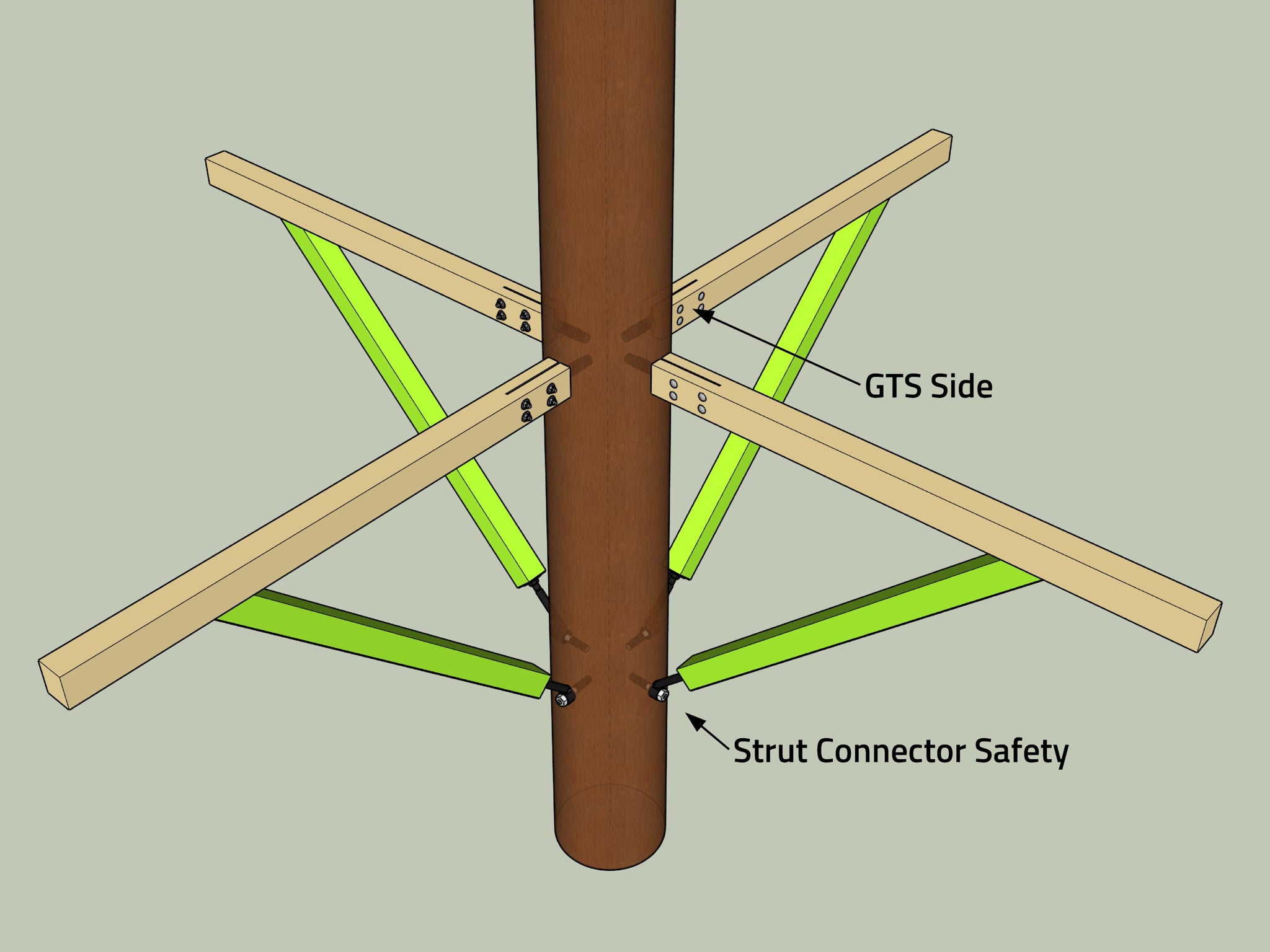

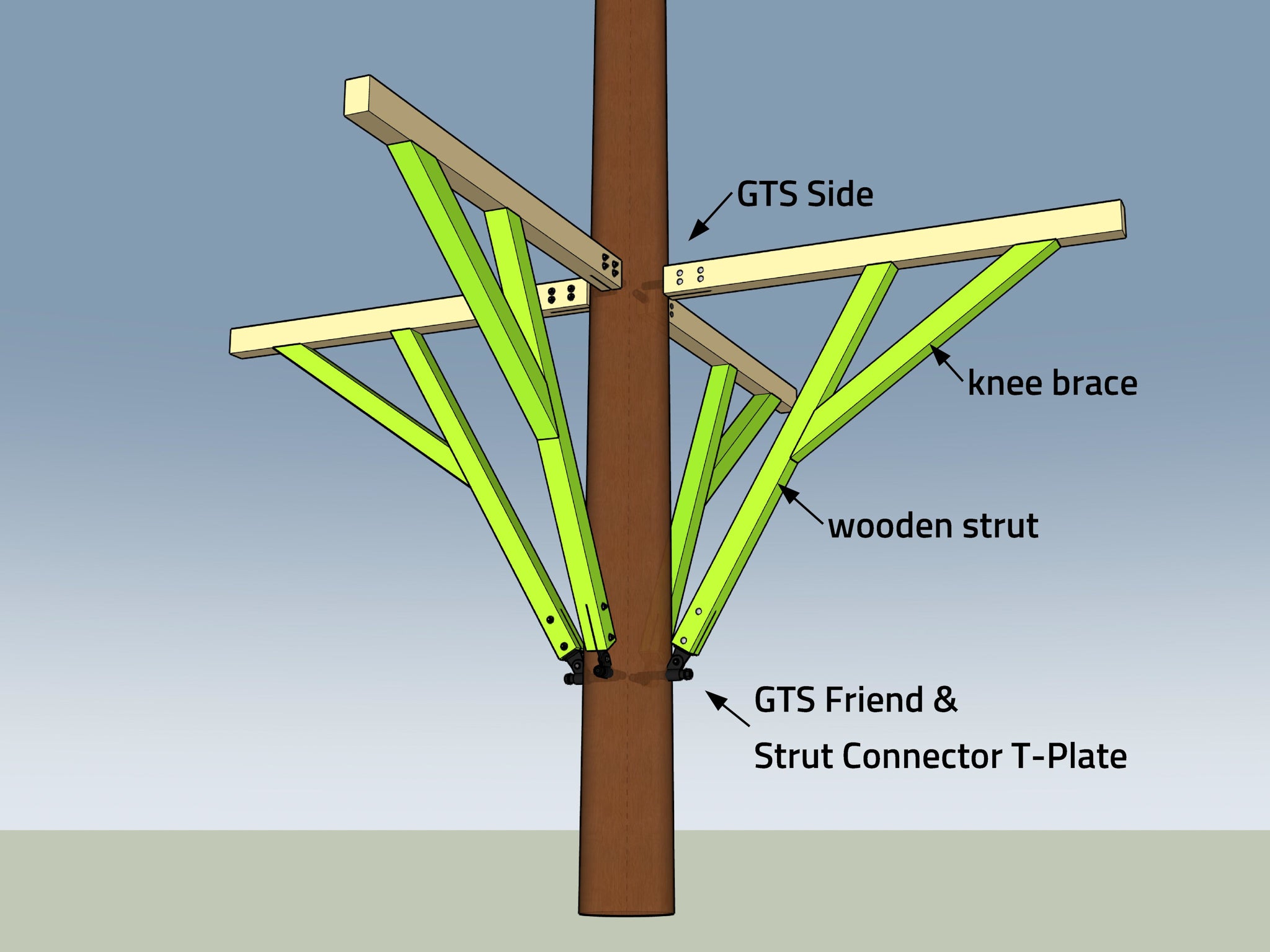

GTS Side – Tree bolt up to 1,200 kg load

Sale price€139,00

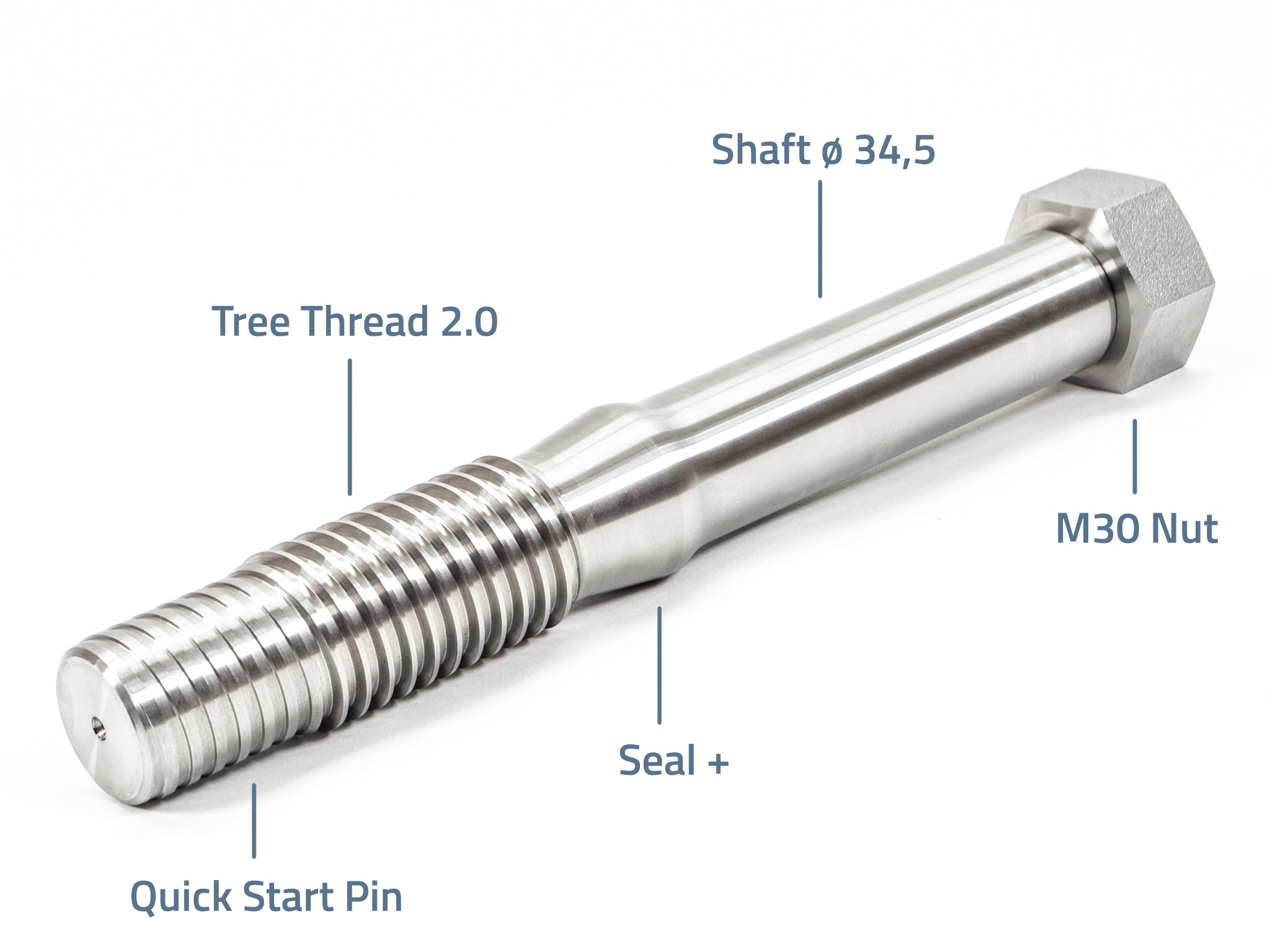

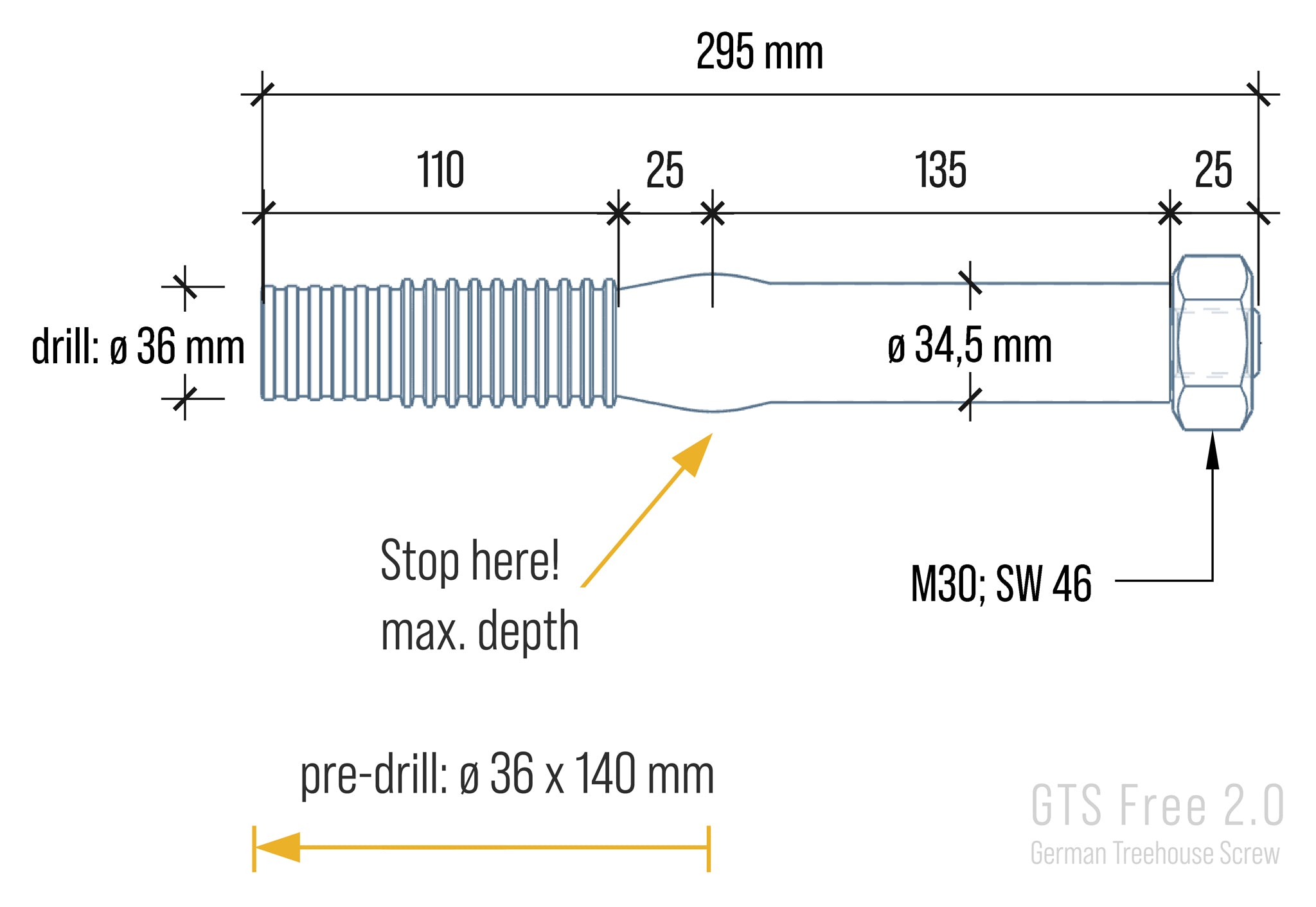

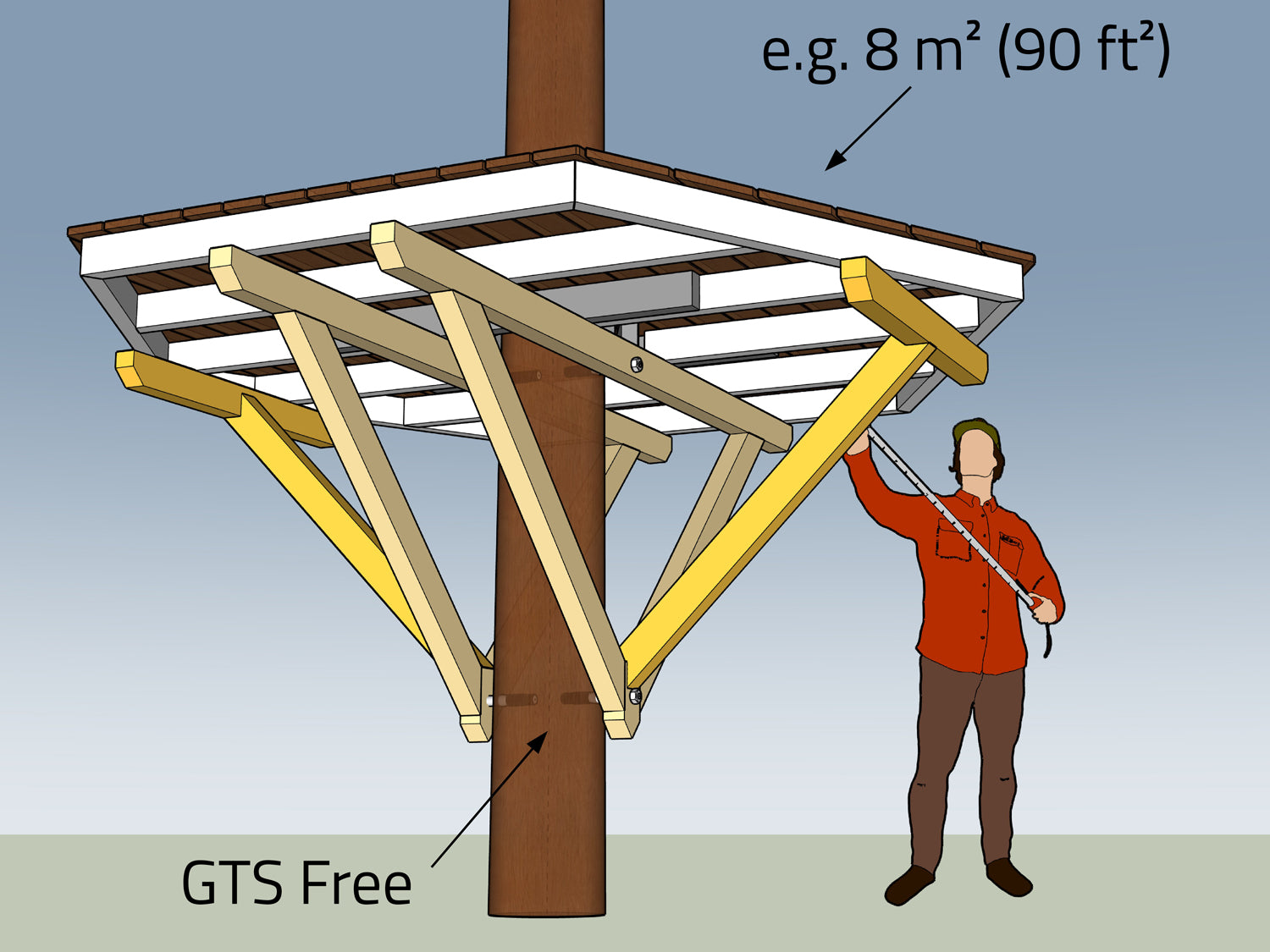

GTS Free – Tree bolt up to 1,400 kg load

Sale price€139,00

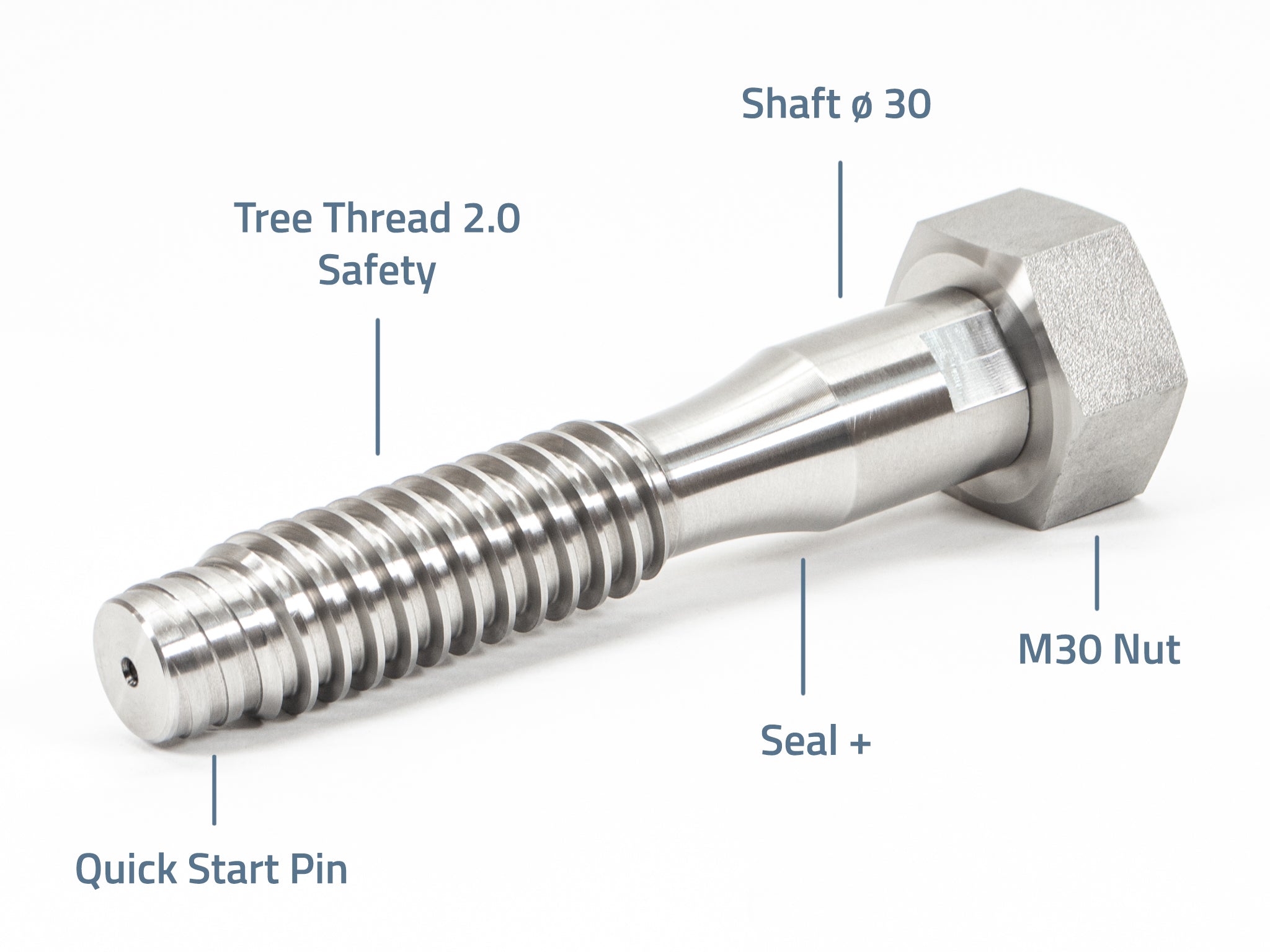

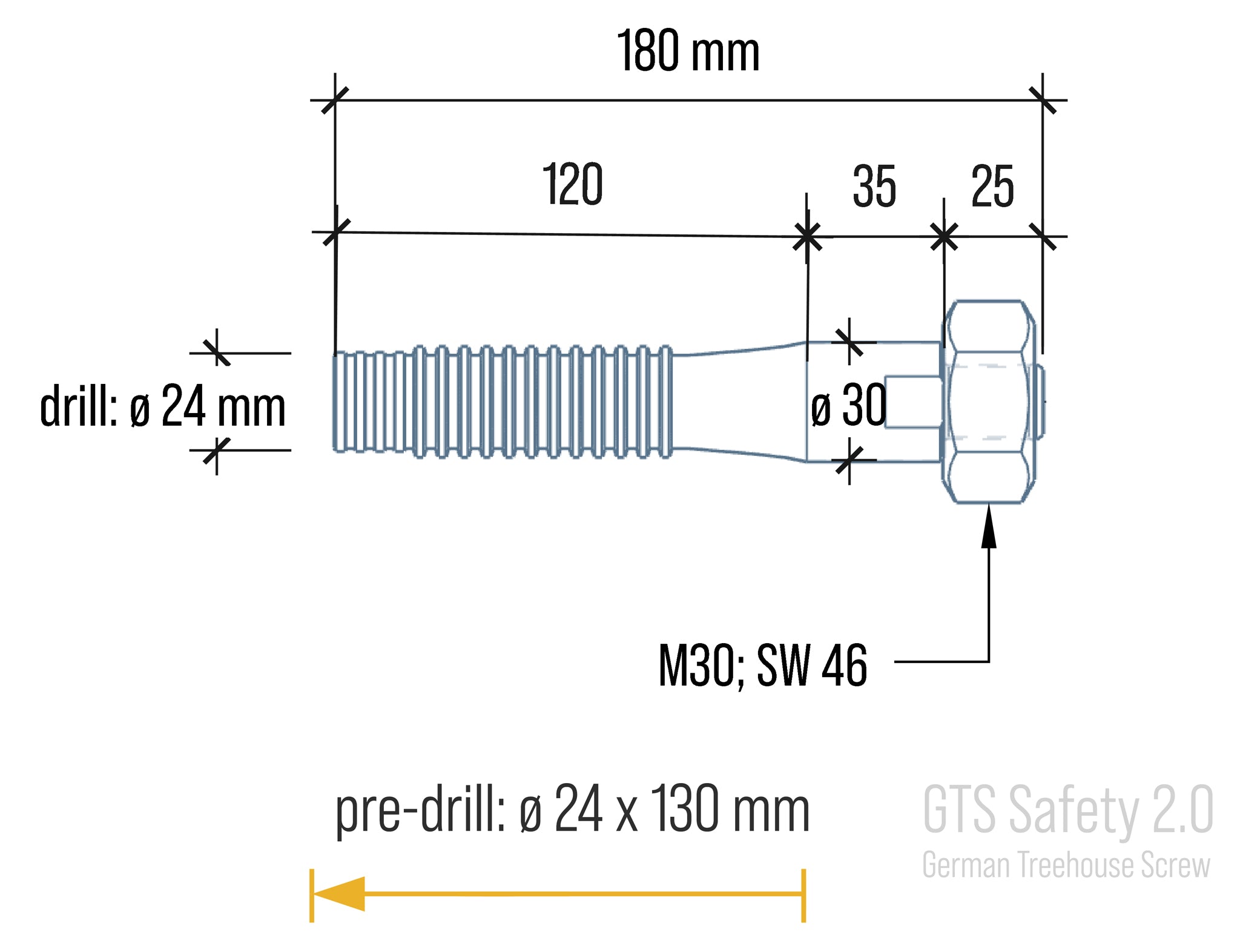

GTS Safety – Tree bolt up to 1,100 kg load

Sale priceFrom €89,00

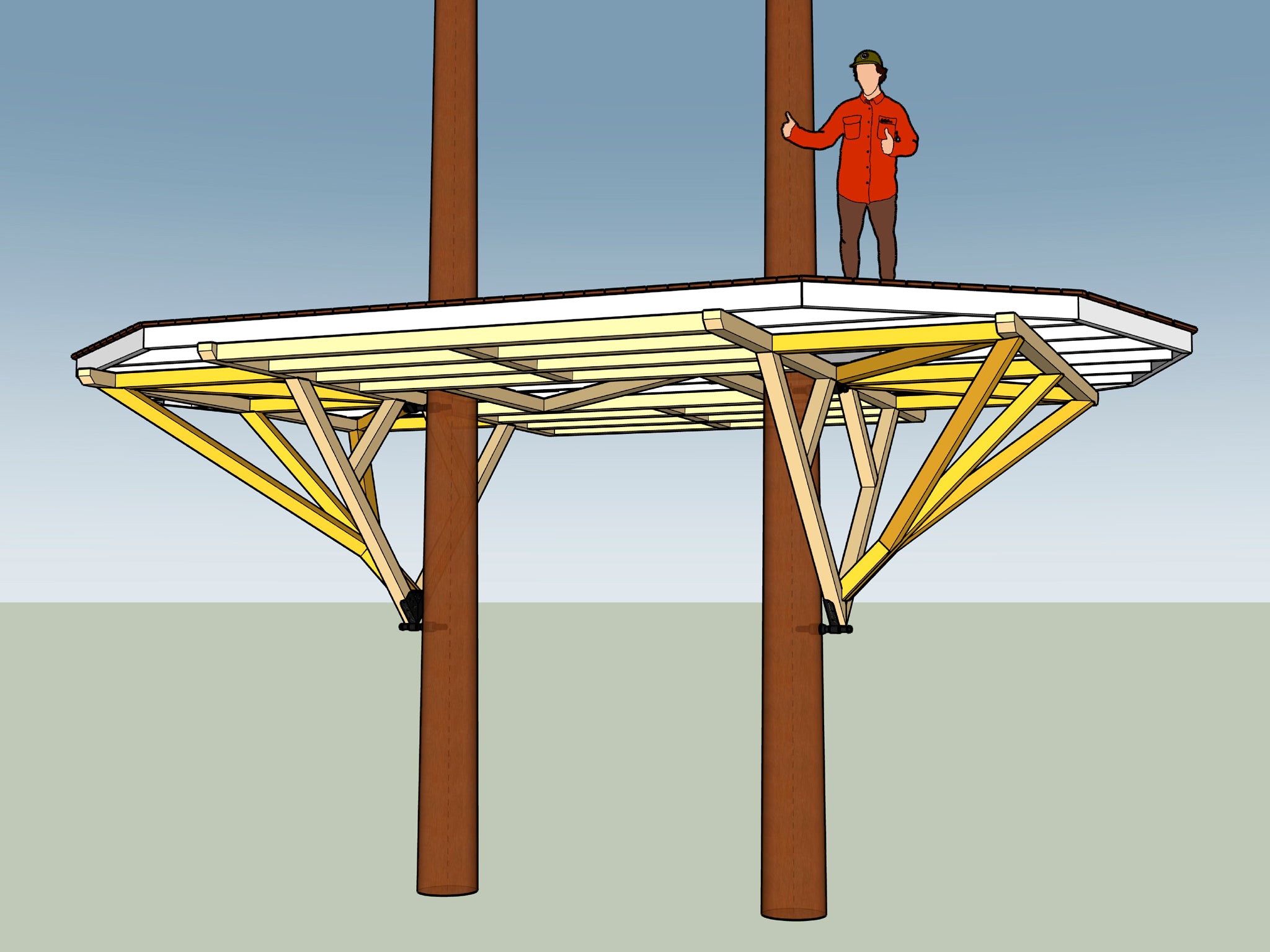

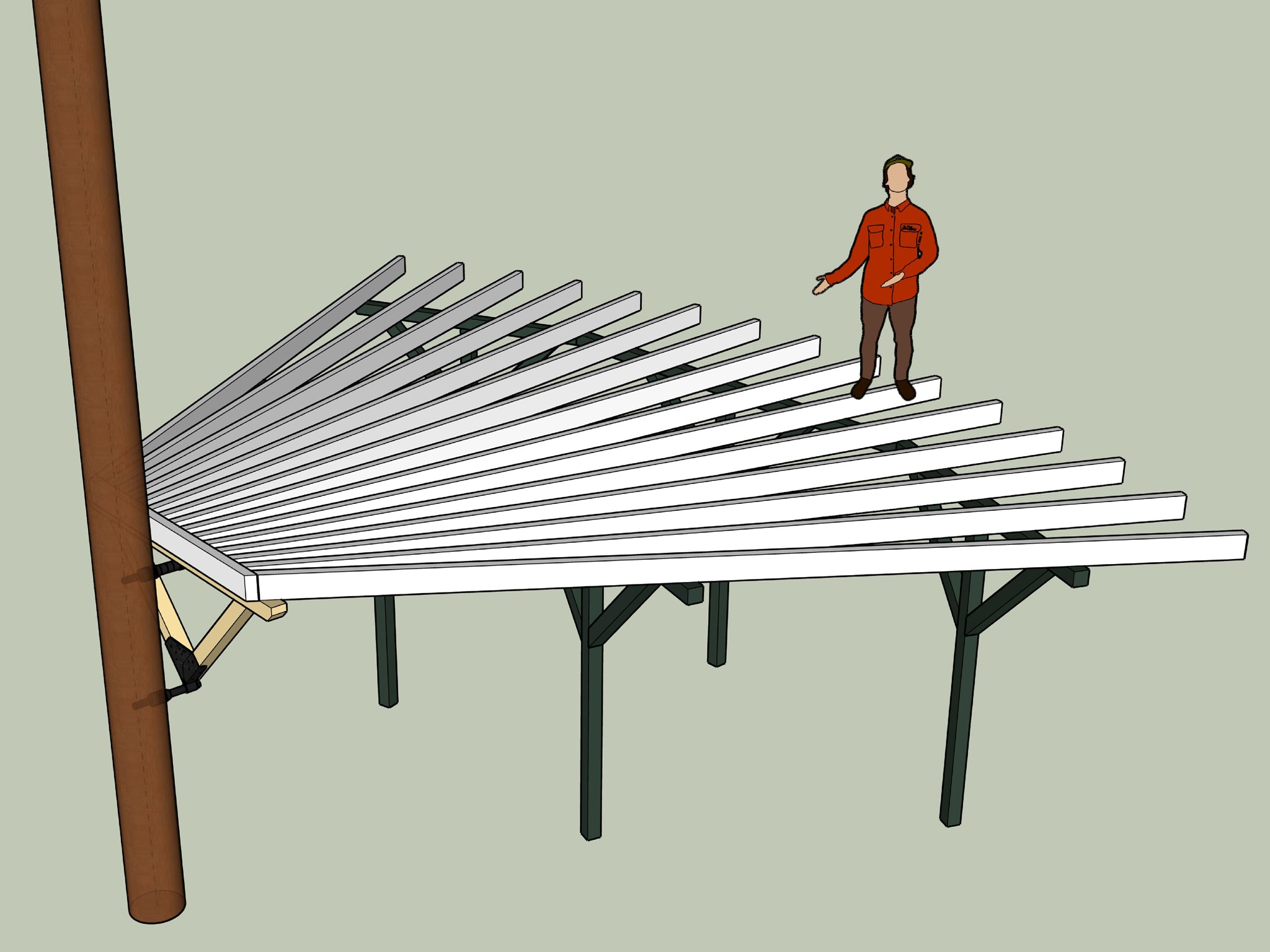

XS Treehouse Hardware Kit for 1-2 Trees, 4 Free

Sale price€556,00

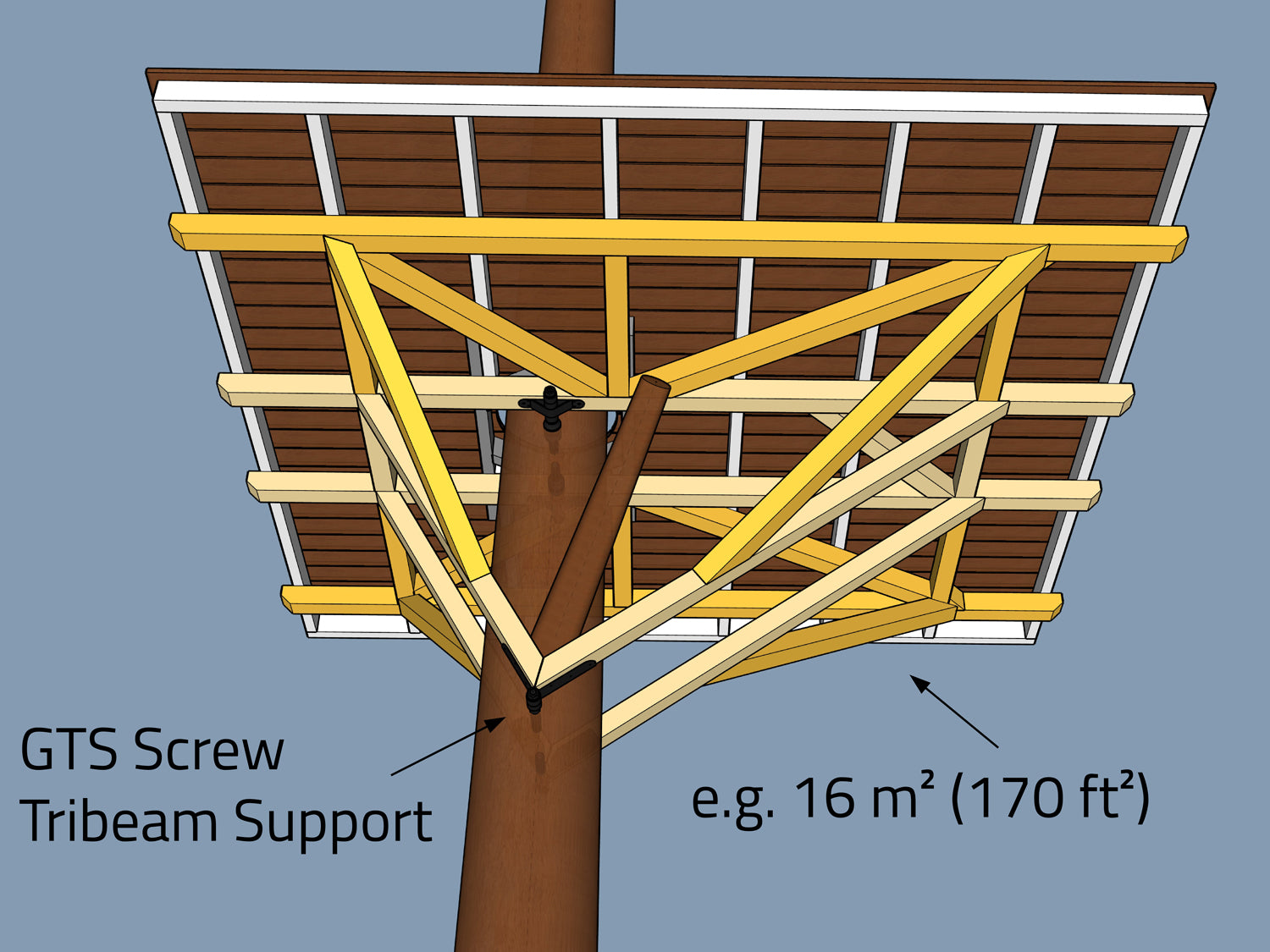

S Treehouse Hardware Kit for 1-2 Trees, Tribeam V90

Sale price€1.196,00

L Treehouse Hardware Kit for 1-2 Trees, Tribeam V60

Sale price€1.510,00

