Step 11: Timber guide

A carpenter and treehouse pro reveals:

✔ The best timber for your needs

✔ Calculate beam height with a rule of thumb

✔ Common dimensions for floorboards, formwork, timber frame construction and roof trusses

✔ The right wood screws: 2/3 rule

✔ Ideal for projects under 100 m³: treehouses, tiny houses, garden sheds, saunas, gazebos or carports

The right timber for your treehouse

Fastened with tree bolts

Treehouse

Timber used in damp non-buildable land (rural zone) must be more robust (e.g. larch) than wood used for interior construction (e.g. spruce).

Suspension bridge

For suspension bridges, narrow, thick boards are used to enable smooth walking. Board dimensions: 3×8×60 to 4×10×100 cm

Floor joists

The floor joists are laid on the substructure and screwed tightly in place. Joists upright: 6×12 to 10×20 cm

3D-Tribeam

3D-Tribeams form a stable support structure for the platform. Beam dimensions: 9×9 to 14×14 cm

Stair treads

Steps are subject to heavy wear and tear and require stable wooden planks with narrow annual rings: 4×20×60 to 5×25×120 cm

1. Buying timber – terms & dimensions

Timber is prefabricated, often standardised wood for timber constructions. There are basically two types:

- Solid wood – directly from the sawmill and dried. Inexpensive and sufficient if absolute dimensional accuracy is not required. It can be more moist and tends to crack, warp and have knotholes.

- Laminated wood & KVH – glued beams or layers made from several pieces of wood. Drier, more dimensionally stable and stronger than solid wood. Its standardised quality makes it ideal for load-bearing constructions, but it is more expensive.

The big advantage of glued wood: it allows dimensions that are hardly ever found in nature without flaws – from huge panels to metre-long, straight glued beams.

1. Buying timber – terms & dimensions

Timber is prefabricated, often standardised wood for timber constructions. There are basically two types:

- Solid wood – directly from the sawmill and dried. Inexpensive and sufficient if absolute dimensional accuracy is not required. It can be more moist and tends to crack, warp and have knotholes.

- Laminated wood & KVH – glued beams or layers made from several pieces of wood. Drier, more dimensionally stable and stronger than solid wood. Its standardised quality makes it ideal for load-bearing constructions, but it is more expensive.

The big advantage of glued wood: it allows dimensions that are hardly ever found in nature without flaws – from huge panels to metre-long, straight glued beams.

Buy timber

Wood dimensions & important terms

You can get these parts directly from the sawmill. The wood cross-section is specified in millimetres (mm) at the time of purchase and for small dimensions. To ensure smooth communication with the sawmill and craftsmen, here are the most important terms:

Square timber

Square timber is a generic term for all thicker square pieces of wood with:

- Thickness (height) d ≥ 40 mm

- Width b ≤ 3 * d

E.g. floor joists 60×120 mm; railing posts 70×70 mm

Beams (solid wood)

Beams are solid, thick pieces of wood with unlimited height:

- Thickness (height) d ≥ 60 mm

- Width b ≥ 200 mm

E.g. frame construction 60×60 mm; support beams 100×300 mm

Engineered solid wood KVH

Most carpenters use KVH, i.e. finger-jointed solid wood, for longer beams. The wood moisture content is standardised at 15 ± 3 %, which ensures stable quality and high dimensional accuracy. Thanks to finger-jointing, very long pieces can be produced that remain straight.

Glued laminated timber / glued laminated timber BSH

Glued laminated timber is used for large spans and high loads. The gluing of several layers of wood makes it particularly stable, dimensionally stable and virtually crack-free. Cross-sectional dimensions and lengths are virtually unlimited – but it is quite expensive.

Bohle

Planks are solid, rather wide pieces of wood thicker than 4 cm:

- Thickness (height) d ≥ 40 mm

- Width b ≥ 40 mm 3 * d

E.g. stair tread 45×200 mm; stair string 50×250 mm

Board

Flat, wide pieces of wood. Either rough-sawn, planed or profiled.

