Beam Bracket – Dynamic

Movable bracket for wooden beams on Tree Bolts

✔ For treehouses between several trees

✔ Decouples the platform from tree movements in wind and weather

✔ Prevents tension – protects trees and construction

✔ Fits: GTS Allstar, Top, Friend

Tax included. Shipping calculated at checkout

Beam Bracket – Dynamic

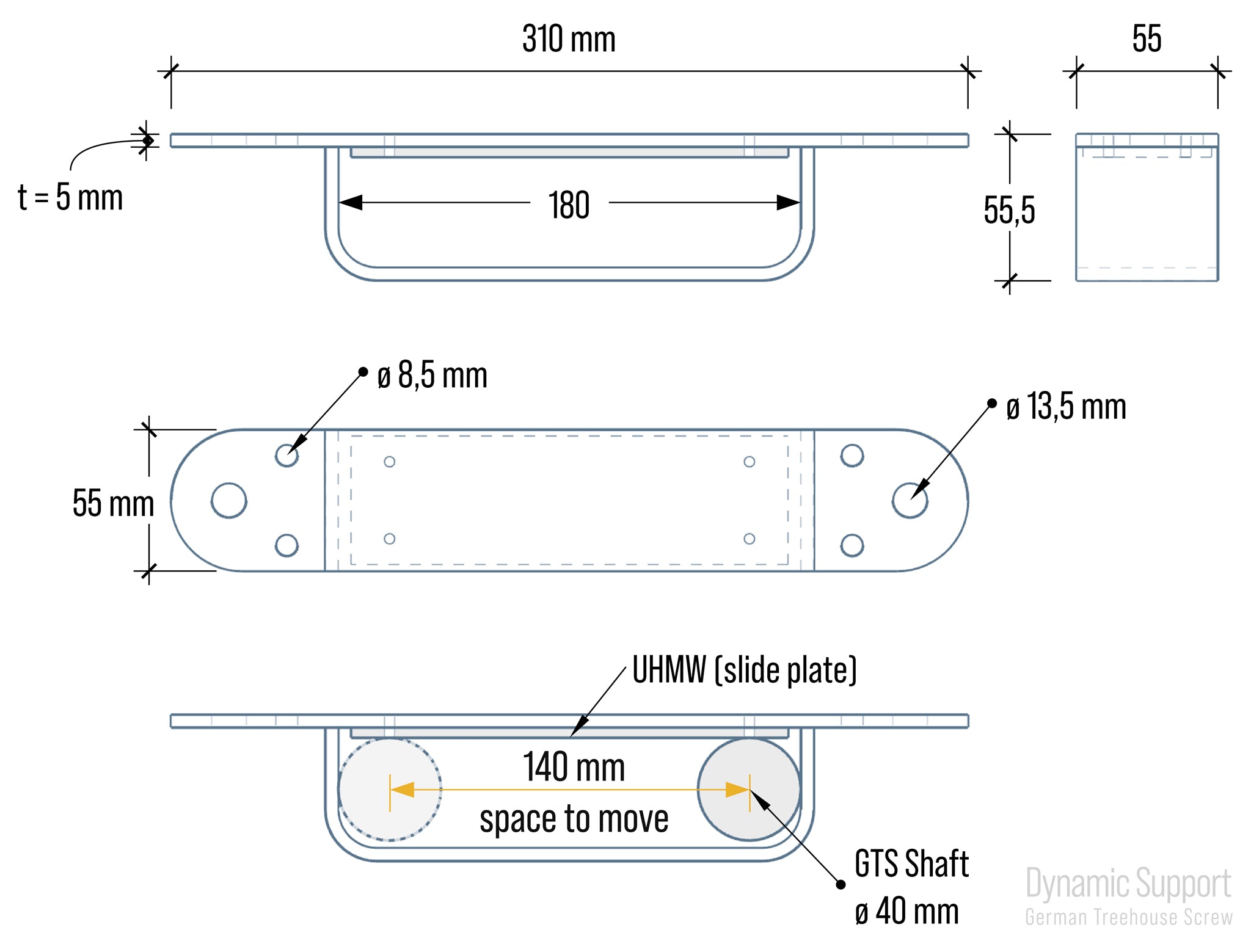

Dimensions & Technical Data

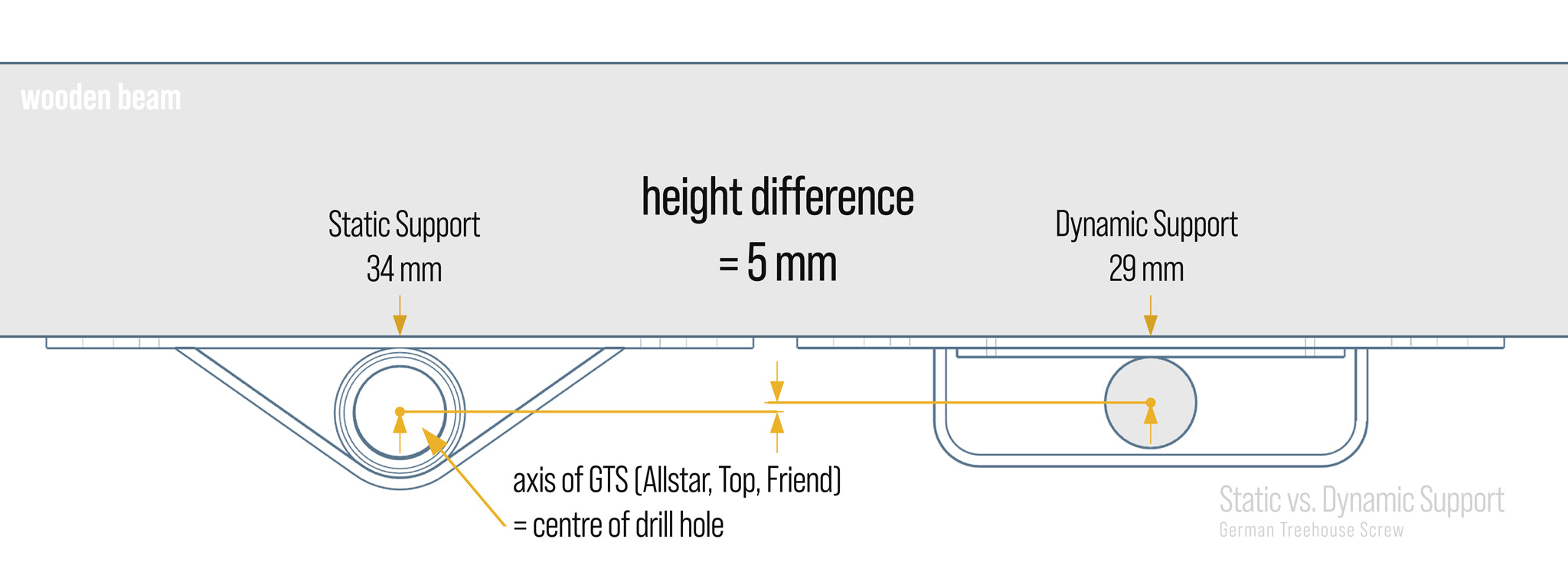

Assembly: Height difference 5 mm

Mounting: from 1,000 kg = double bracket

If the sliding bearing is overloaded, the UHMW sliding plate may bulge, especially if the shaft is thin and moves a lot. Static considerations do not really play a role here, but we nevertheless recommend the following:

✔ If the load is less than 1,000 kg and the movement is minimal, one Dynamic Support is sufficient.

✔ For loads exceeding 1,000 kg and significant movement, two Dynamic Supports should be used side by side.

Assembly: Screw on wooden beams

- For low loads, it is sufficient to secure the wooden beam with our Screw Set (see image).

- For high loads and a lot of movement, the beam must be secured with suitable carriage bolts ø 12 mm!

Detailed instructions are available here ...