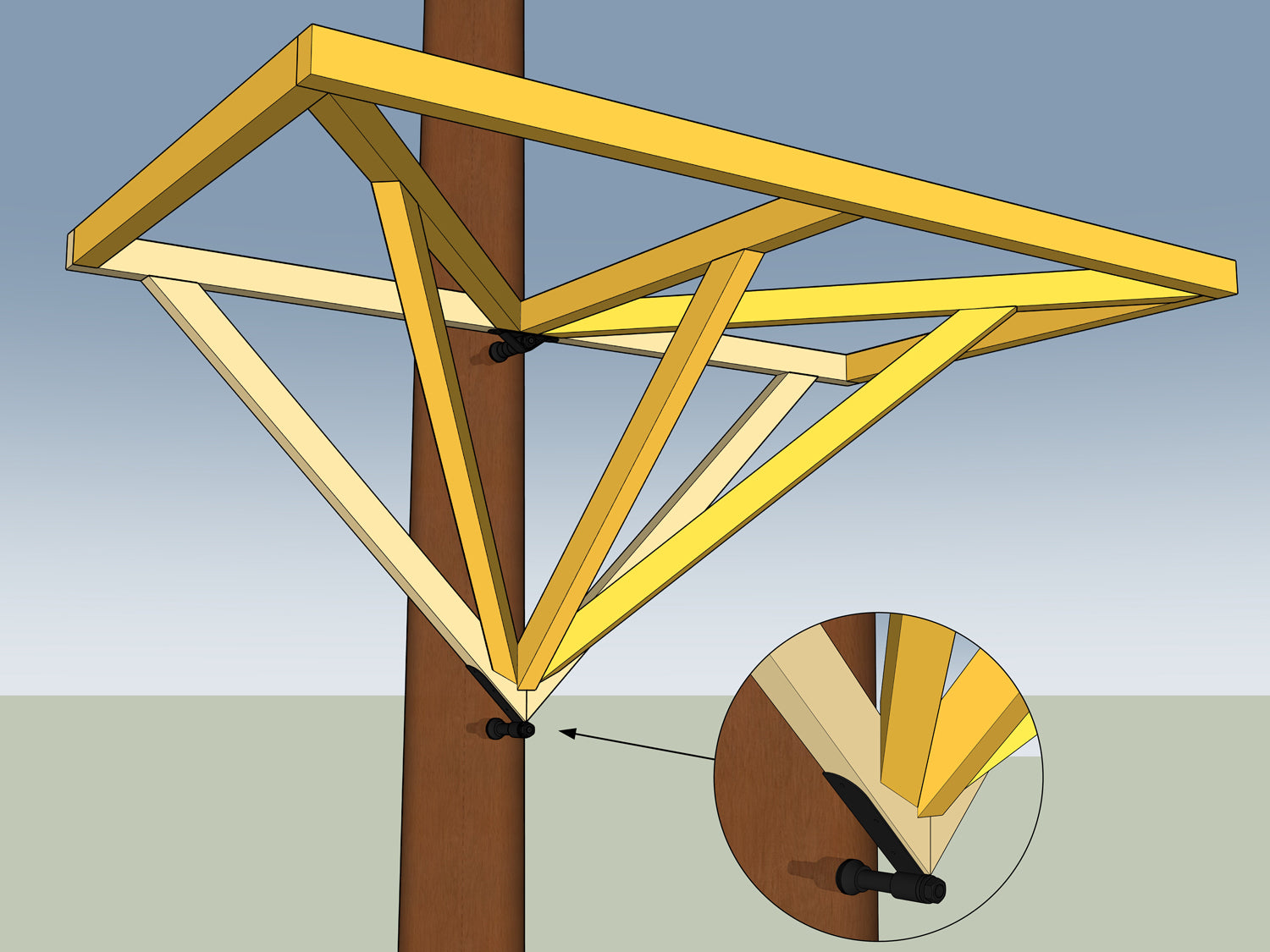

XL Treehouse Hardware Kit for 1-2 Trees, Tribeam D90

Sale price€1.668,00

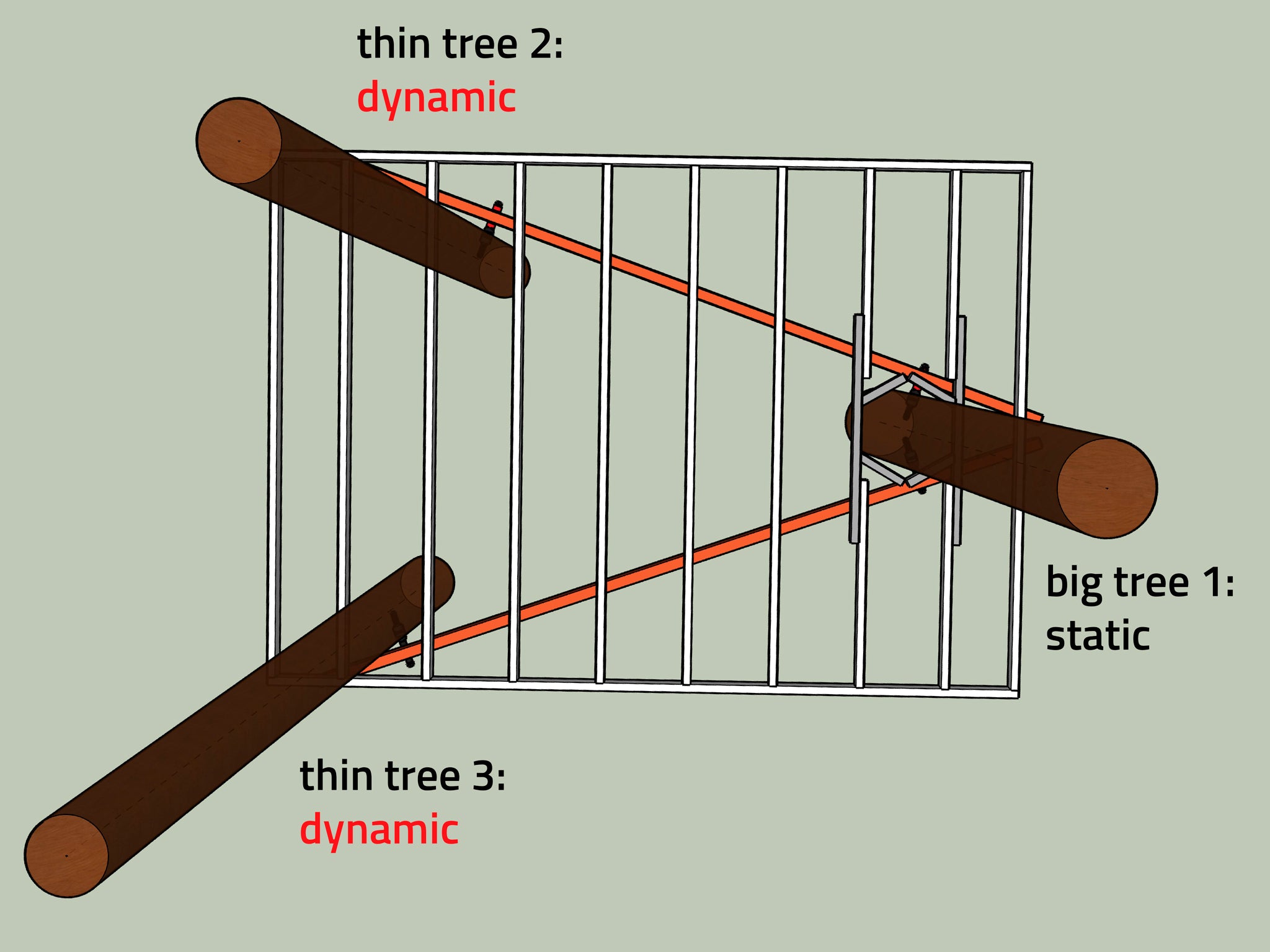

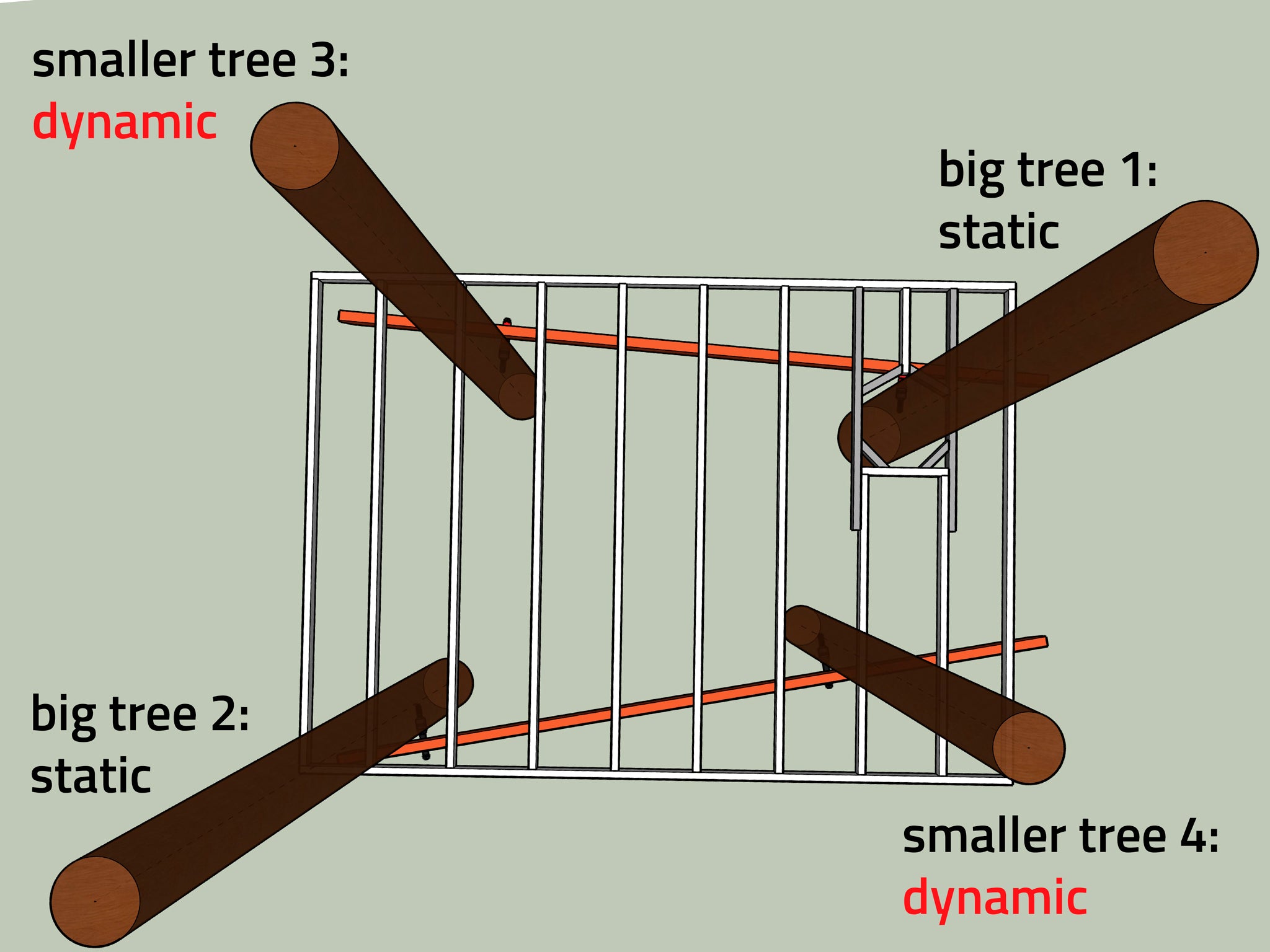

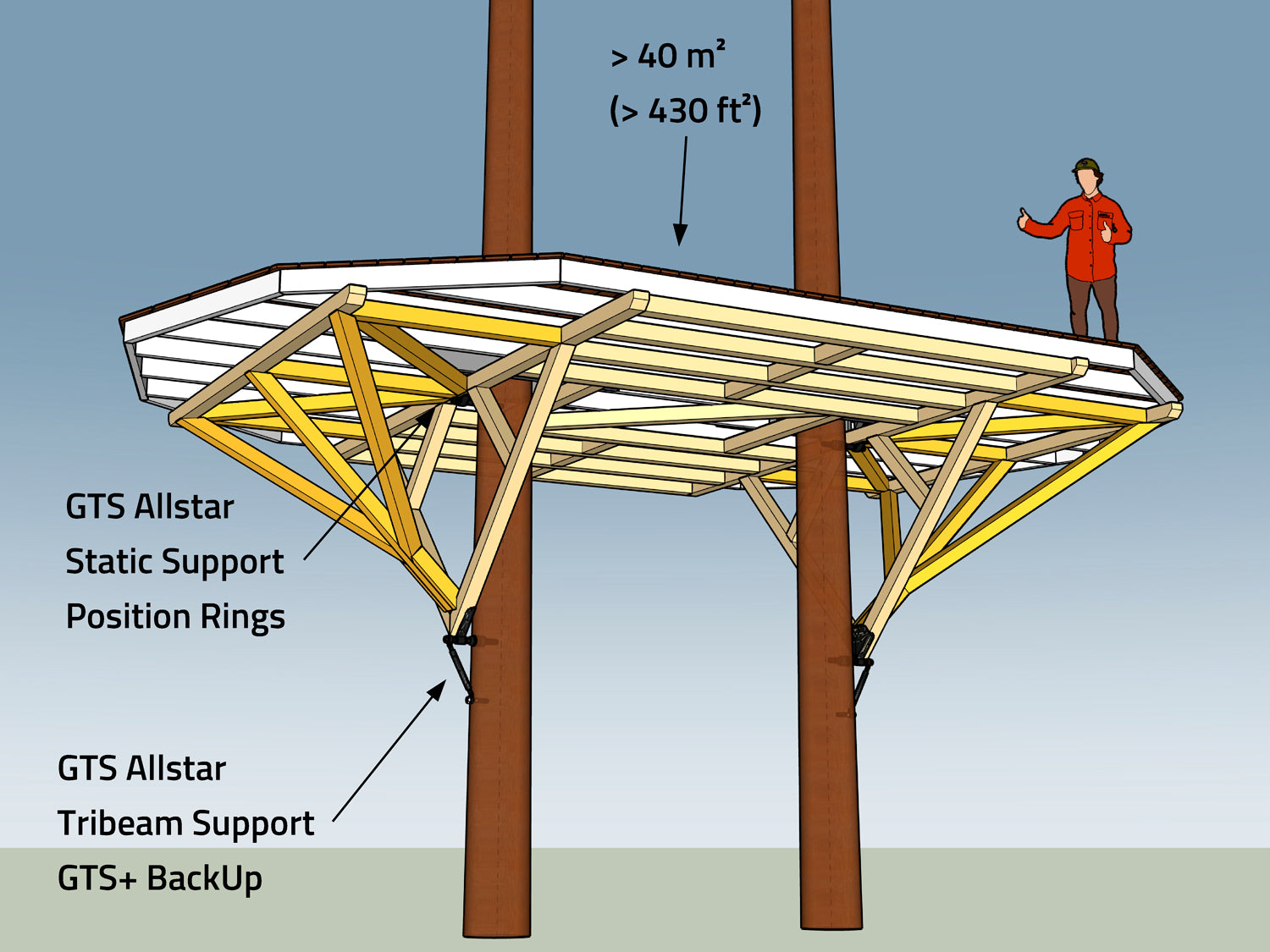

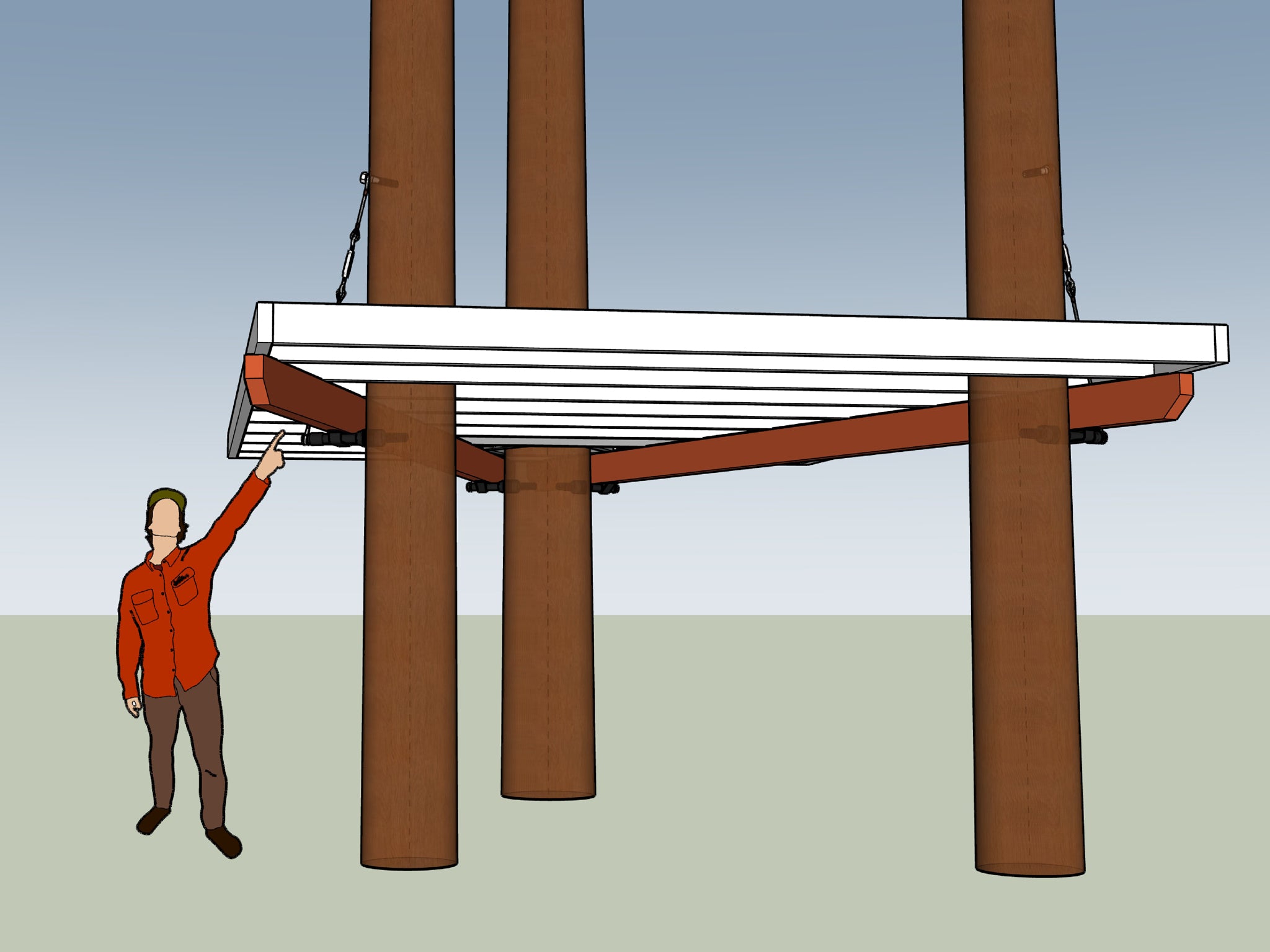

XL Treehouse Hardware Kit for 2-4 Trees, Dynamic

Sale price€1.534,00

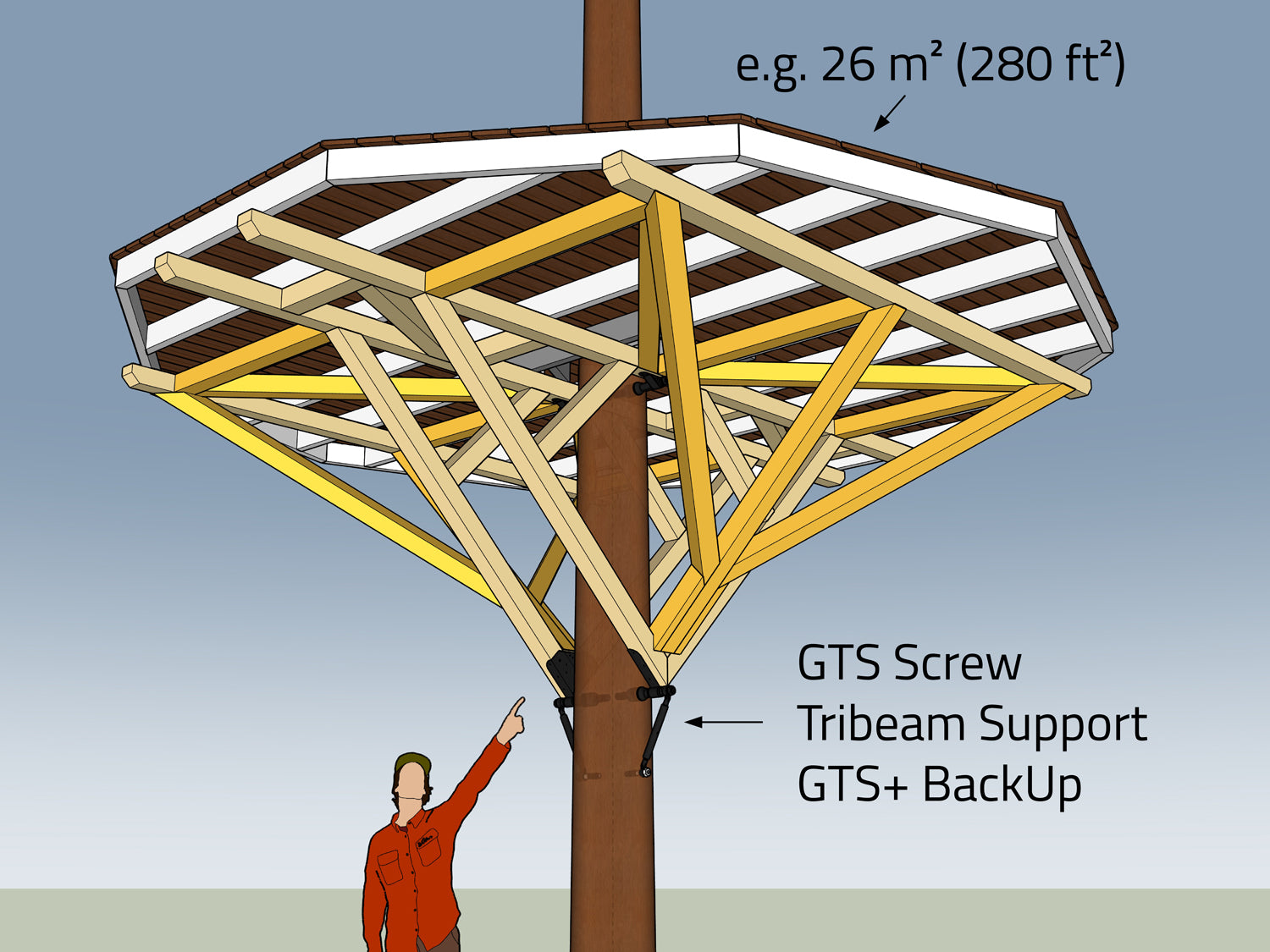

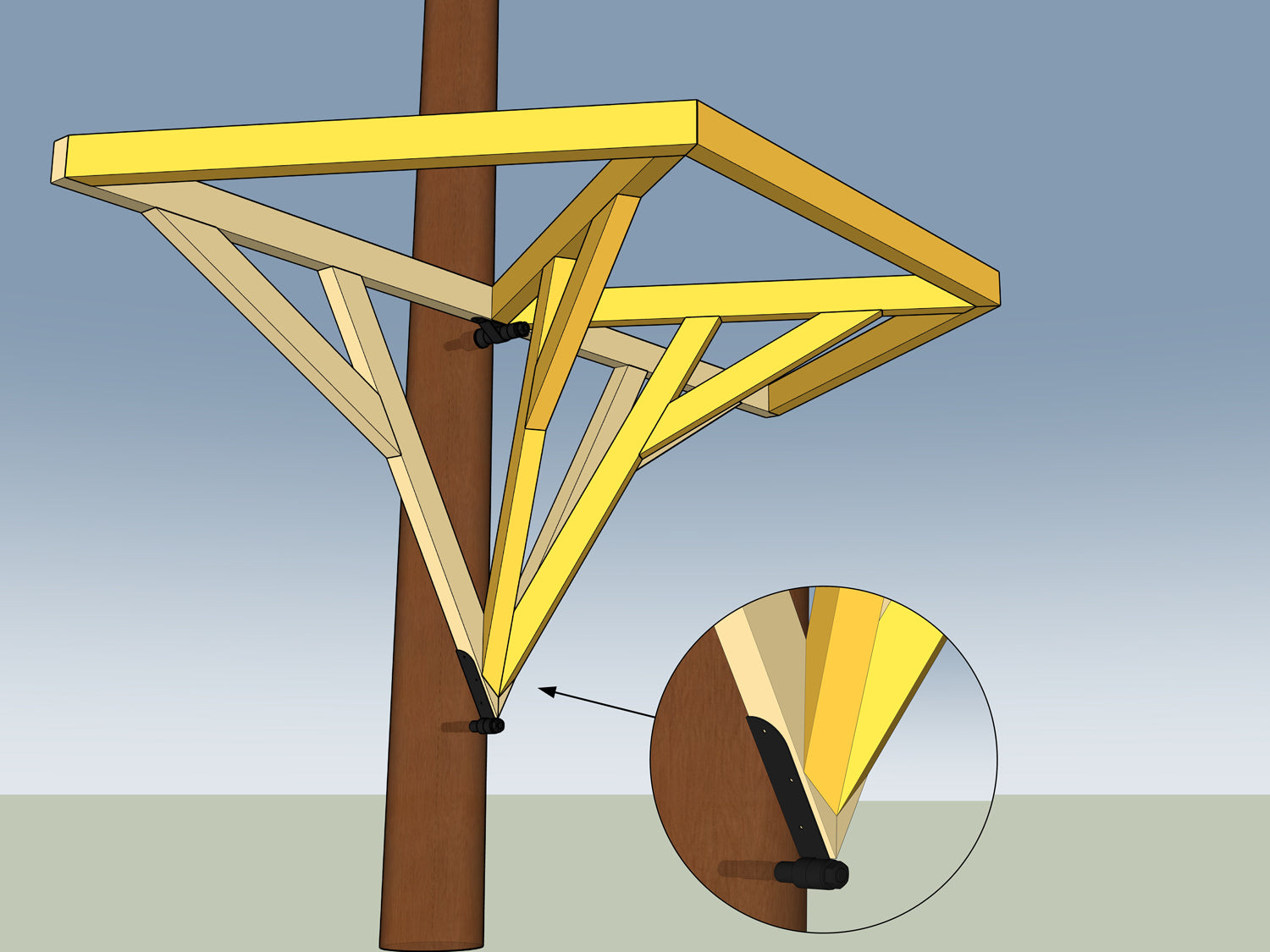

XXL Treehouse Hardware Kit for 1-2 Trees, Tribeam GTS+

Sale price€2.112,00

XXL Treehouse Hardware Kit for 2-4 Trees, Dynamic GTS+

Sale price€1.932,00

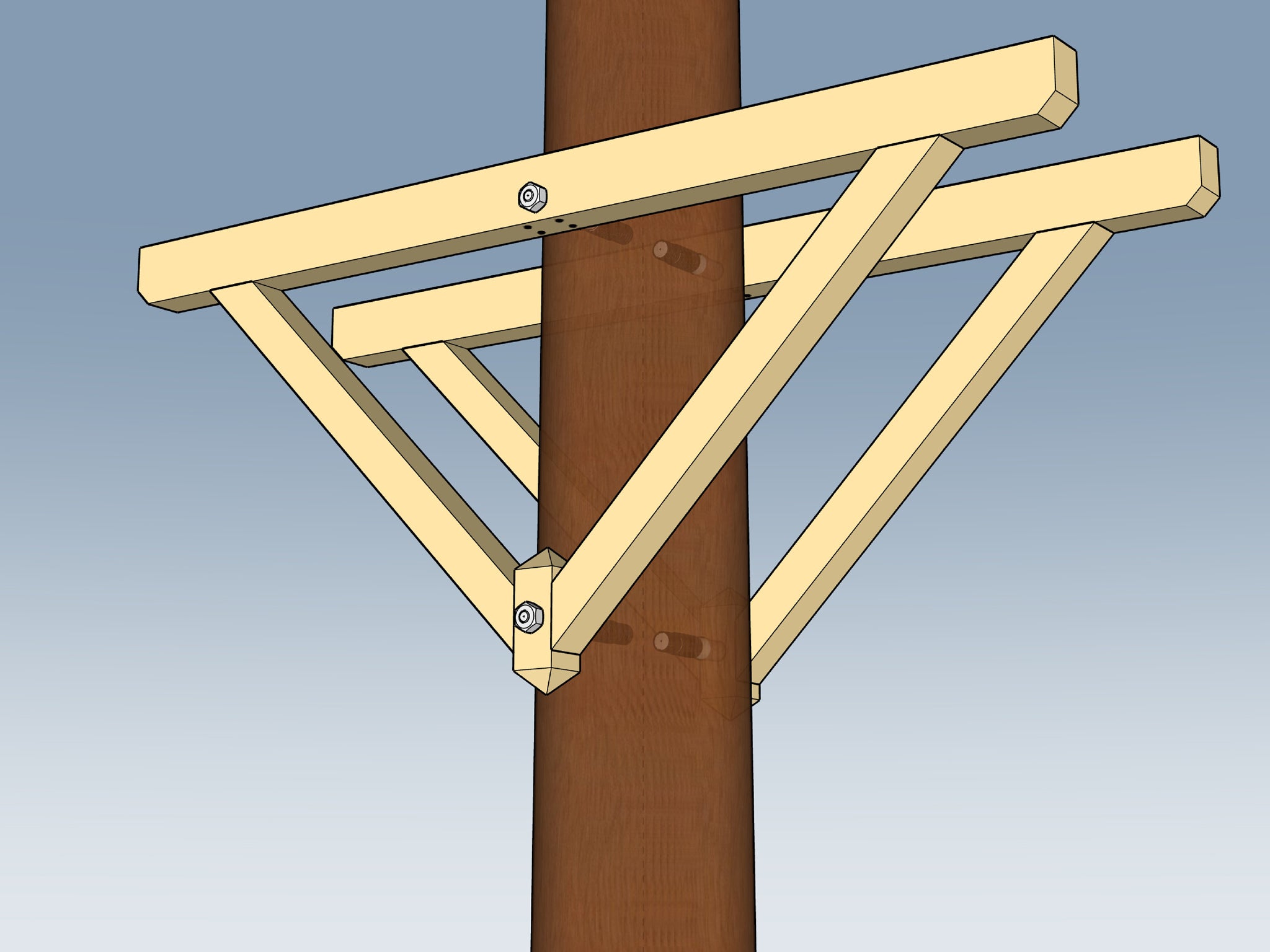

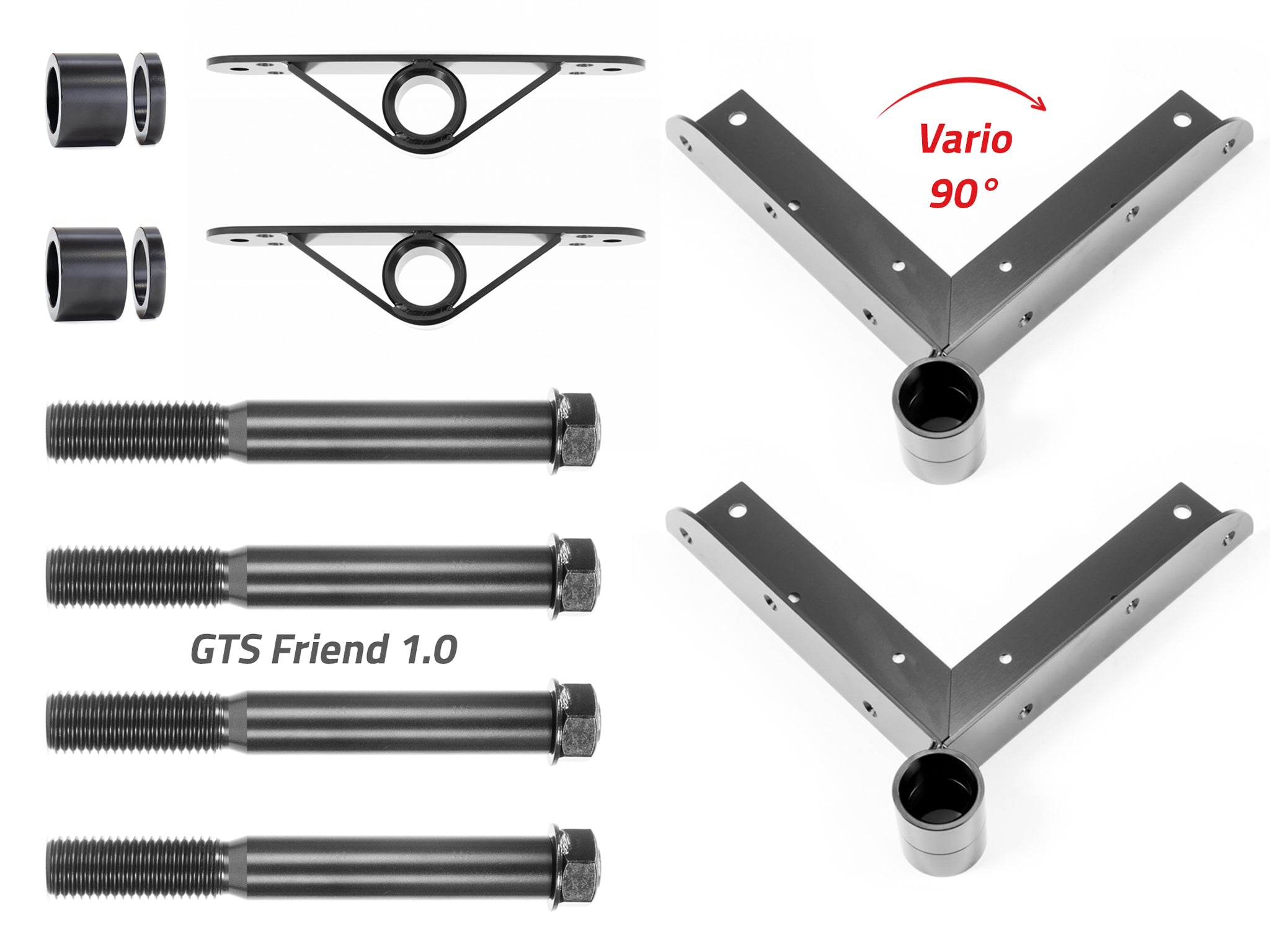

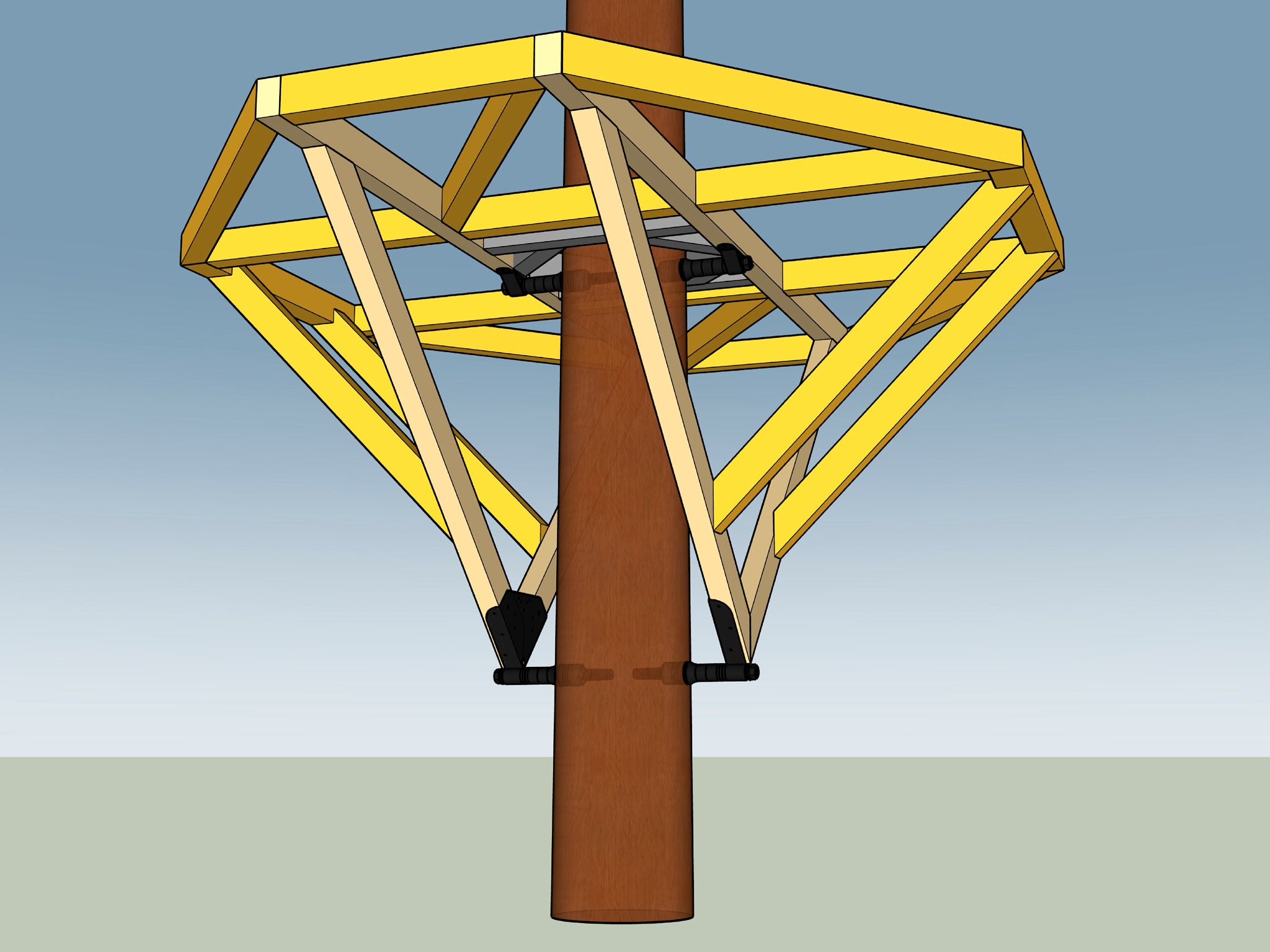

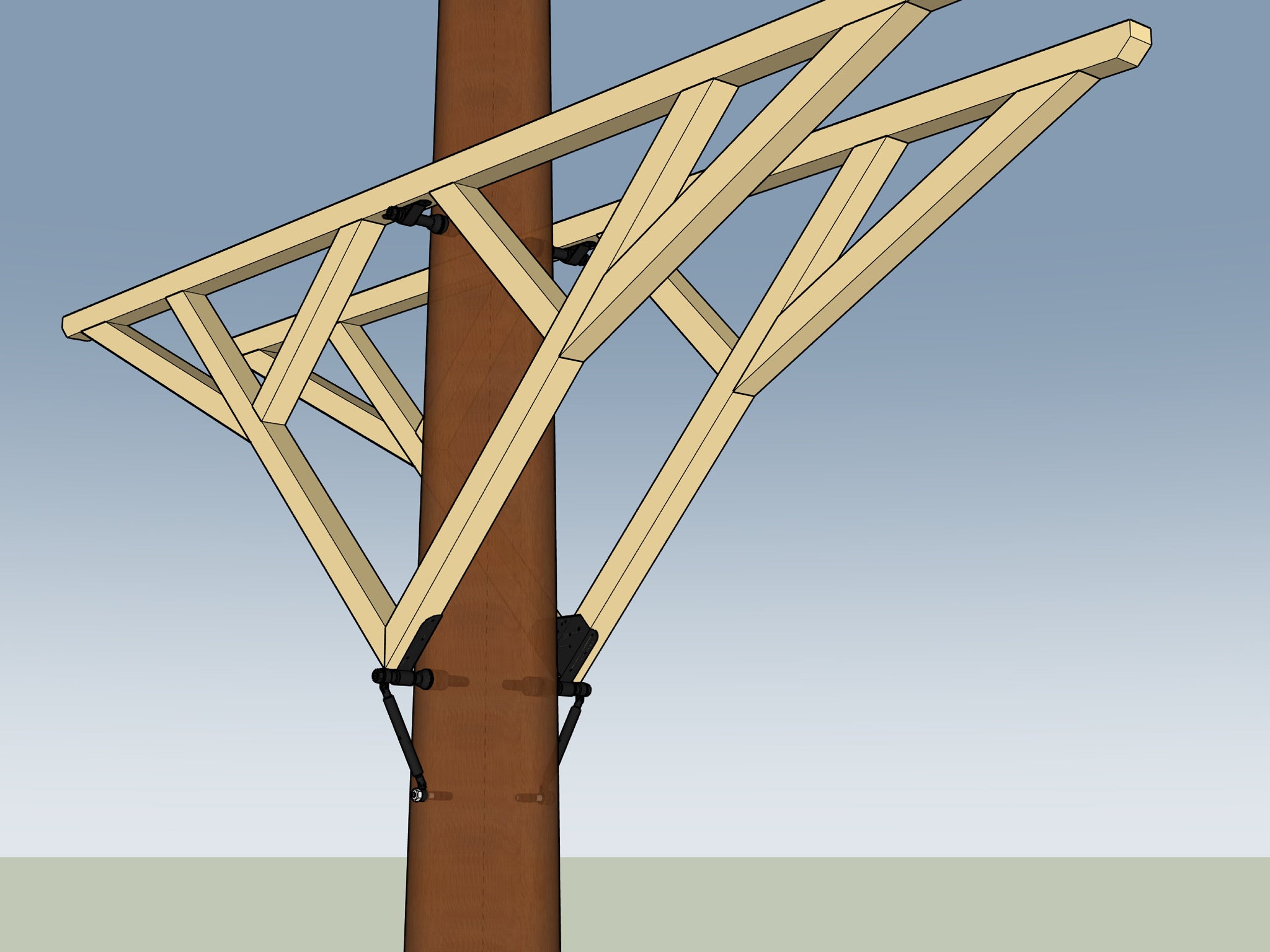

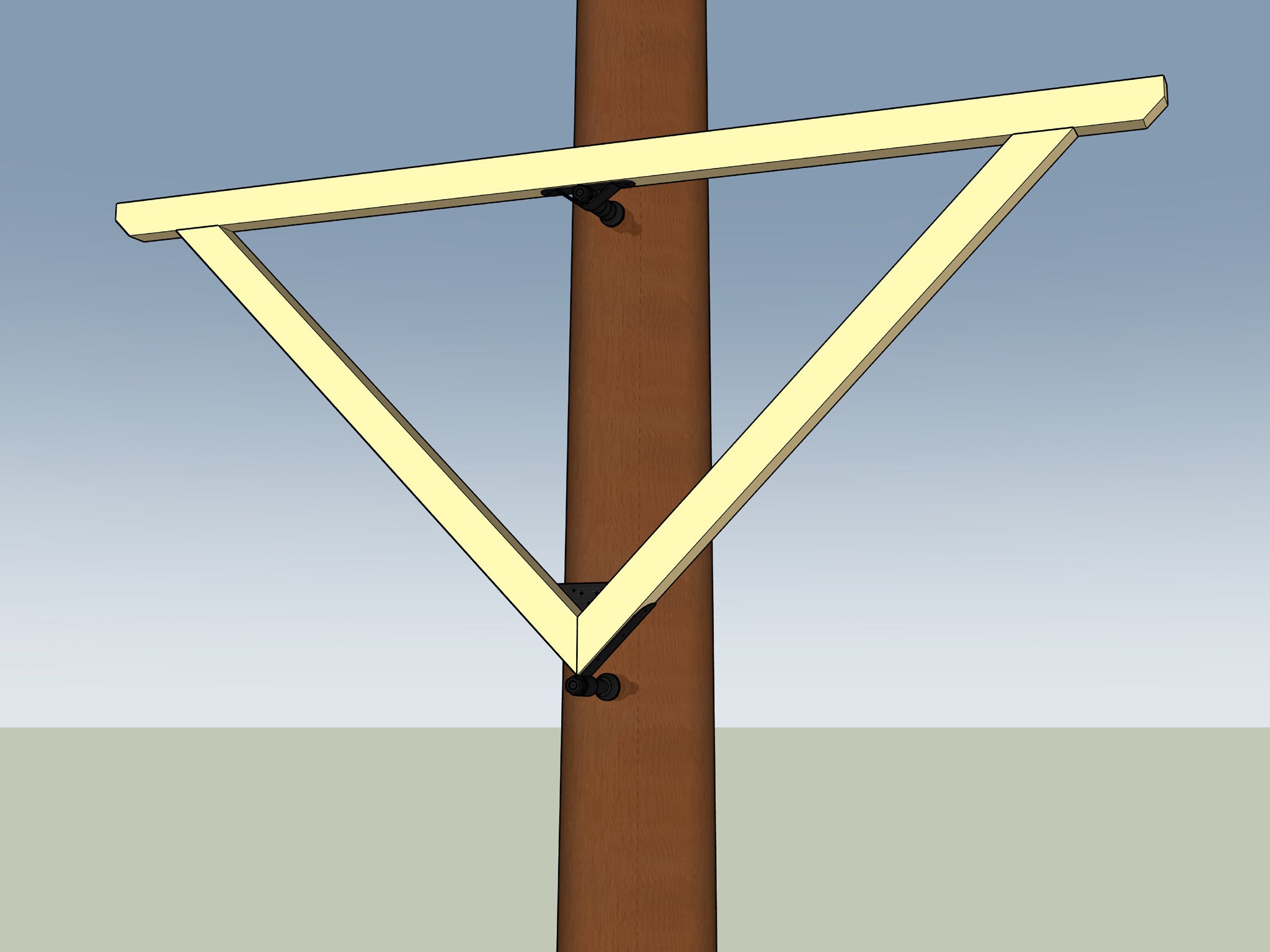

XS Tribeam Attachment Kit, 2 Free

