TREEHOUSE SCREW – GTS FREE 2.0

Much adventure for little money!

The GTS Free was specially developed for children’s treehouses, small platforms and lookout points. Whether public climbing forest or private secret project in the forest – wherever only low loads are expected, the GTS Free is a cost-effective solution.

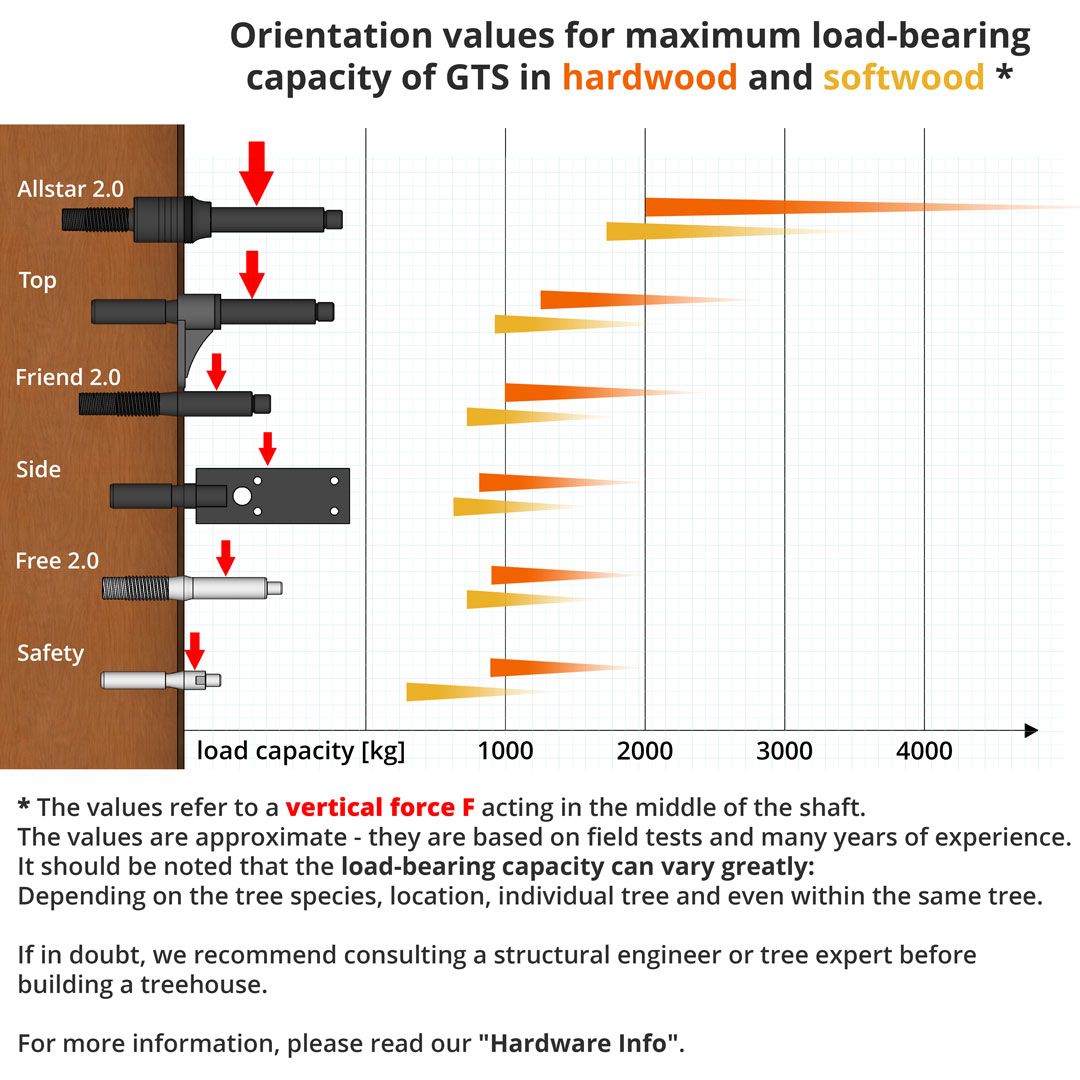

The tree trunk should have at least ø > 25 cm (10 in). The load capacity in the tree is approximately that of the GTS Friend, approx. 600 kg in softwoods and approx. 800 kg in hardwoods.