- Thickness (height) d ≤ 40 mm

- Width b ≥ 80 mm

E.g. decking boards 25×145 mm; façade boards 20×120 mm

Slats

Small-format, square wood for railings, facades or battens.

- Thickness (height) d ≥ 40 mm

- Width b ≥ 60 mm

E.g. railing bars 25×45 mm; roof battens 35×50 mm

Round timber (natural)

Natural growth form of the tree, not cut, only debarked.

- Diameter ø ≥ 40 mm

E.g. balusters ø 50 mm; stilts ø 100 mm

Always buy your wood directly from the sawmill or your local timber merchant. If they find out that you are building a treehouse, they will be particularly happy to help you ;)

Buy timber

Laminated wood & panel materials

Panel materials are indispensable in timber construction and treehouse building. They are available in all sizes, thicknesses and quality grades, adapted to the respective area of application – whether for indoor or outdoor use, vapour-permeable or waterproof. They are used for walls, floors, roofs, for bracing, sealing and as decorative surfaces.

Important: In damp and wet areas, the glue must be suitable for outdoor use!

OSB boards

OSB boards (Oriented Strand Board) consist of glued wood chips that are pressed crosswise. They are relatively inexpensive, yet dimensionally stable, durable and versatile – whether for walls, floors or roofs, indoors or outdoors – a real all-rounder!

Plywood & multiplex

These boards consist of several thin layers of wood glued together crosswise. This layer bonding ensures high stability and prevents warping or cracking. Ideal for furniture and panelling, but can quickly become expensive.

3-layer panels

3-layer panels are essentially plywood made from three slightly thicker glued layers. They are usually slightly cheaper and resemble solid wood in terms of appearance, feel and workability. Due to their homogeneous, ‘soft’ surface, they are often used for visible surfaces in interior design.

2. Inner zone vs. non-buildable land (rural zone)

Good timber comes at a price. That's why high-quality, durable wood should only be used where it's needed – for load-bearing parts or in non-buildable land (rural zone). For interior work, especially in areas that are not visible, a simpler wood quality is often sufficient.

It is best to use local wood from a regional sawmill or timber merchant. You will receive expert advice and fair prices – and by keeping transport distances short, you will not only save time but also CO₂.

It is best to avoid tropical woods such as teak. Not only are they ecologically questionable, but they are also simply too heavy and impractical for many applications, such as treehouse construction.

2. Inner zone vs. non-buildable land (rural zone)

Good timber comes at a price. That's why high-quality, durable wood should only be used where it's needed – for load-bearing parts or in non-buildable land (rural zone). For interior work, especially in areas that are not visible, a simpler wood quality is often sufficient.

It is best to use local wood from a regional sawmill or timber merchant. You will receive expert advice and fair prices – and by keeping transport distances short, you will not only save time but also CO₂.

It is best to avoid tropical woods such as teak. Not only are they ecologically questionable, but they are also simply too heavy and impractical for many applications, such as treehouse construction.

Non-buildable land (rural zone)

Timber exposed to the elements must be suitable for outdoor use, as it is freely exposed to environmental influences (rain, moisture, dirt, etc.). In our carpentry workshop, we always use untreated, local larch, Douglas fir or cedar for outdoor use – the wood is light, sufficiently strong and easy to work with.

Outdoor use – heavy-duty

If the wood is screwed directly to the tree or lies on the ground in an area exposed to splashing water (e.g. support feet, stair treads, door thresholds), it should be particularly resistant (oak, robinia, etc.).

Indoors – dry

Wood that is protected and installed in dry areas does not require high stability. Wood types such as spruce, fir, pine or poplar are ideal. They offer excellent value for money, are very easy to work with, lightweight and yet stable.

Non-buildable land (rural zone)

Timber exposed to the elements must be suitable for outdoor use, as it is freely exposed to environmental influences (rain, moisture, dirt, etc.). In our carpentry workshop, we always use untreated, local larch, Douglas fir or cedar for outdoor use – the wood is light, sufficiently strong and easy to work with.