Sale price€278,00

S Tribeam Attachment Kit, V90

Sale price€646,00

L Tribeam Attachment Kit, V60

Sale price€755,00

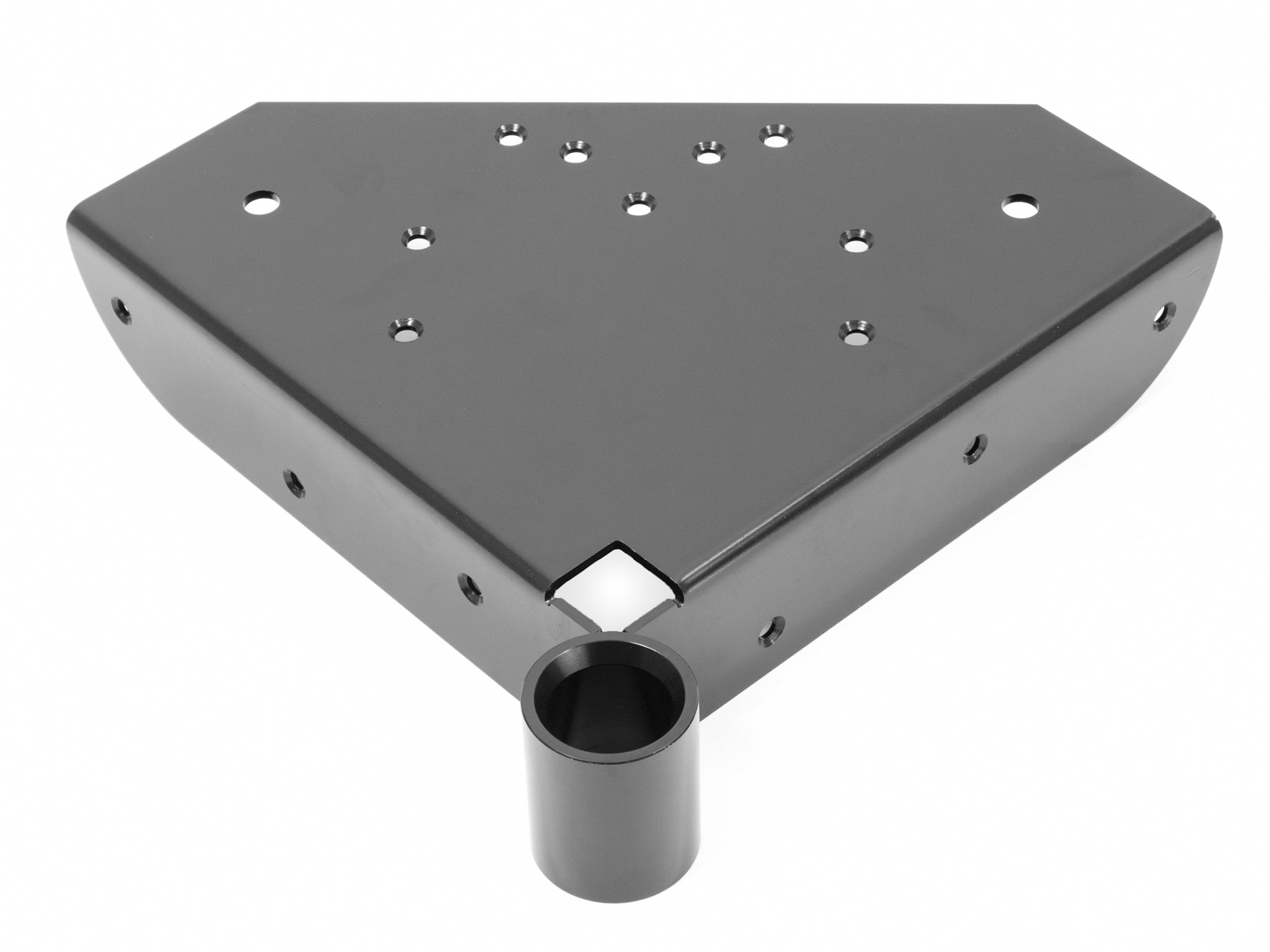

XL Tribeam Attachment Kit, D90

Sale price€834,00

XXL Tribeam Attachment Kit, D90 GTS+

Sale price€1.056,00

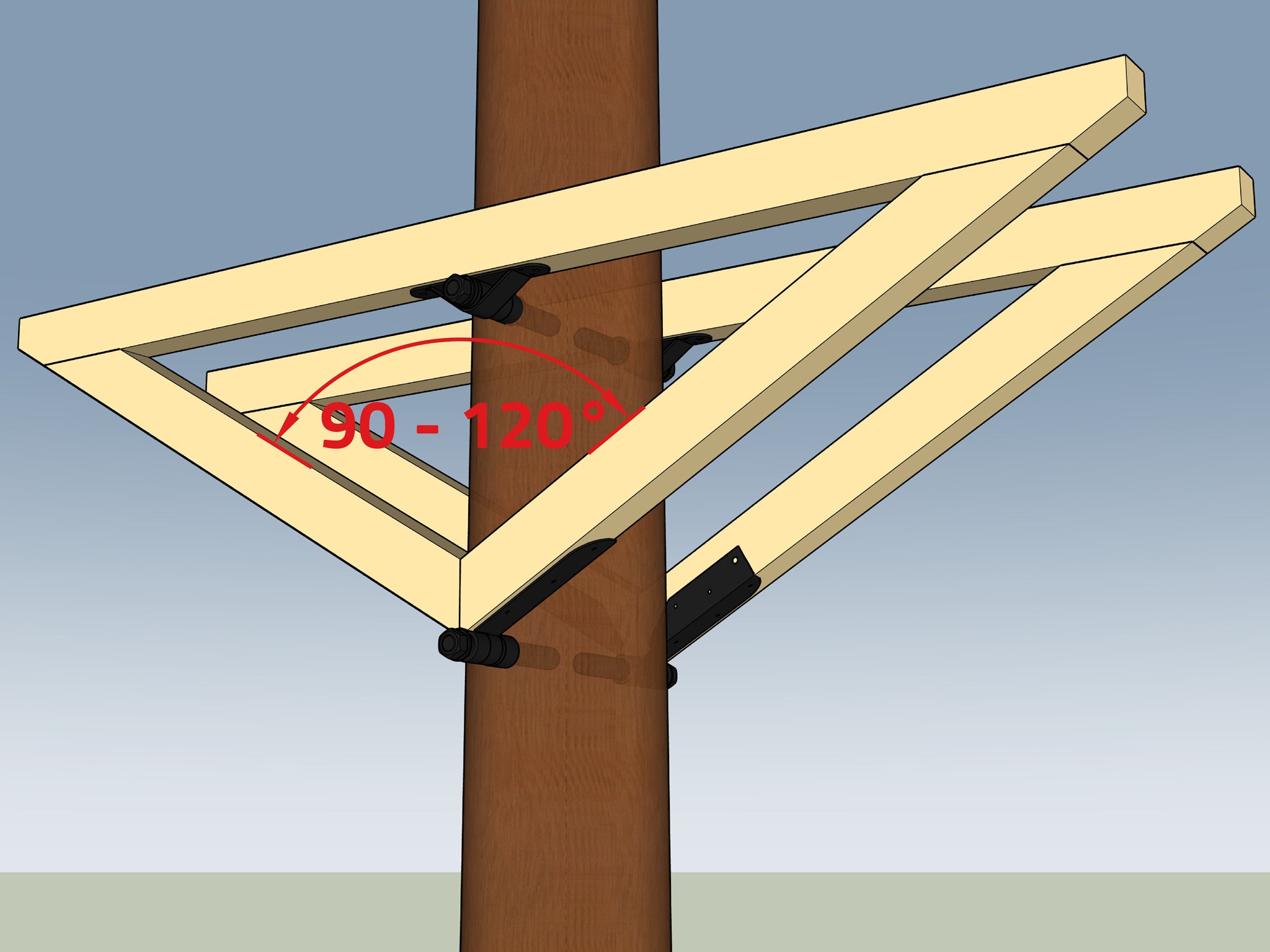

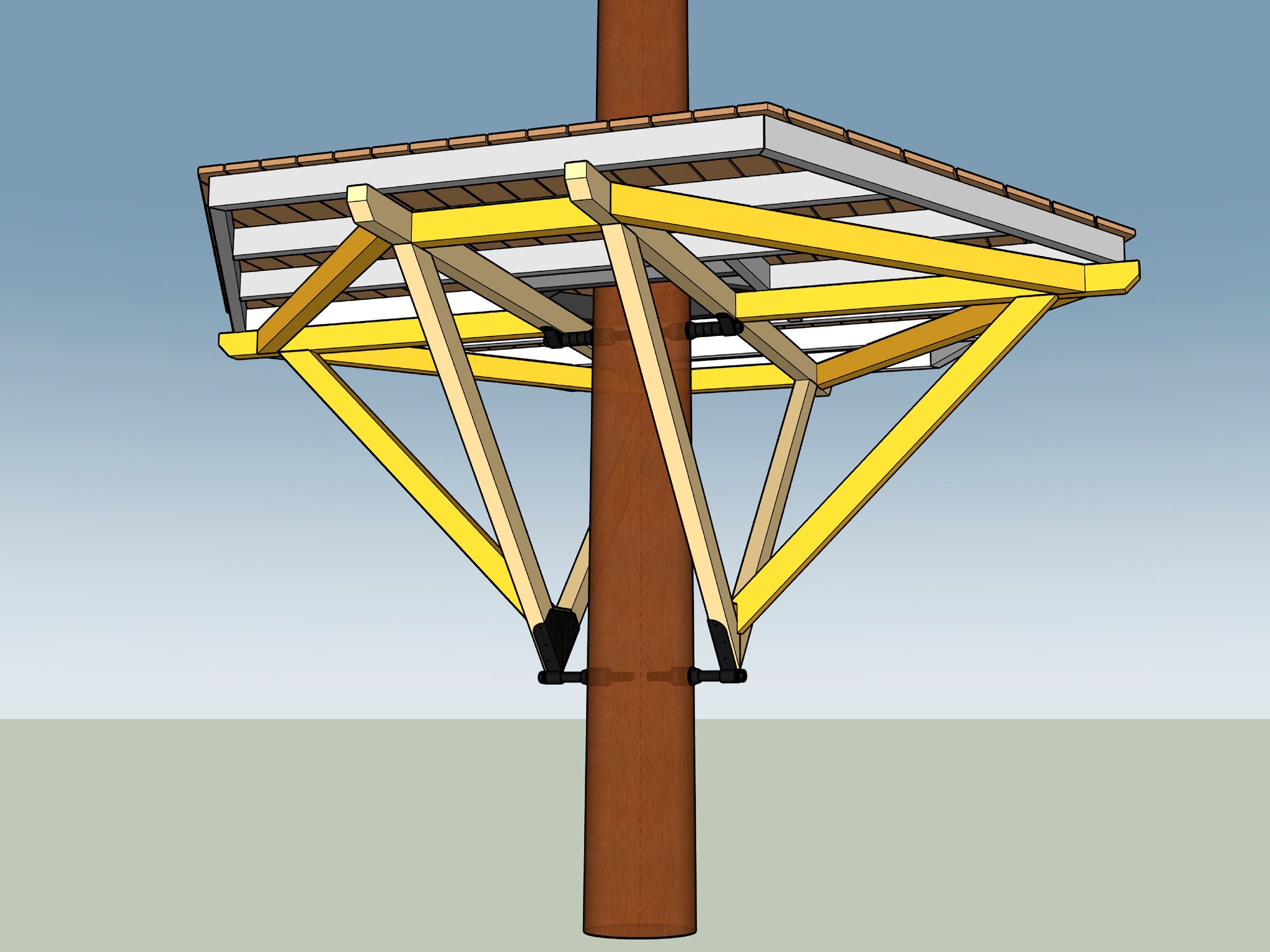

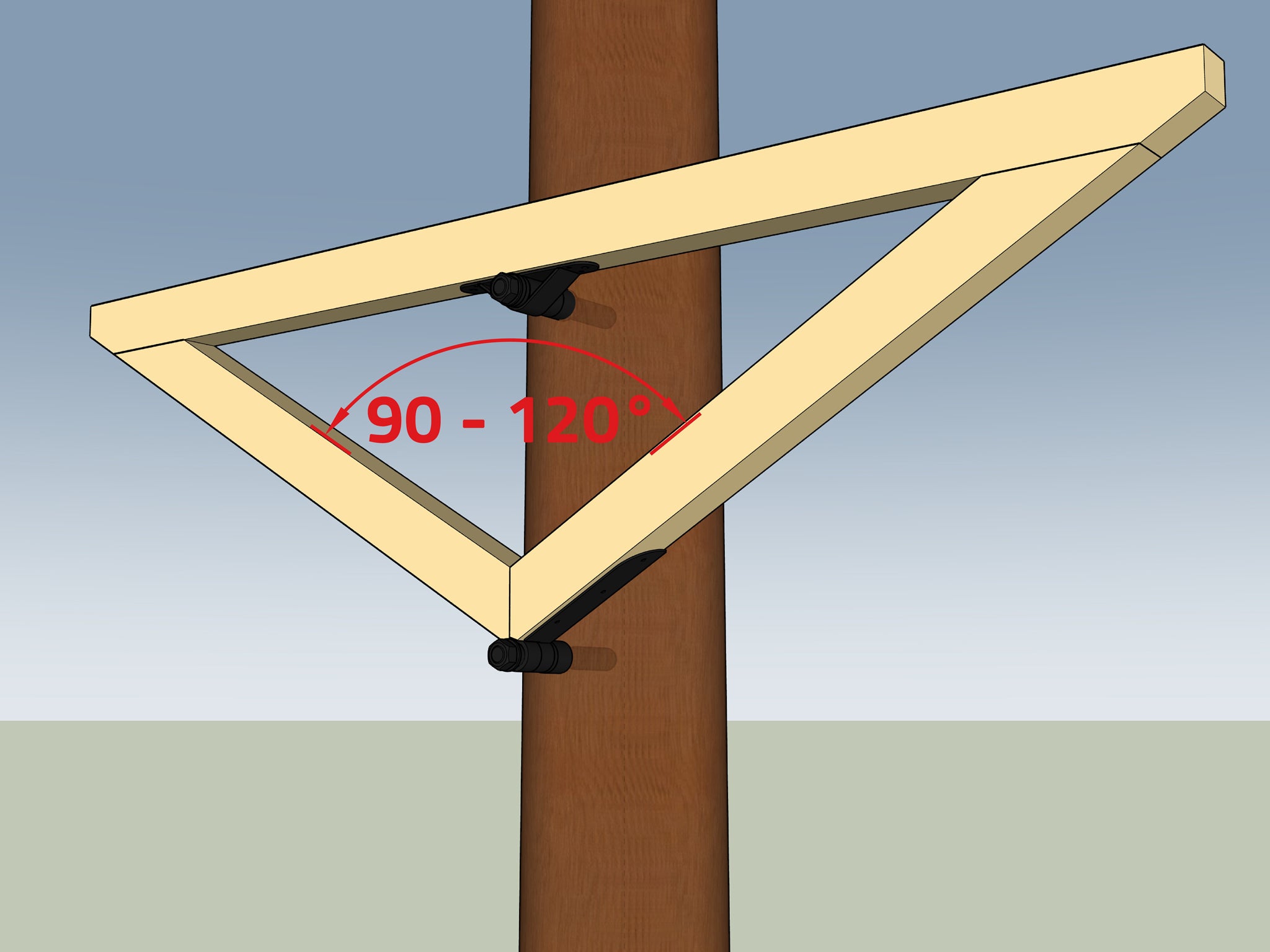

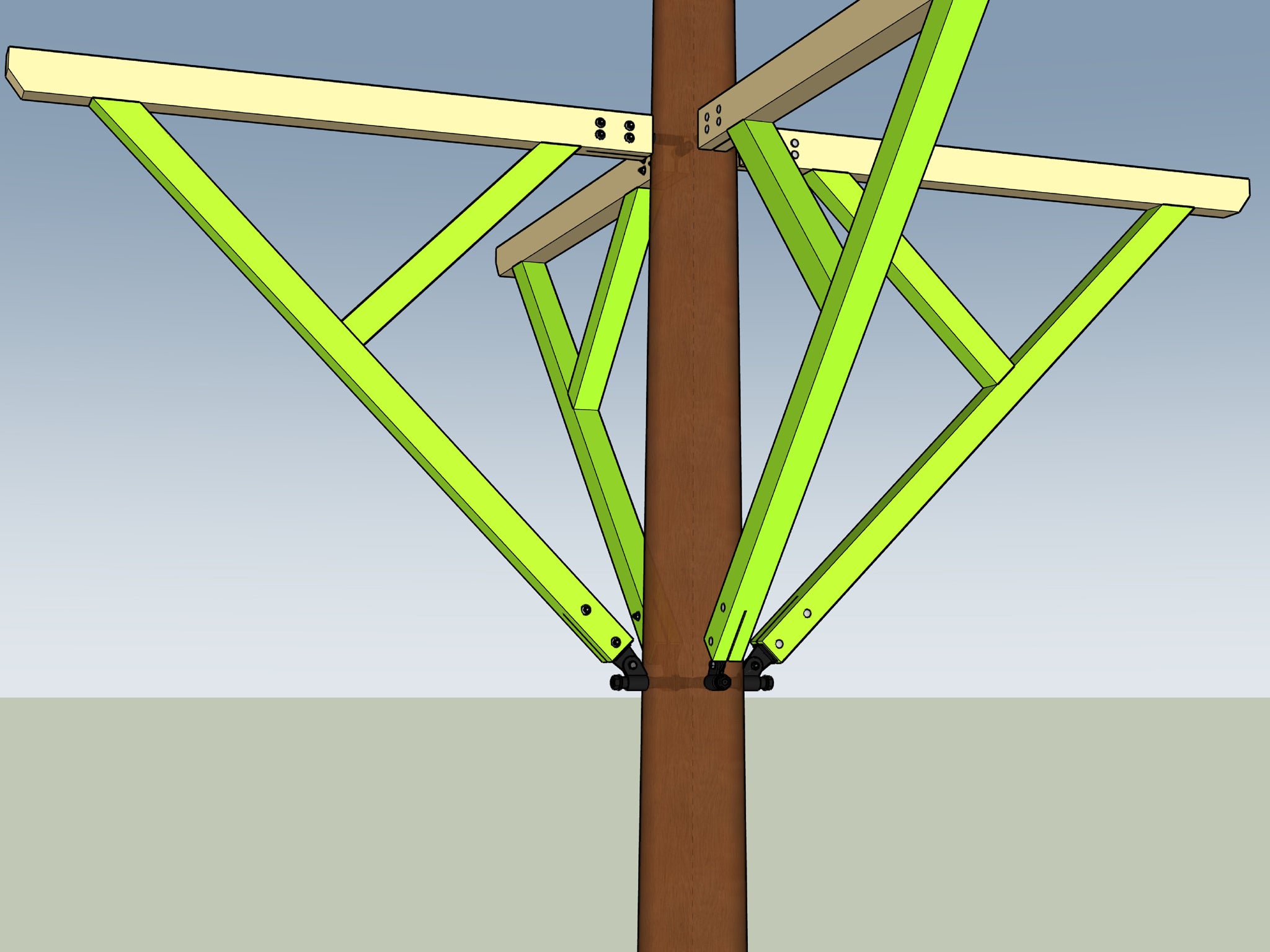

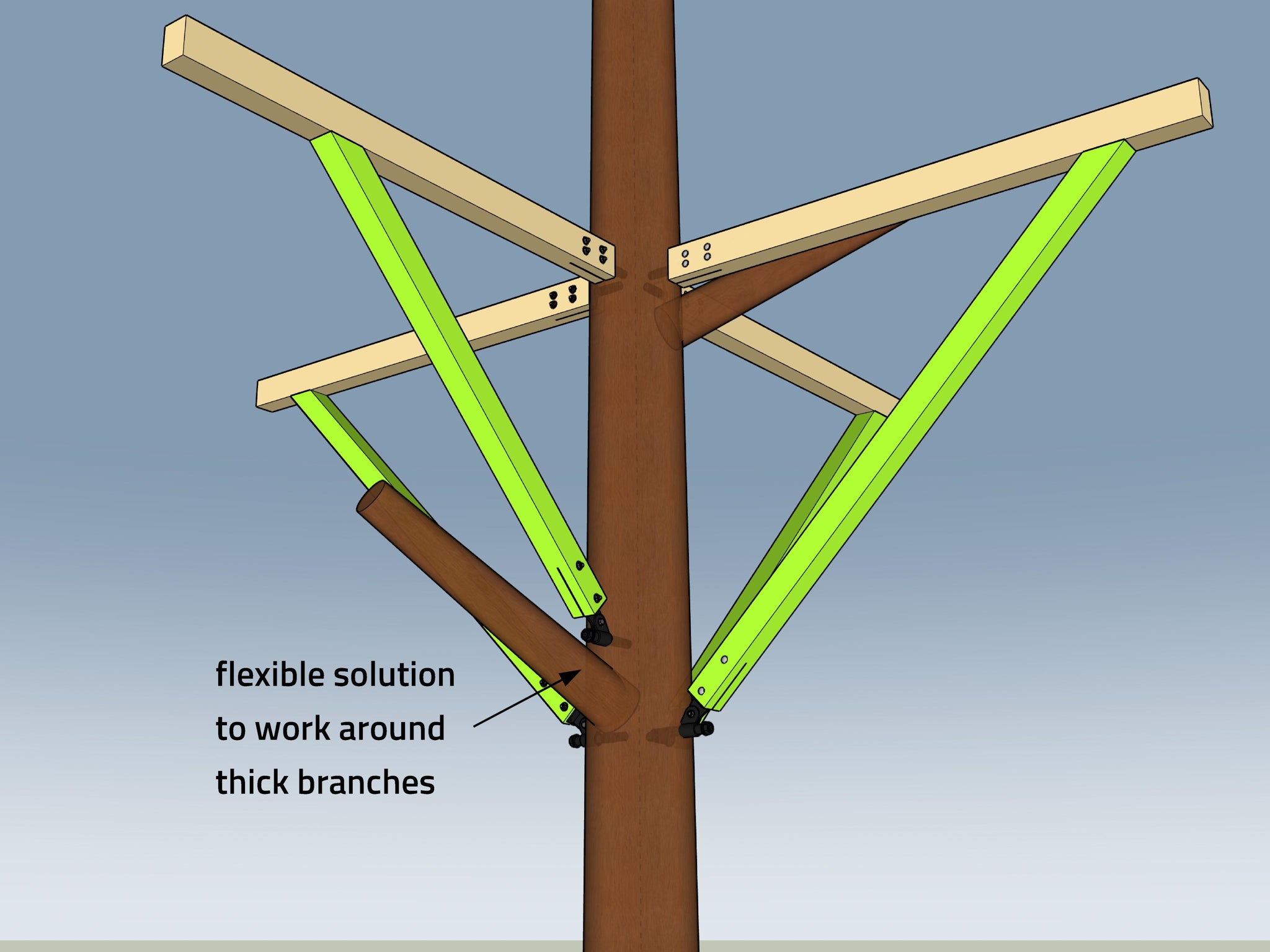

M Treeangle Assembly Kit for 1-2 Trees, Adjust

Sale price€1.352,00

L Treeangle Assembly Kit for 1-2 Trees, T-Plate

Sale price€1.720,00

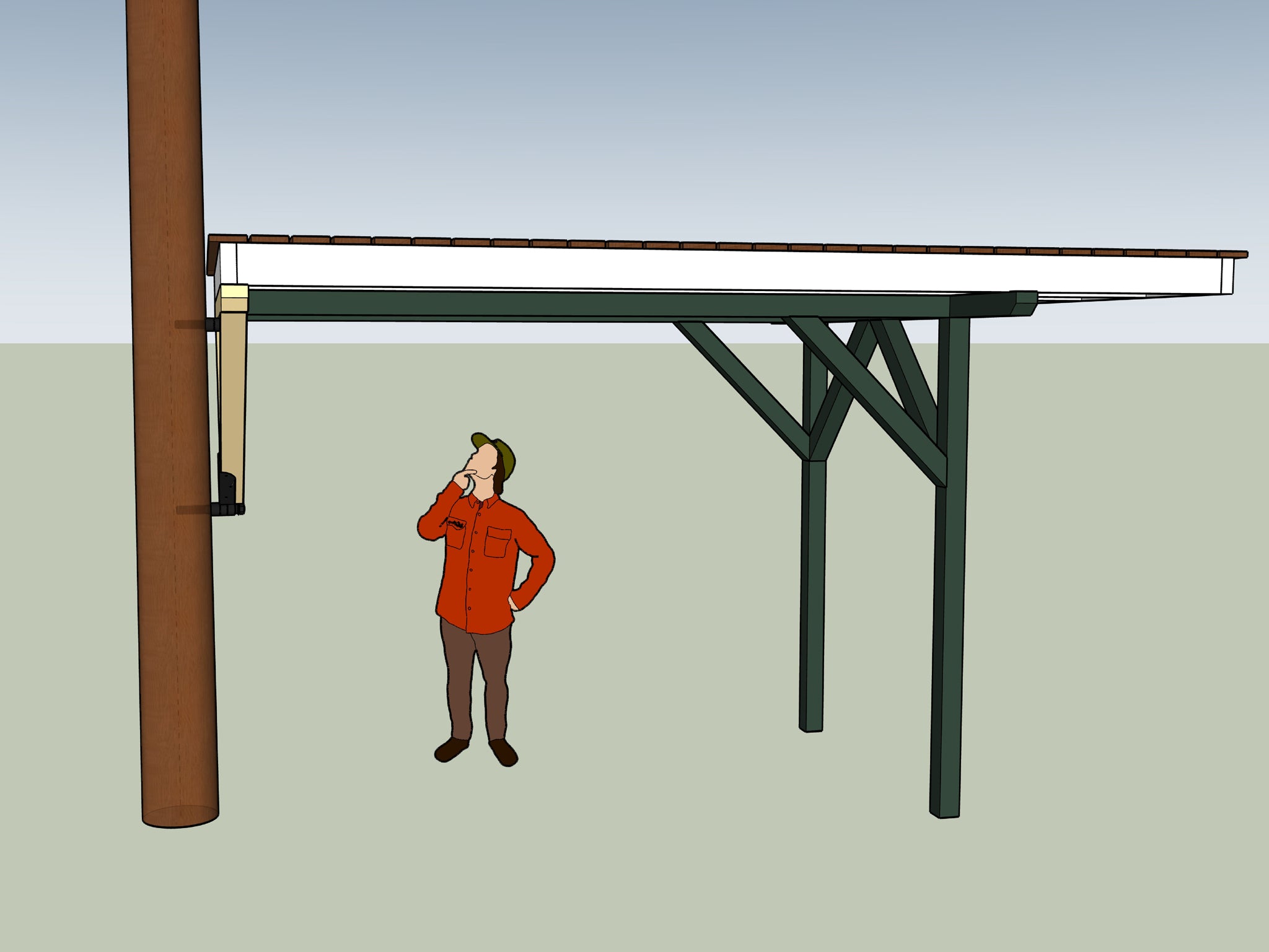

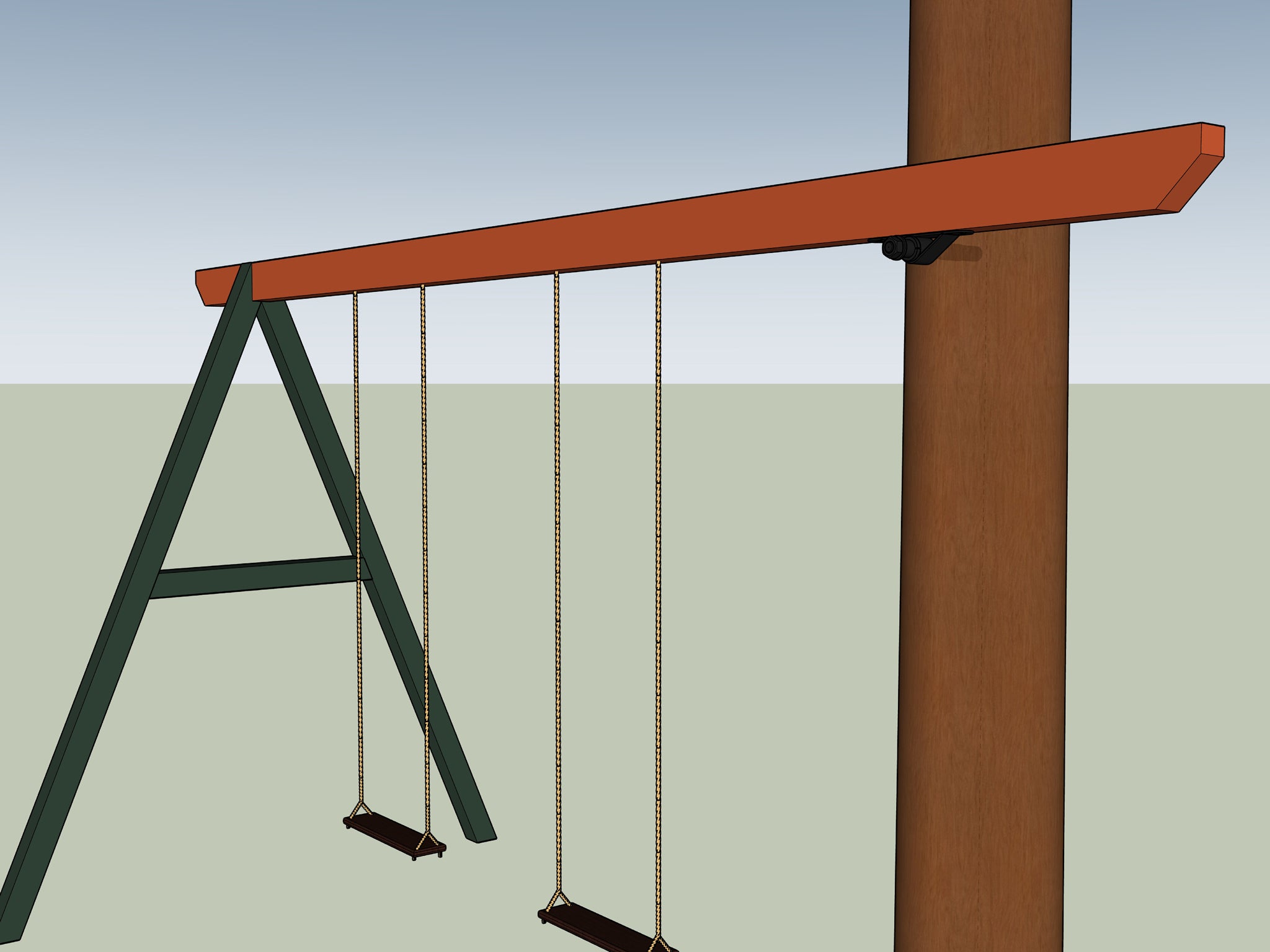

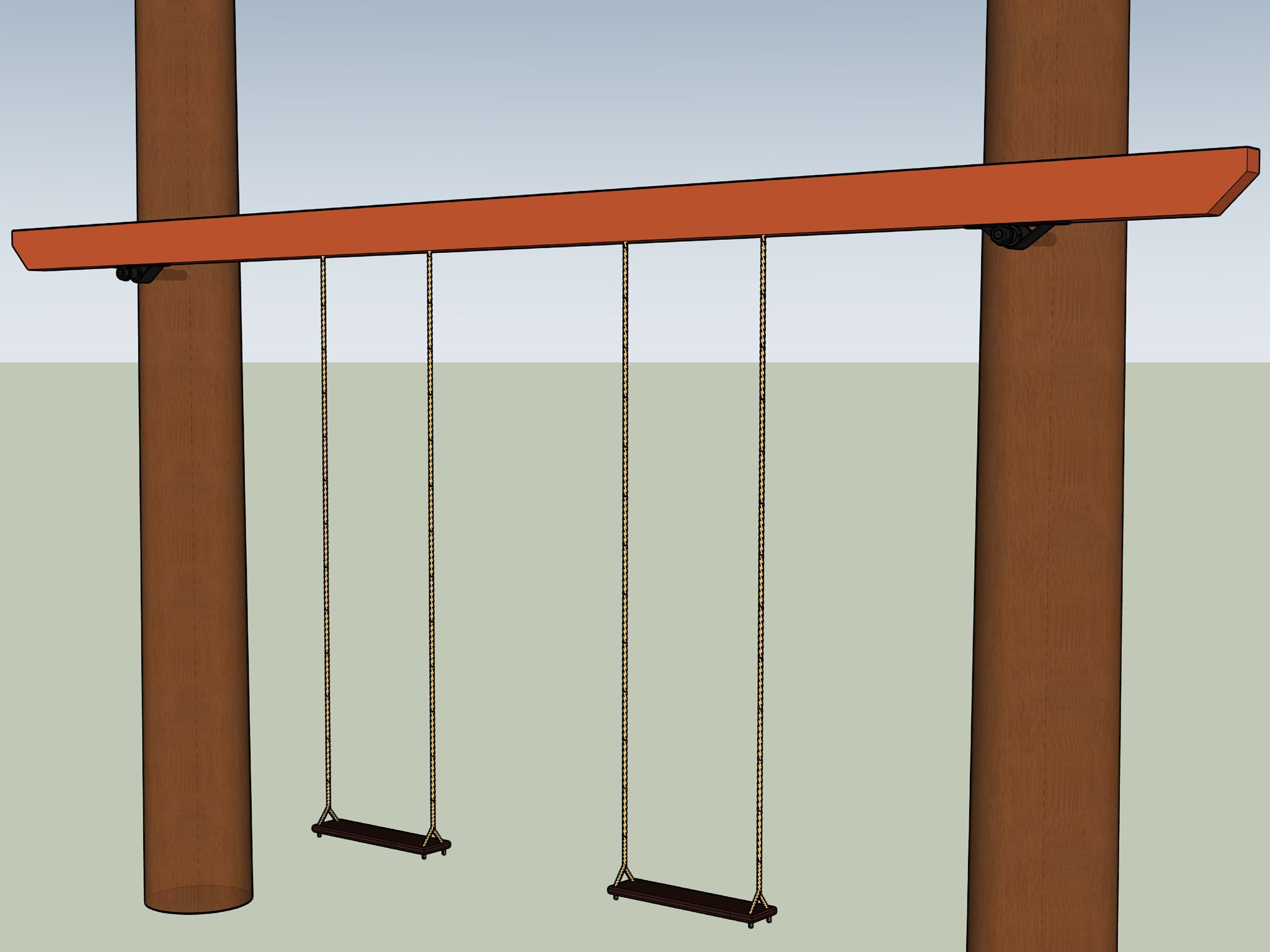

Swing Beam Attachment Kit for 1 Tree – Bracket

Sale price€301,00

Swing Beam Attachment Kit for 2 Trees – Bracket