129,00 €

incl. VAT plus shipping

Only 5 left in stock

Only 5 left in stock

| ✓ Made in Germany | ✓ 50 Years Warranty | ✓ 30 Days Return |

Entering the world of treehouses

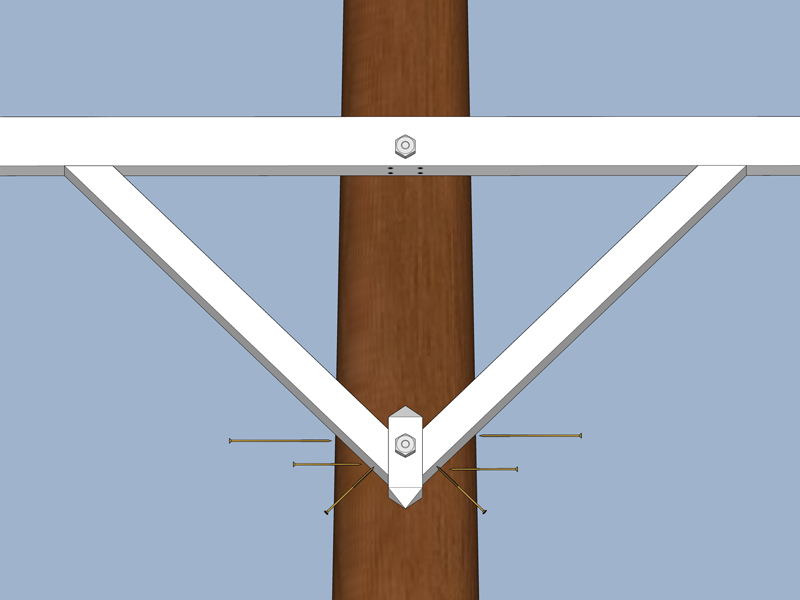

The NEW GTS Free 2.0 is a secure fastening for small children's treehouses and light beginner projects < 10 m² (107 sq ft). The stainless steel Screw works without a support and can be fastened directly to the wooden support beam – making it a cost-effective alternative to our large black GTS Screws. DIYers can build their own supports (e.g. with sliding plates).

Not recommended for swing beams, cantilevered, rotating or swinging elements – better use our large GTS Screws + Accessories here!

Keep it small

Only for low static load

To avoid overloading the support beam, the GTS Free should only be used for small, uniform platforms with little movement. Lever arms, torsion and jerky movements such as swings and suspension bridges should be avoided.

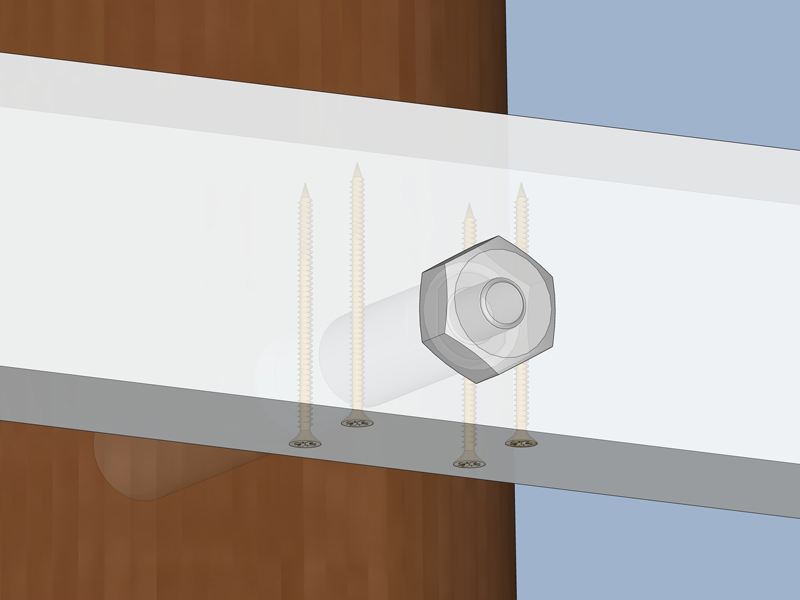

Reinforce wooden beam

4 x Fully threaded screws

To ensure that the connection between the GTS Free and the support beam holds securely, the wooden beam must be reinforced around the drill hole. For this purpose we supply 4 x wood screws with full thread. For higher loads and torsional loads, the drill hole must be additionally reinforced with steel plate.