Outdoor use – heavy-duty

If the wood is screwed directly to the tree or lies on the ground in an area exposed to splashing water (e.g. support feet, stair treads, door thresholds), it should be particularly resistant (oak, robinia, etc.).

Indoors – dry

Wood that is protected and installed in dry areas does not require high stability. Wood types such as spruce, fir, pine or poplar are ideal. They offer excellent value for money, are very easy to work with, lightweight and yet stable.

Pro tip: Sorting wood

Not all wood is the same! If you have bought a large stack of timber, sort out the best pieces and place them in a separate stack, stored in a dry place and well ventilated:

✔ narrow annual rings = particularly stable!

✔ few cracks and knotholes

✔ straight and not warped

✔ attractive grain

Use this high-quality wood for beams, thresholds, supports and visible areas that will be subjected to heavy loads.

Ugly, resinous and flawed wood, on the other hand, should be used where no one can see it. You can cut heavily warped pieces to size and reuse them for shorter components.

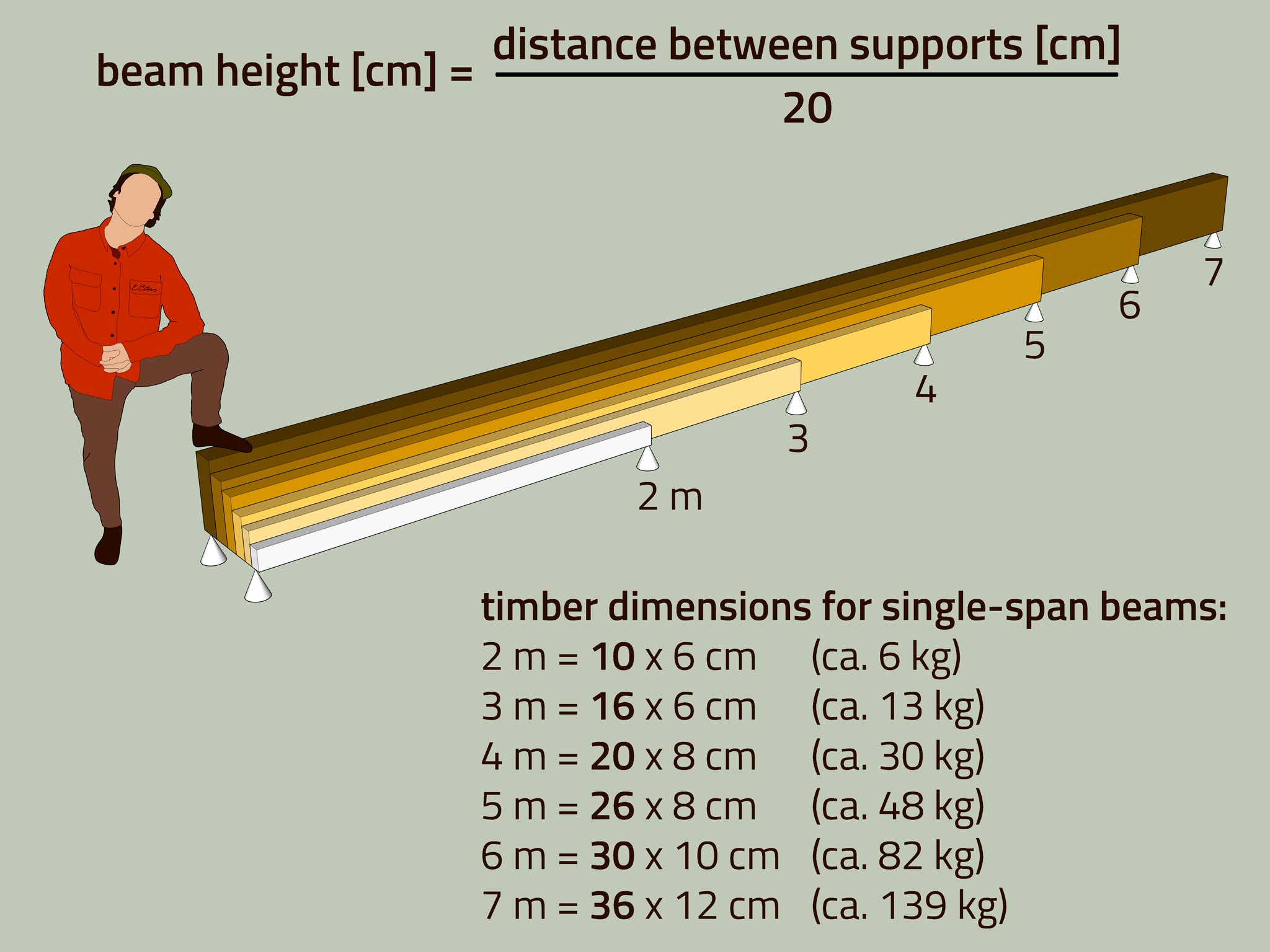

3. Rule of thumb for calculating wooden beams

The supporting structure of the treehouse must always be able to withstand the ‘worst case scenario’:

✔ Extreme weather, squalls, heavy wet snow, etc.

✔ Defects in the timber, e.g. cracks, knotholes, rotten areas, wear and tear

✔ Many dynamic loads that do not occur in normal houses on the ground

✔ Additional loads caused by people (e.g. sitting on the railing)

3. Rule of thumb for calculating wooden beams

The supporting structure of the treehouse must always be able to withstand the ‘worst case scenario’:

✔ Extreme weather, squalls, heavy wet snow, etc.

✔ Defects in the timber, e.g. cracks, knotholes, rotten areas, wear and tear

✔ Many dynamic loads that do not occur in normal houses on the ground

✔ Additional loads caused by people (e.g. sitting on the railing)

Calculate the height of wooden beams

Load-bearing wooden beams are installed upright - Use this rule of thumb to calculate the height of your wooden beams:

Beam height [cm] = bearing distance [cm] / 20

✔ The formula applies to normal, flat loads for classic timber (spruce / larch / KVH / BSH).

✔ For single-span beams, i.e. beams that only rest on two points.