Sale price€602,00

Beam Bracket – Stay

Sale price€121,00

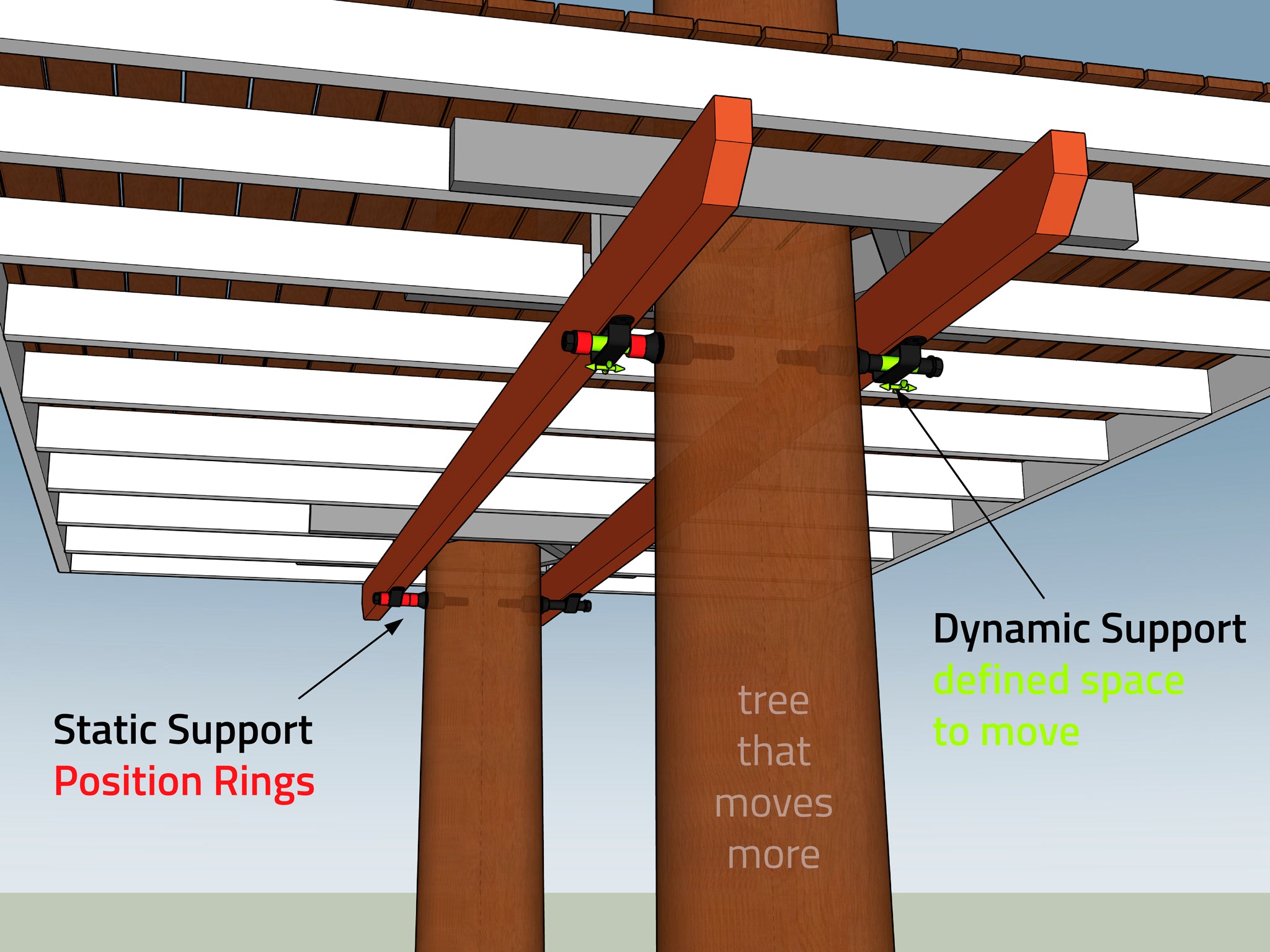

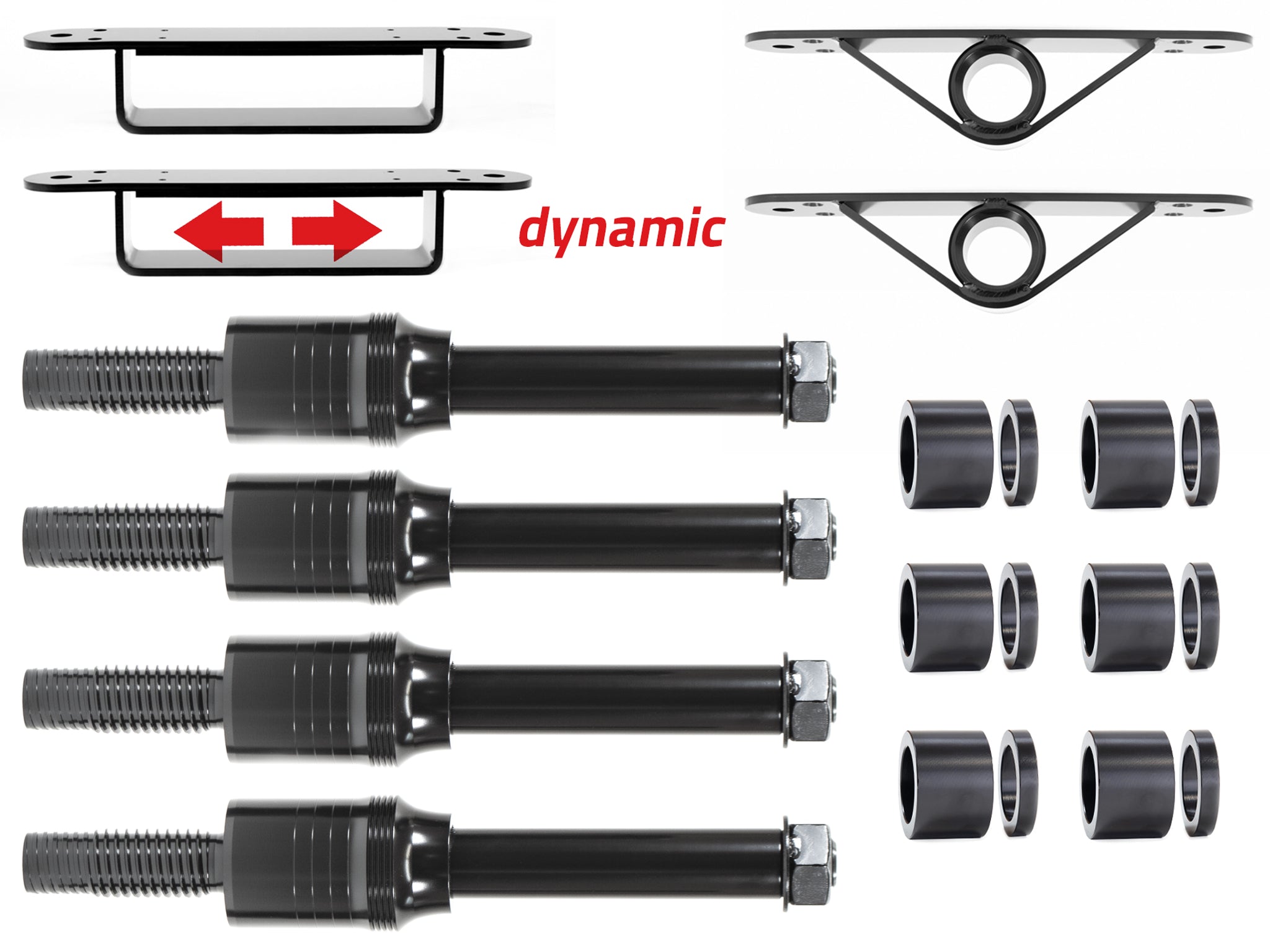

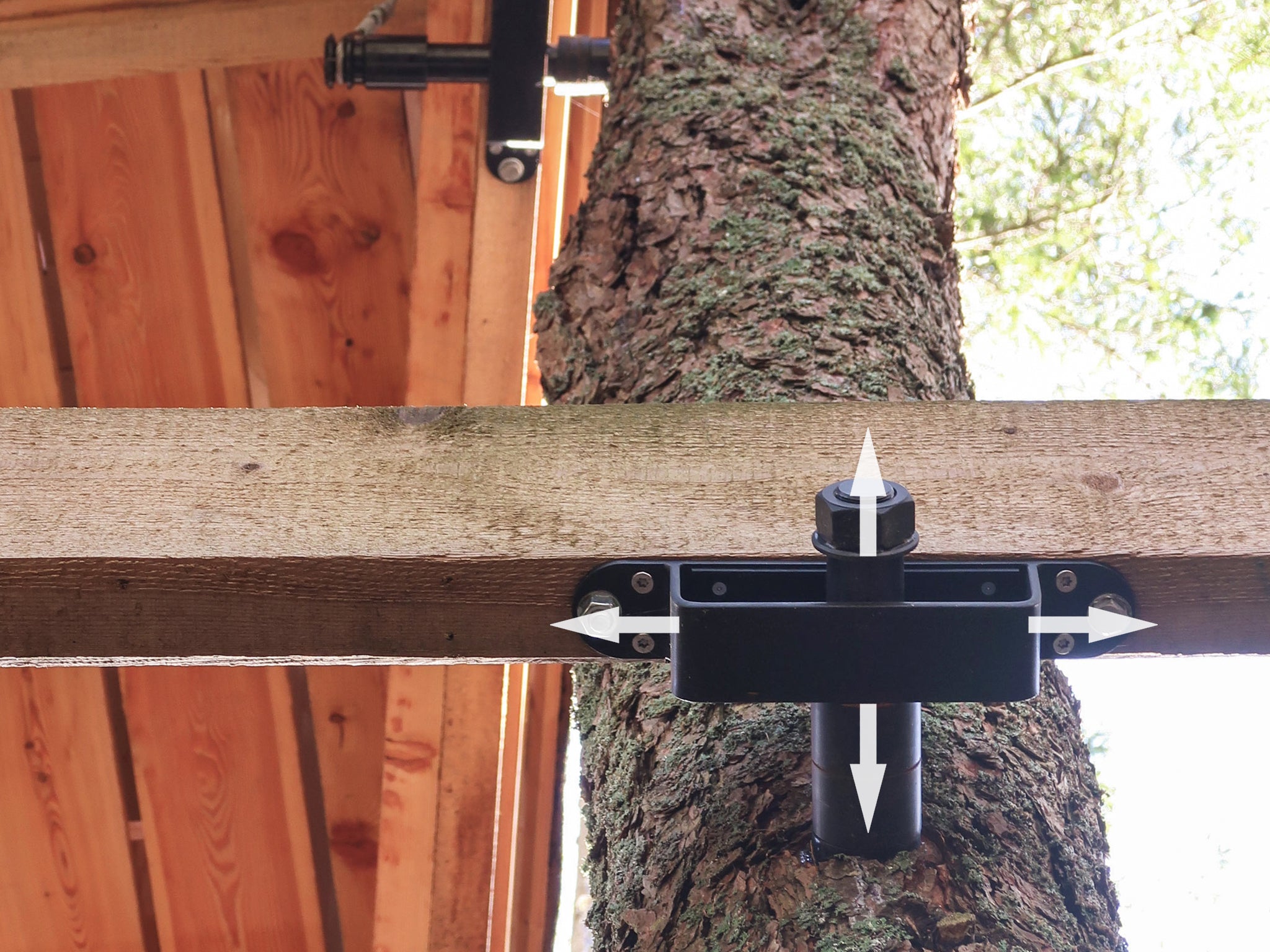

Beam Bracket – Dynamic

Sale price€132,00

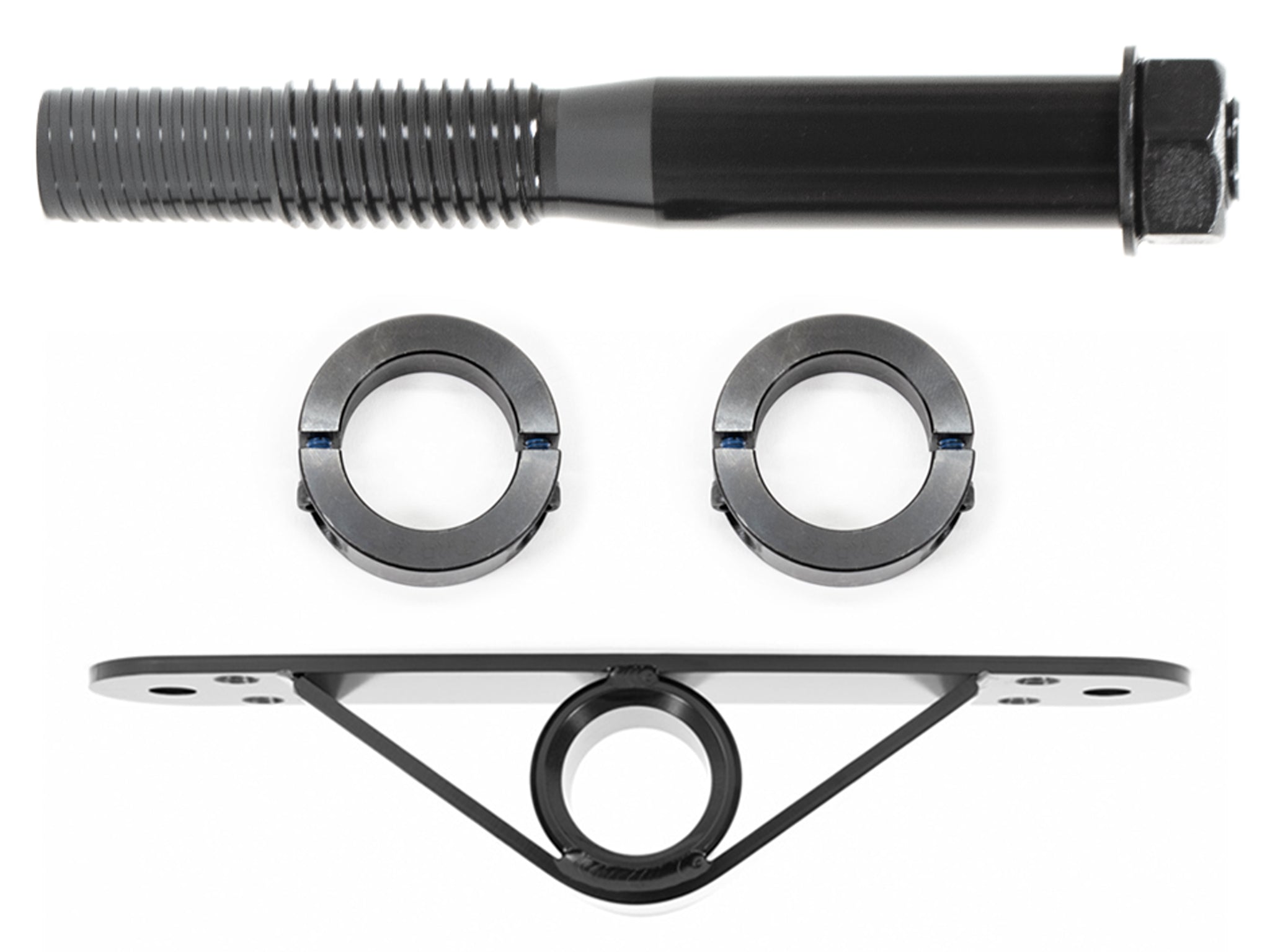

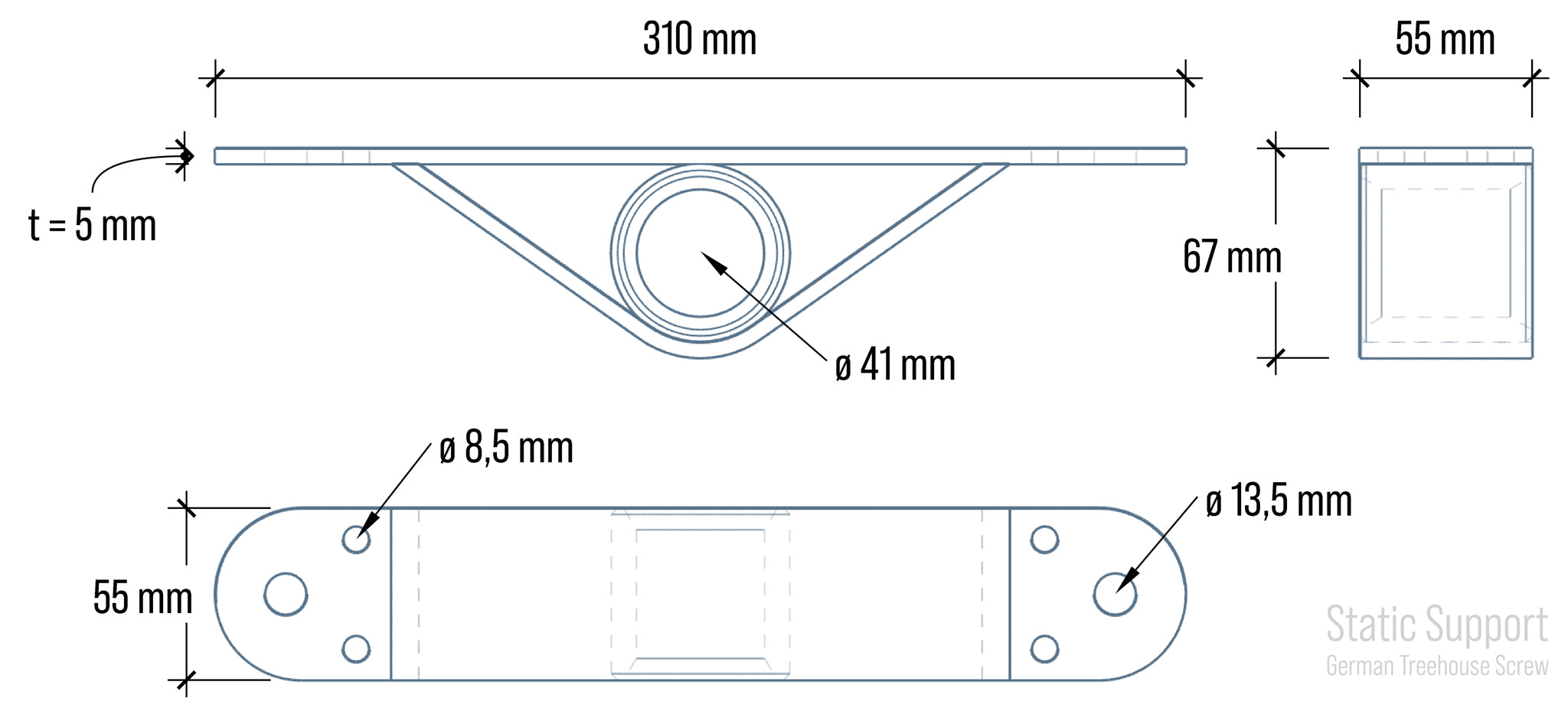

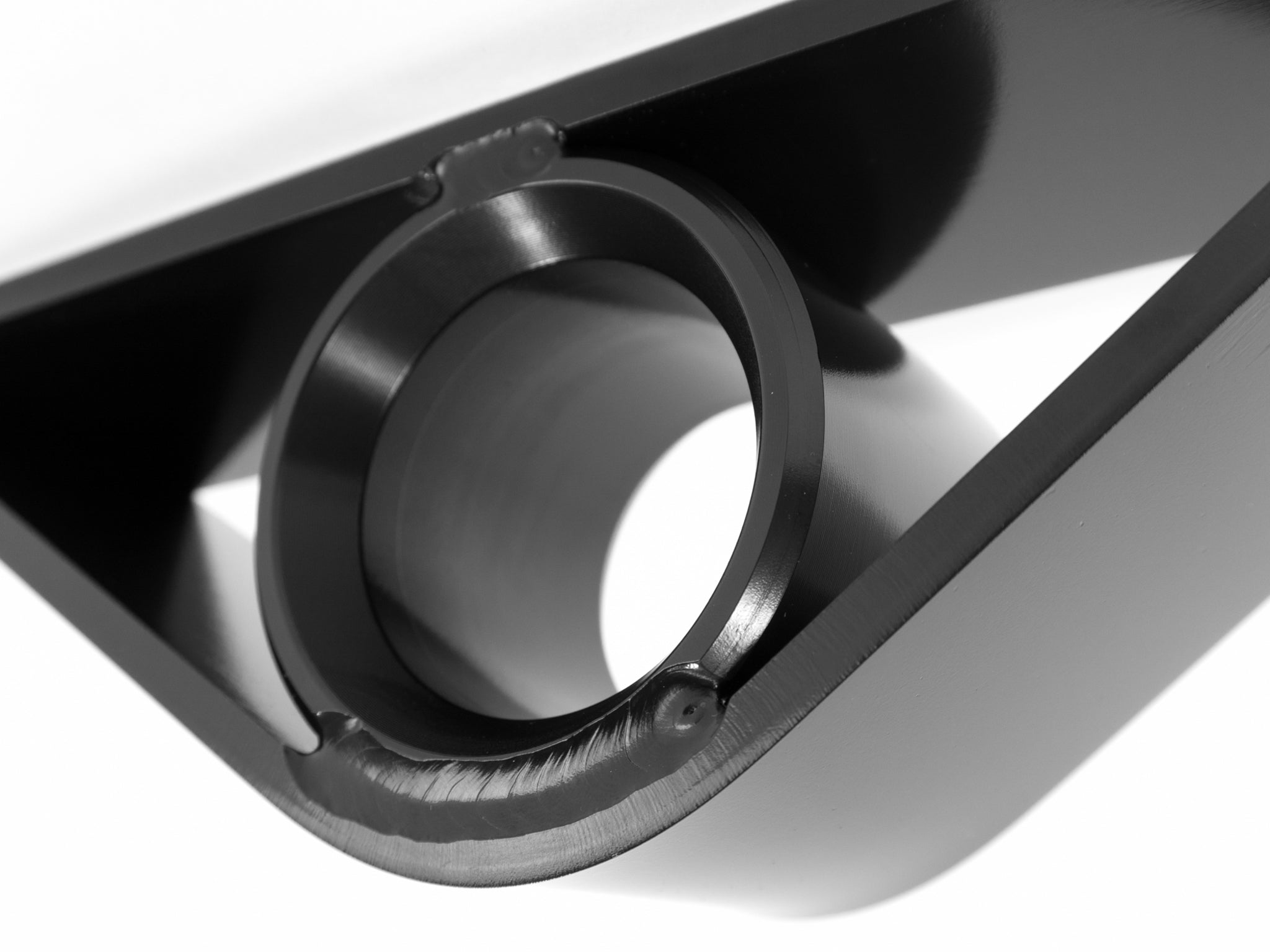

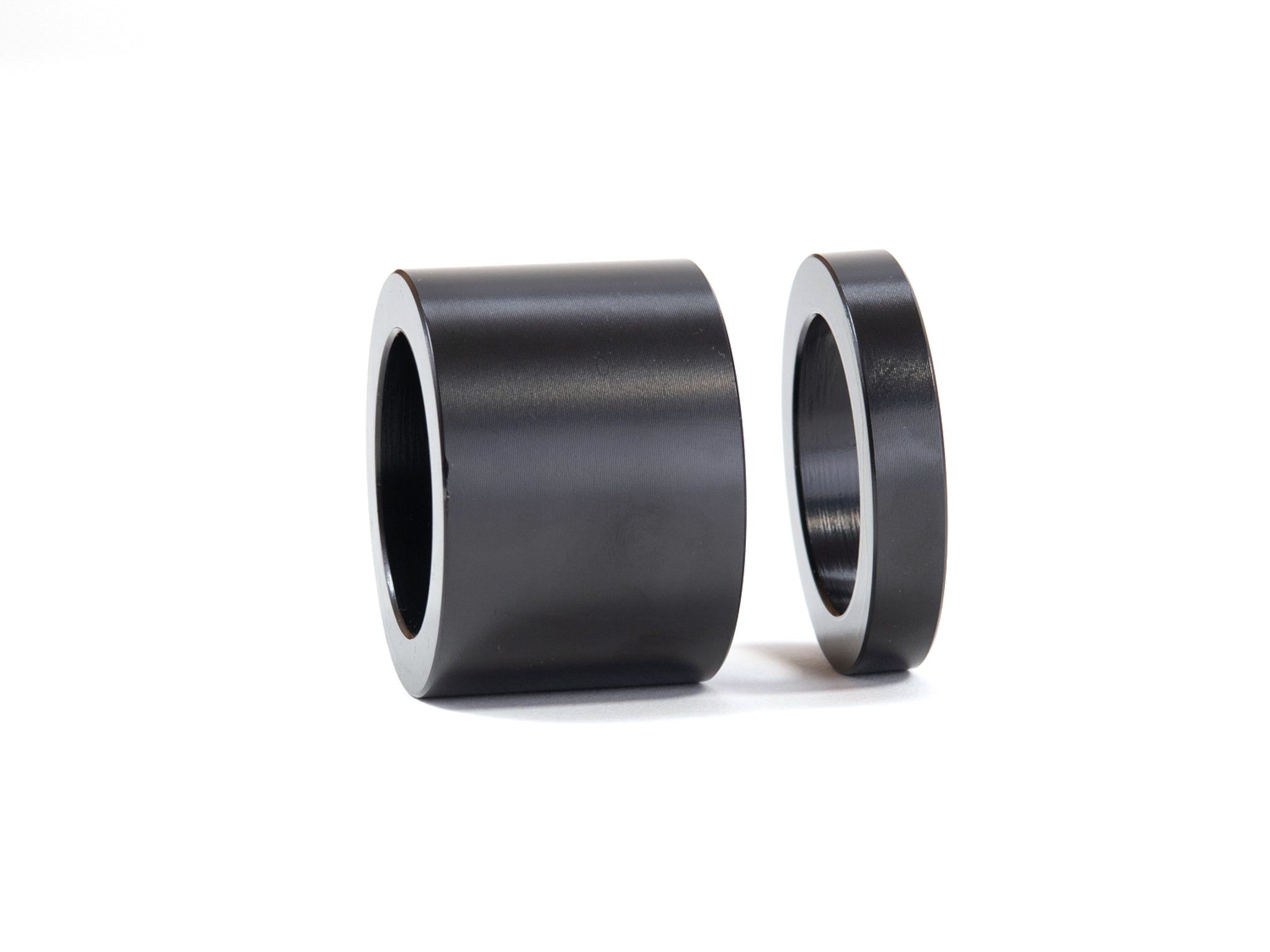

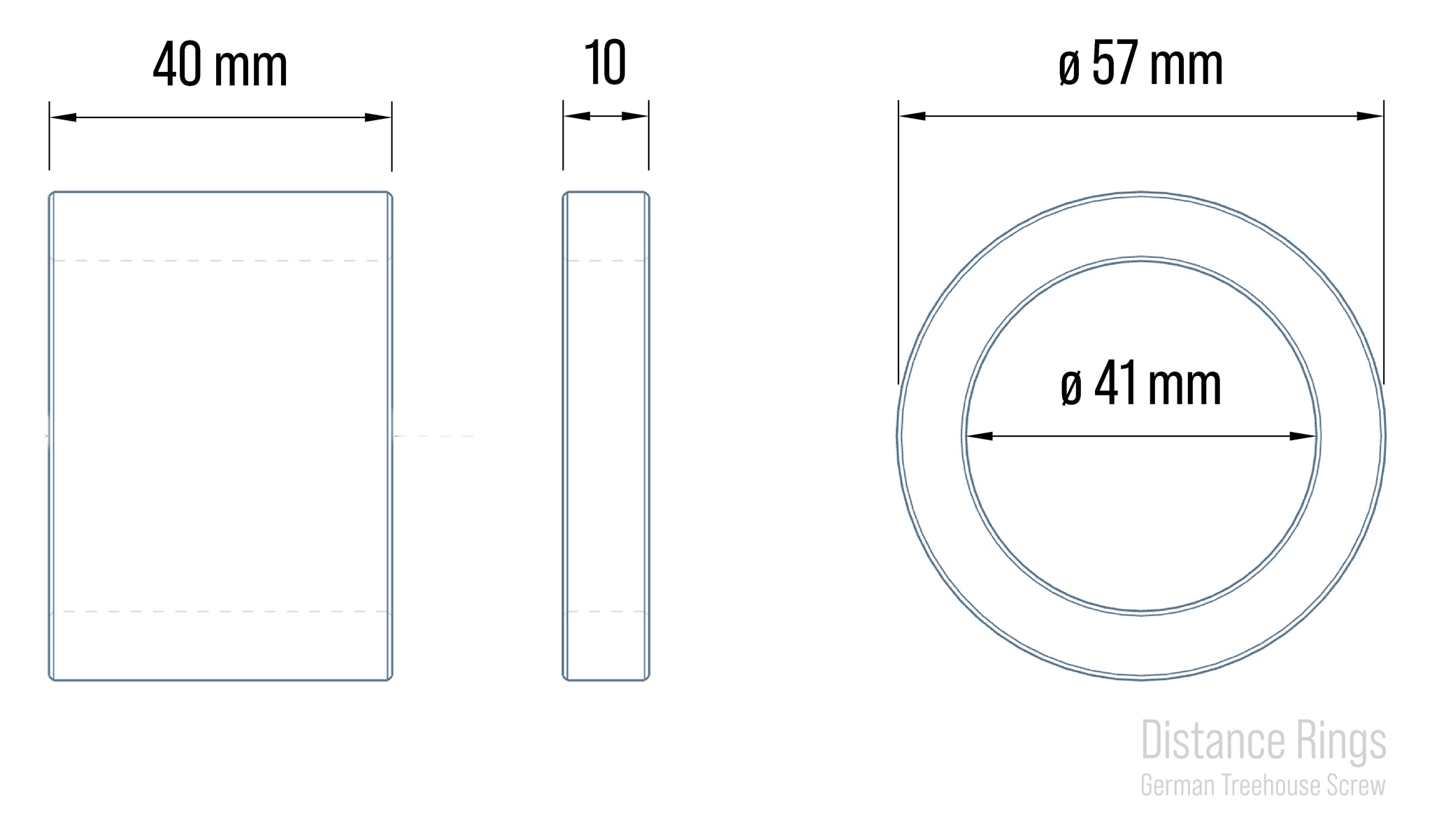

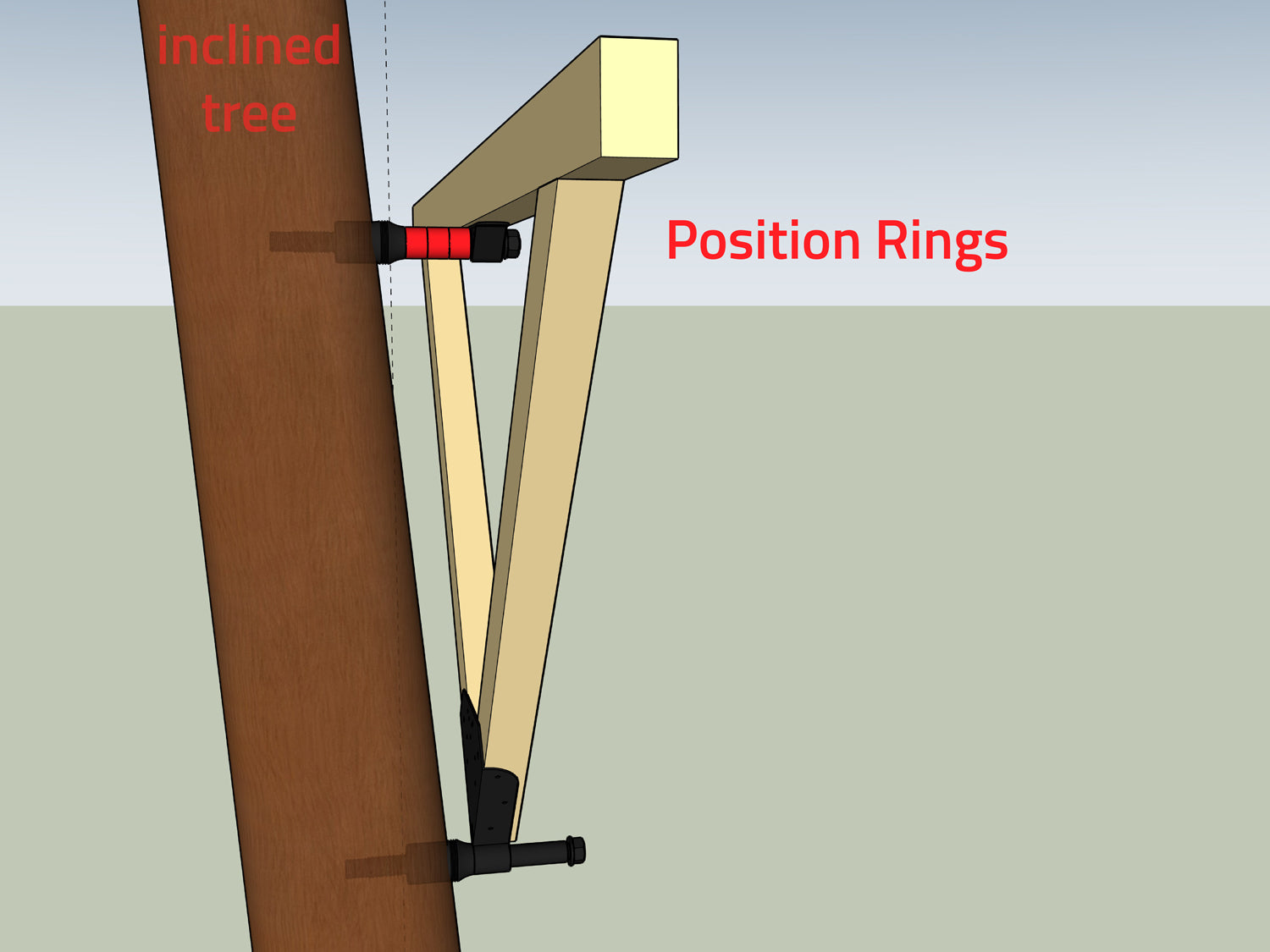

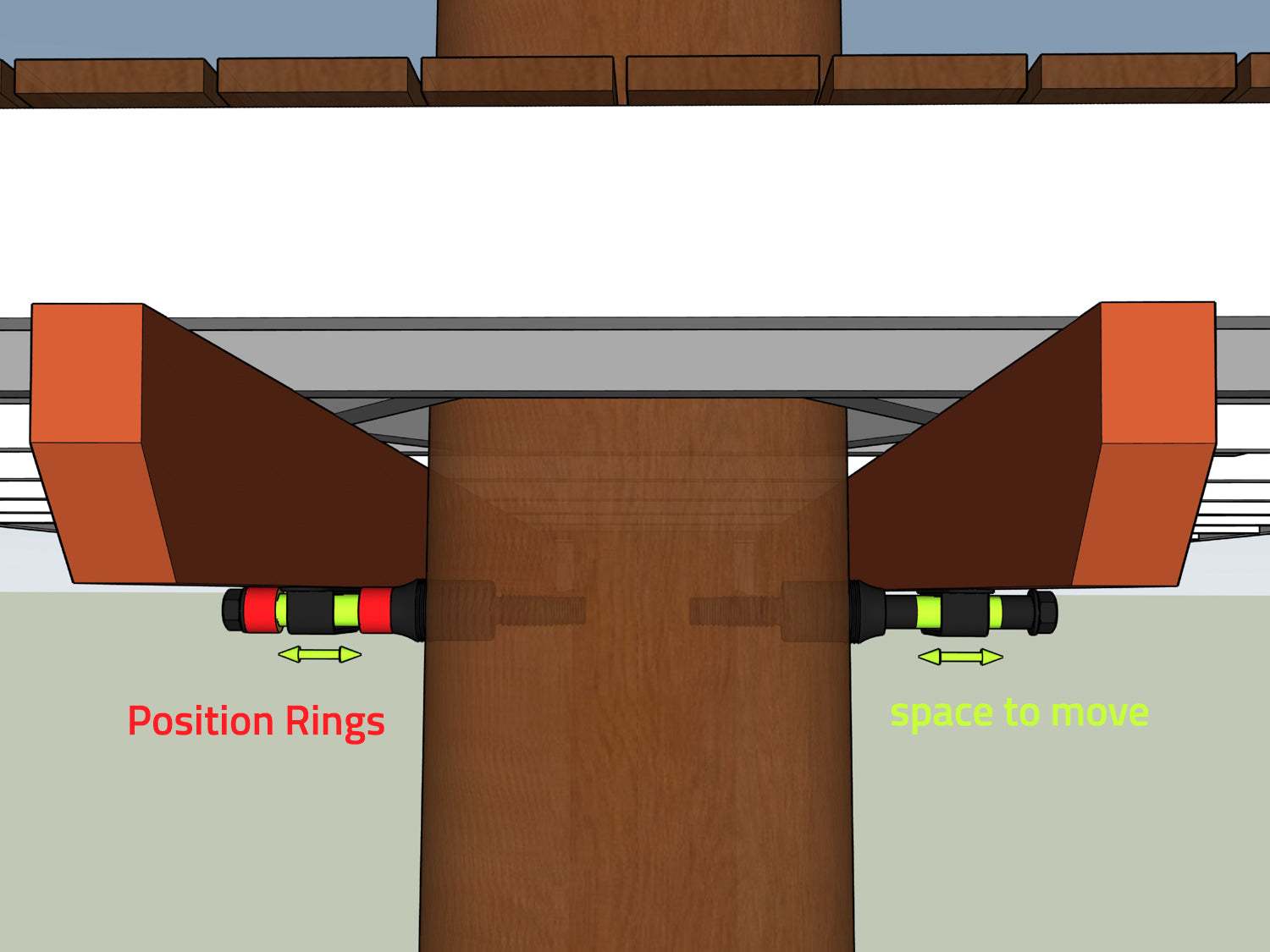

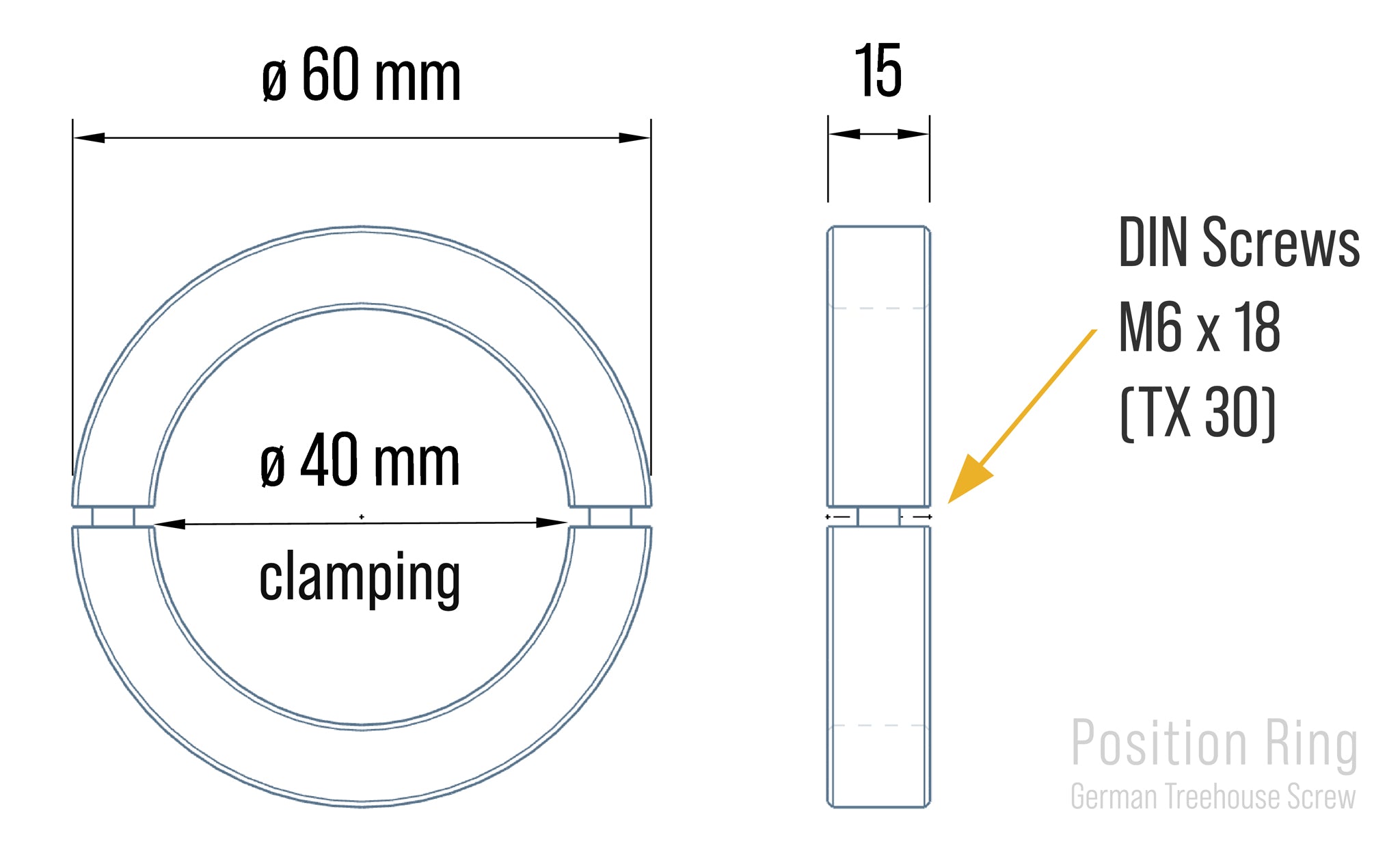

Position Ring

Sale price€24,00

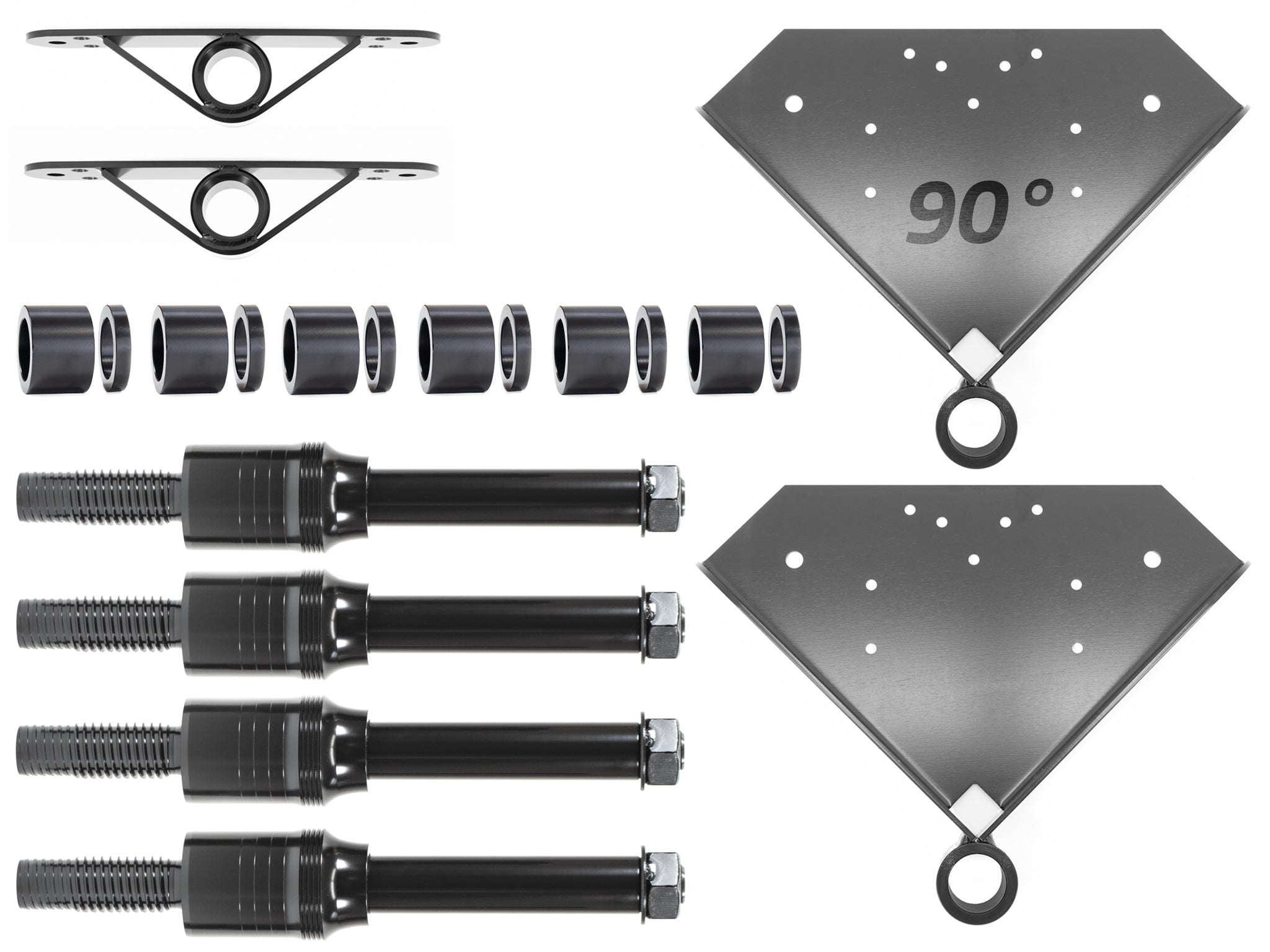

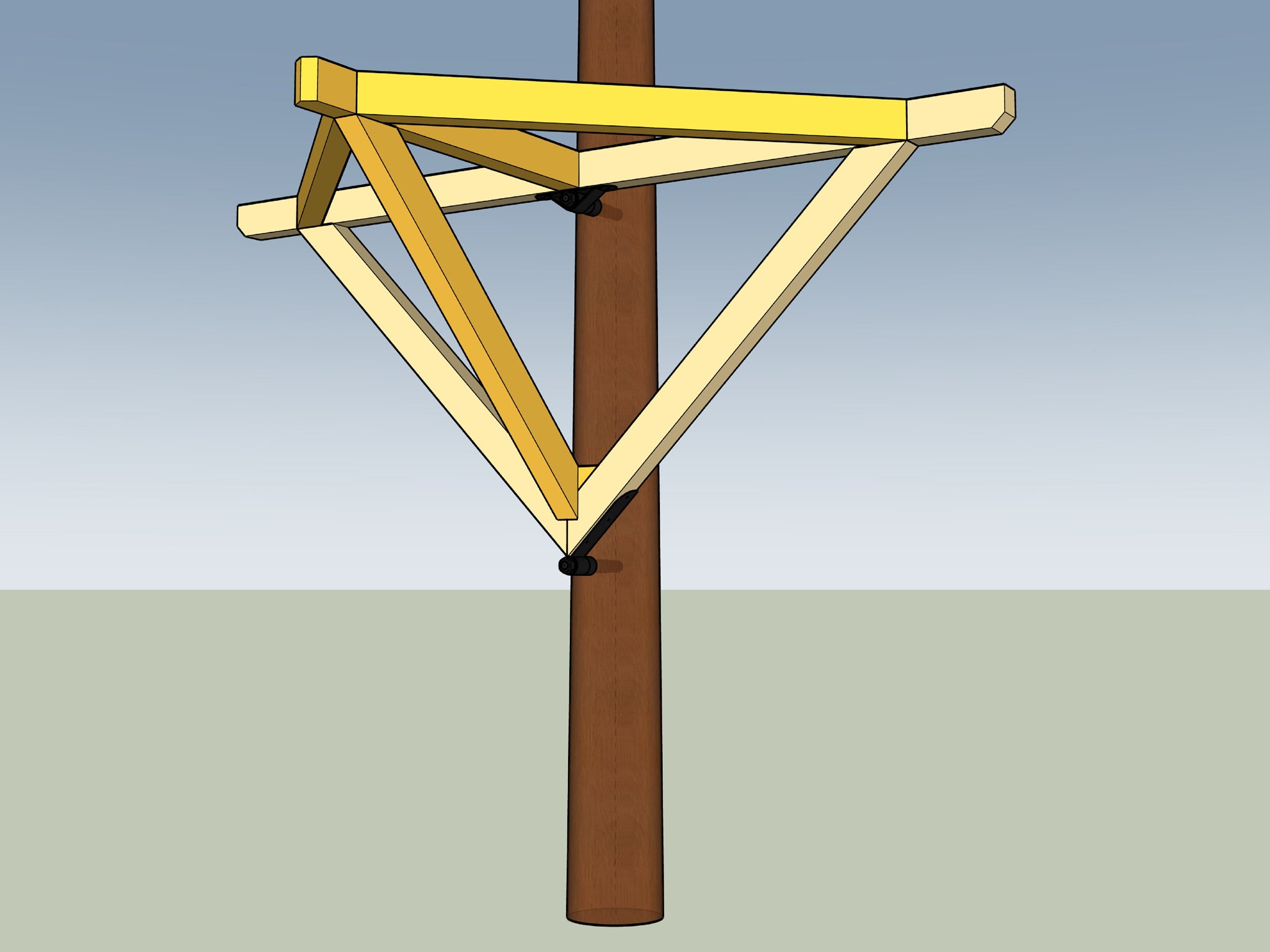

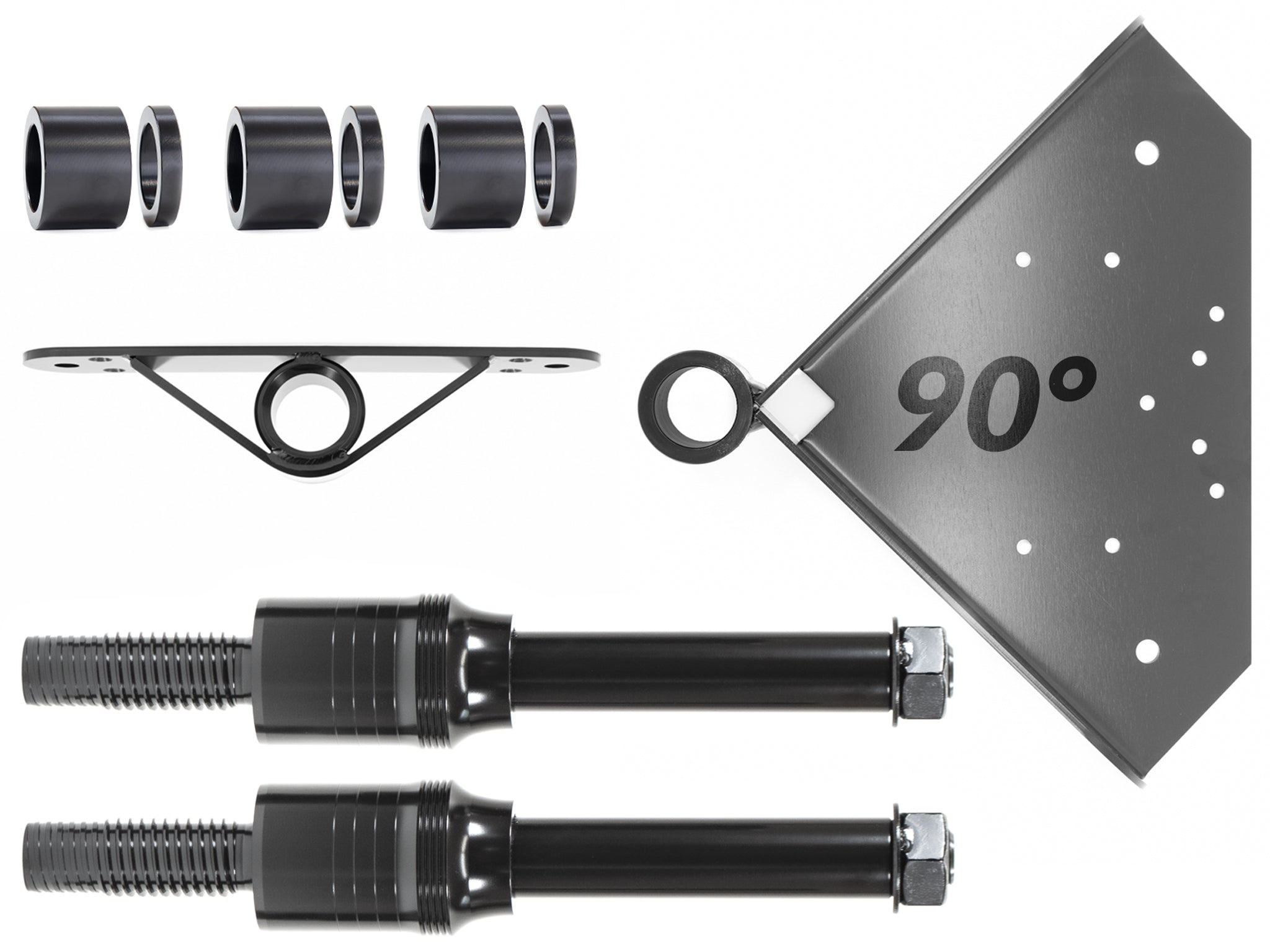

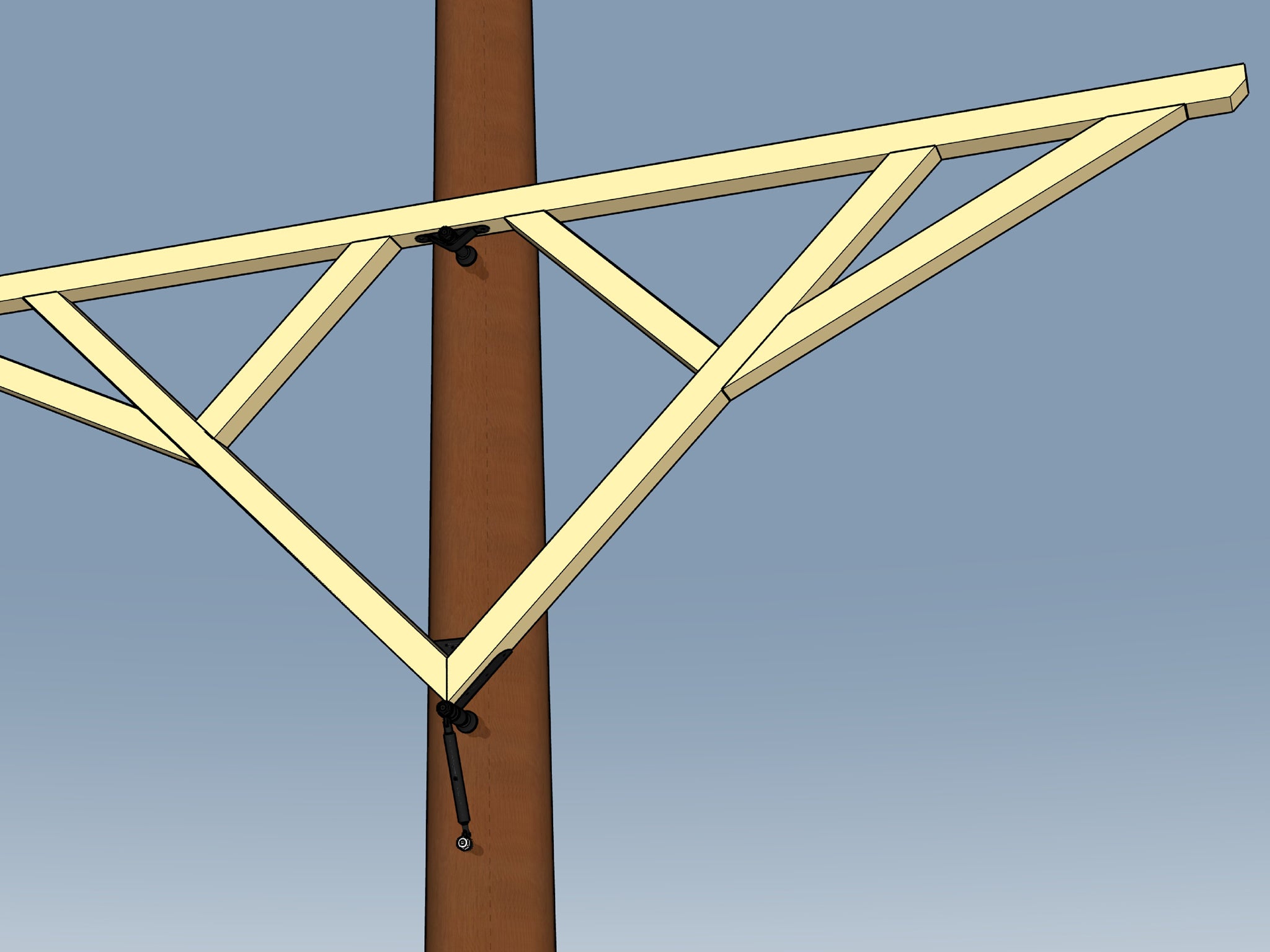

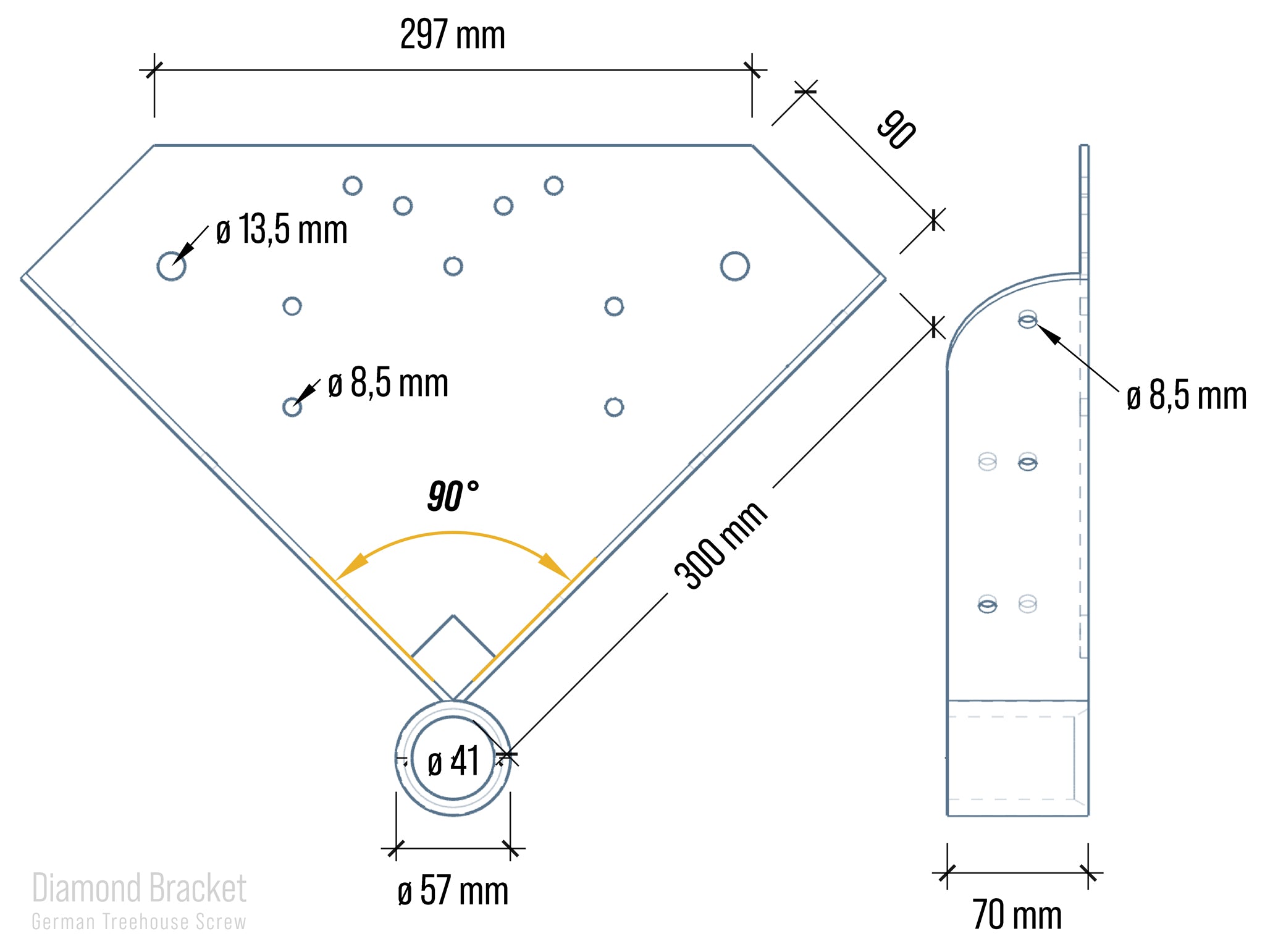