Easy assembly

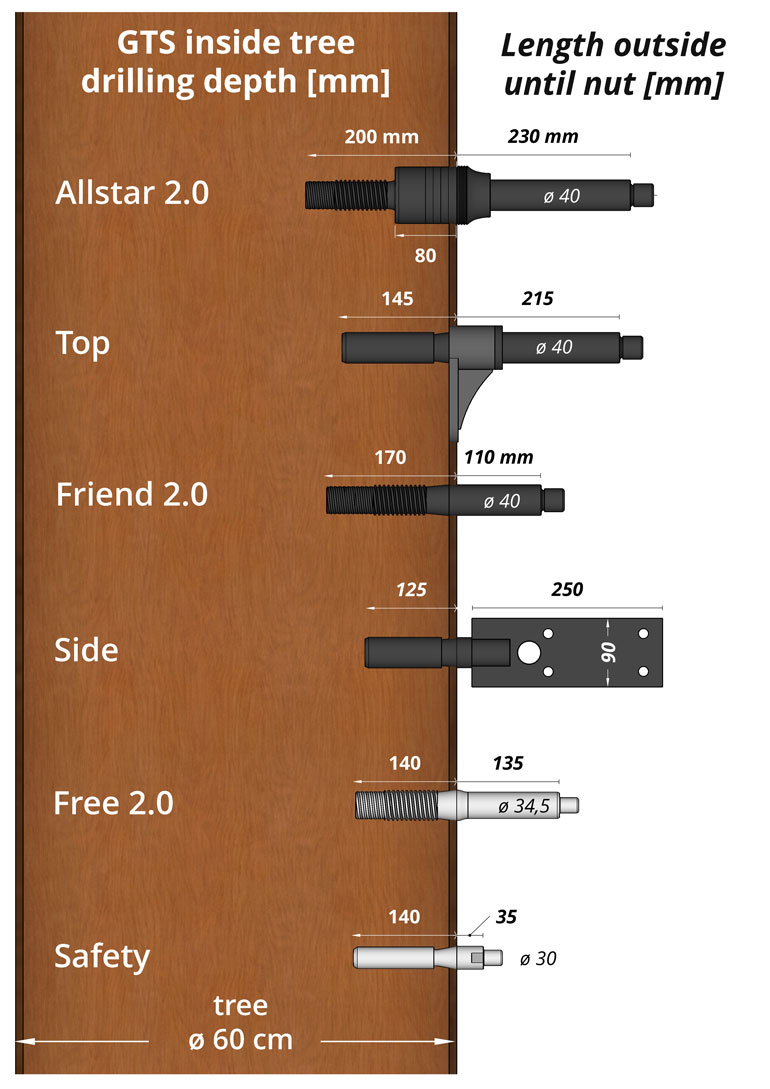

To assemble the GTS Free, you only need a 36 mm Auger-Bit. Use it to drill the hole in the tree as well as the hole through your wooden beam.

Here is the link to the installation of the GTS Free.

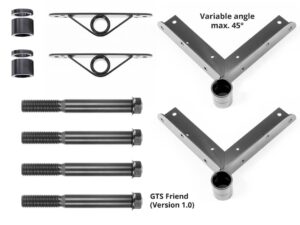

What is delivered?

- 1 x GTS Free 2.0 (incl. nut greased)

- 4 x Full thread wood screws ø8×120 mm (TX30 galv.) for free!

Product Details 2.0

- NEW – Tree Thread 2.0: The double thread coarse thread was developed for the living tree. The special thread shape guarantees a high pull-out resistance (500 – 1000 kg = 1100 – 2200 lbs) and an optimal force flow with significantly easier assembly.