✔ The weight was calculated using KVH spruce (460 kg/m³).

KVH is available in timber merchants up to a height of 24 cm. For larger cross-sections, more expensive laminated timber (BSH) must be purchased.

Increase bar height?

The height of the wooden beam should be increased by 2 to 4 cm if:

✔ A large load is not distributed evenly but acts selectively in the middle of the beams (see example).

✔ Large amounts of snow or crowds of people are expected.

Pro tip: High load, high quality!

Large knotholes and cracks greatly reduce the stability of a wooden beam. Only use the best wood for load-bearing beams that are subject to heavy loads. Large knotholes must not be located in the middle or on the underside of the beam!

Reduce beam height?

The above formula calculates ‘on the safe side’. Even if you choose a beam that is 1-2 cm lower, it will still support the load without any problems. However, if you choose a beam that is 3-4 cm lower, it will probably bend or spring slightly, which is not visually appealing and is not ideal from a physical point of view.

The beam height should be reduced by a maximum of 1-2 cm:

✔ For multi-field beams with low surface loads.

✔ If the beam is effectively supported by additional suspensions or struts (including knee braces, timber knee braces) (see below).

The correct beam width

The load capacity of a wooden beam depends mainly on its cross-sectional height. Try it out by placing a wooden board between two points and placing weight on it once horizontally and once vertically.

The width of the load-bearing beams is of secondary importance in terms of statics, but should always be at least 6 cm so that any defects (knotholes and cracks) are not so serious and there is enough space to screw the beams without splitting them.

Buy treehouse bracketsWooden beam overhang / projection

This rule of thumb is a reliable guide for estimating the overhang of a wooden beam:

Beam overhang [cm]* = beam height [cm] x 5

✔ The formula applies to classic timber.

✔ The beams are firmly anchored and cannot tip over.

* Note: As the calculation is somewhat more complex in this case, this formula should only be used for rough estimates. The values are very safe for normal loads, e.g. a cantilevered terrace with a few adults standing on it.

- With a multiplier of beam height x 6, it is still safe.