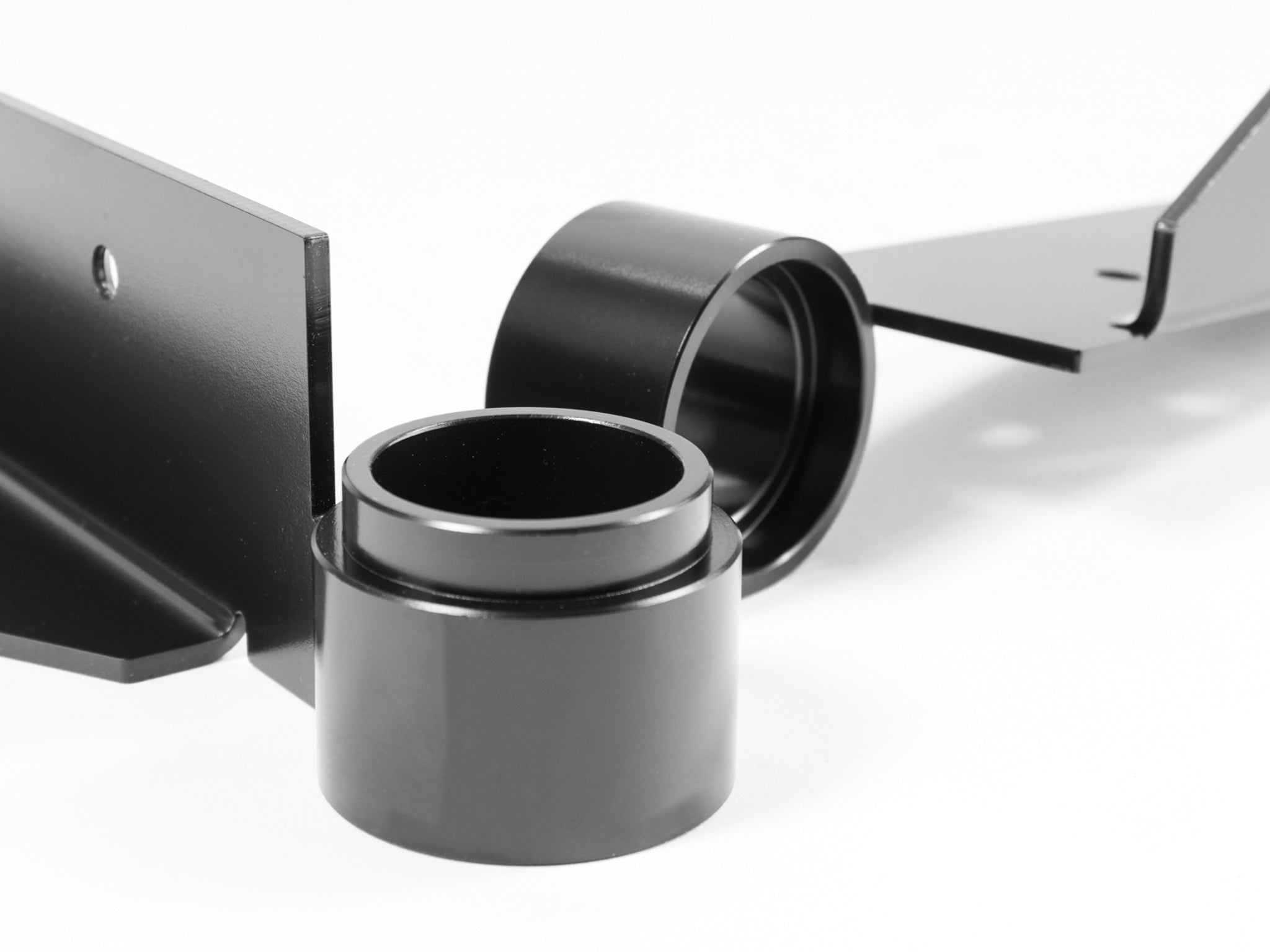

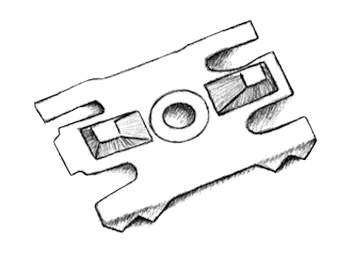

Tribeam Bracket – Diamond 90

Sale price€199,00

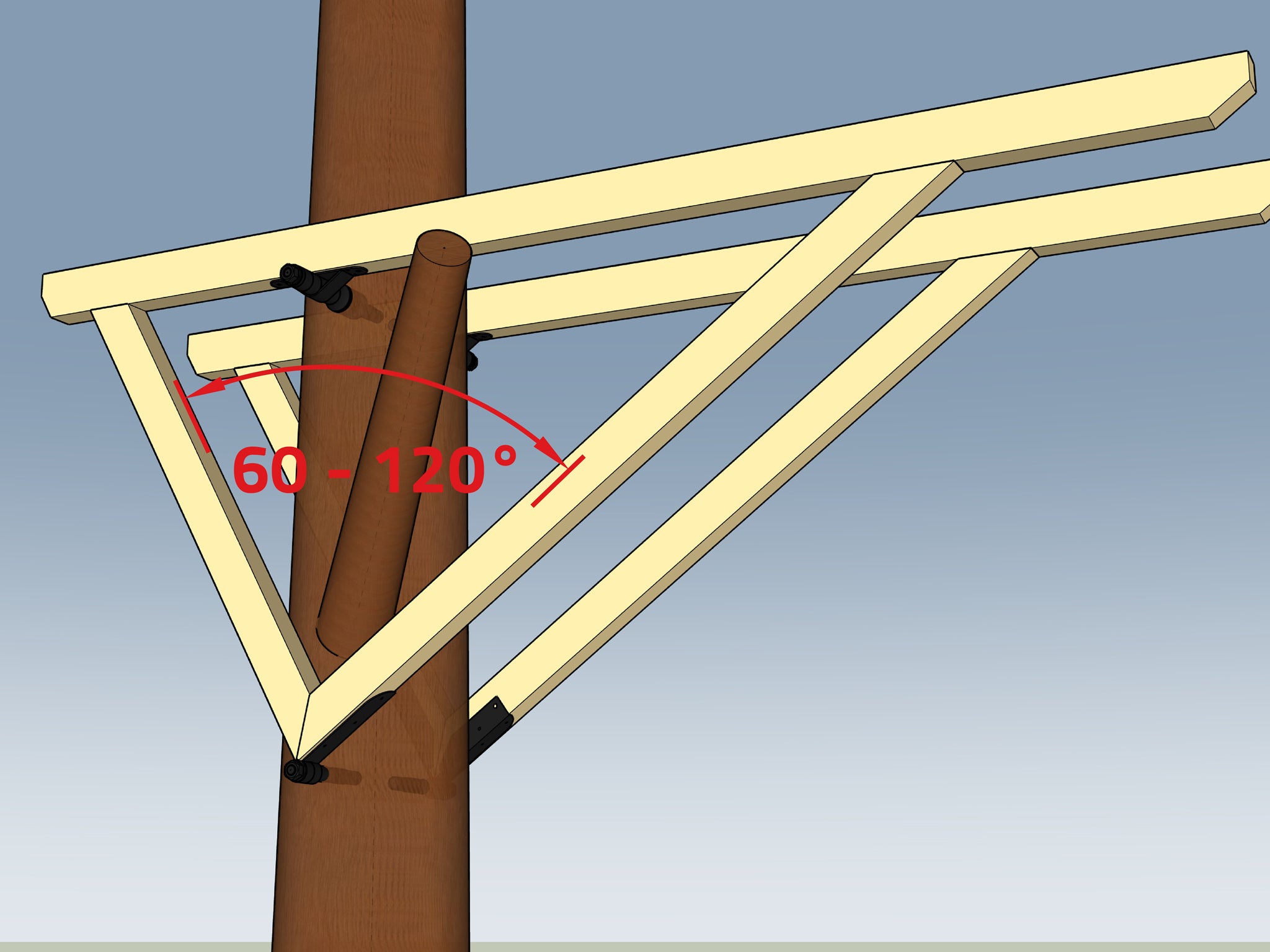

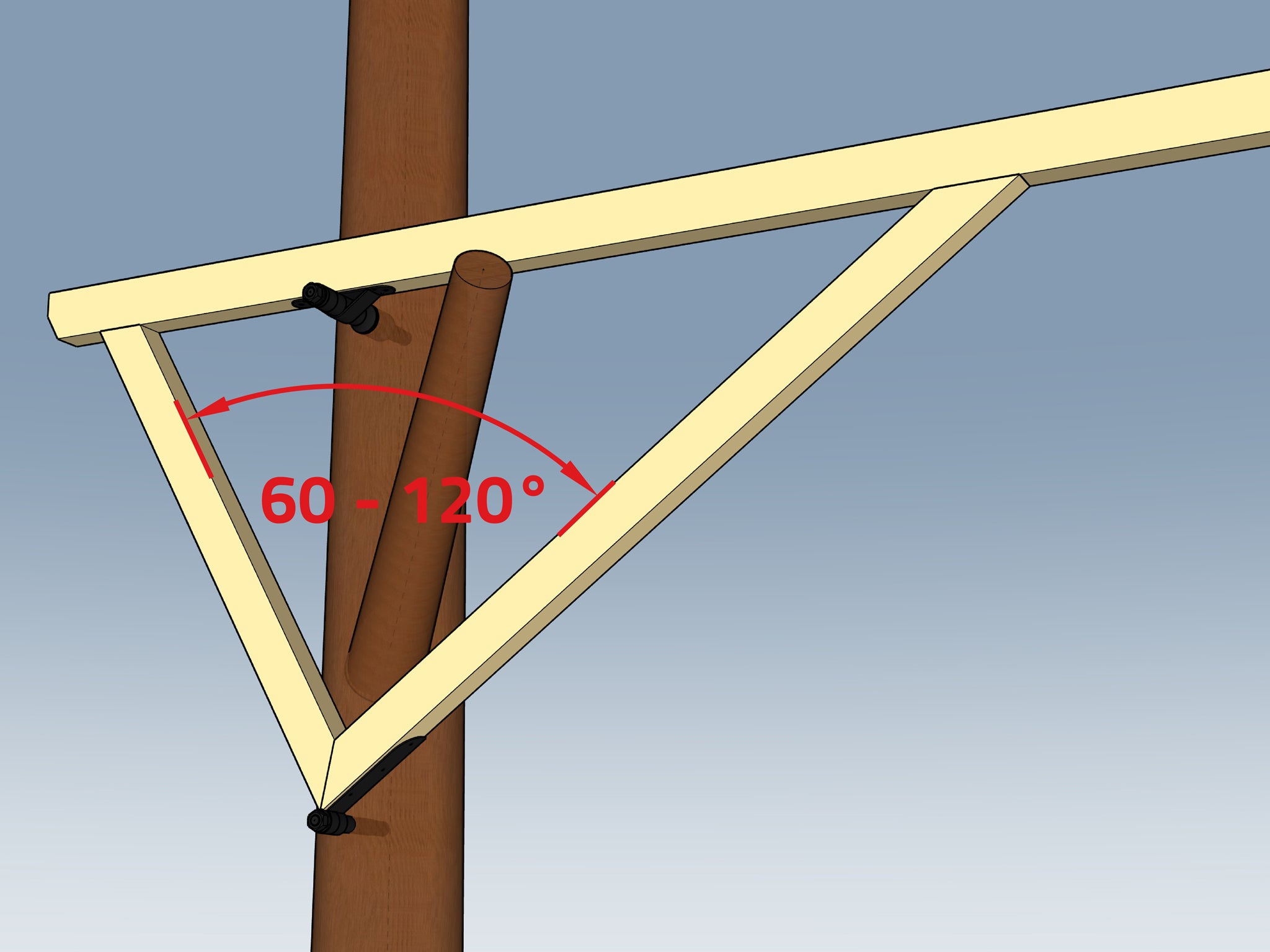

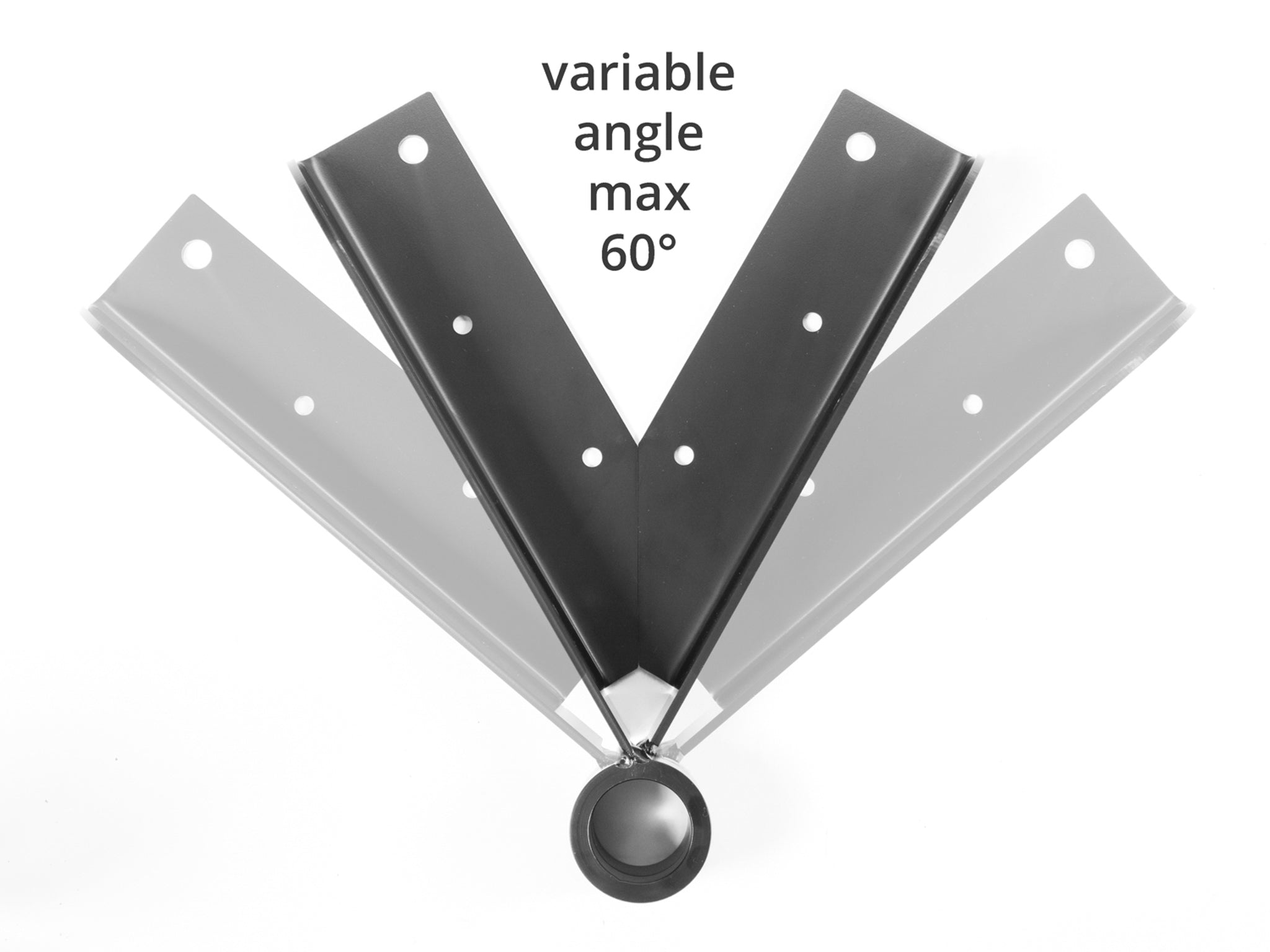

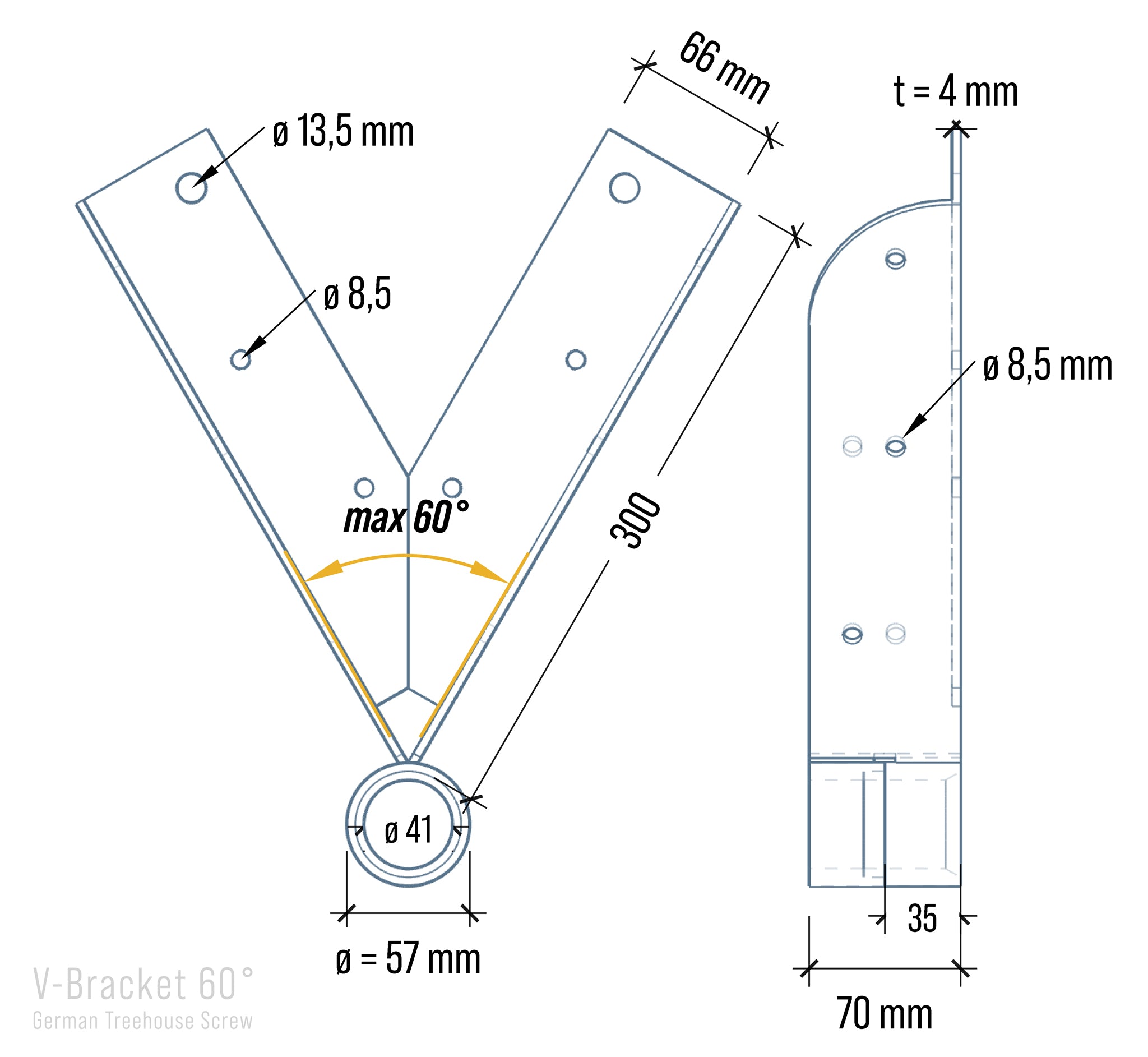

Tri-Beam Bracket – Vario 60

Sale price€209,00

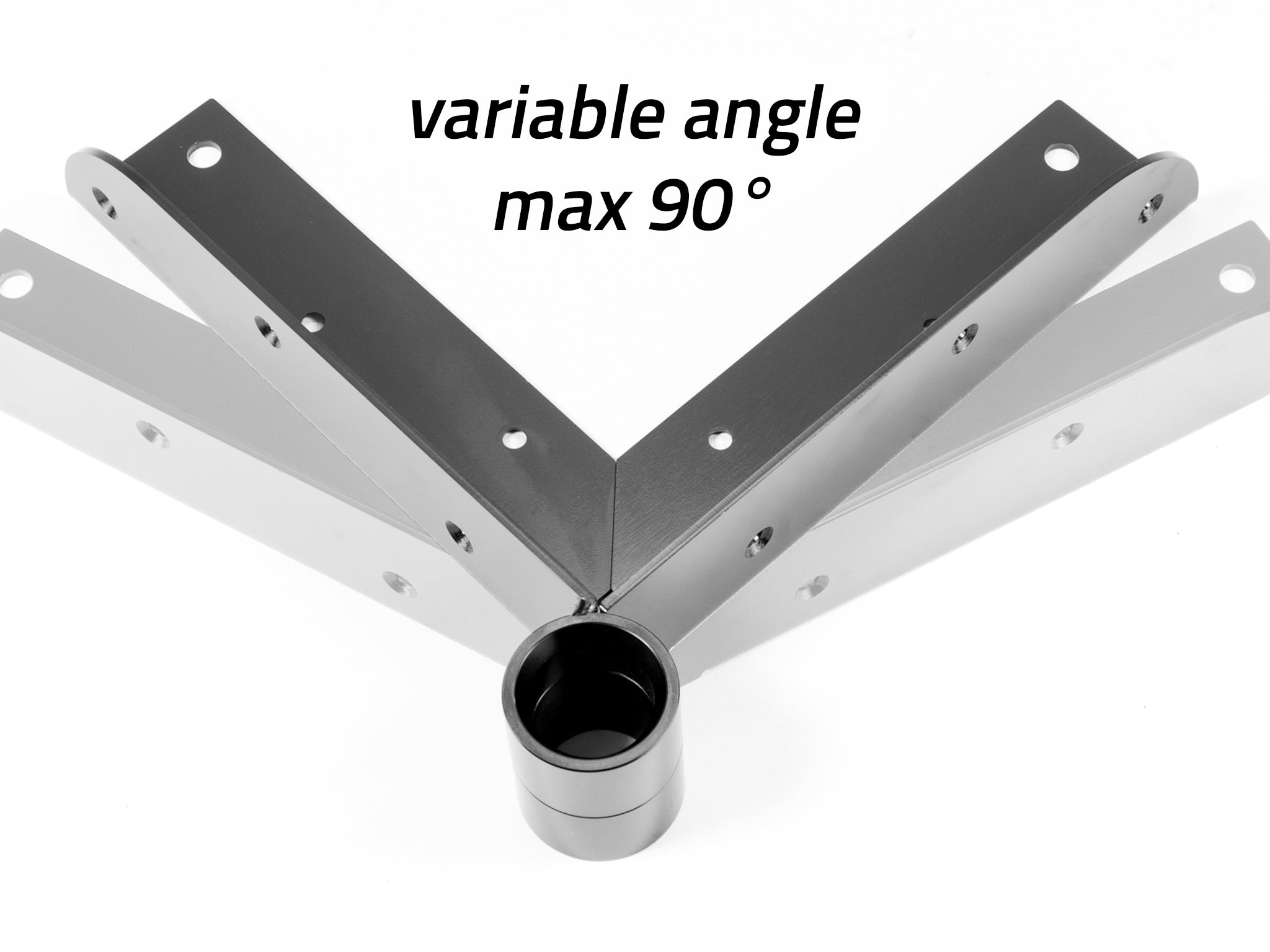

Tri-Beam Bracket – Vario 90

Sale price€189,00

Regular price€209,00

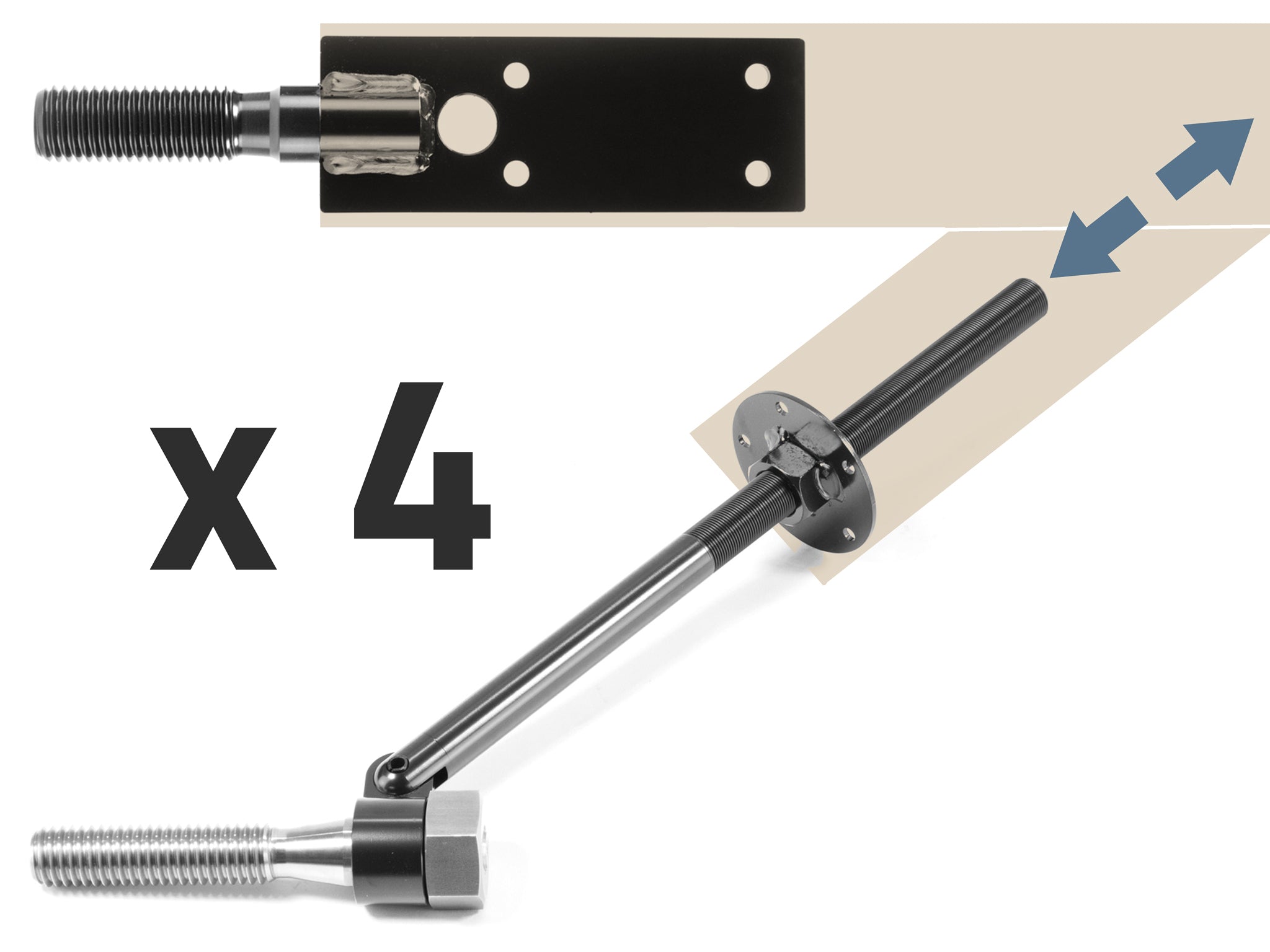

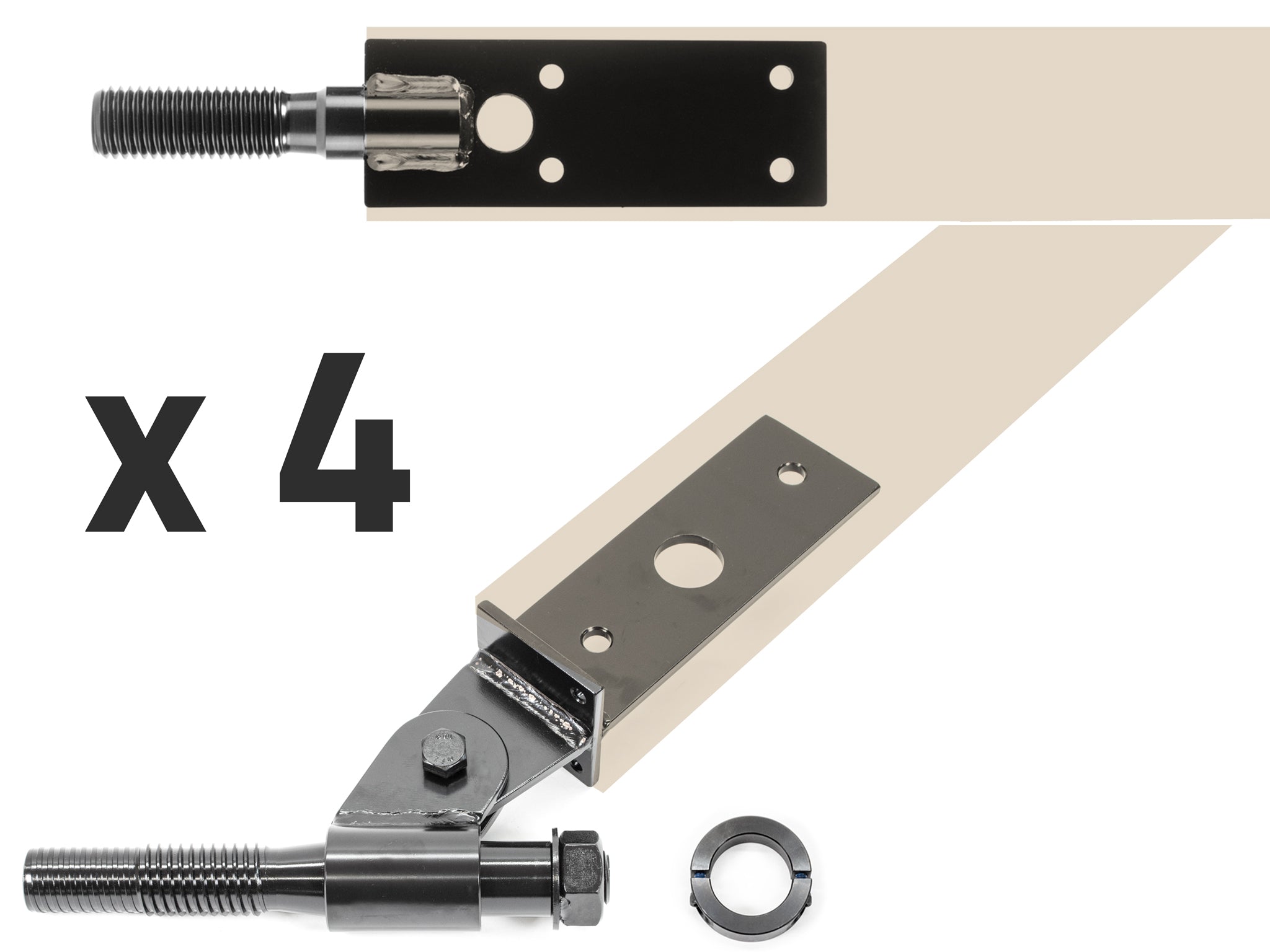

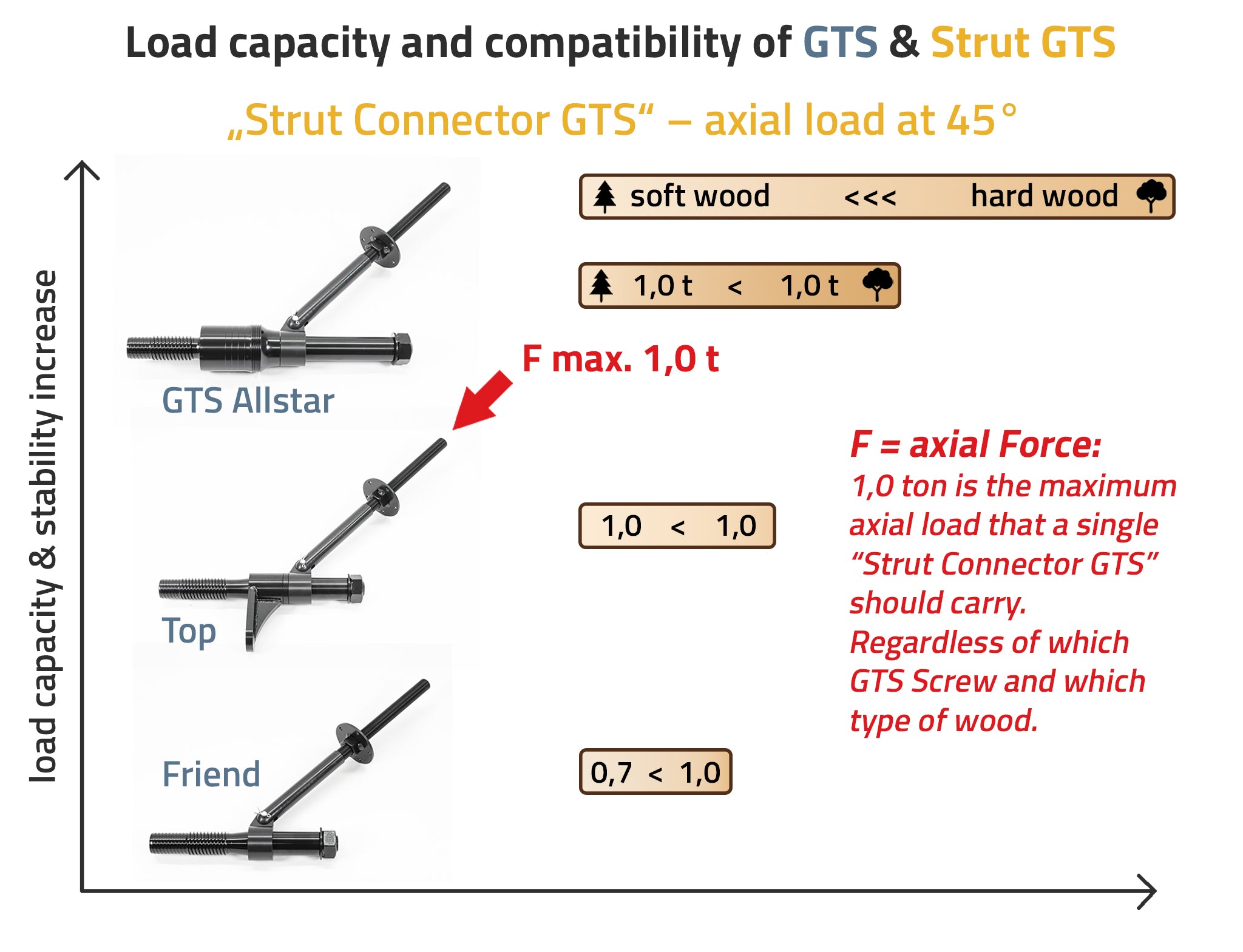

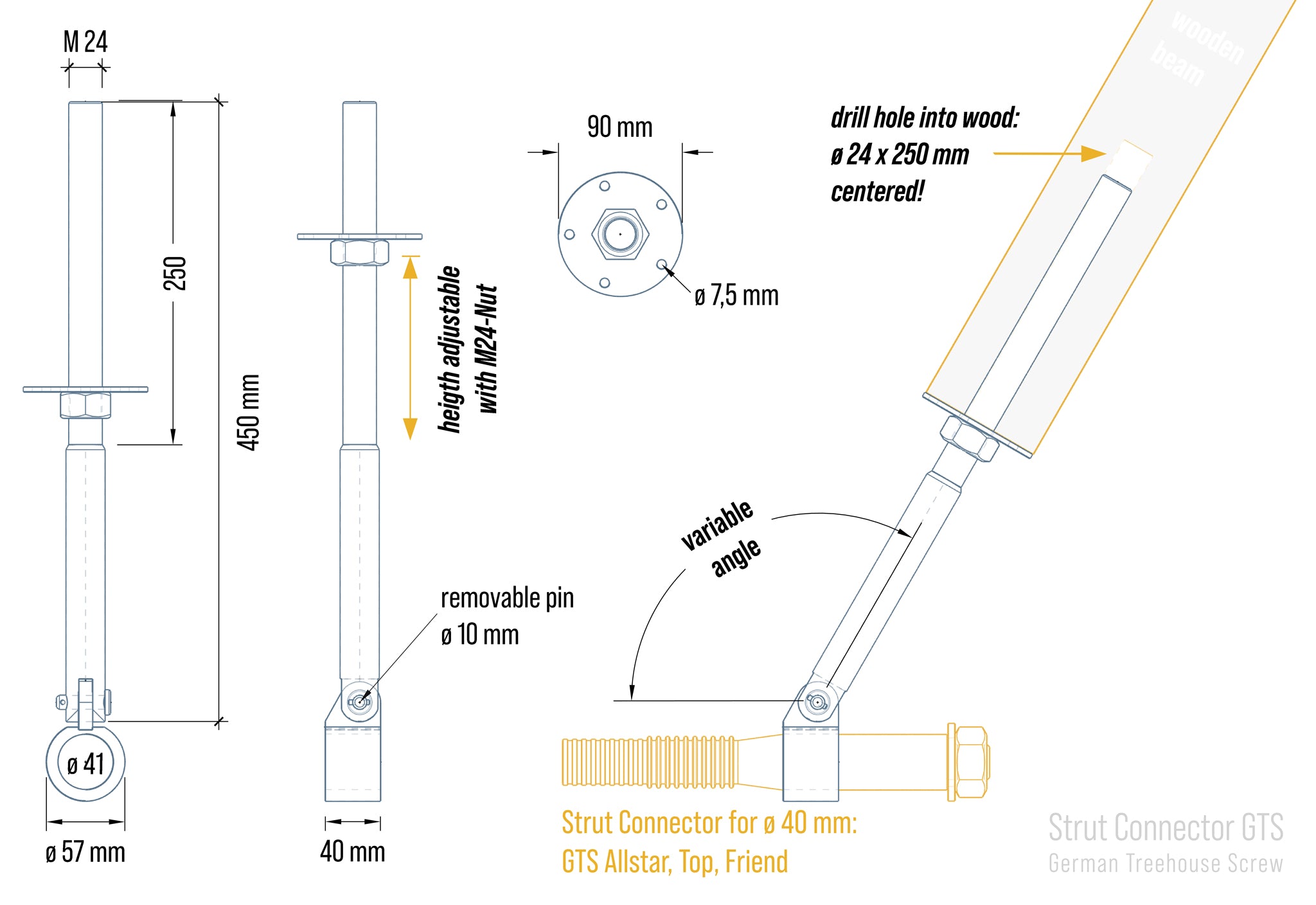

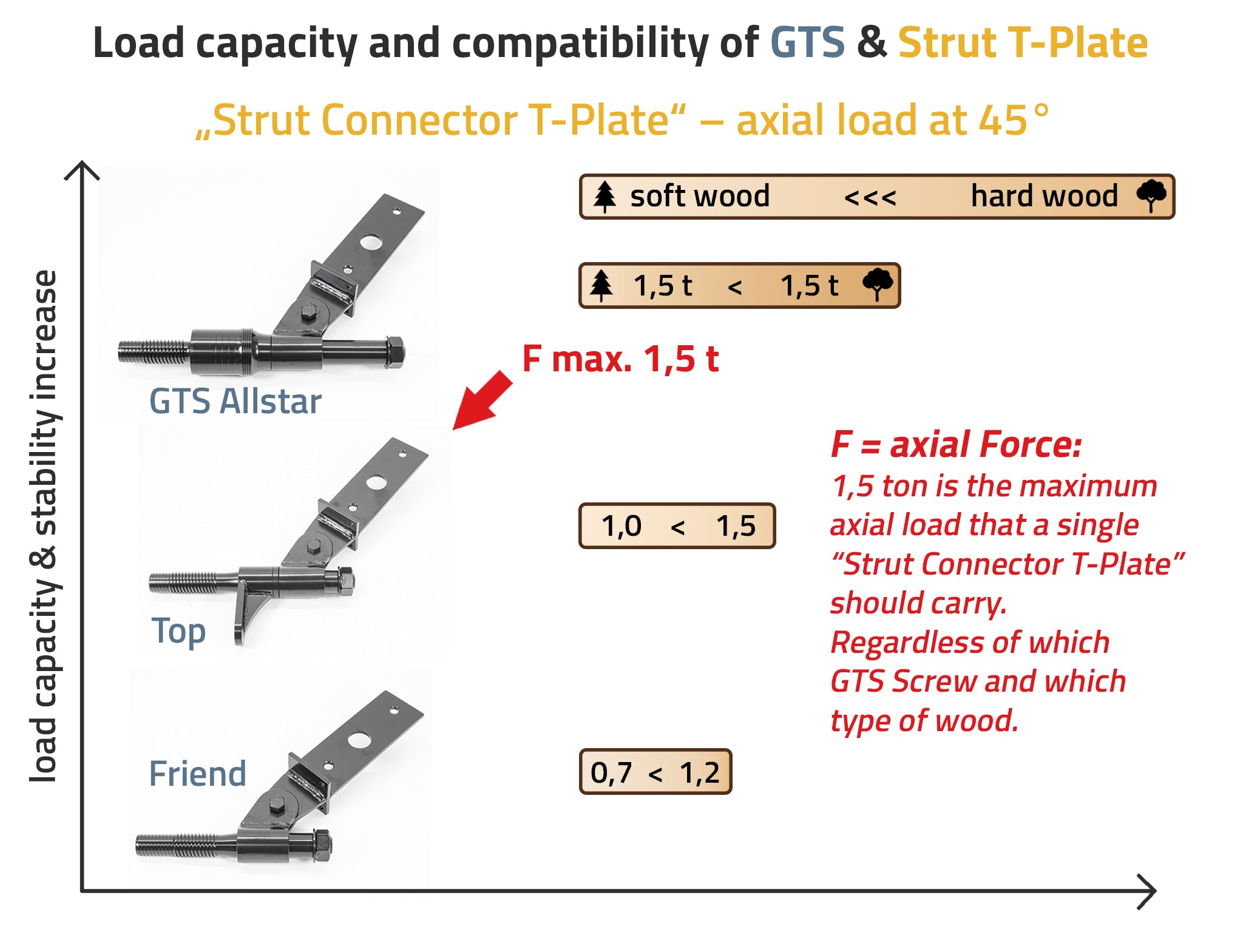

Strut-Connector GTS

Sale price€131,00

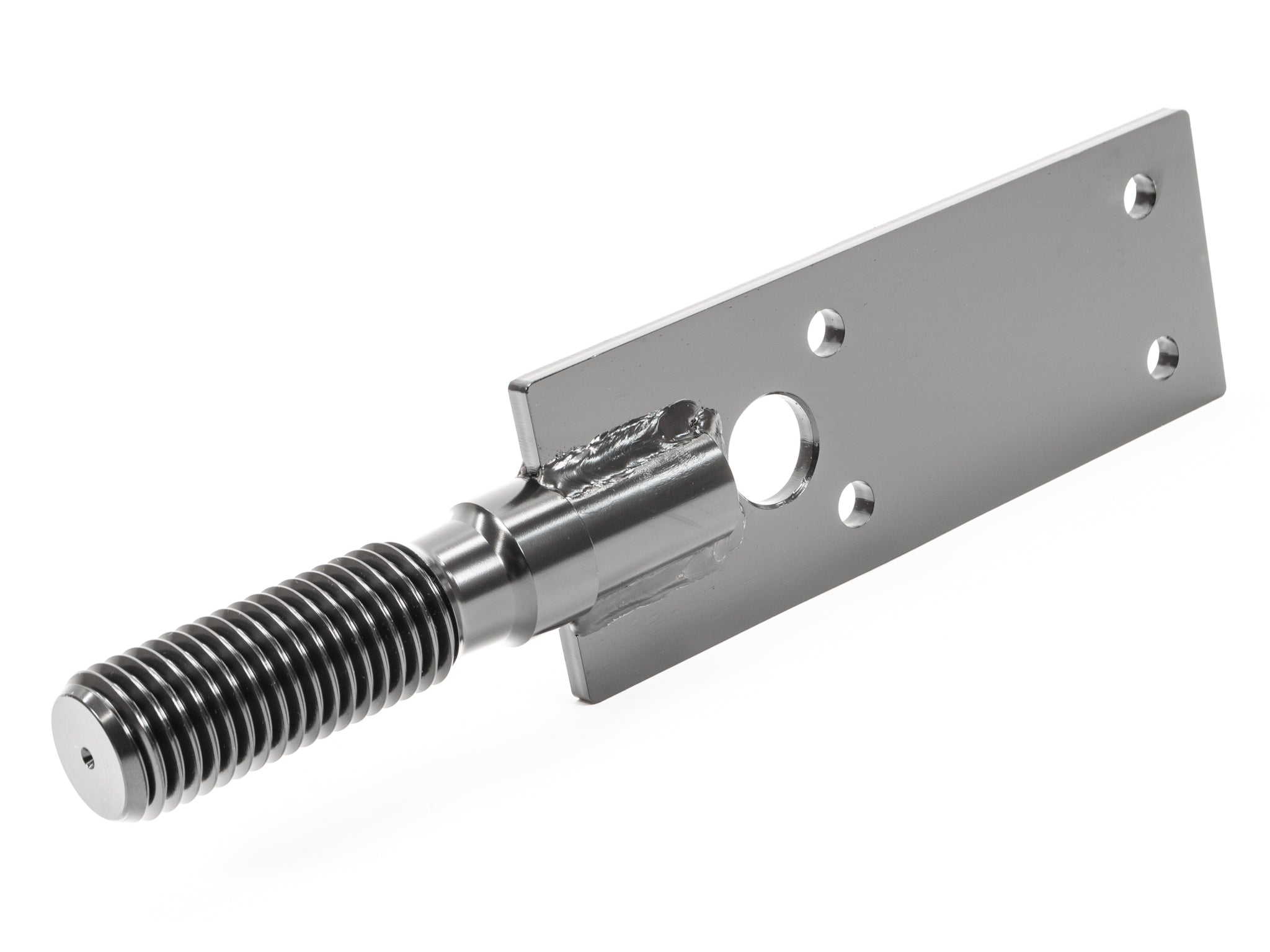

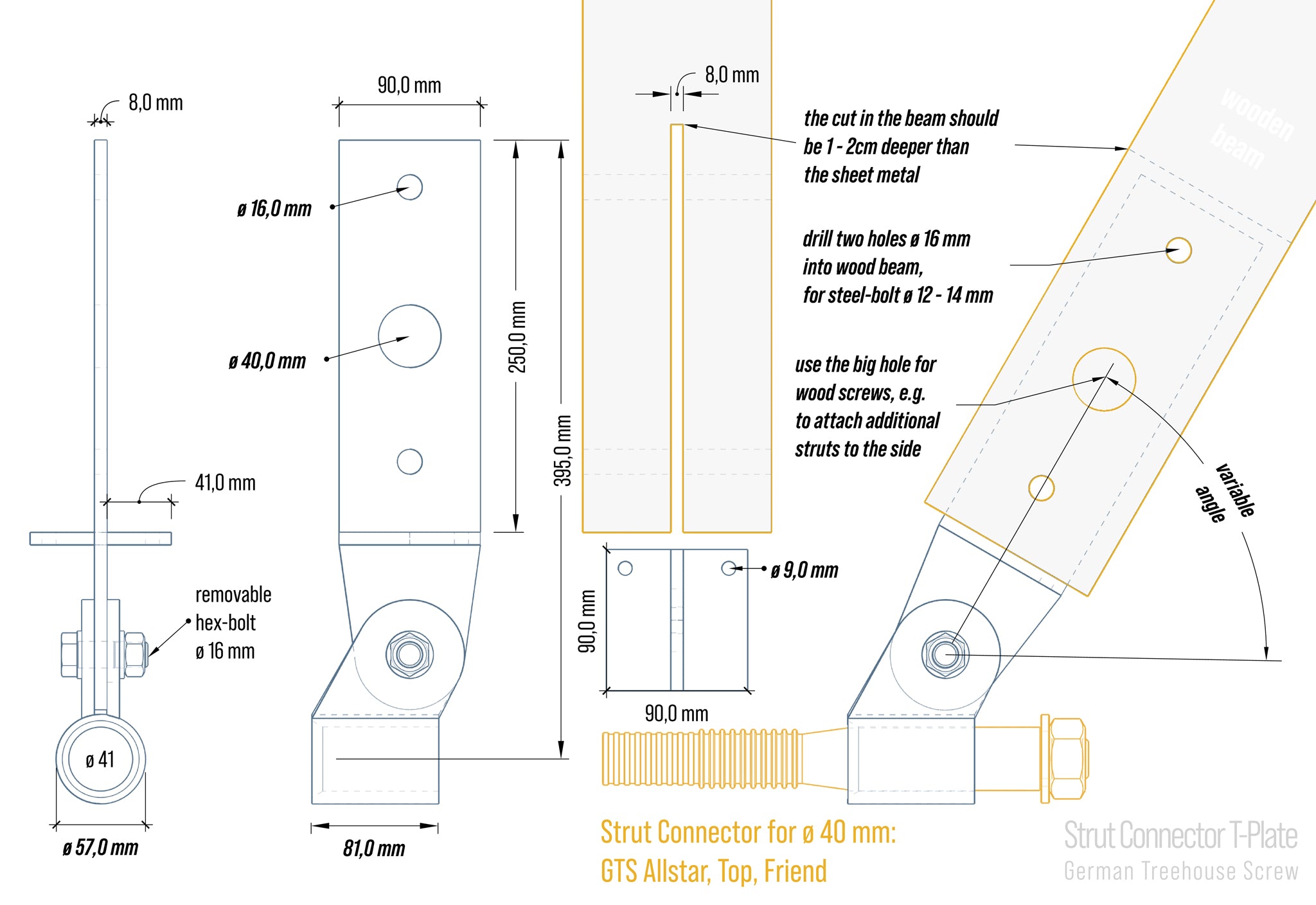

Strut-Connector T-Plate

Sale price€135,00