Shipping & Delivery

Assembly & construction instructions

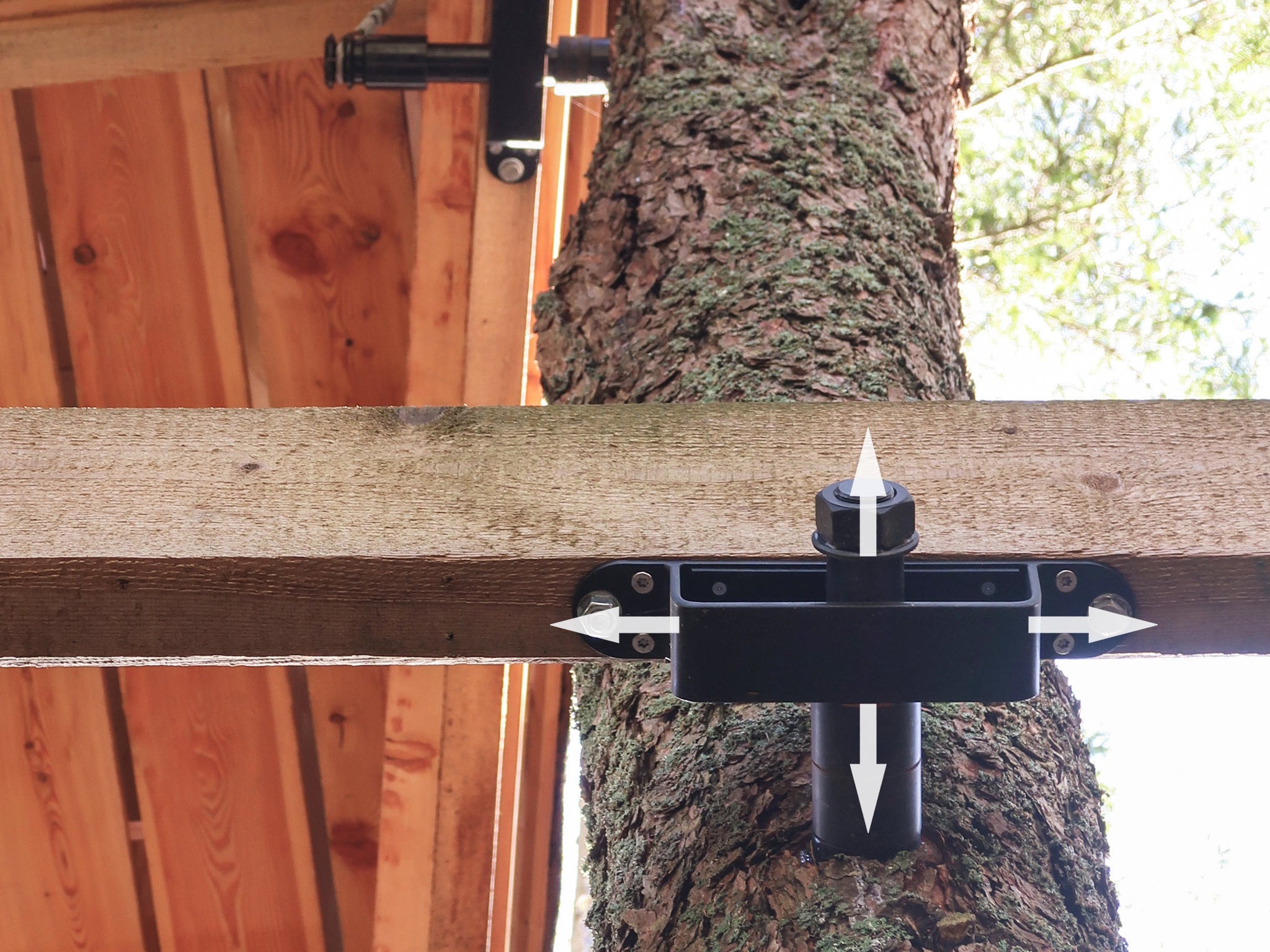

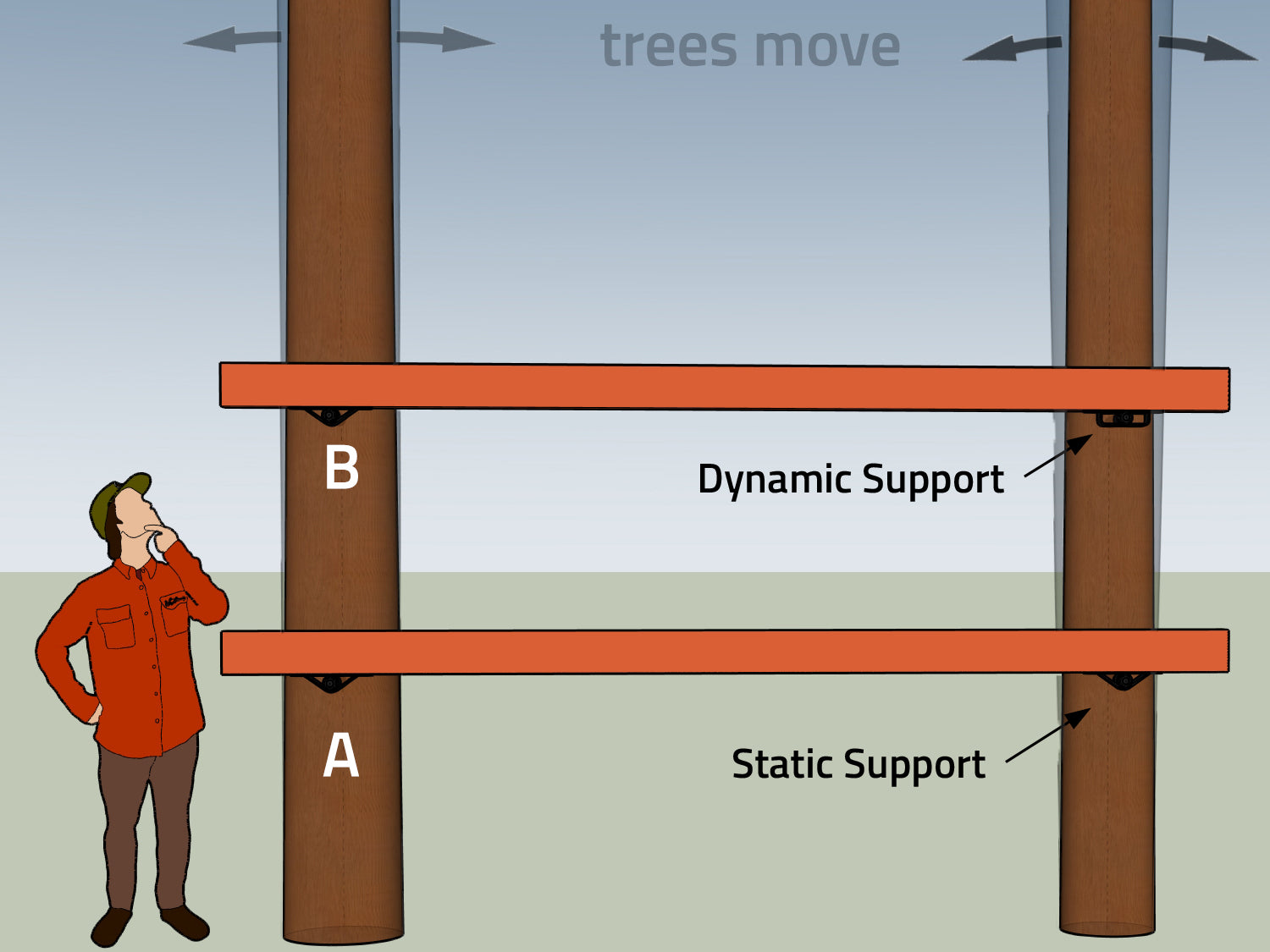

Trees dance

During storms, the trunk swings irregularly in all directions. This movement must remain possible. It is therefore important to mount the platform in a flexible/dynamic manner and to decouple the trees.

