You are here: Home / Service / Installation Instructions /

General installation instructions for our products

The right screws for connecting supports and wooden beams

It is important that all supports are very tightly connected to the wooden beams. Naturally, the treehouse will want to sway, tilt and turn – all these forces will hit the screw connection of your supports.

Our supports have a variety of small holes ø 8.5 mm and large holes ø 13.0 mm – it is safest to use all holes to fix your wooden beam.

Wood screw: Partial thread, countersunk head

Hexagon wood screw

Carriage bolt (+washer +nut)

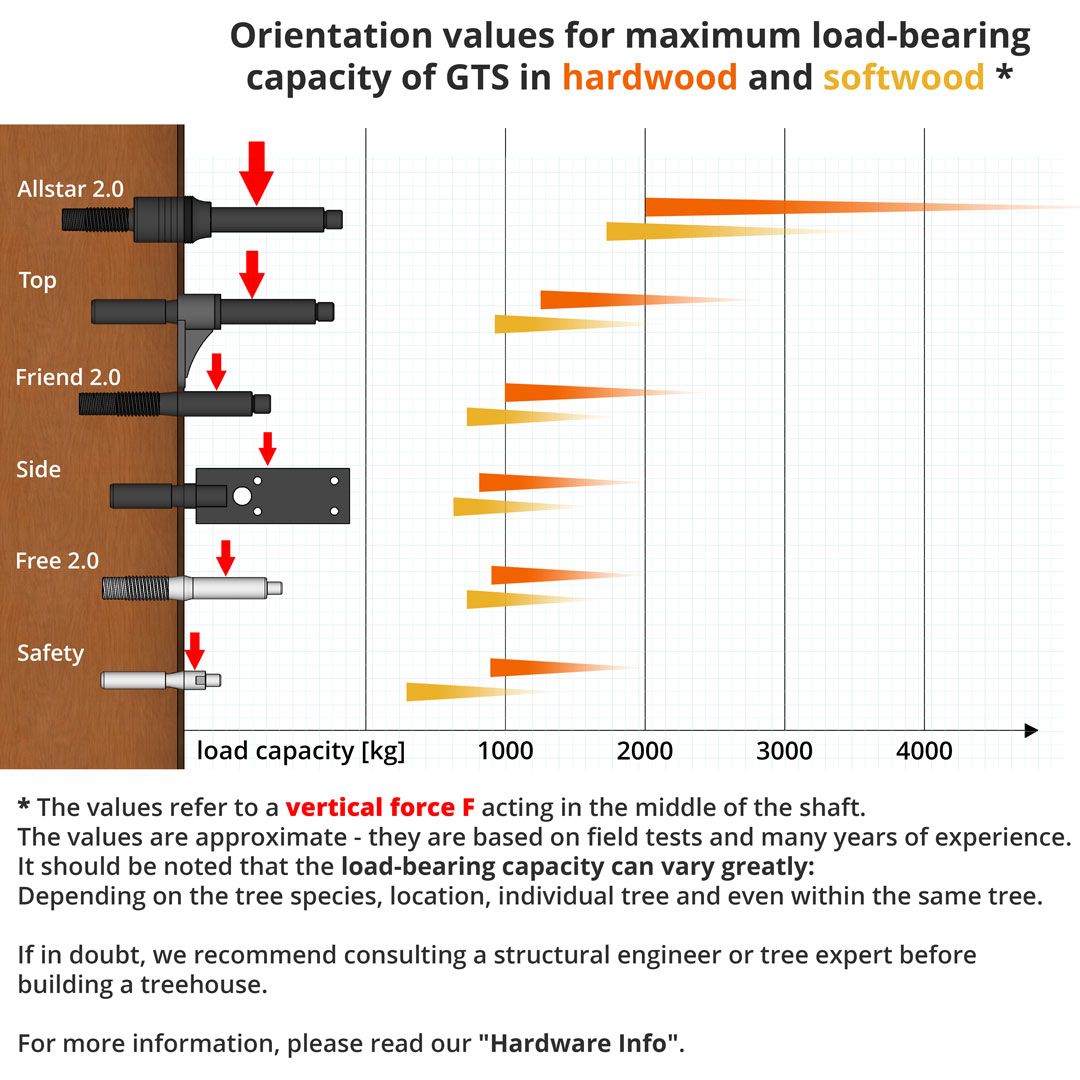

Load capacity of the German Treehouse Screws GTS

The load capacity of the screws depends on the following factors:

- Tree species (general, see here)

- Individual tree (growth form, strength, age)

- Local wood quality (in place of drilling)

- Lever arm (where the screw is loaded)

- Type of load (static, jerky or swinging)

- Fitting accuracy

It is difficult to make exact statements regarding the load-bearing capacity, as we are dealing with living trees with completely individual characteristics, and not with standardised and tested construction timber.

All information on the load-bearing capacity of our screws is therefore only intended as a guide – a safety factor of >2 should always be applied!

I.e. instead of 4 tons of load (average value of our tests in hardwood), the GTS Allstar should only be loaded vertically with 2 tons at medium lever arm.

Lever arm:

Load capacity of the GTS Allstar depending on lever arm and pivot point (e.g. 4 – 2 tons in hard hardwood)

In addition to the wood properties, the lever arm has a great influence on the load-bearing capacity of the screws; the lever arm is the distance from the pivot point of the GTS inside the tree to the support point of the bearing.

The pivot point of the GTS Allstar is about 11 cm (4,3 in) inside the tree; the smaller GTS Friend and Free pivot around 9 cm (3,5 in).

The closer the construction is to the tree, the higher the load capacity: half the lever arm = double the load capacity!

For normal loads, we recommend a distance of approx. 10 cm between the beam and the bark, which is a perfect compromise between load-bearing capacity and enough space for the tree to grow in width.

Distance Rings help to limit the movement of the support, and thus the lever arm.

The load capacity of the GTS can be doubled with Strut GTS+ or Cable Suspension!

Assembly and alignment of the GTS tree screws:

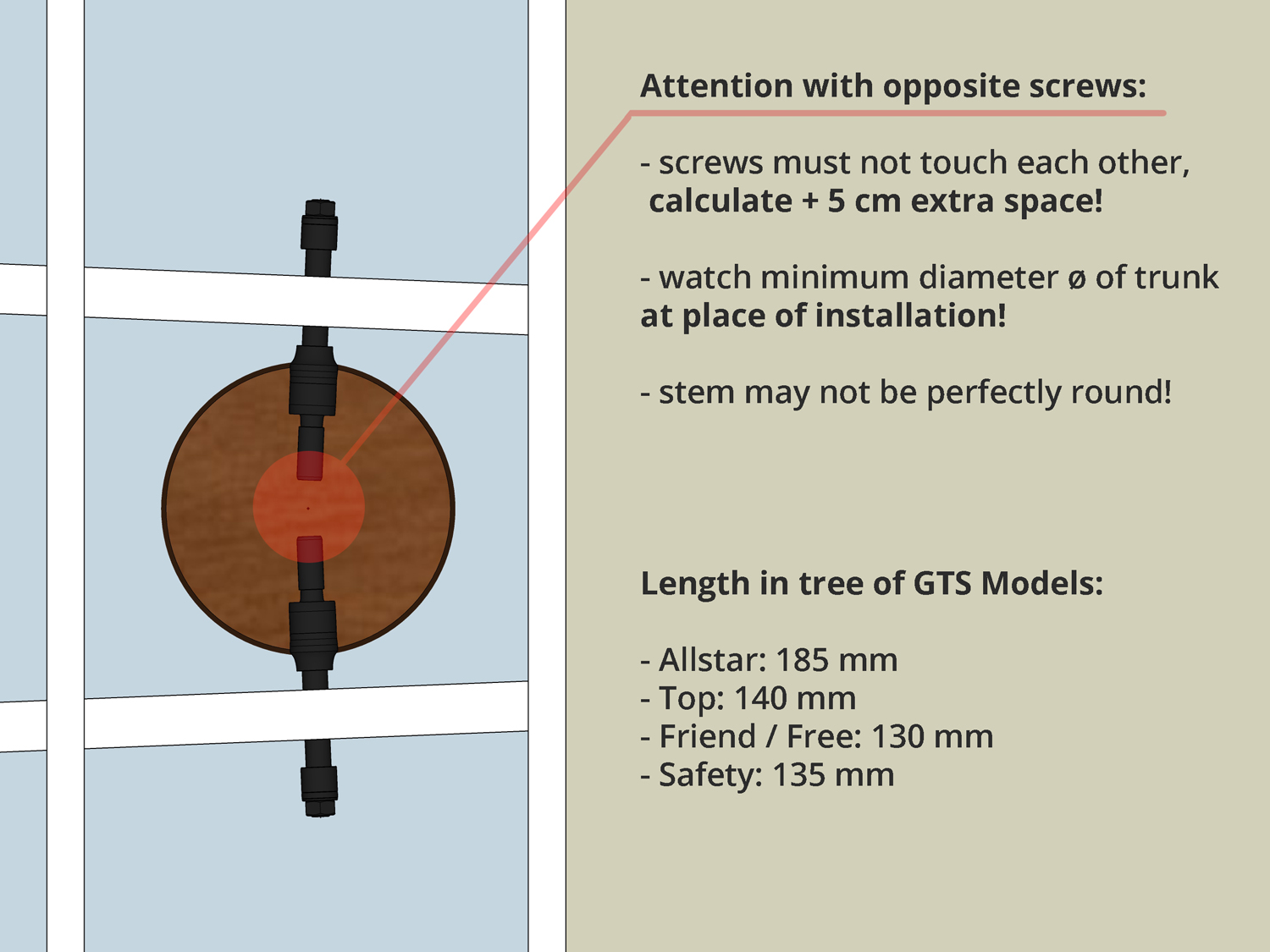

The screws must not touch each other in the tree trunk!

- Check how far the respective GTS screws have to be pre-drilled (see picture).

- Allow at least + 5 cm extra space.

- Remember that the trunk is rarely completely round

If necessary, you can mount the screws at different heights and adjust your beam construction accordingly.