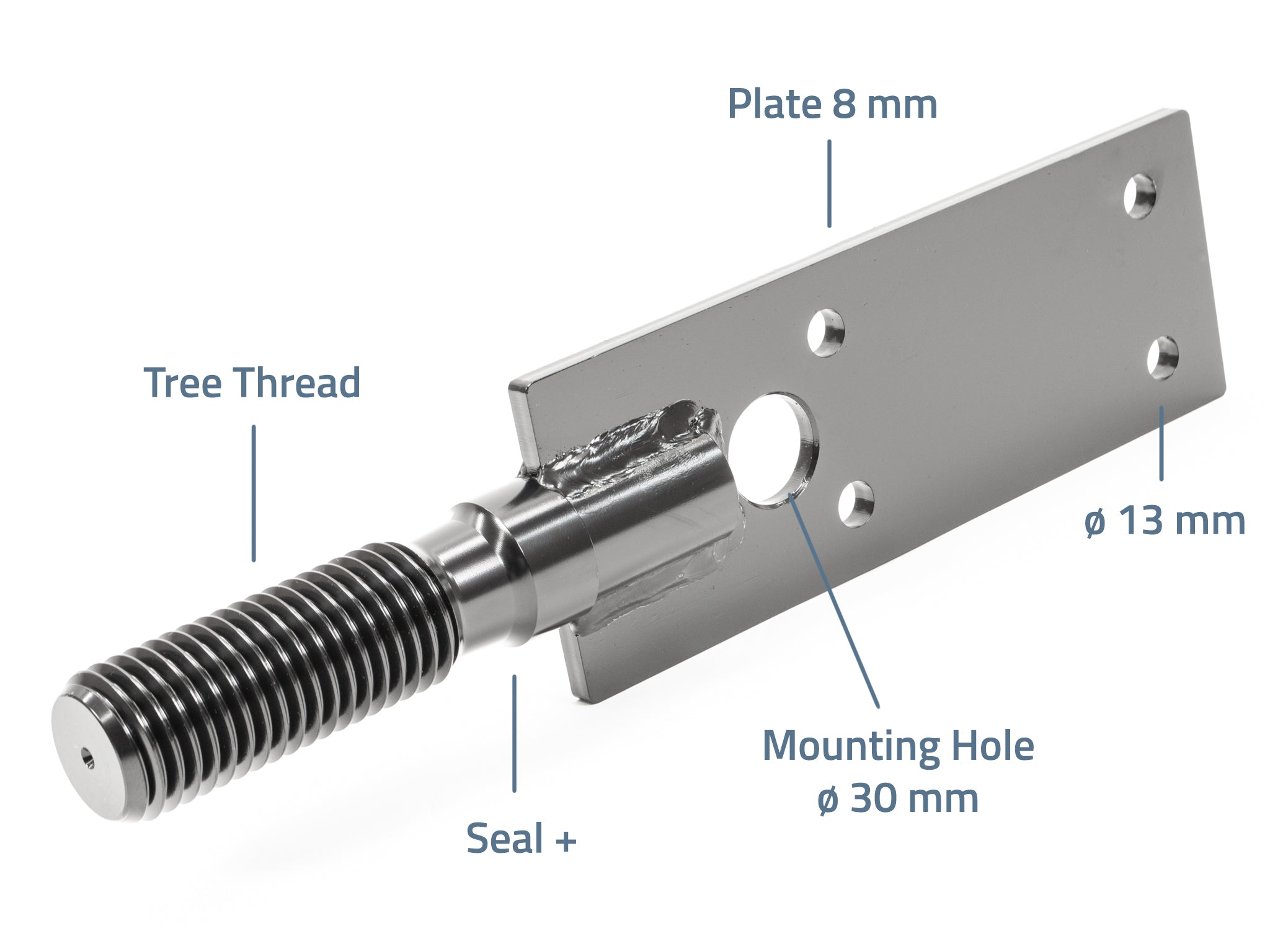

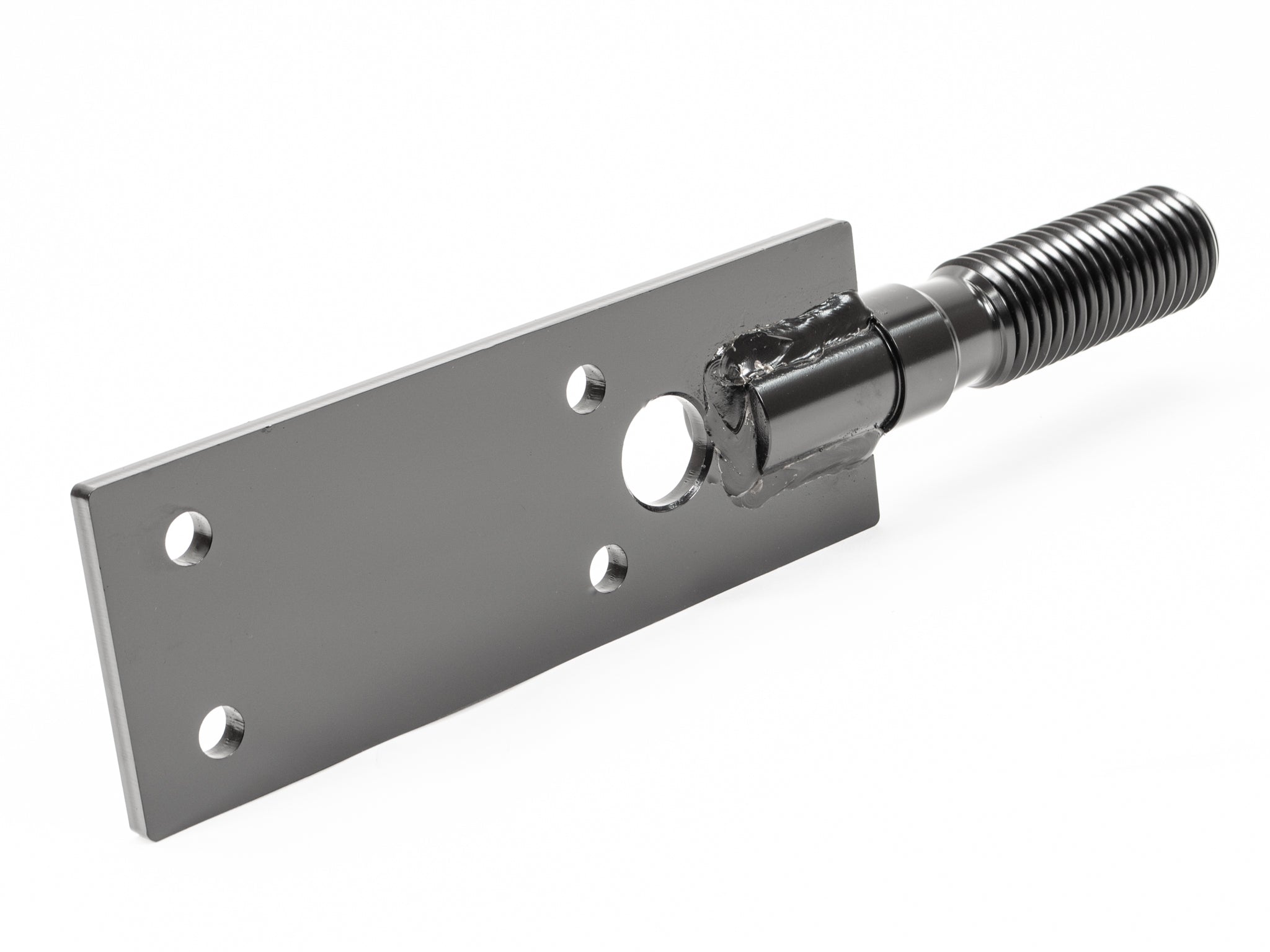

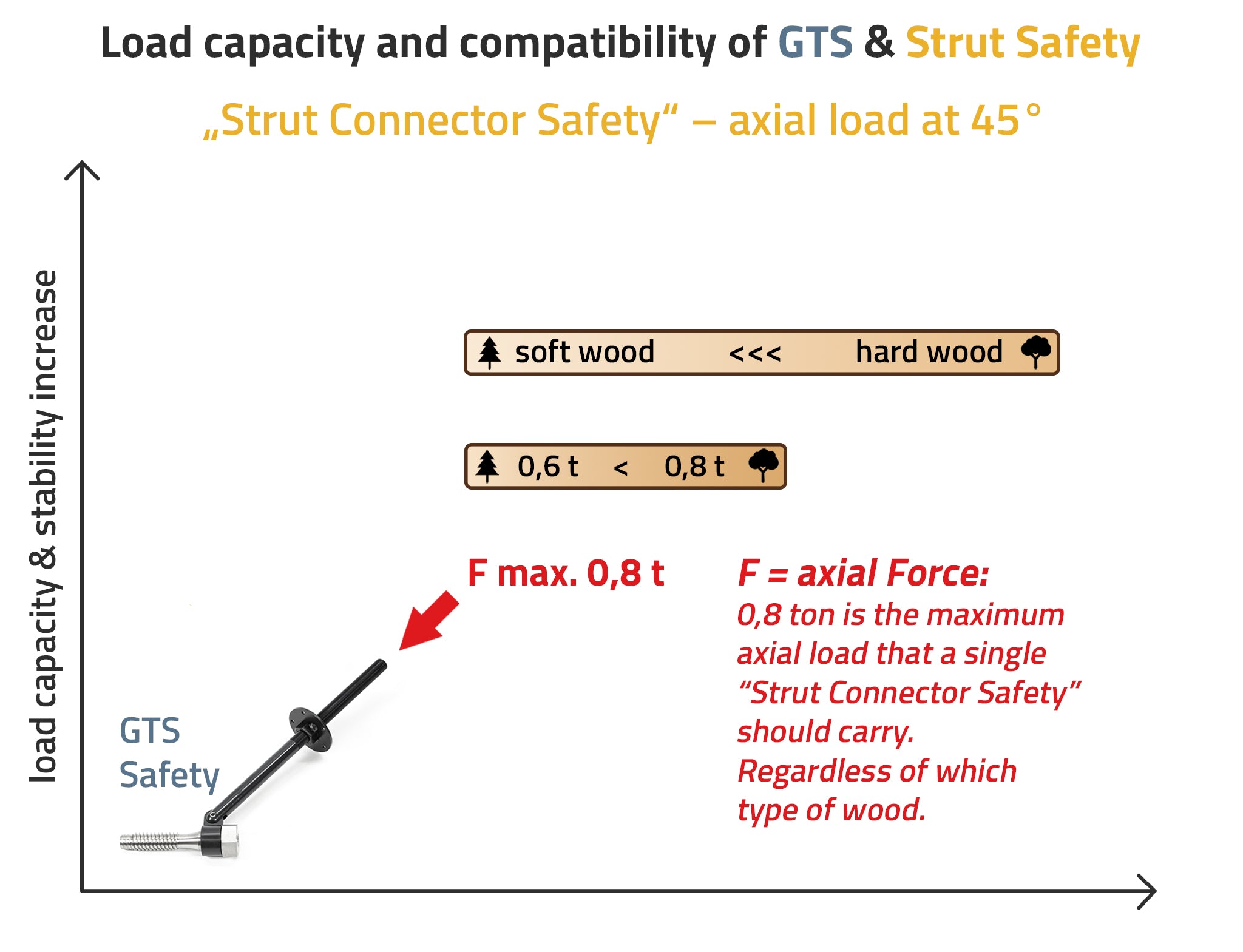

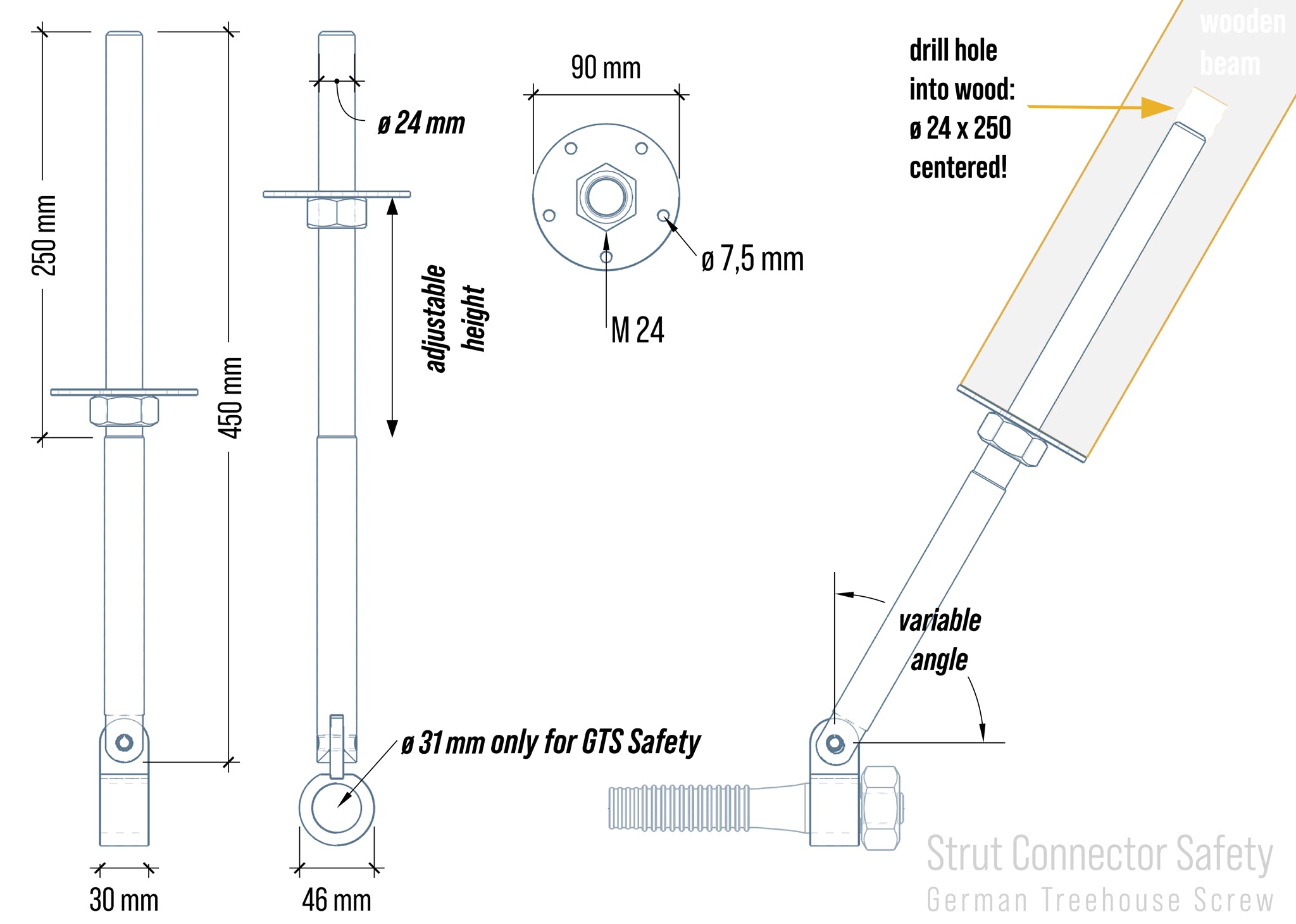

Strut-Connector Safety

Sale price€199,00

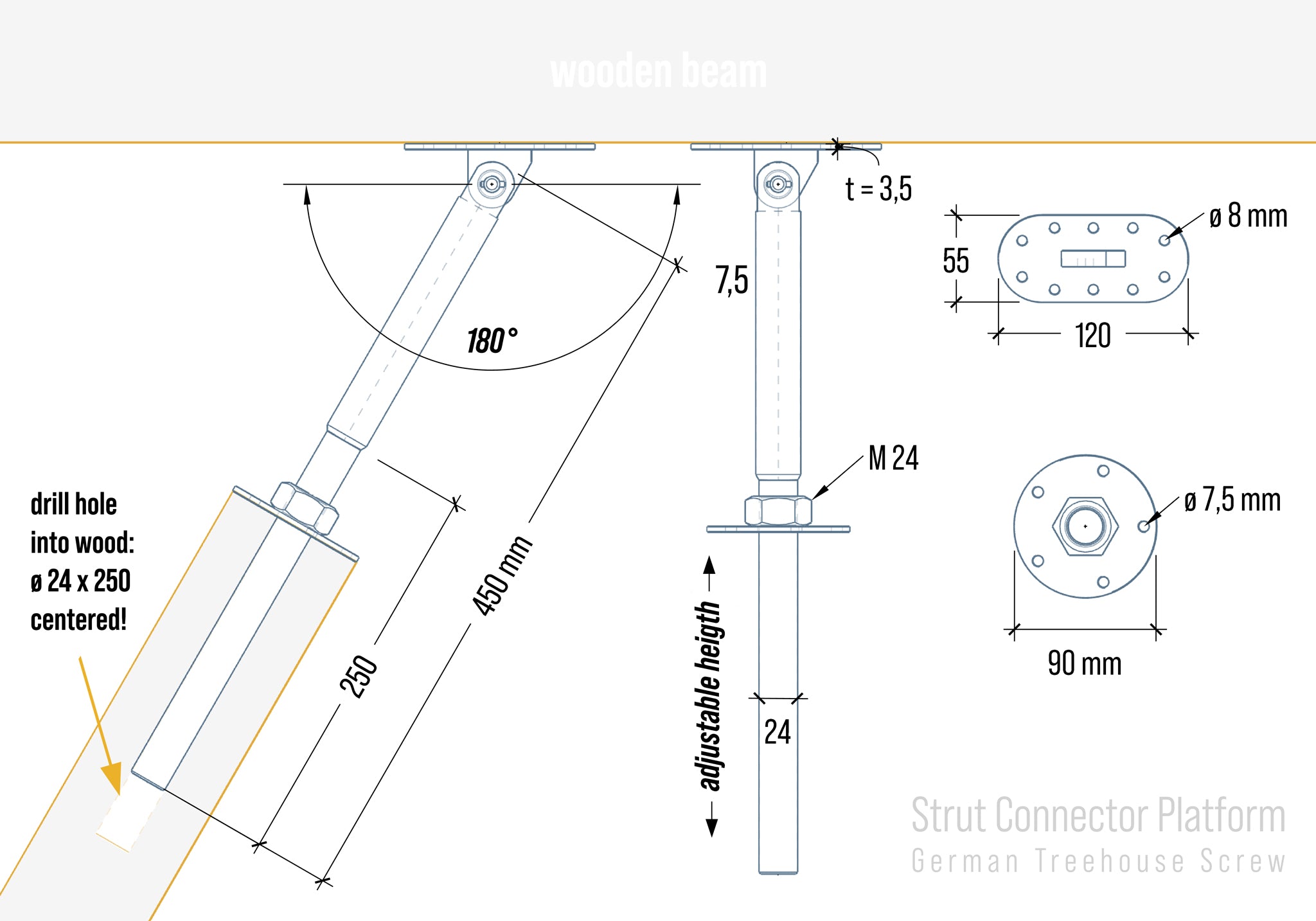

Strut-Connector Platform

Sale price€131,00

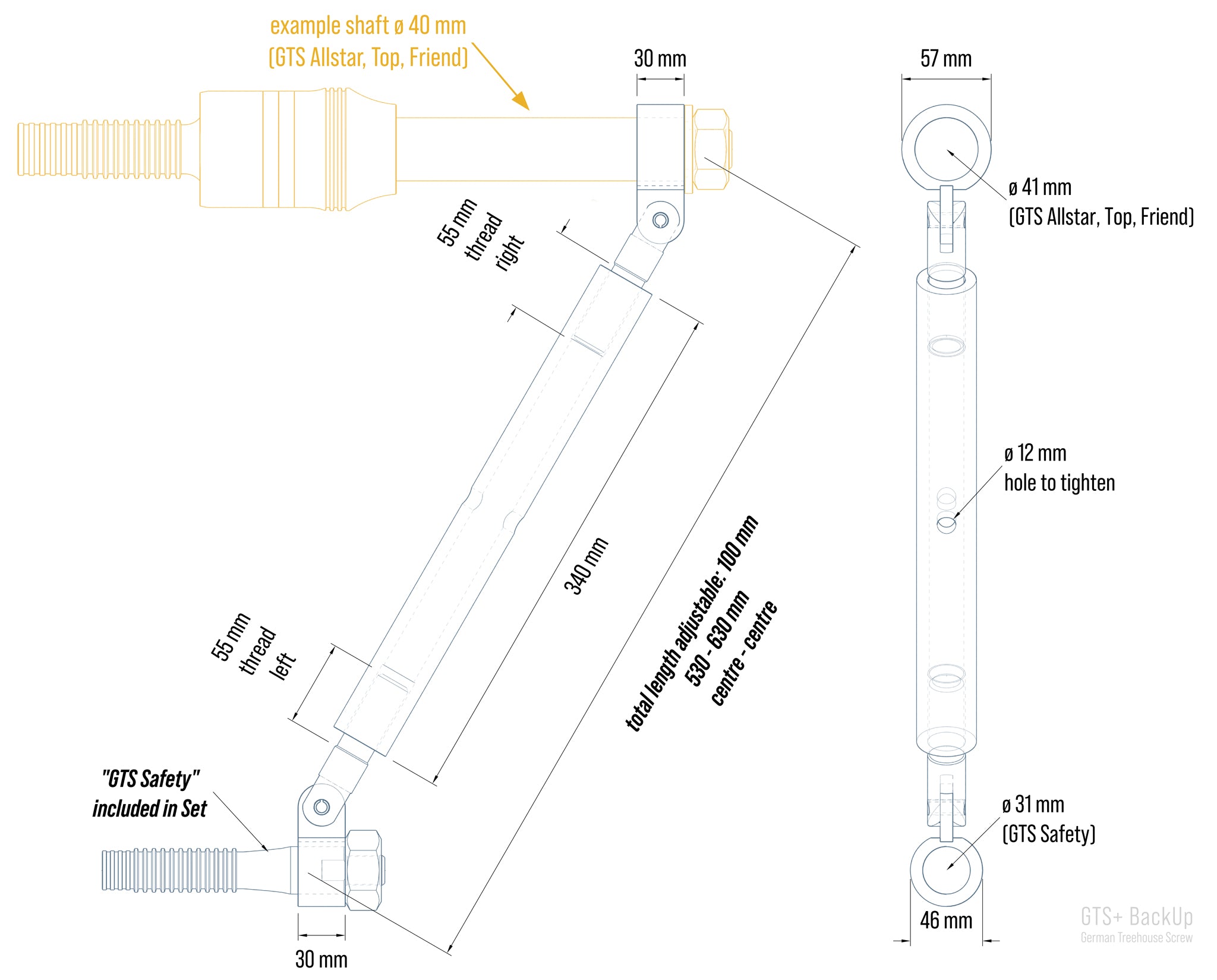

GTS+ BackUp System

Sale price€222,00

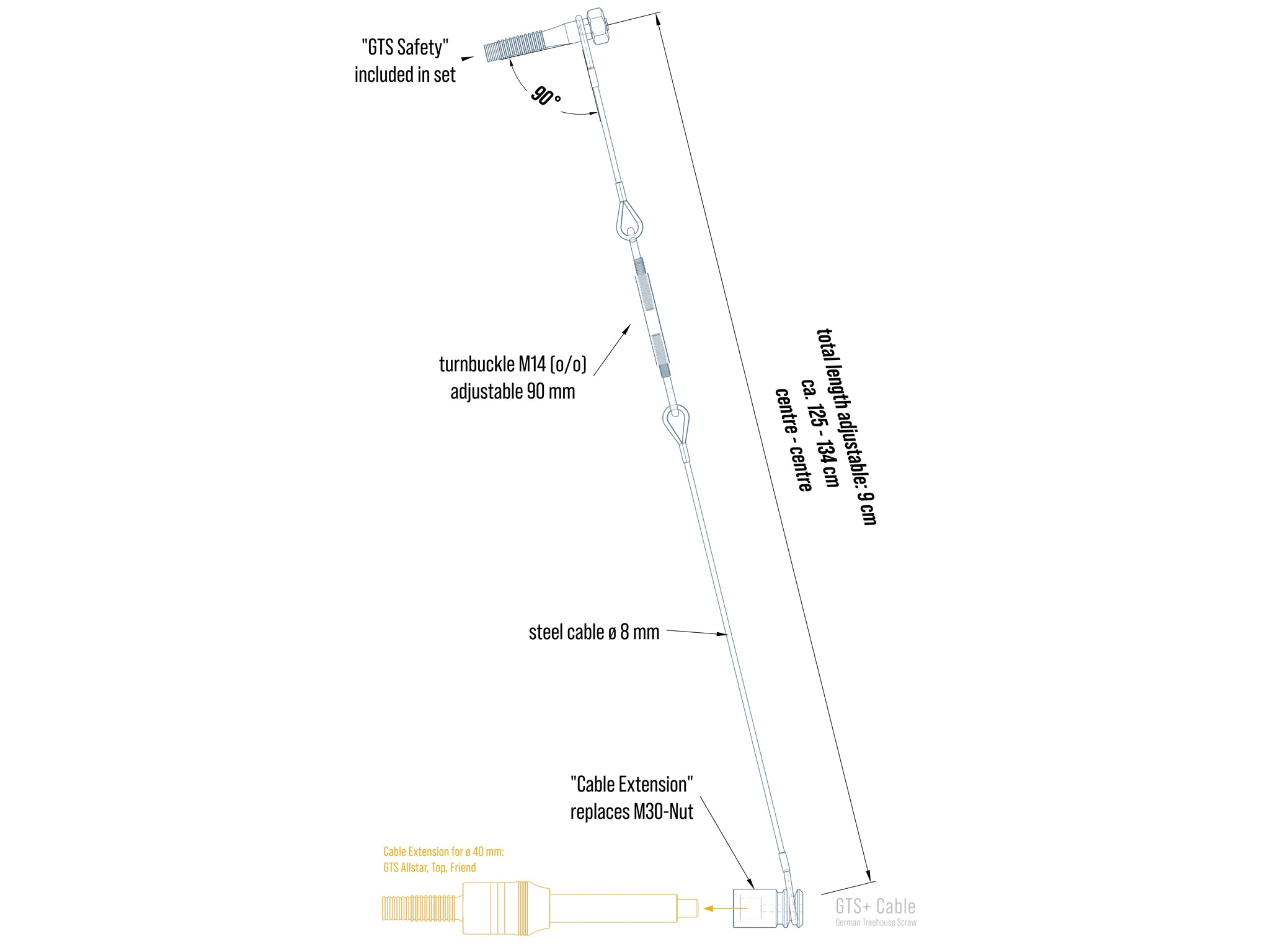

GTS+ Cable System

Sale price€199,00

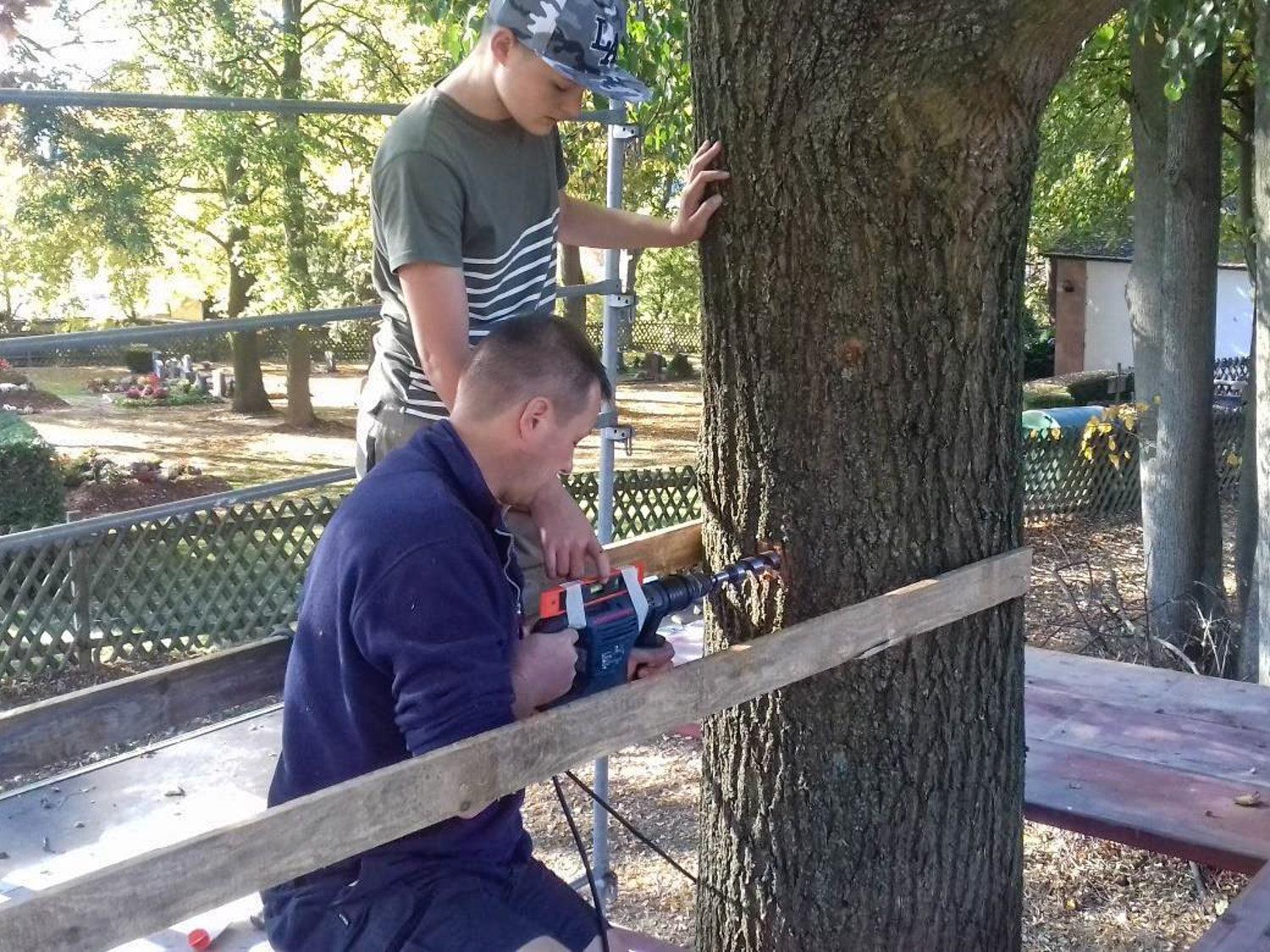

Auger Drill GTS

Sale priceFrom €27,00

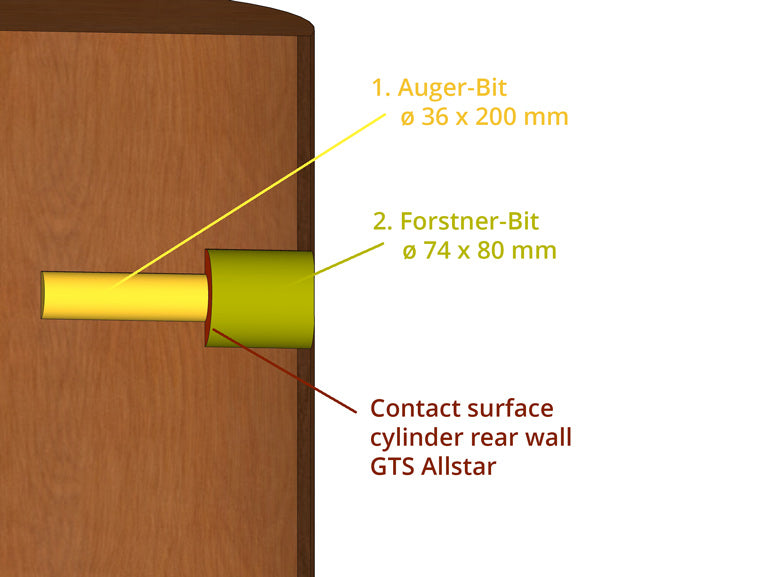

Drill-Kit GTS Allstar

Sale price€160,00

Ratchet GTS 1

Sale price€354,00

Tool-Kit x Bit Magic

Sale price€59,00

Regular price€70,00

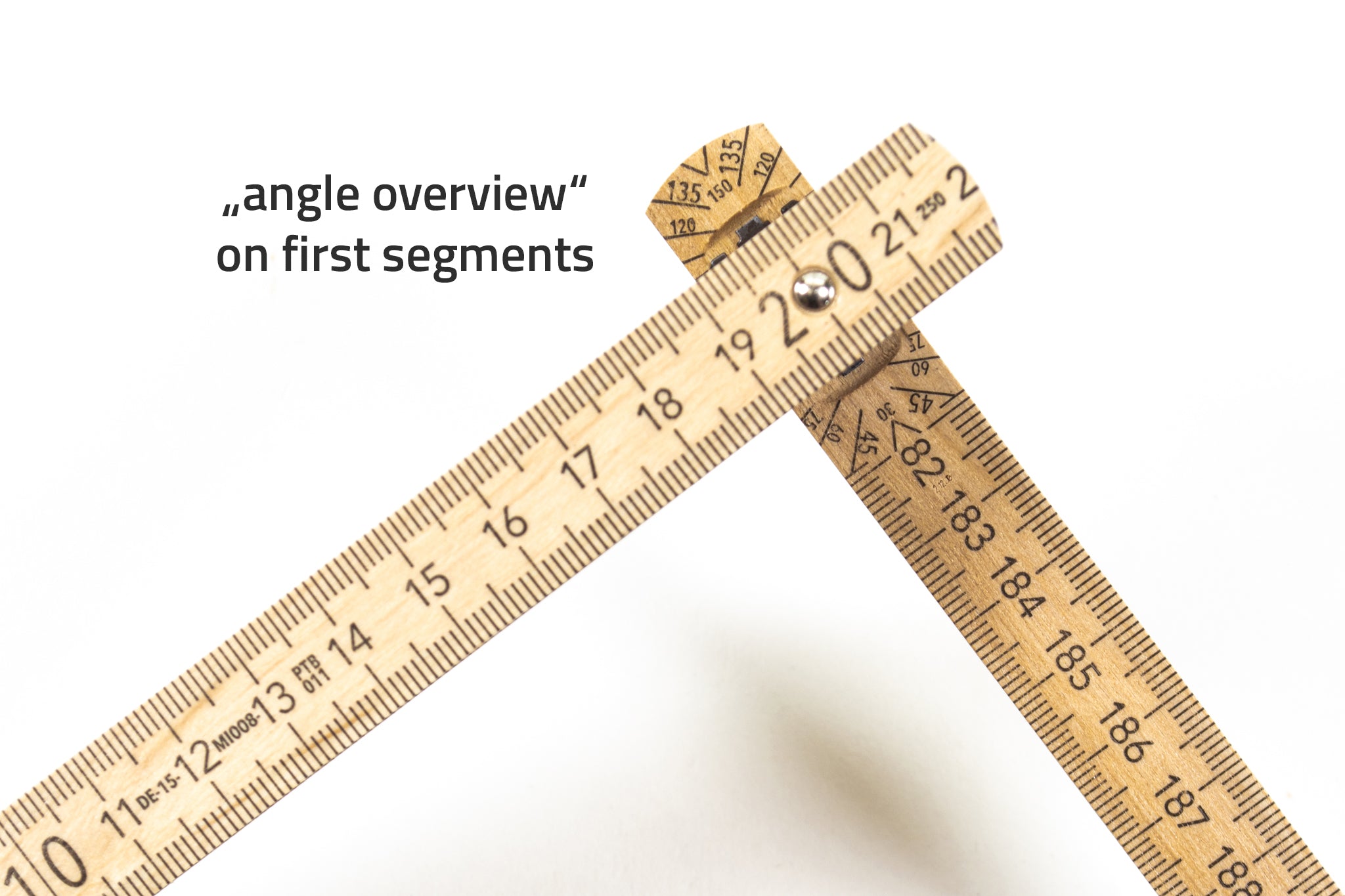

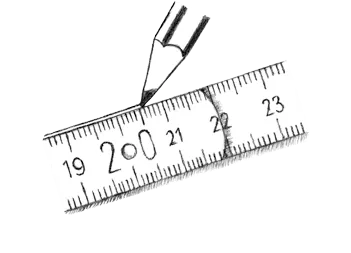

Metreec Folding Rulder "Always on Top"