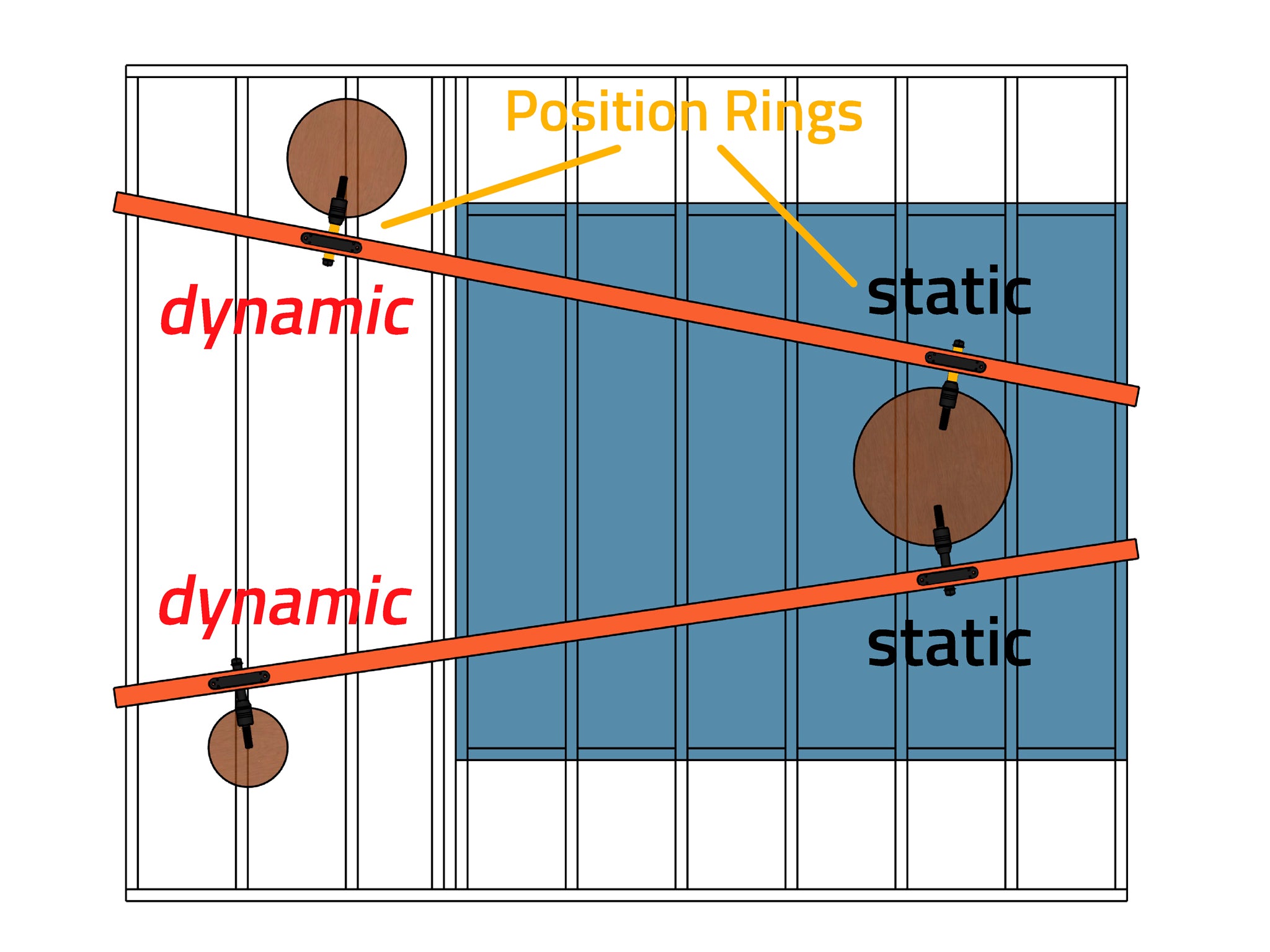

When do I need to disconnect?

The movement increases the thinner the tree and the higher the platform. In a thick tree (> 45 cm) low down, there is little movement; in this case, two fixed brackets (A) should be used. For more movement: 1x fixed & 1x dynamic (B).

The thickest tree as a landmark

If possible, always mount the fixed point on the thickest tree. The thinner trees get movable brackets.

Example: Maximum Movement

In this example, we reinforce the GTS Allstar with the ‘GTS+ BackUp System’ and maximise its load capacity in soft spruce wood. Now the Dynamic Support can slide all the way out on the shank (approx. 17 cm lever arm!) without overloading the screw.

€222,00

€132,00