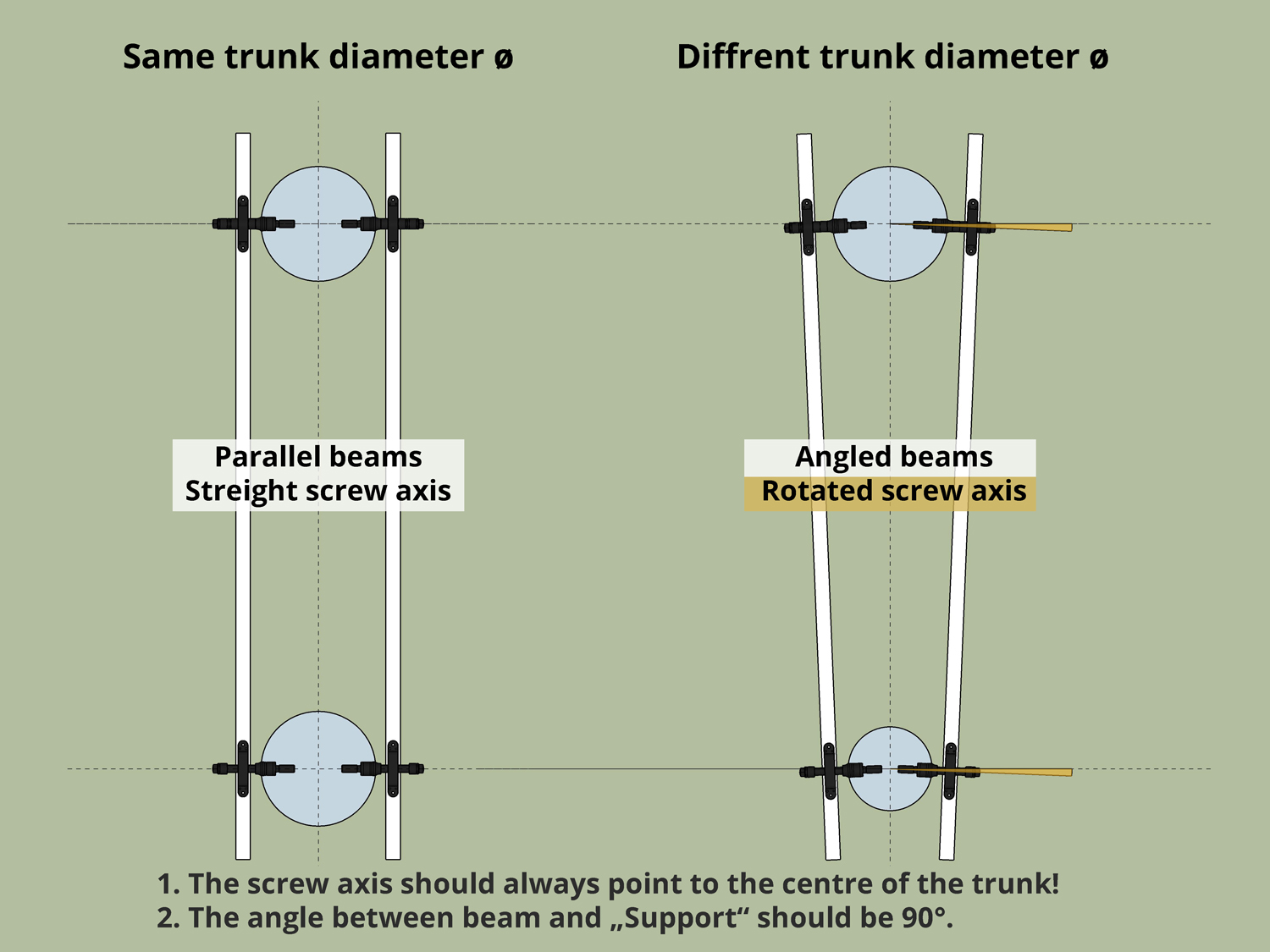

Pay attention to the exact alignment of your beams, supports and GTS screws:

- The screws should point towards the centre of the log.

- The screw axis should always be perpendicular (90°) to the beam.

Hardware Info

We place reliable, high quality information and honest, transparent dealings with our customers first.

The information refers to all products manufactured by TheTreehouse.Shop (Treehouse Screws and Treehouse Screw Accessories); for products of other manufacturers (tools, ropes, soft goods, etc.) the respective manufacturer’s specifications apply.

Liability – Use at your own risk

The buyer bears all responsibility for the installation and use of our products. We – Vitus Wahlländer / TheTreehouse.Shop – accept no liability for the use of our products, for damage to trees, buildings or persons.

The products manufactured by us (Treehouse Screws and Treehouse Screw Accessories) have no official structural approval – All load specifications are without guarantee!

Quality guarantee

We at TheTreehouse.Shop guarantee the highest quality of our products and their manufacture by officially trained professionals – 100% Made in Germany, Bavaria, Schliersee!

All our products have been extensively tested by us and have proven to be functional and safe in practice for decades. Similar products from other manufacturers have also proven themselves around the world in professional tree house construction.

A permanently safe connection is guaranteed if the tree is absolutely healthy, the screw hardware is professionally installed and the proposed load limits including safety factor > 2 are not exceeded.

No compromises in the quality of statically load-bearing products!

We expressly advise against self-produced, non-expert, DIY welding products! In the living tree, through wind and human movement, the fasteners are subjected to very high alternating loads, where even the smallest manufacturing error can have fatal consequences.

Many of our products are made of special steel alloys and cannot be welded. Any modification of our products will void the warranty!

Professional assembly

The professional assembly of our products is essential for a permanently secure fastening of the platform or tree house in the tree. Even smaller tree houses can easily reach a total weight of more than 10 tons (with dead load, interior fittings, crowds, heavy window and door elements, etc.). Especially for public buildings, projects in stormy and snowy regions and fixing heights greater than five meters, we strongly recommend the advice of an expert (i.e. structural engineer, tree structural engineer, tree surveyor, master carpenter).

Please also observe all local building regulations and building codes.

Vitus Wahlländer – TheTreehouse.Shop