Sale price€9,95

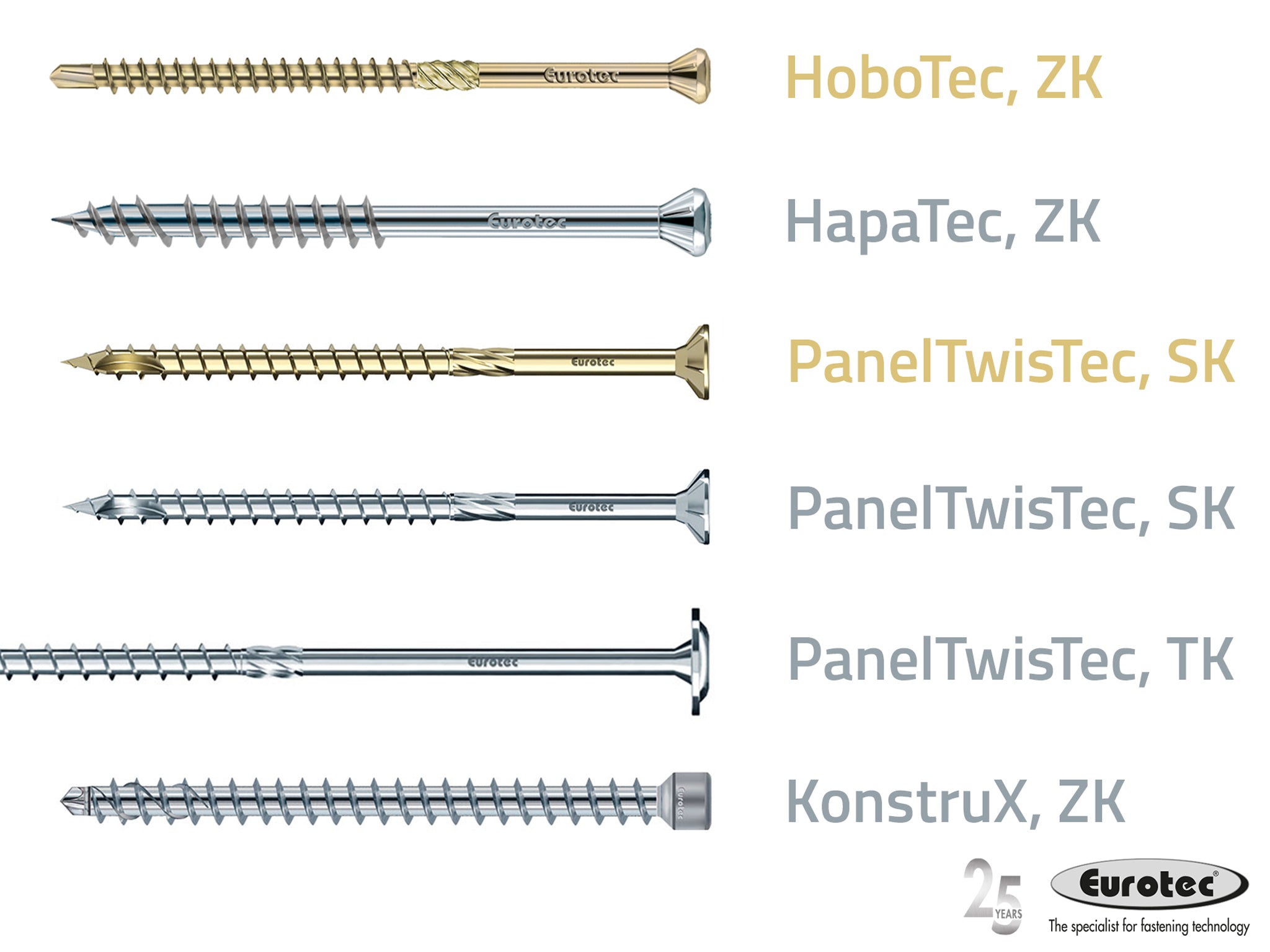

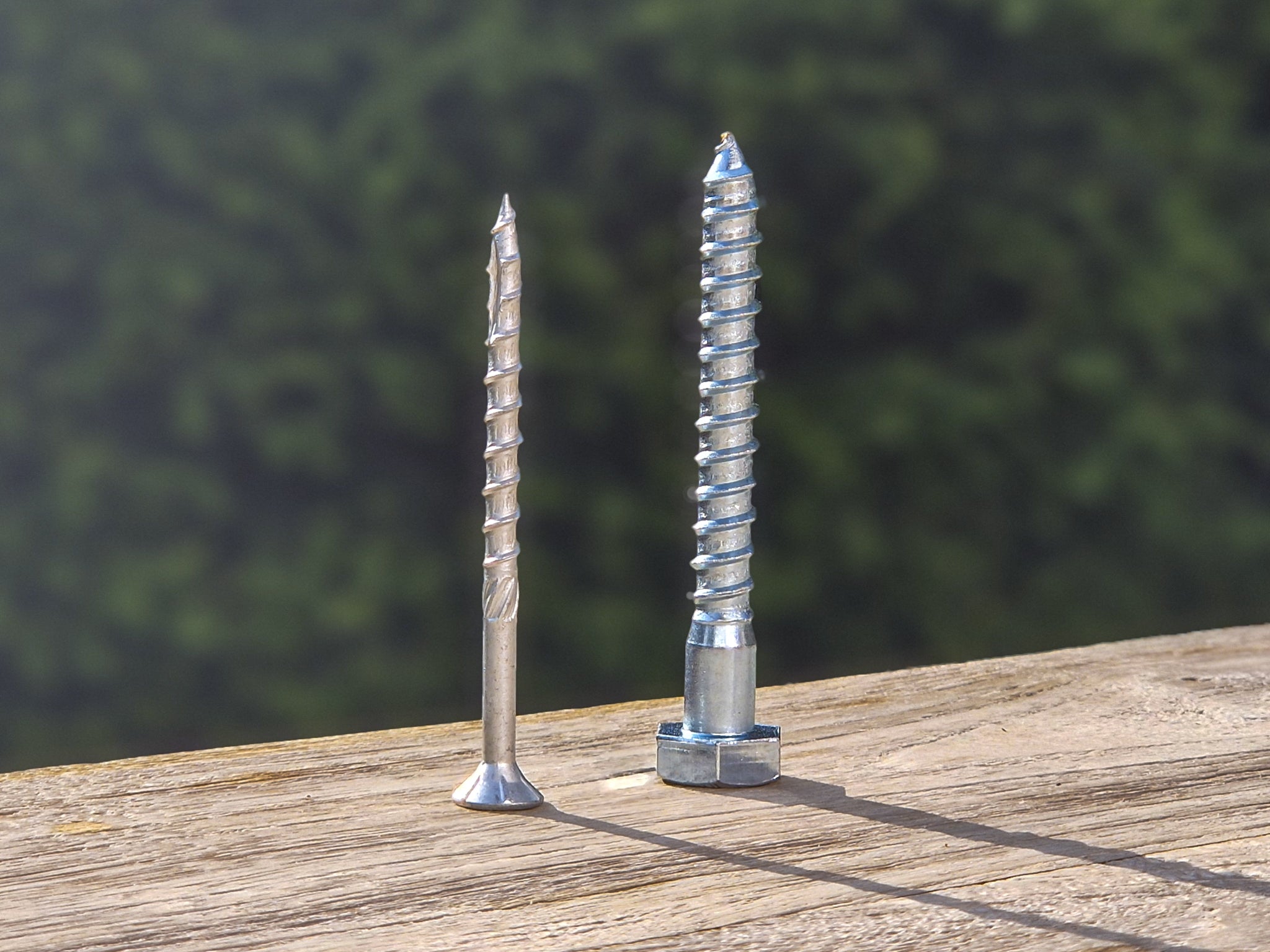

Wood Screw Kit – Treehouse Essentials

Sale price€483,00

Regular price€589,95

Tree Attachment Sling

Sale priceFrom €47,00

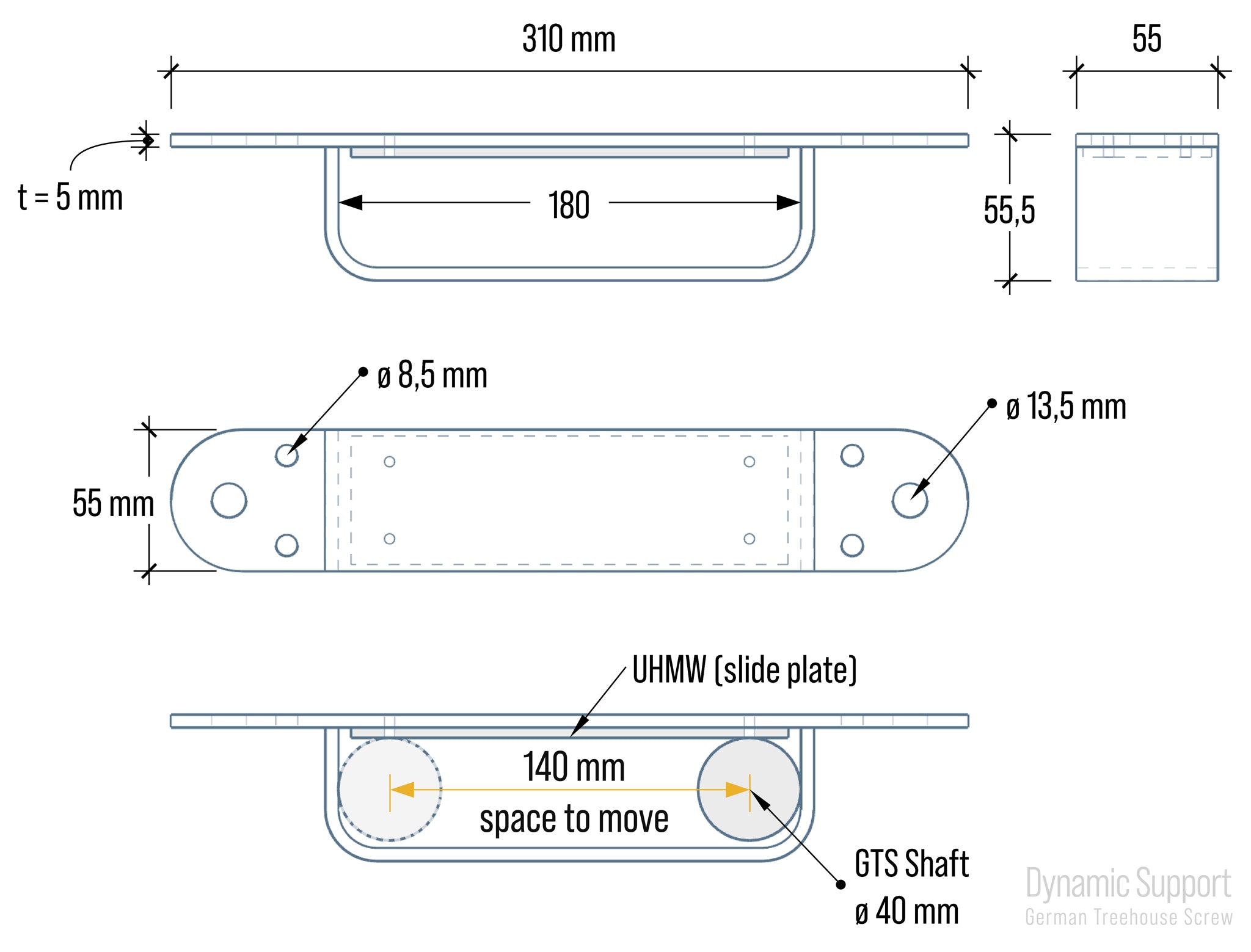

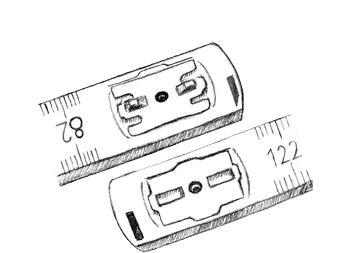

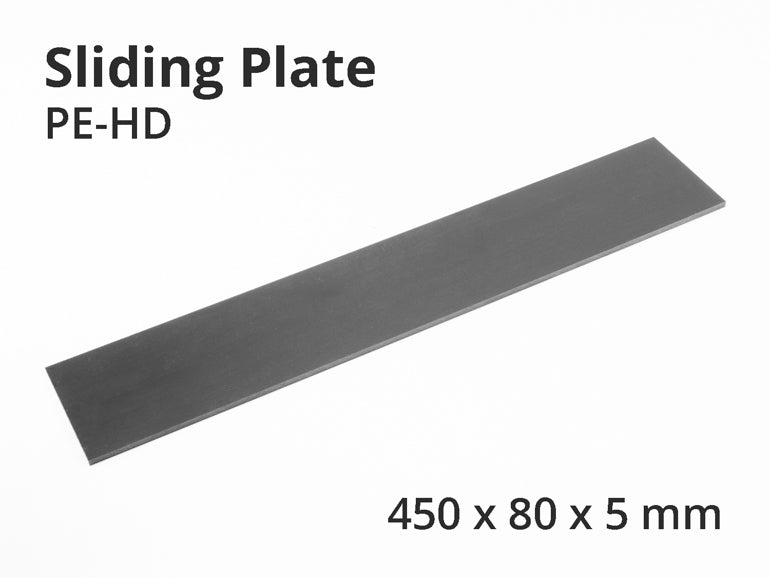

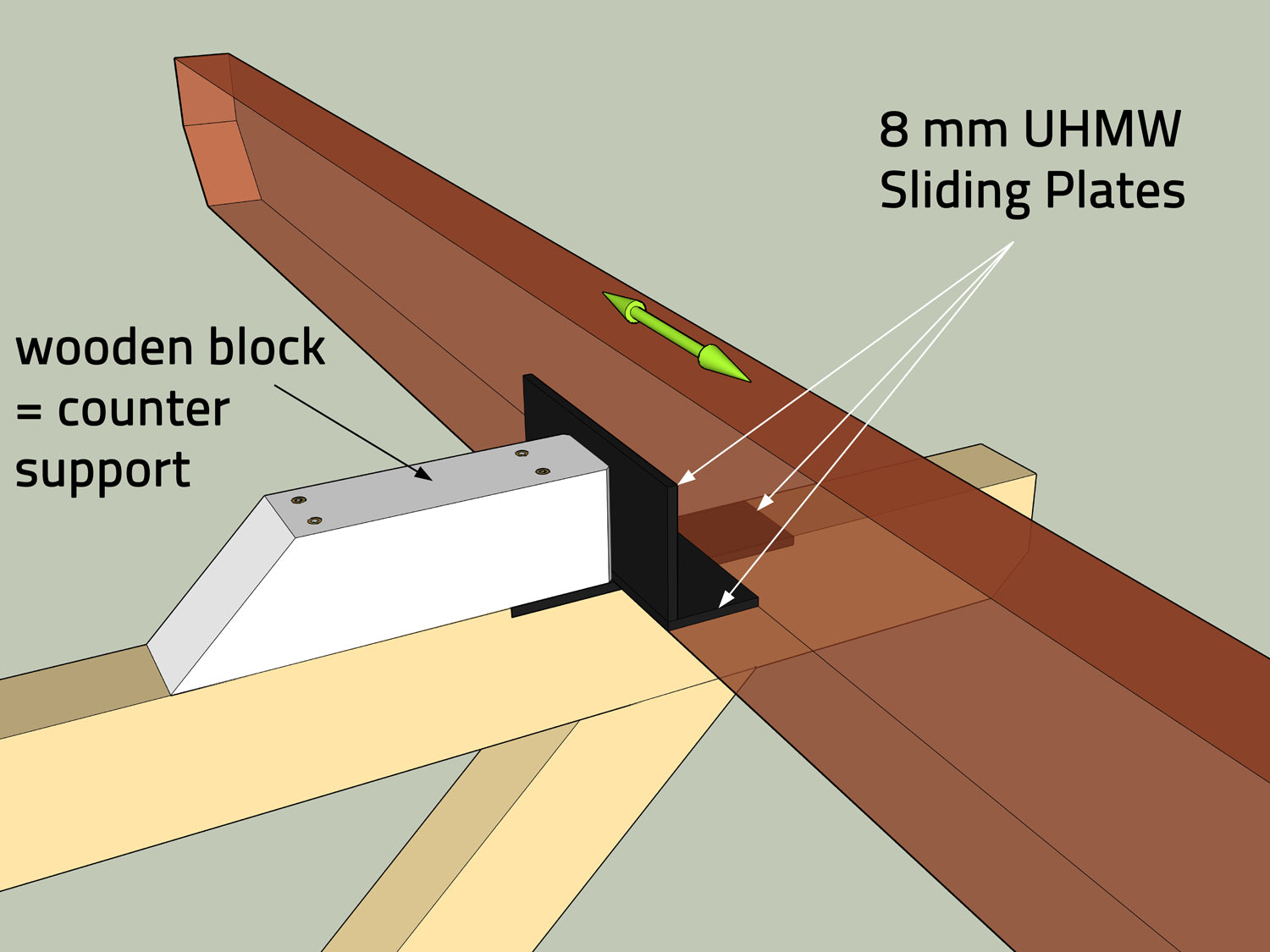

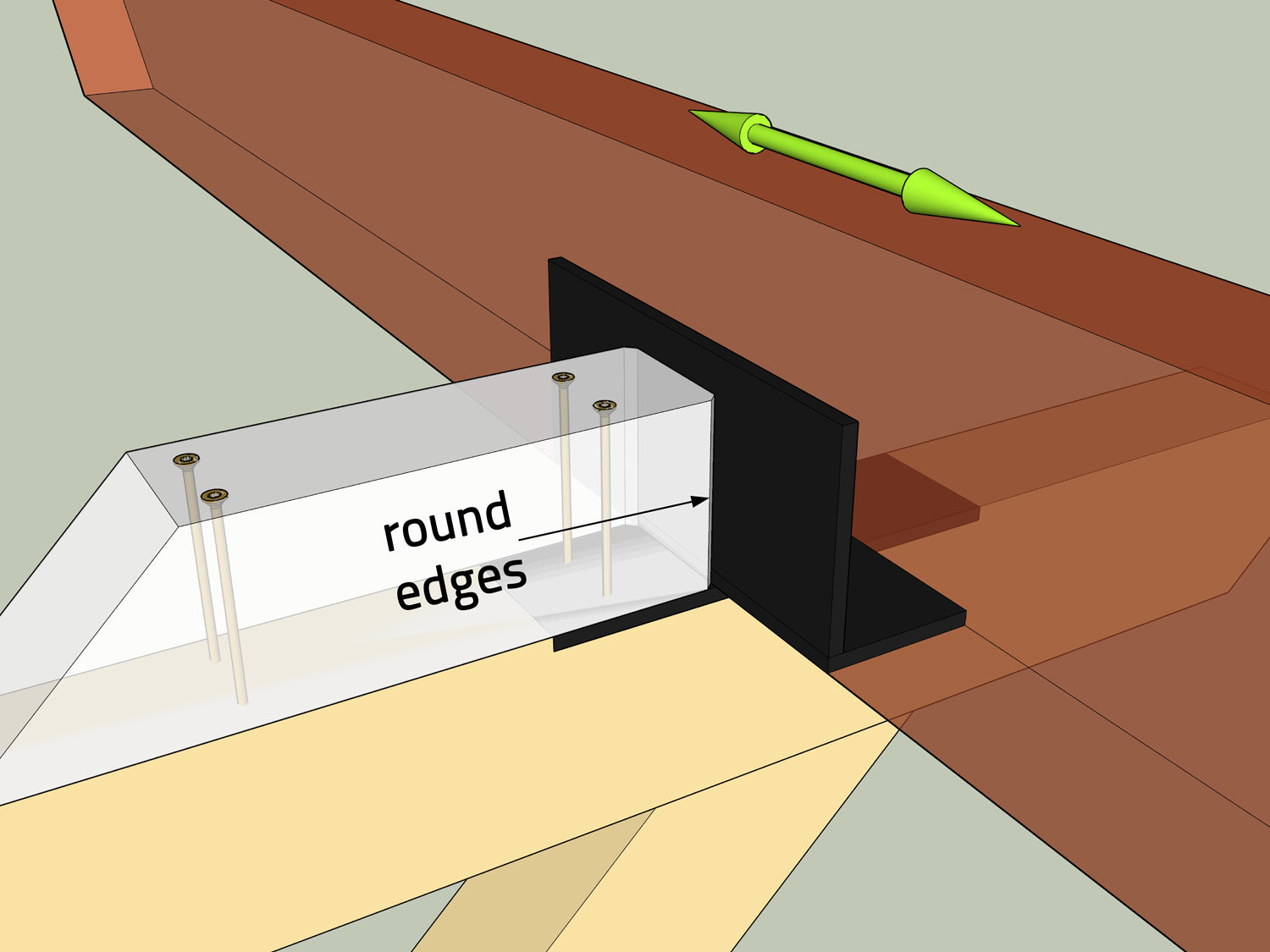

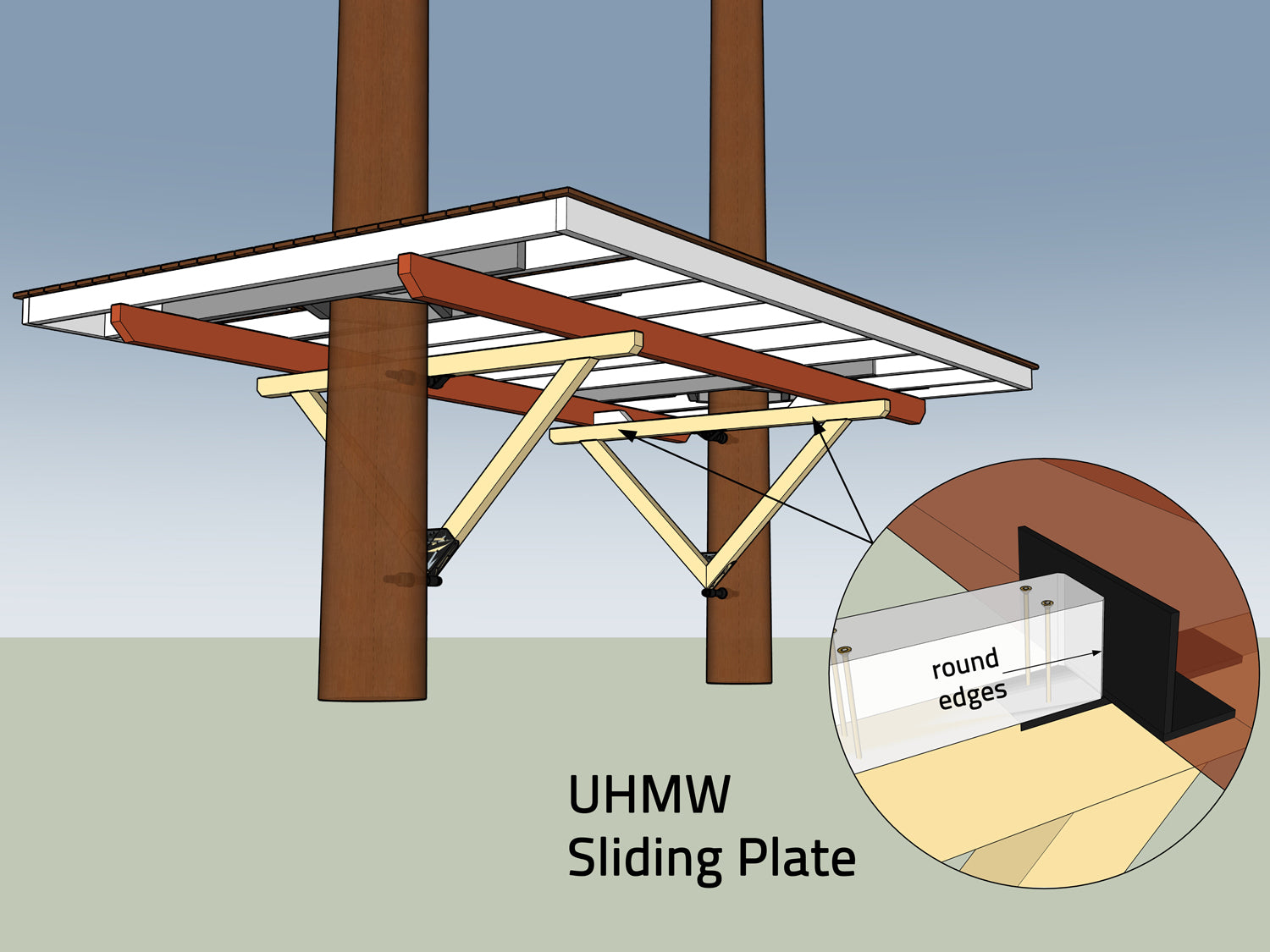

DIY Sliding Plate

Sale price€7,00

Regular price€7,79

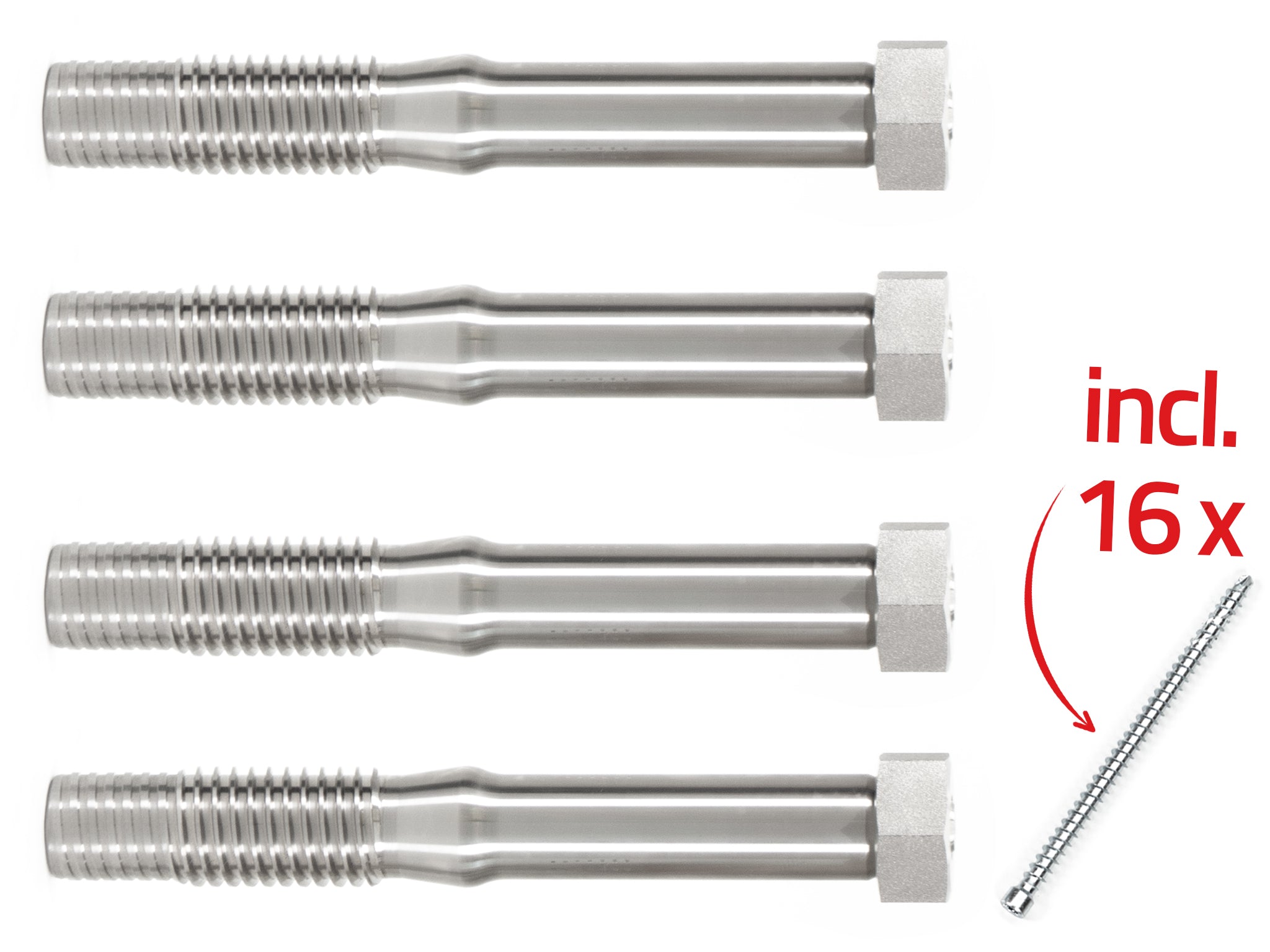

Wood Screw Set – Stay Dynamic

Sale price€8,44

Regular price€9,90

Wood Screws Set x Tri-Beam Vario

Sale price€8,12

Regular price€9,63

Wood Screw Set x Tri-Beam Diamond

Sale price€9,92

Regular price€10,89

Cord-Cap x Treehouse Logo

Sale price€29,00

Five-Panel-Cap x Treehouse Logo

Sale price€29,00

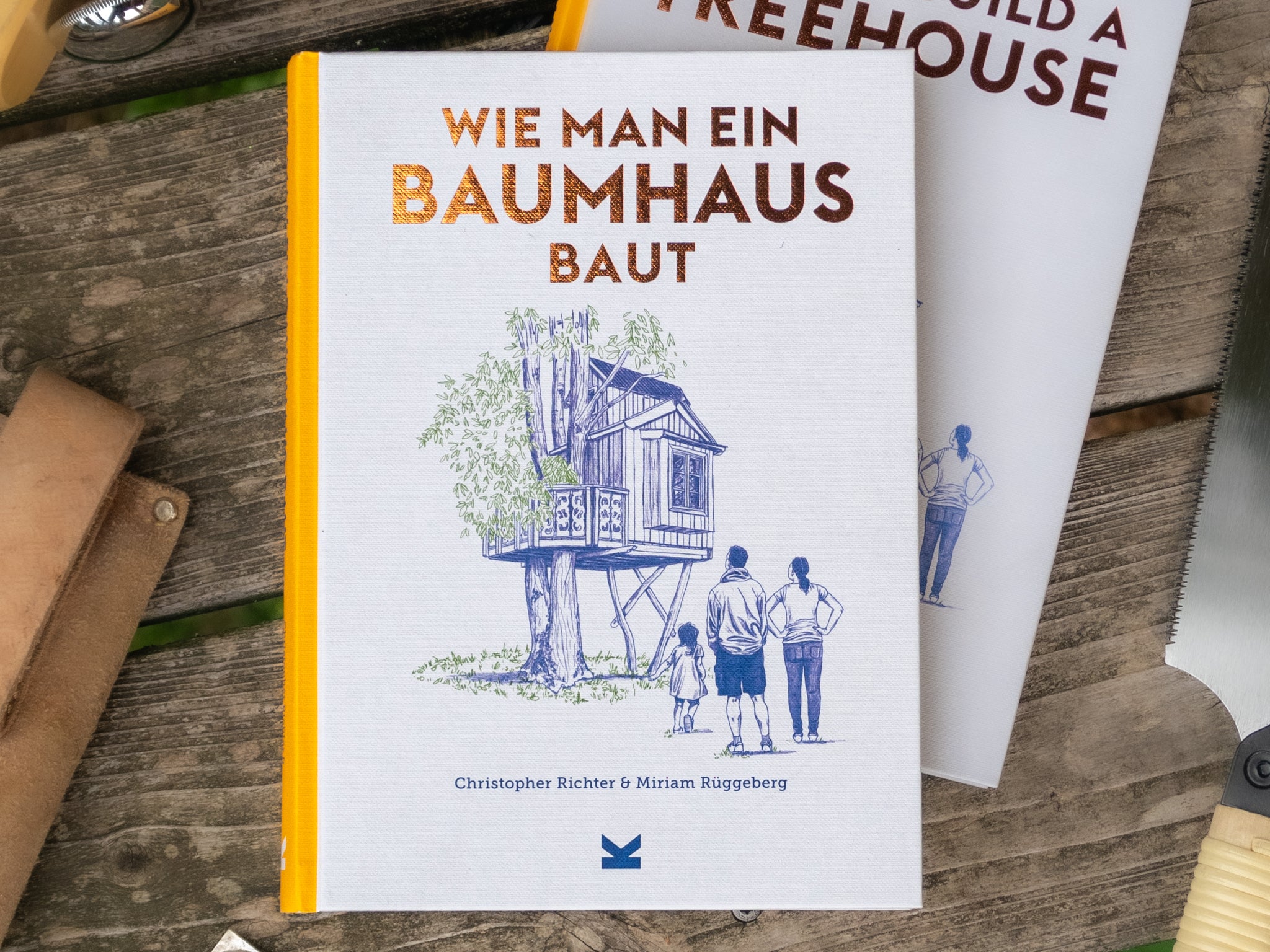

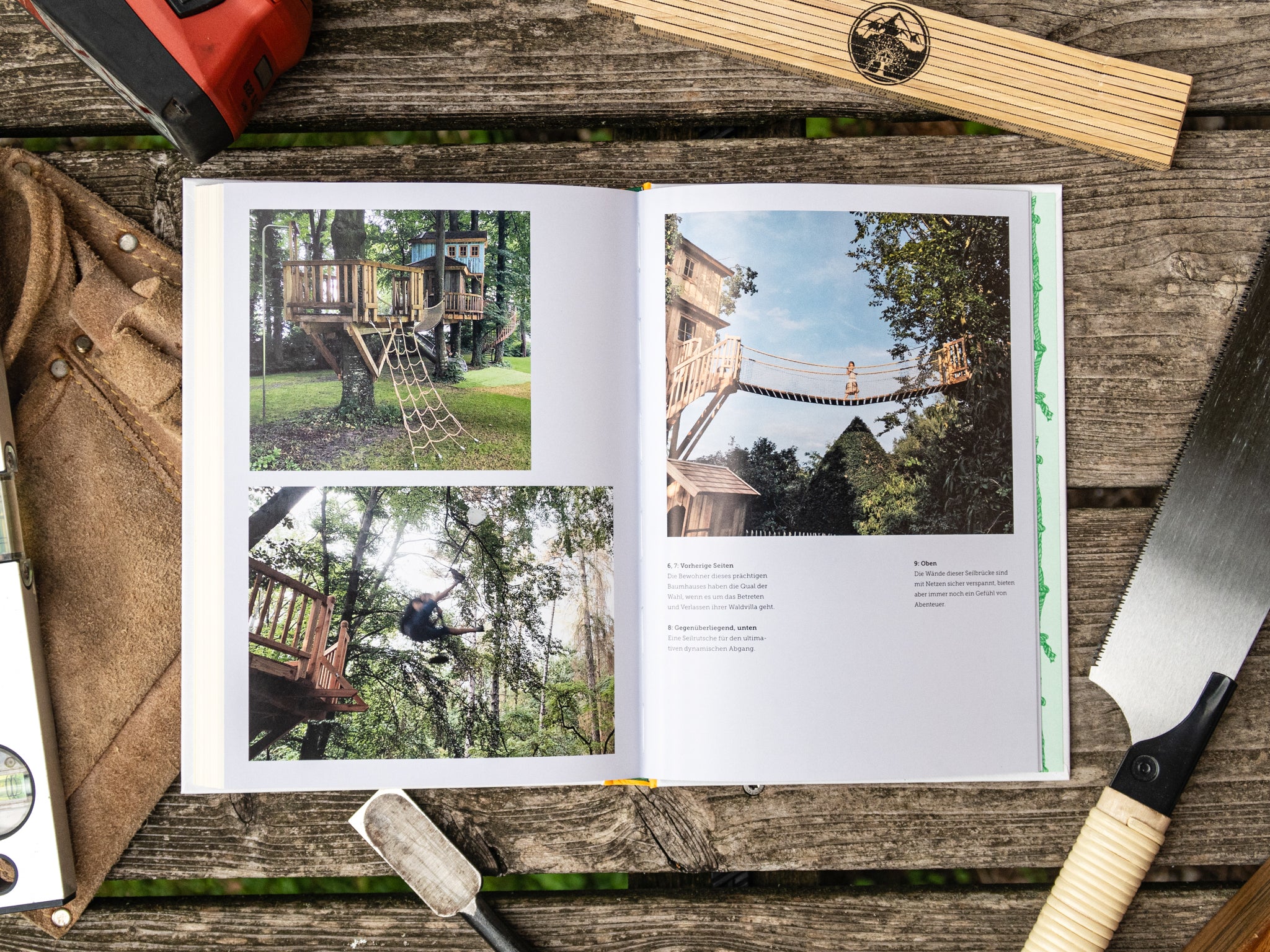

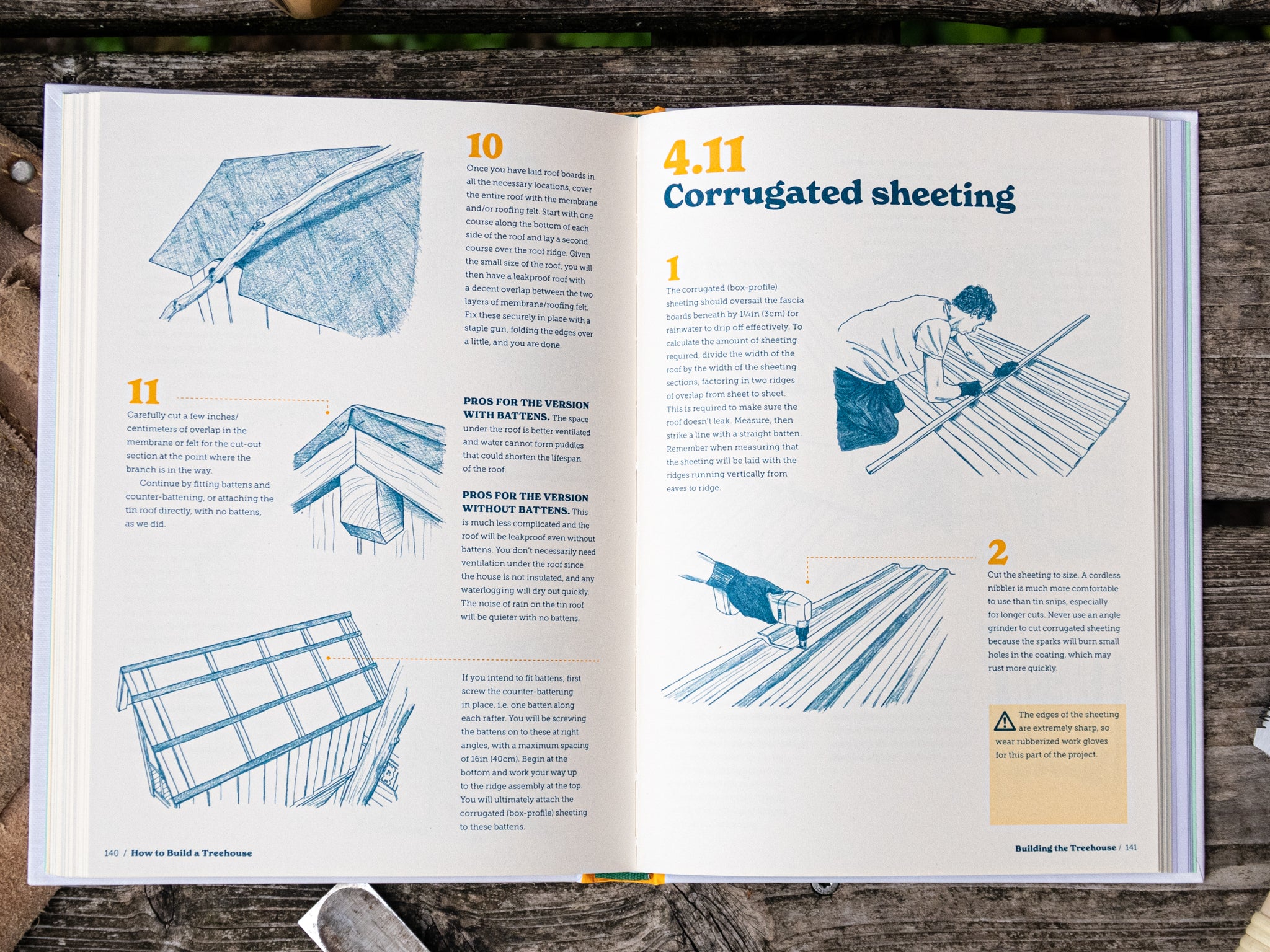

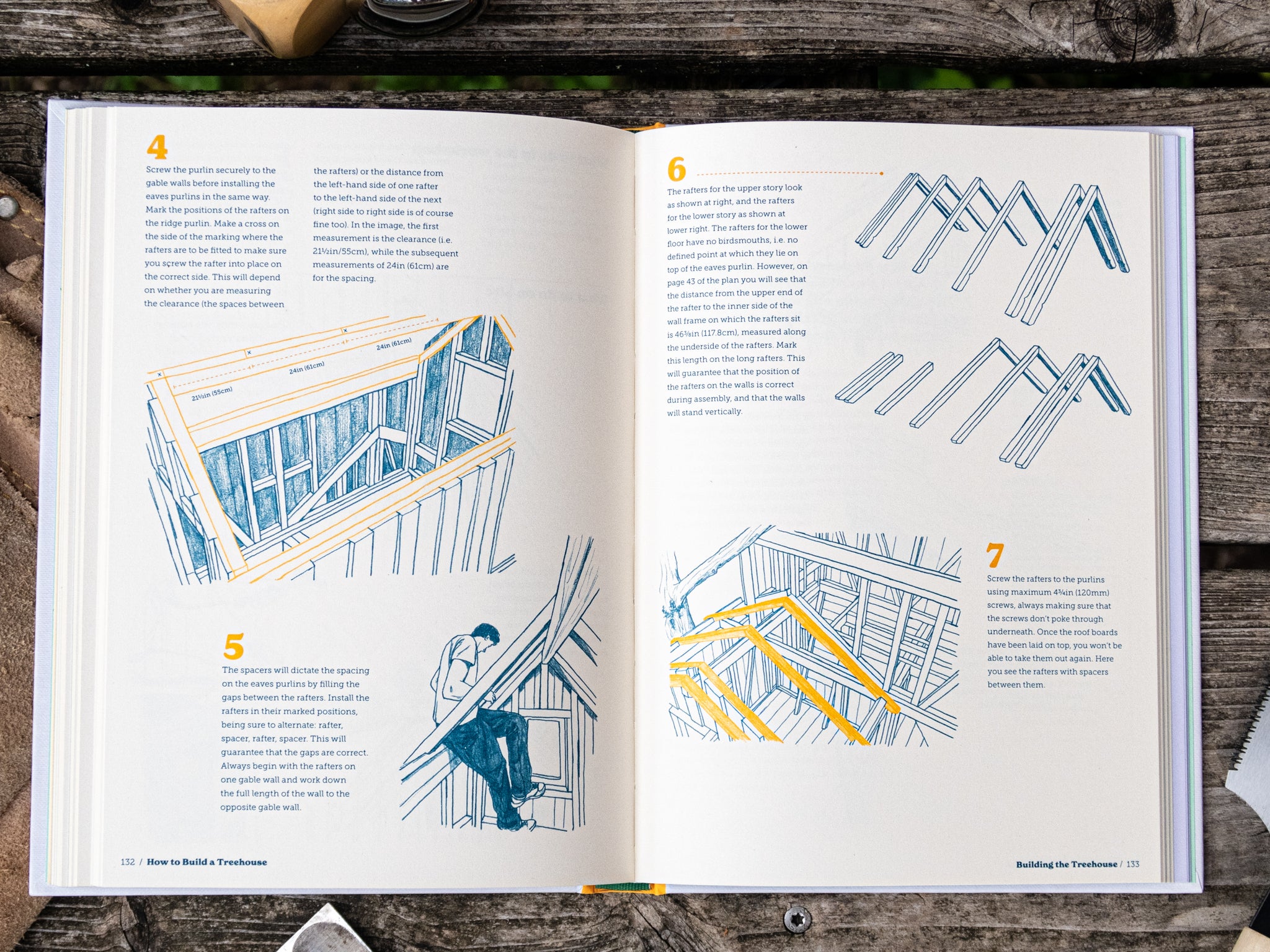

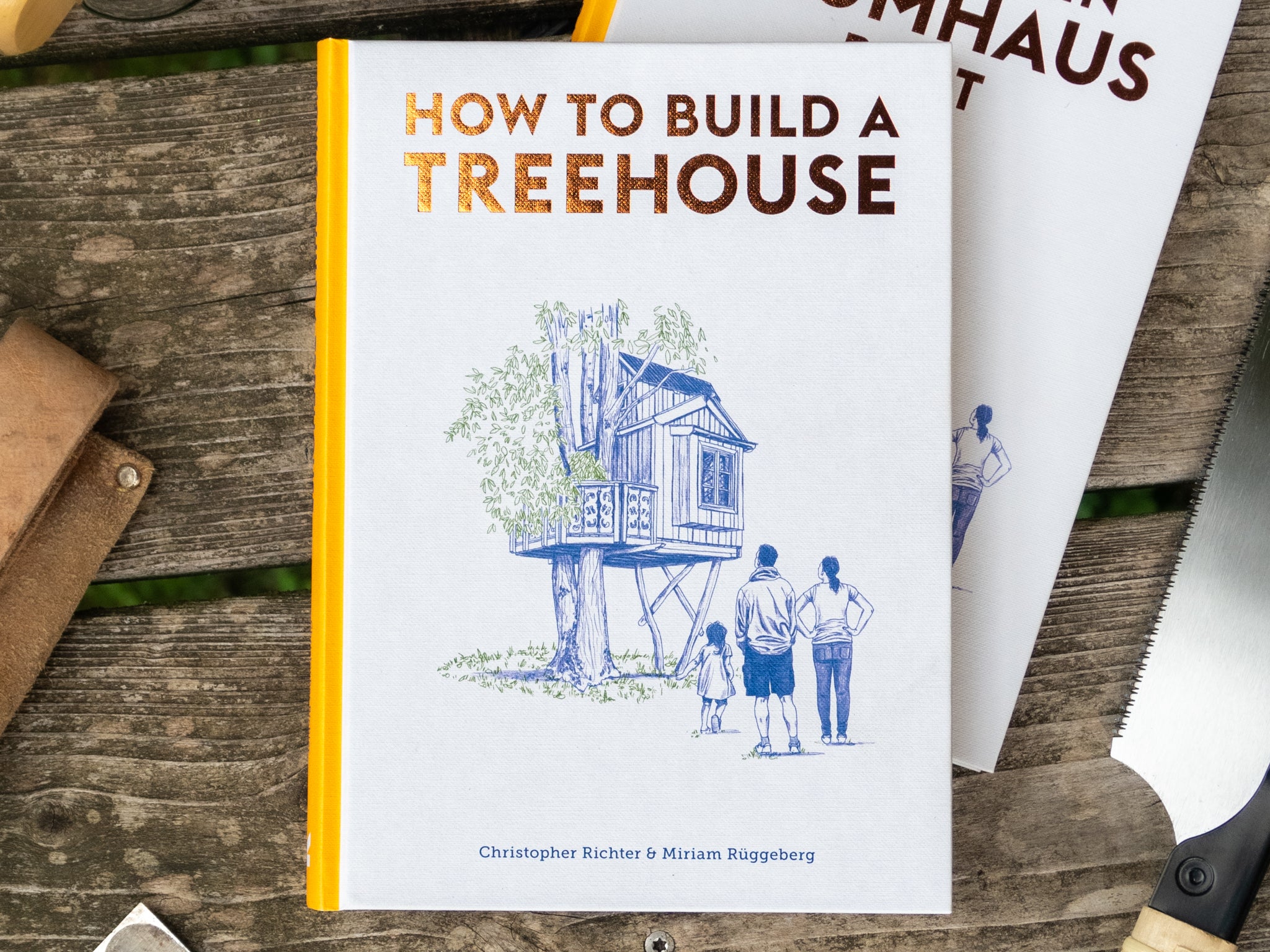

Book "How to Build a Treehouse"