- Seal +: The NEW thickened thread spout seals the drill hole.

- Shaft 34.5: With the diameter ø 34.5 mm (1,36 in), the Screw can be inserted through the hole of the Auger-Bit ø 36 mm.

Technical Data 2.0

- Certified DIN stainless steel A2

- Dimensions:

- ltotal = 295 mm (11,6 in)

- lthread = 110 mm (4,3 in)

- lshaft = 120 mm (4,7 in)

- øshaft = 34.5 mm (1,36 in)

- Weight: 2498 g (5,5 lbs; incl. Nut & wood screws)

- Nut M30: Stainless steel SW 46

- Article-No.: TTS1005

- HS-Code (Customs): 73181542

Assembly of GTS Free

- Pre-drilling tree and tragalken (Auger-Bit ø 36 mm)

- Screw in (Ratchet 1″ for nut M30, SW46)

Dimension of the support beams

- Wood type for outdoor use: e.g. larch or Douglas fir.

- Minimum dimension of the support beams: 6 × 12 cm.

- The longer the beam and the higher the load, the greater the height of the wooden beam must be.

- The drill hole is pre-drilled in the support beam with the same Auger-Bit ø 36 mm.

- The drill hole is drilled to 1/3 of the height (measured from below) so that there is more wood above the GTS.

- Reinforcement with perforated plates or welded steel plates is always advisable!

Reinforcement of the support beams

A drilled hole in the wooden beam is automatically a weak point because the wood fibres are interrupted here and the wood can crack or split more easily. Therefore, the hole must be reinforced. Fully threaded screws act like reinforcement in reinforced concrete and hold the individual wood fibres together.

The ø 8 mm screws should be pre-drilled with a ø 6 mm wood drill and have at least 2 cm distance to the edge of the beam and the drill hole.

Installation Instruction

Assembly Video

Shipping Service

Hardware Info

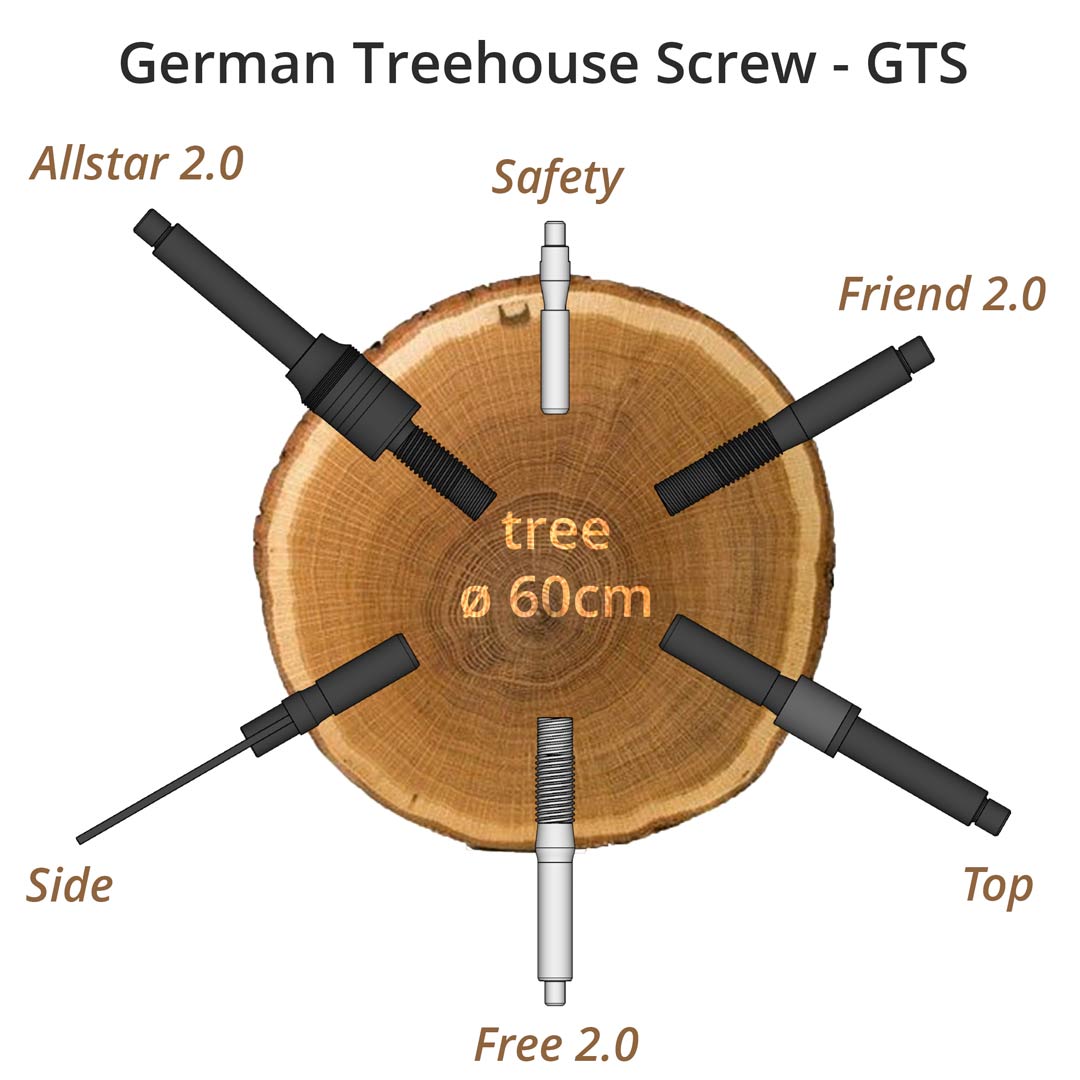

6 Treehouse Screws

Find the right Screw

The GTS Free is our low-priced entry-level Screw for the lowest loads! If you have the possibility to invest a little more money, we always recommend one of our larger GTS Screws with support in the long term. This is not only safer, but you also have many more design options with the accessories. Our product guide will help you!

Frequently Asked Questions

How to mount the GTS Screw in the tree?

- Pre-drill the hole in the tree (Auger-Bit 36 mm).

- Predrill the hole in the wooden beam (Auger-Bit 36 mm)

- Screw in the GTS (large Ratchet).

- Push the beam onto the GTS Free.

- Done!

The tools are all available in our online shop. You can find detailed installation videos on our Youtube-Channel.

Will my treehouse grow up with the tree?

Don’t worry, you don’t have to extend your ladder every year. Trees only sprout at their branch tips. The rest of the tree then only grows in width (thickness growth, annual rings). You can easily observe this by looking at the carvings on the trunk, they remain at the same height for the rest of the tree’s life – just like your treehouse.

Can I also use screws from the DIY store to build treehouses?

To fasten a tree house to the tree – No!

- The screws available in DIY stores are not designed for the extreme loads of a treehouse.

- Treehouse Screws are made of a special steel alloy, have a large diameter (ø = 40 mm) and an optimised geometry.

- The frequent alternating loads caused by wind fluctuations, which can lead to spontaneous fatigue fractures in normal wood screws in the long run, are particularly problematic.

- The treehouse construction must have distance to the tree so that it can grow further in width, the distance and the associated leverage forces can only be handled by professional Treehouse Screws!

Is my tree hardwood or softwood?

The decisive factor for anchoring the treehouse with Treehouse Screws is the compressive strength along the wood grain.

Hardwood (> 2.5 KN/cm²) – very suitable for Treehouse Bolts:

- Hardwoods: maple, beech, oak, ash, walnut, sycamore, robinia.

Medium hardwood (2 – 2.5 KN/cm²) – well suited for Treehouse Bolts:

- Hardwoods: birch, sweet chestnut, alder, cherry tree, lime tree

- Softwoods: Douglas fir, pine, larch, spruce, fir

Softwood (< 2 KN/cm²) – moderately suitable for high loads on Treehouse Bolts:

- Hardwoods: aspen, poplar, pear, horse chestnut, elm, willow

- Coniferous woods: cedar

IMPORTANT: These are only rough guide values – wood strength varies from tree to tree, from place to place and even within a tree! Wound healing and compartmentalisation also play an important role. You can find out how to analyse your treehouse-tree on this page: Which tree is suitable?