Sale price€24,00

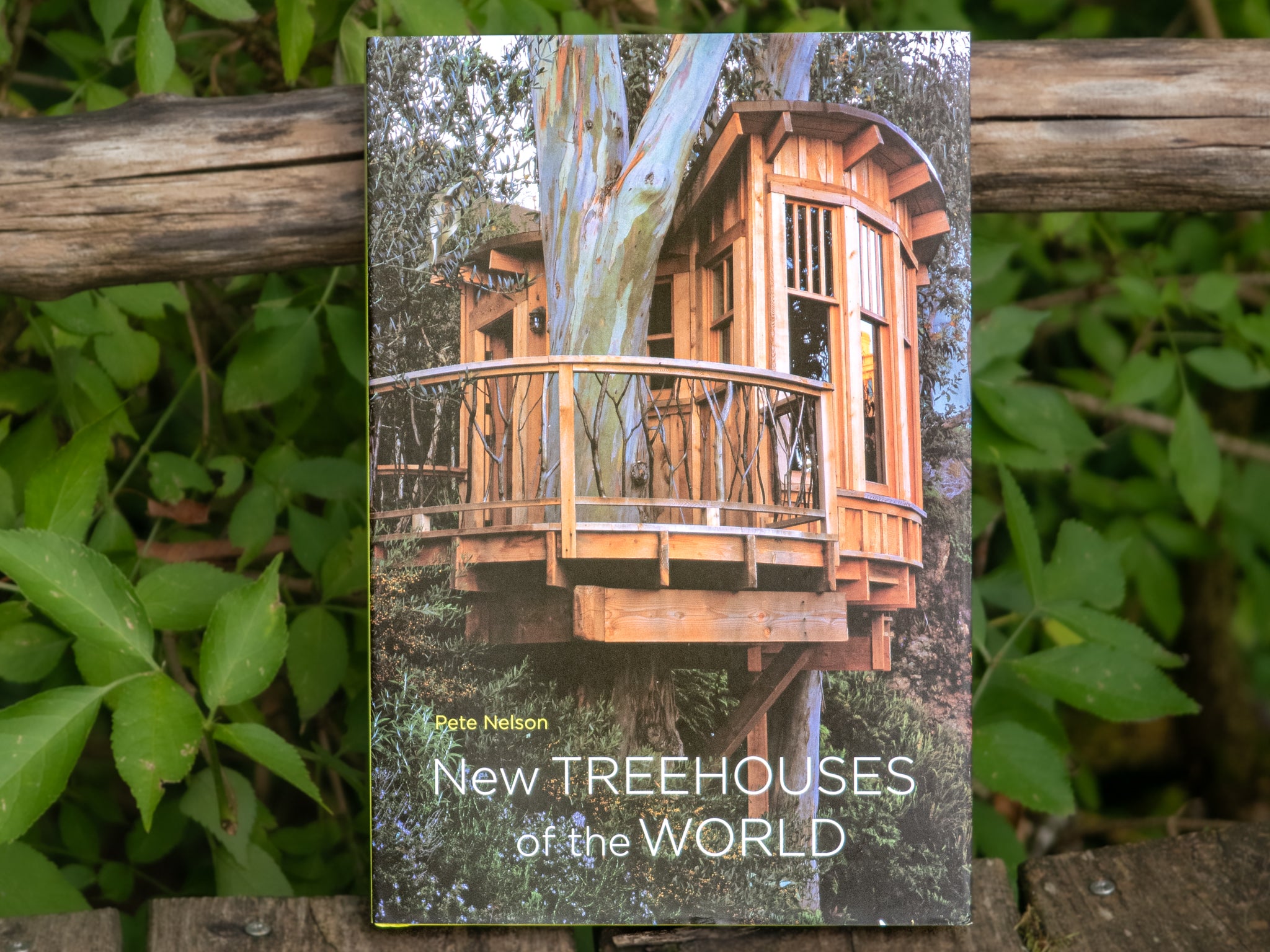

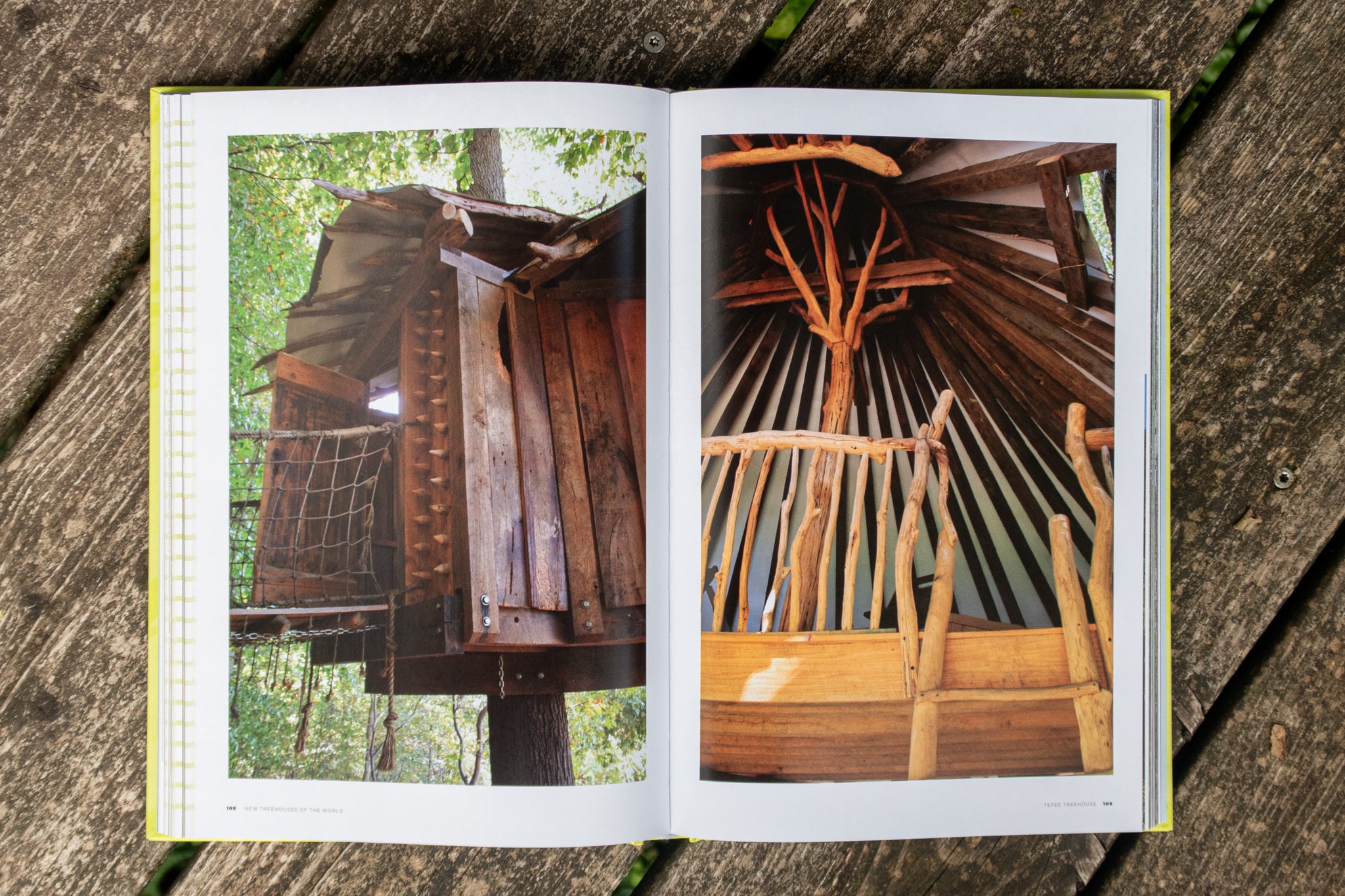

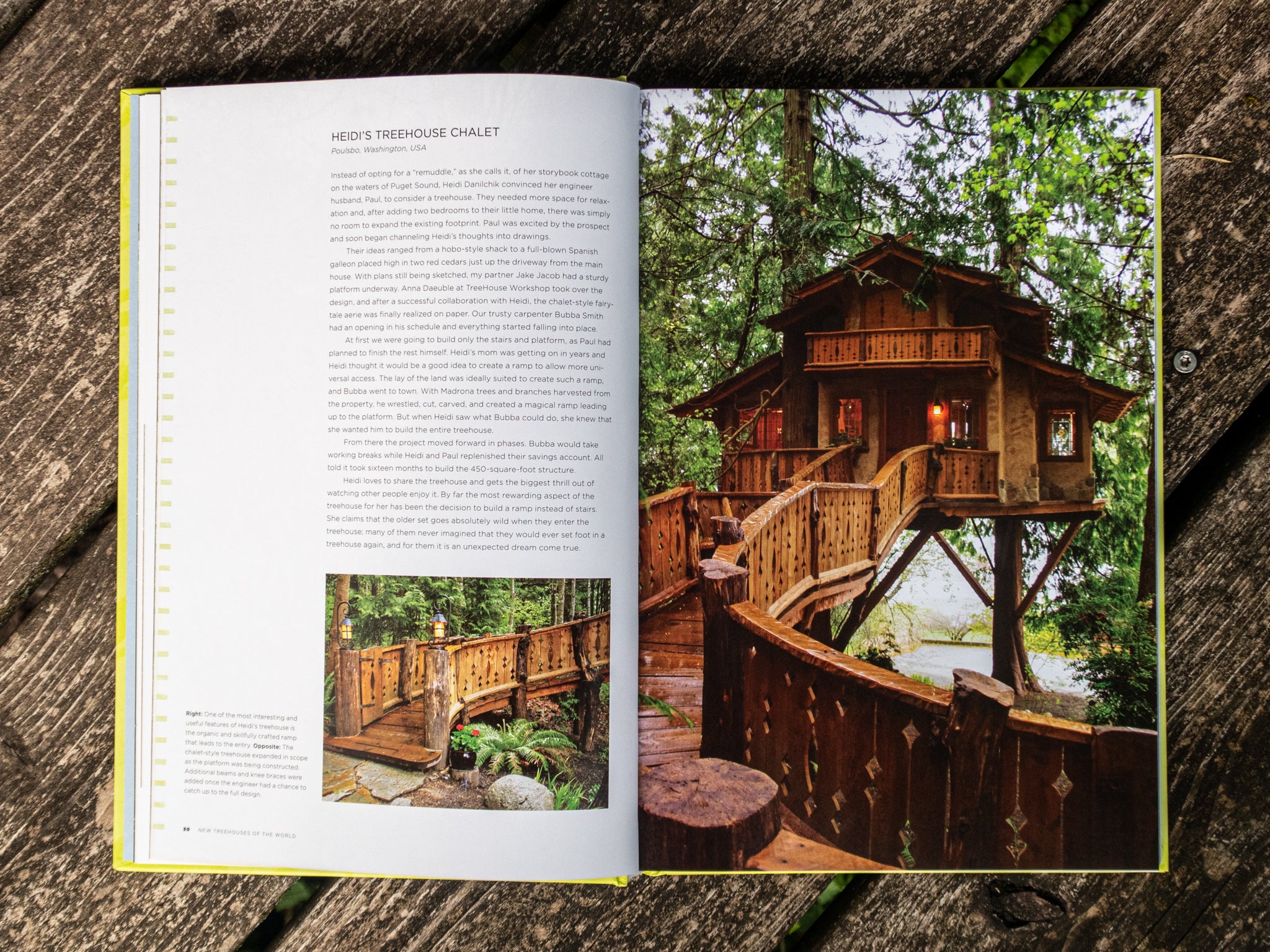

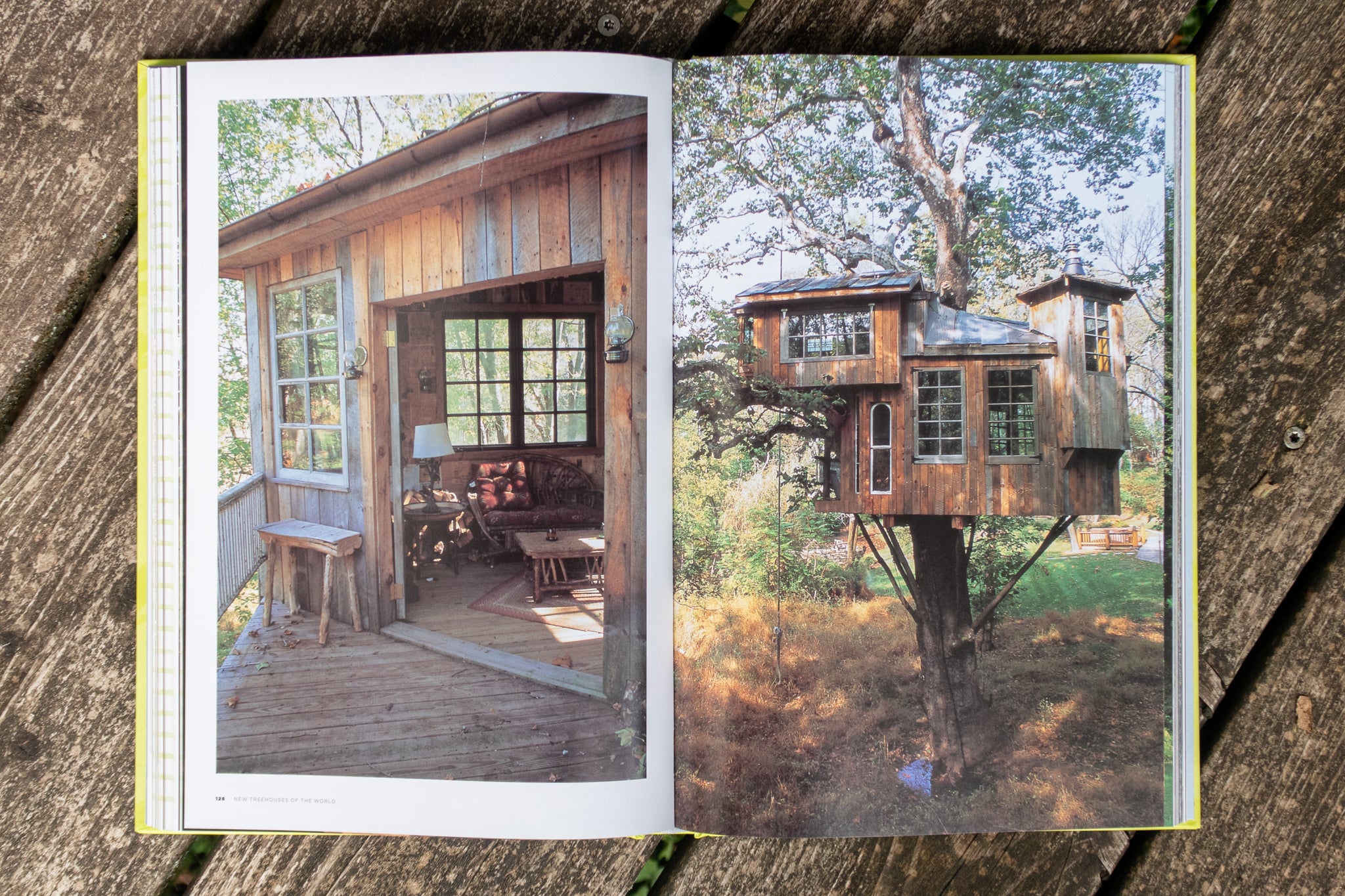

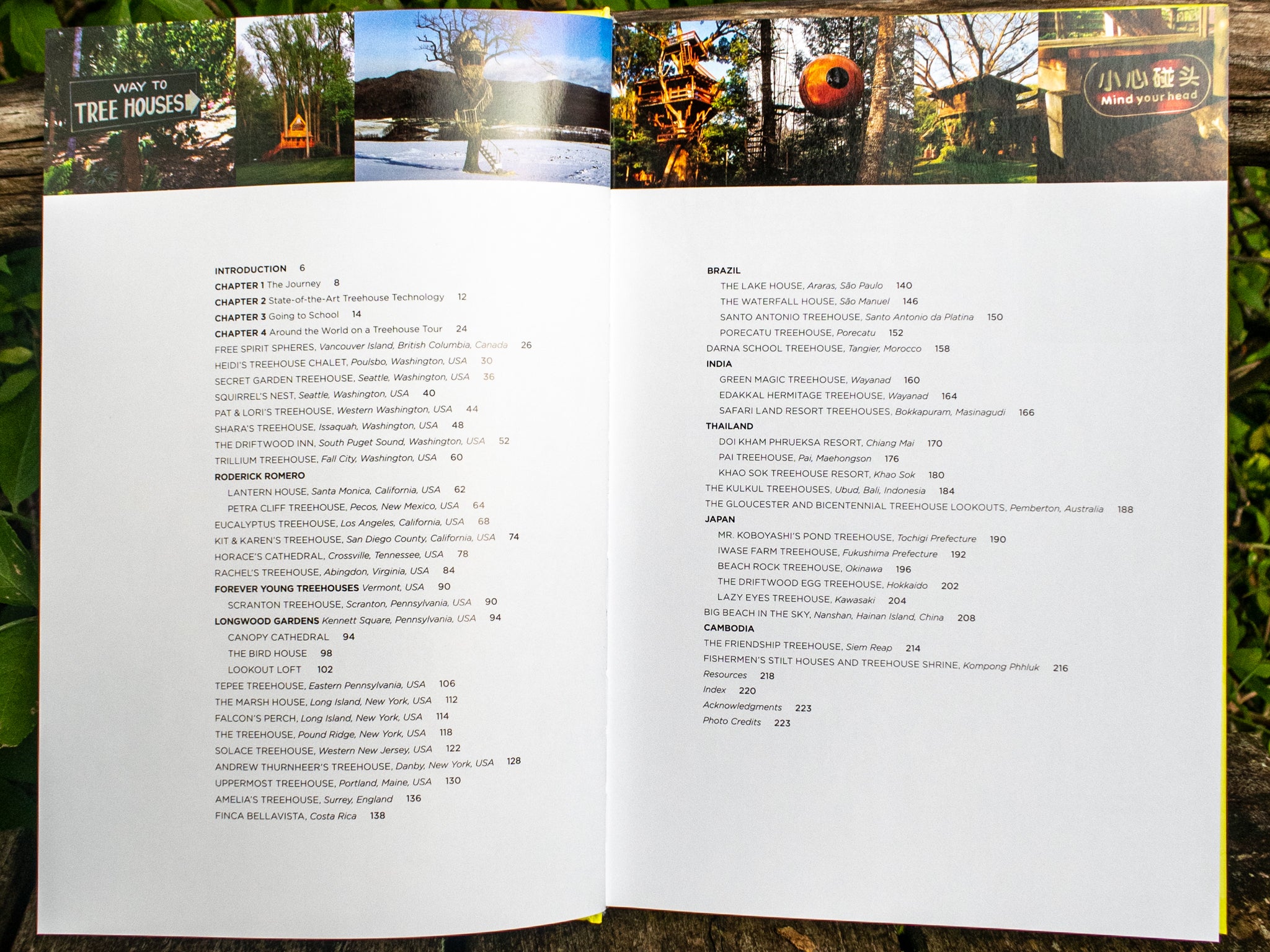

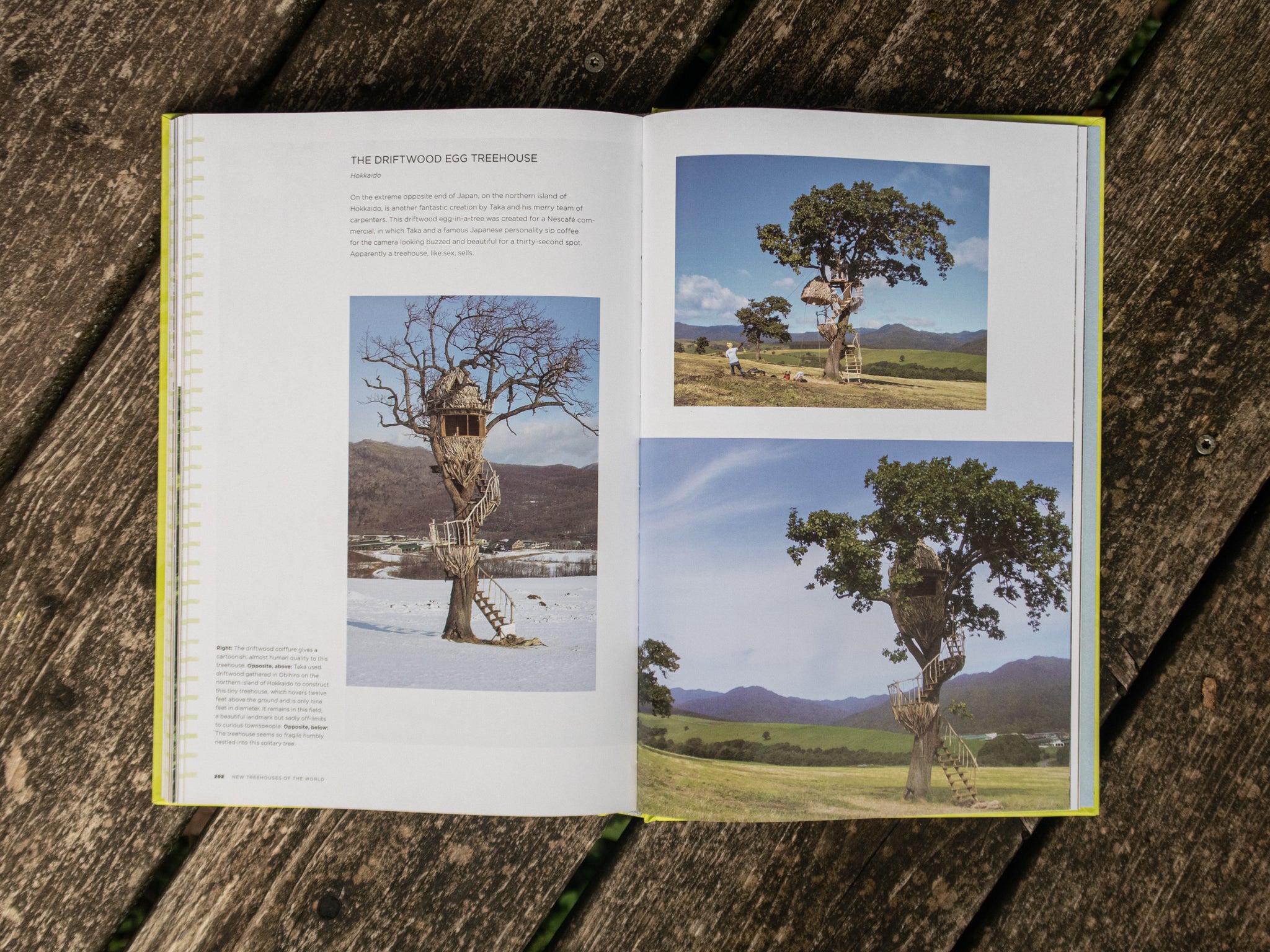

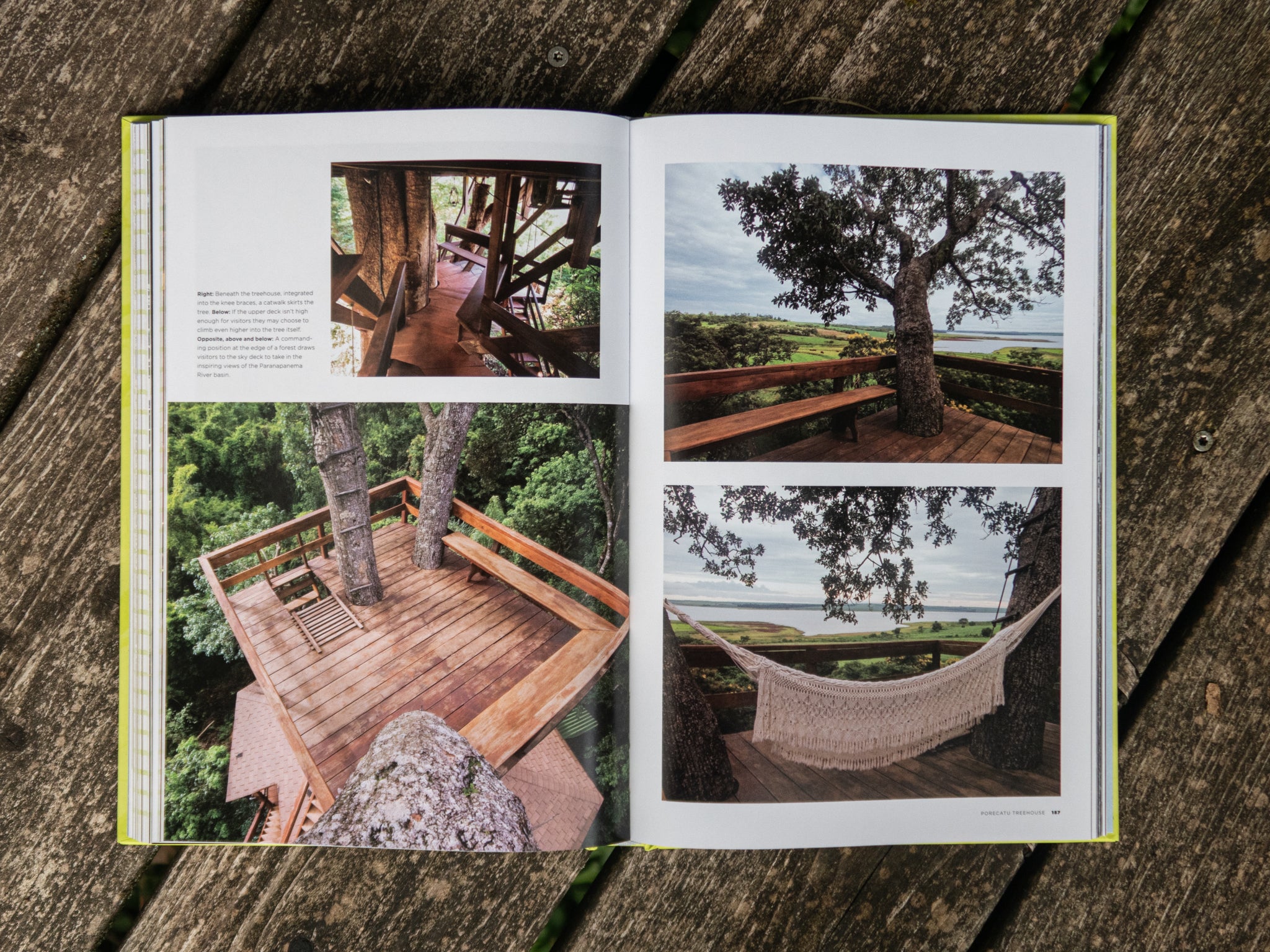

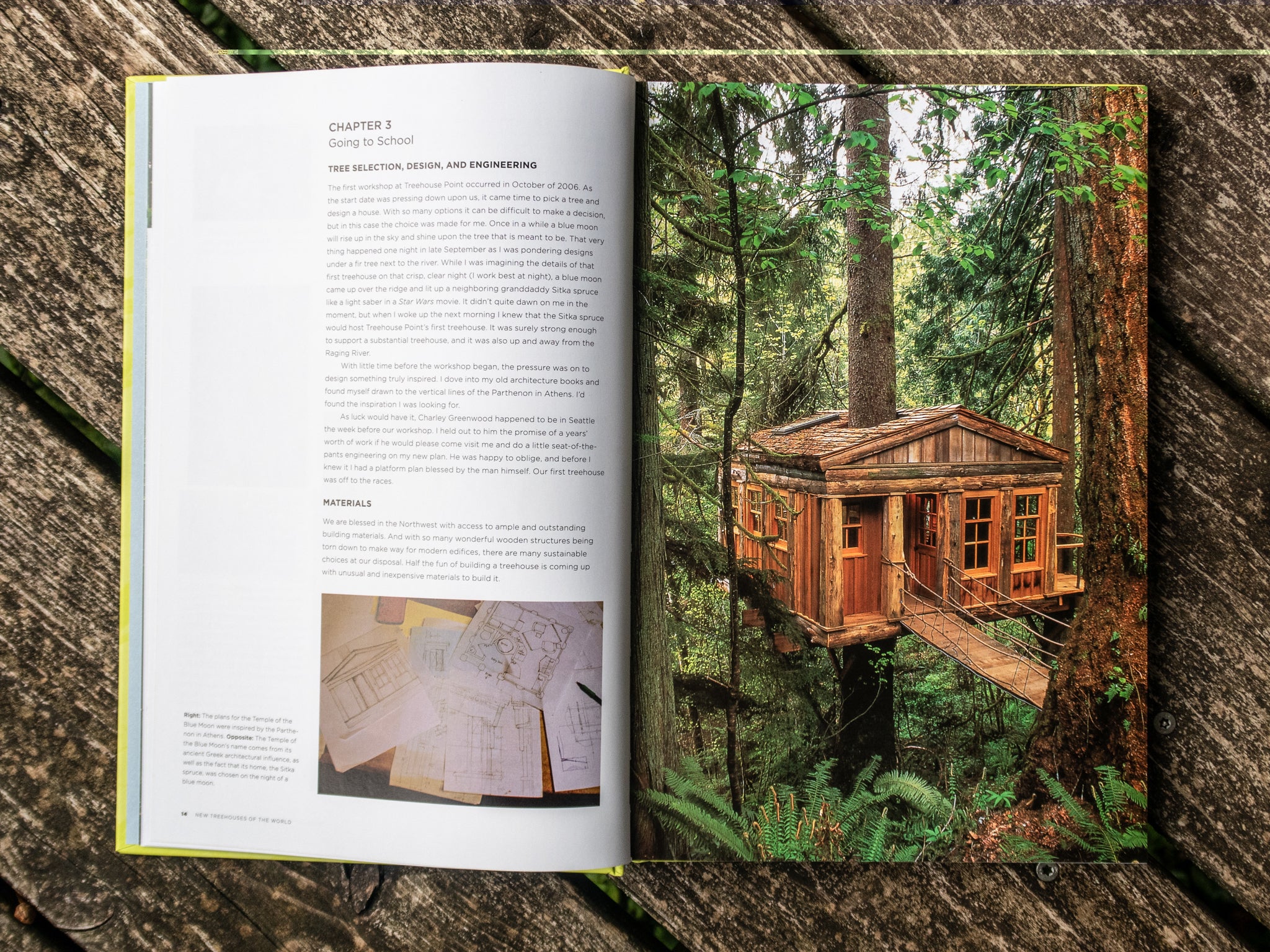

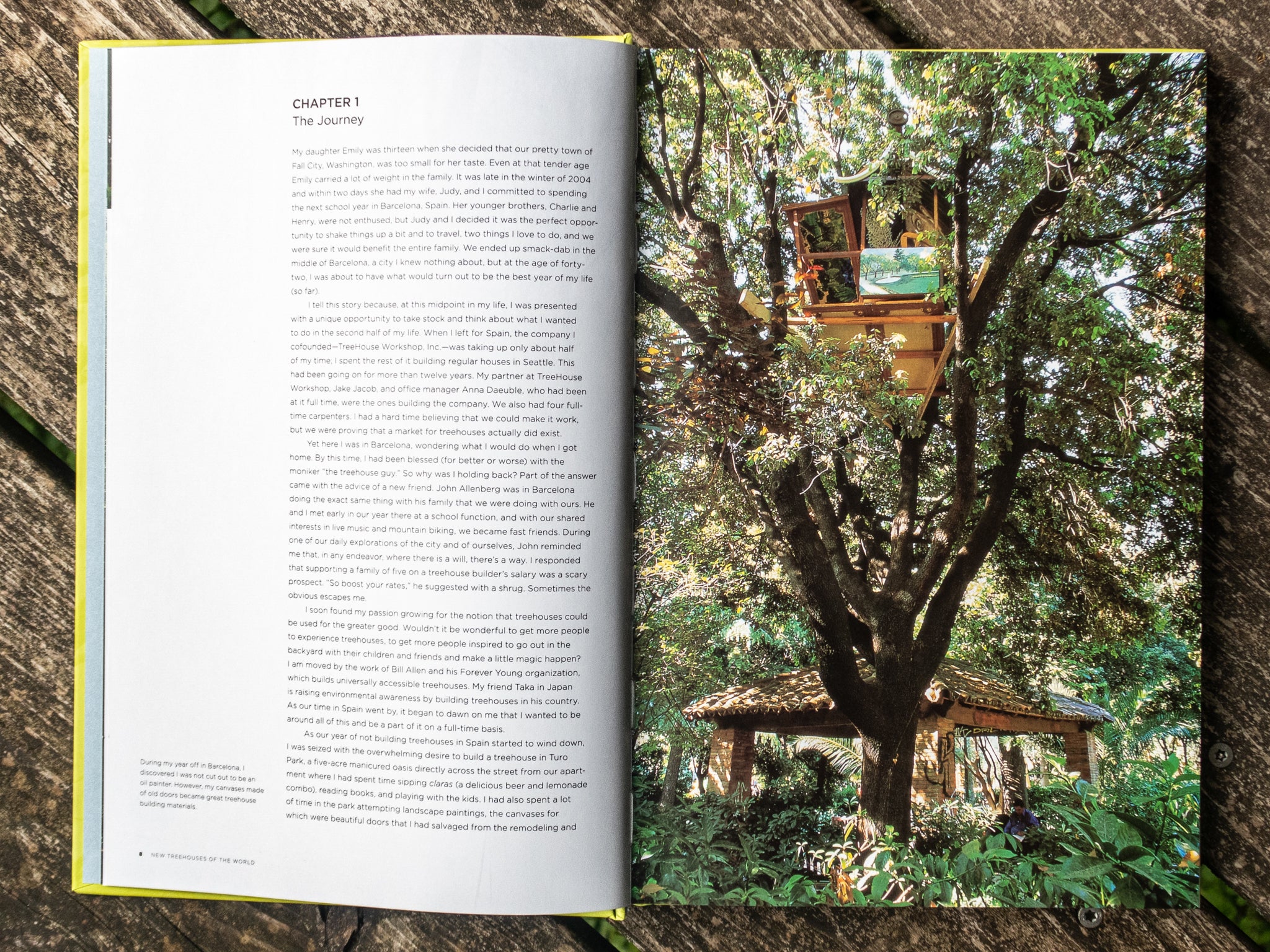

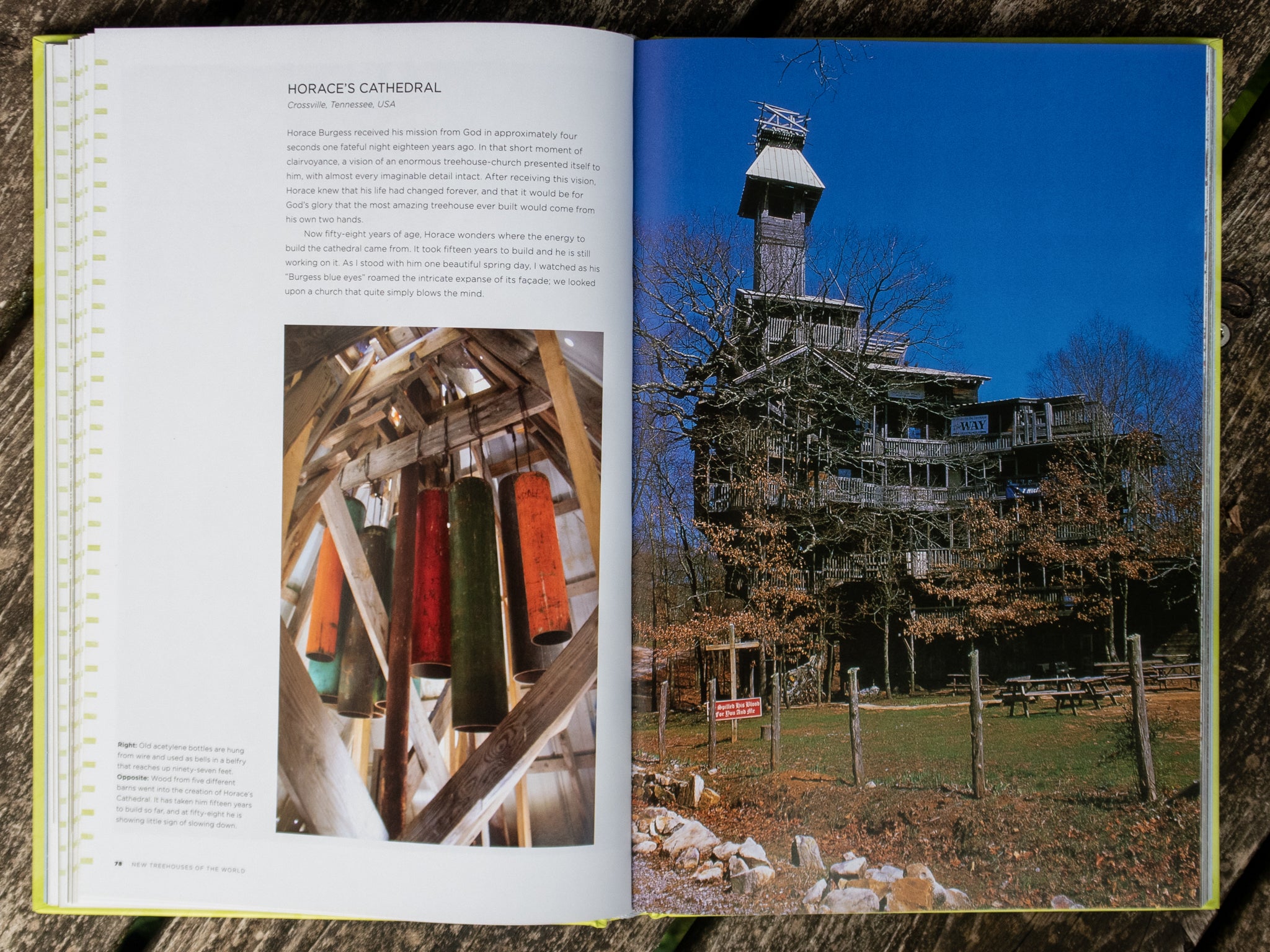

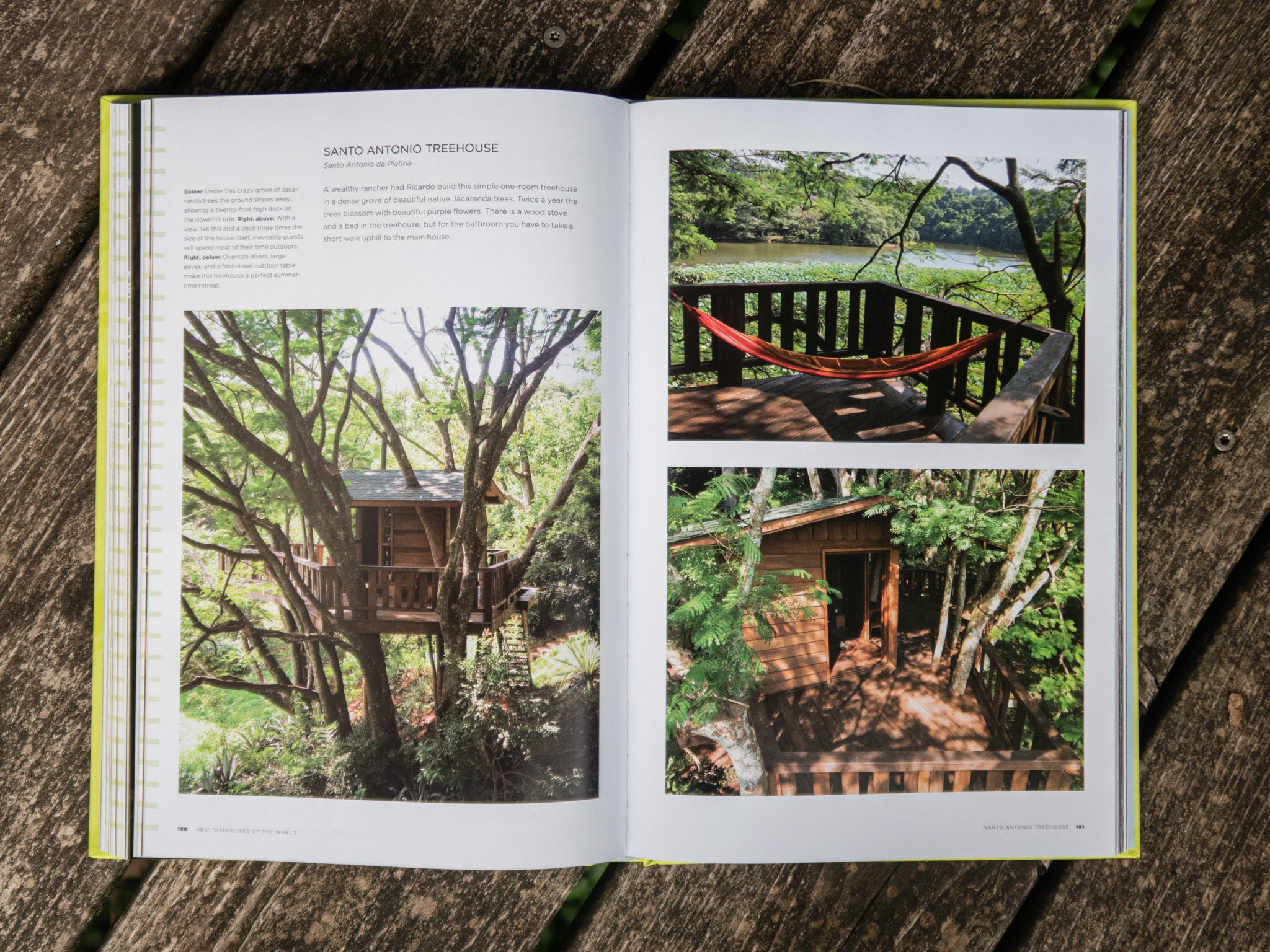

Book “Pete Nelson – New Treehouses of the World”

Sale price€38,00

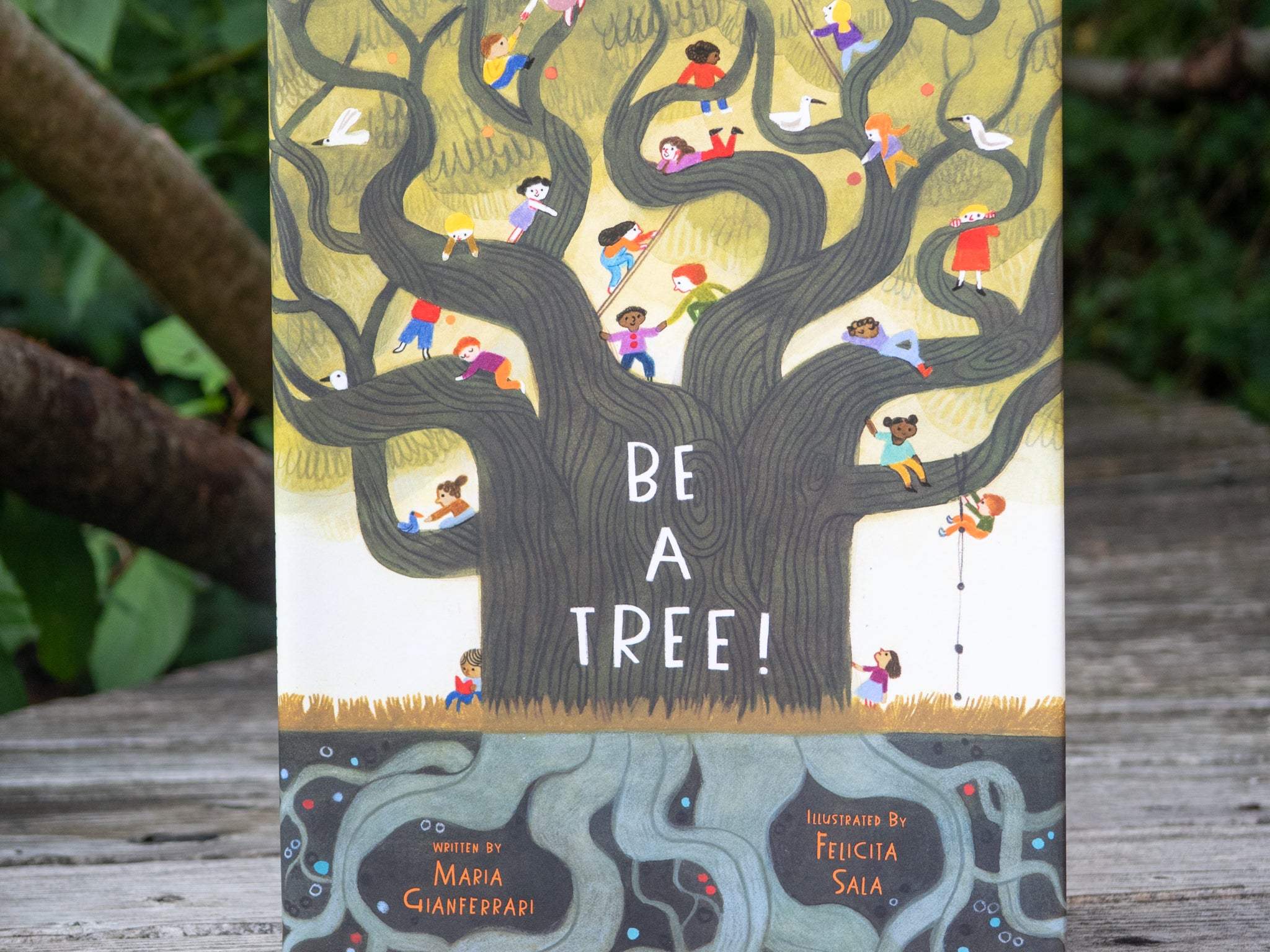

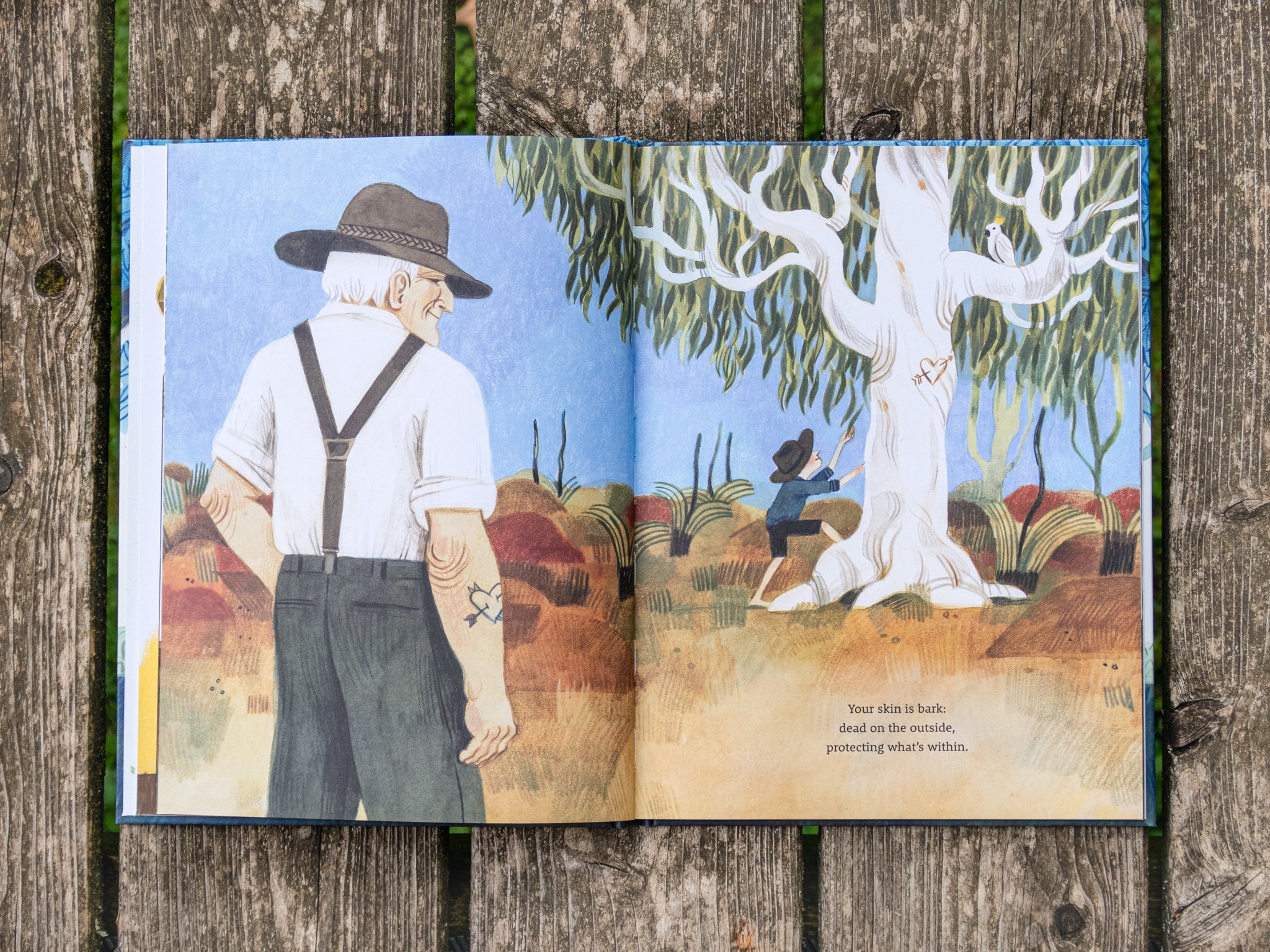

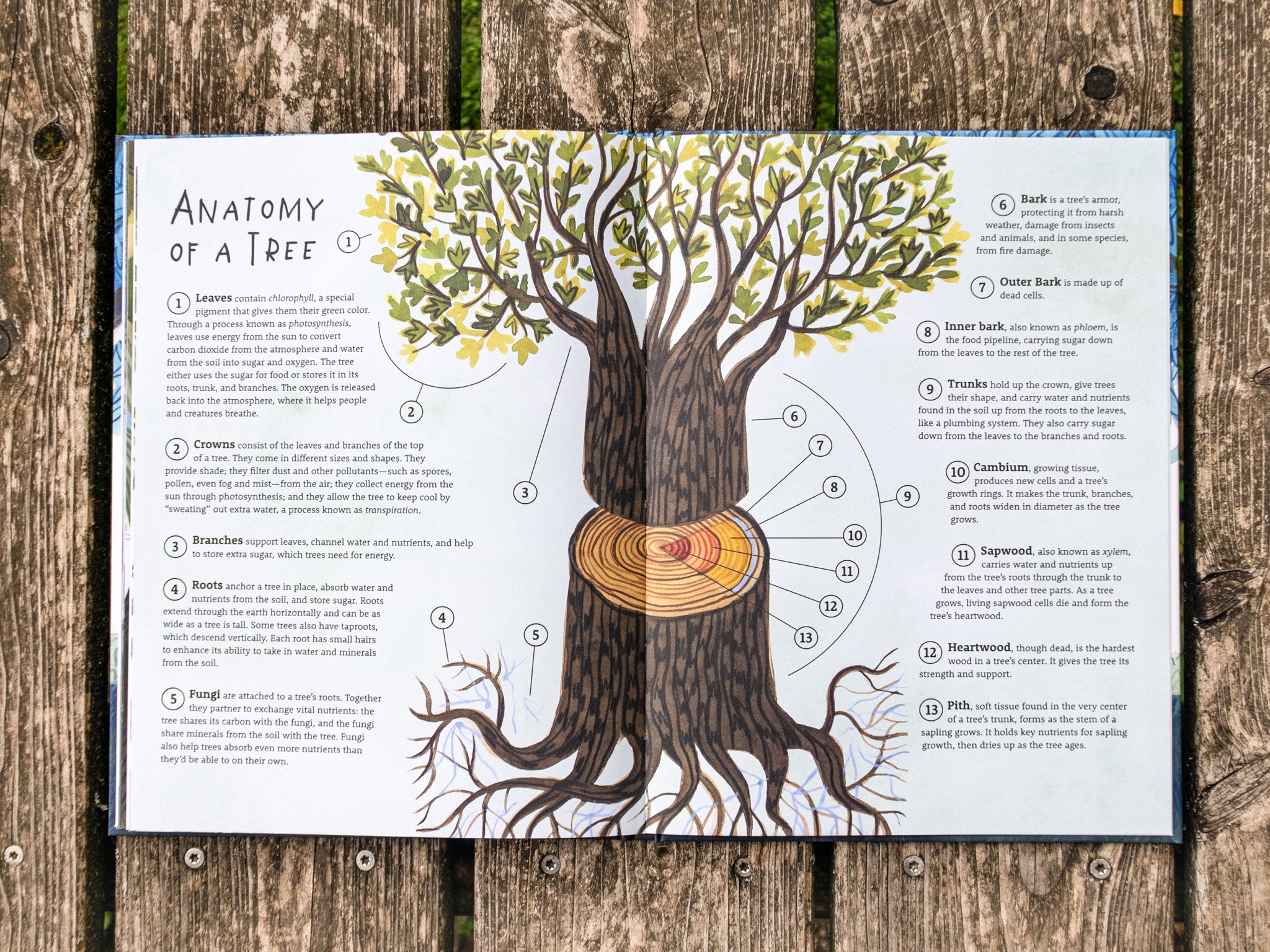

Kids Treehouse Book “Be a Tree"

Sale price€16,00

Really good products and professional service. You can tell that they have a lot of experience and know all the pitfalls.

Per M. H. – Treehouse Norway

Vitus helped us a lot with tips and advice when questions arose before and during the construction period. Highly recommended!

Sabine C. – Treehouse Germany

Thank you very much for the excellent products and advice, the tree bolts are amazing and have made our best summer project possible.

Wasilis P. – Treehouse Austria

100% Made in Germany

Certified specialists – modern technology – uncompromising quality!

Direct Pro Contact

With us, you talk to real treehouse professionals – Contact us!

Shipping & Delivery

Whether in the EU or worldwide – we deliver safely and reliably!

Secure payment

Pay securely and conveniently with all major payment methods!