- A multiplier of beam height x 7 is still acceptable, but the beams will bend and rock slightly under higher loads.

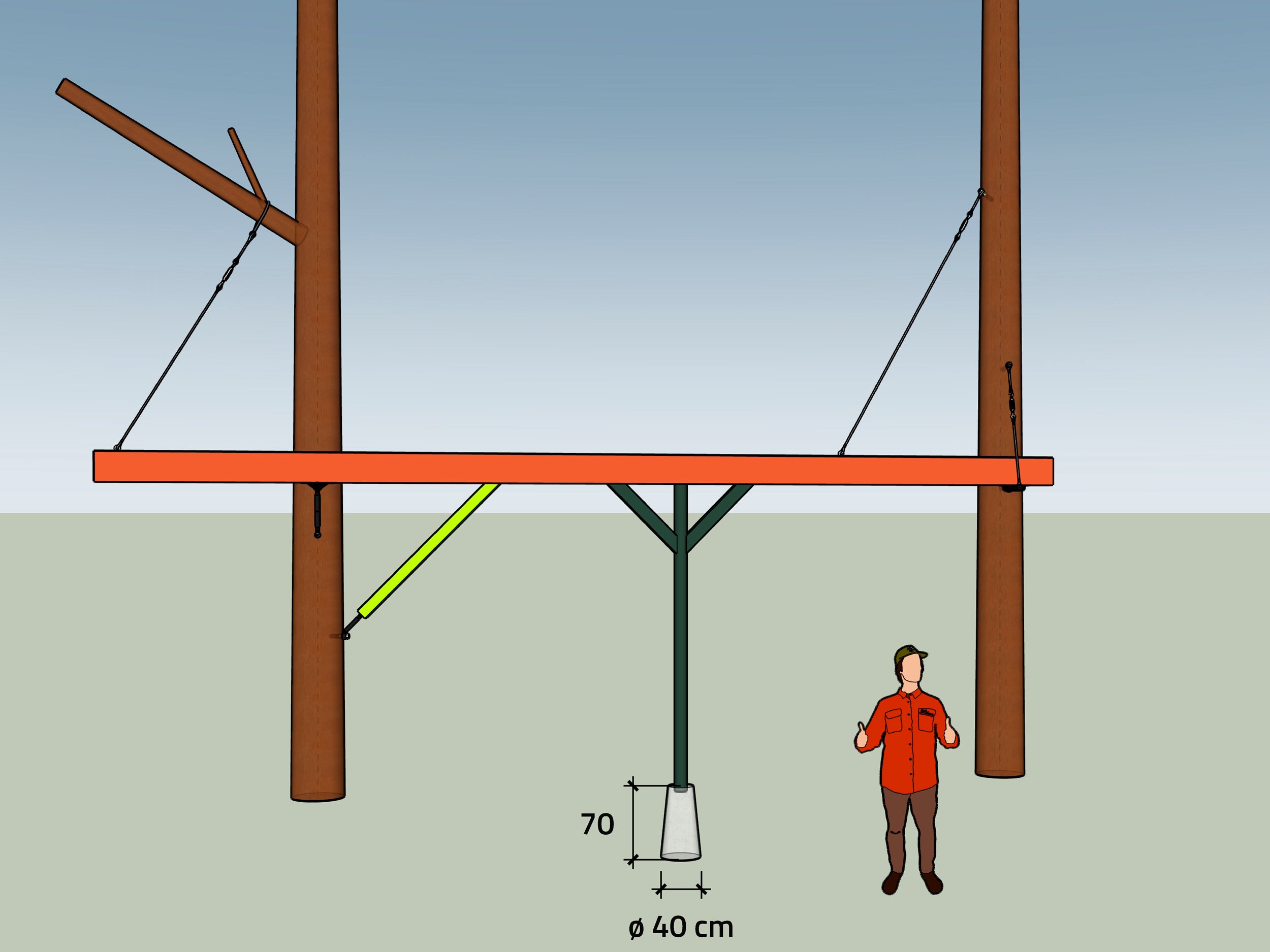

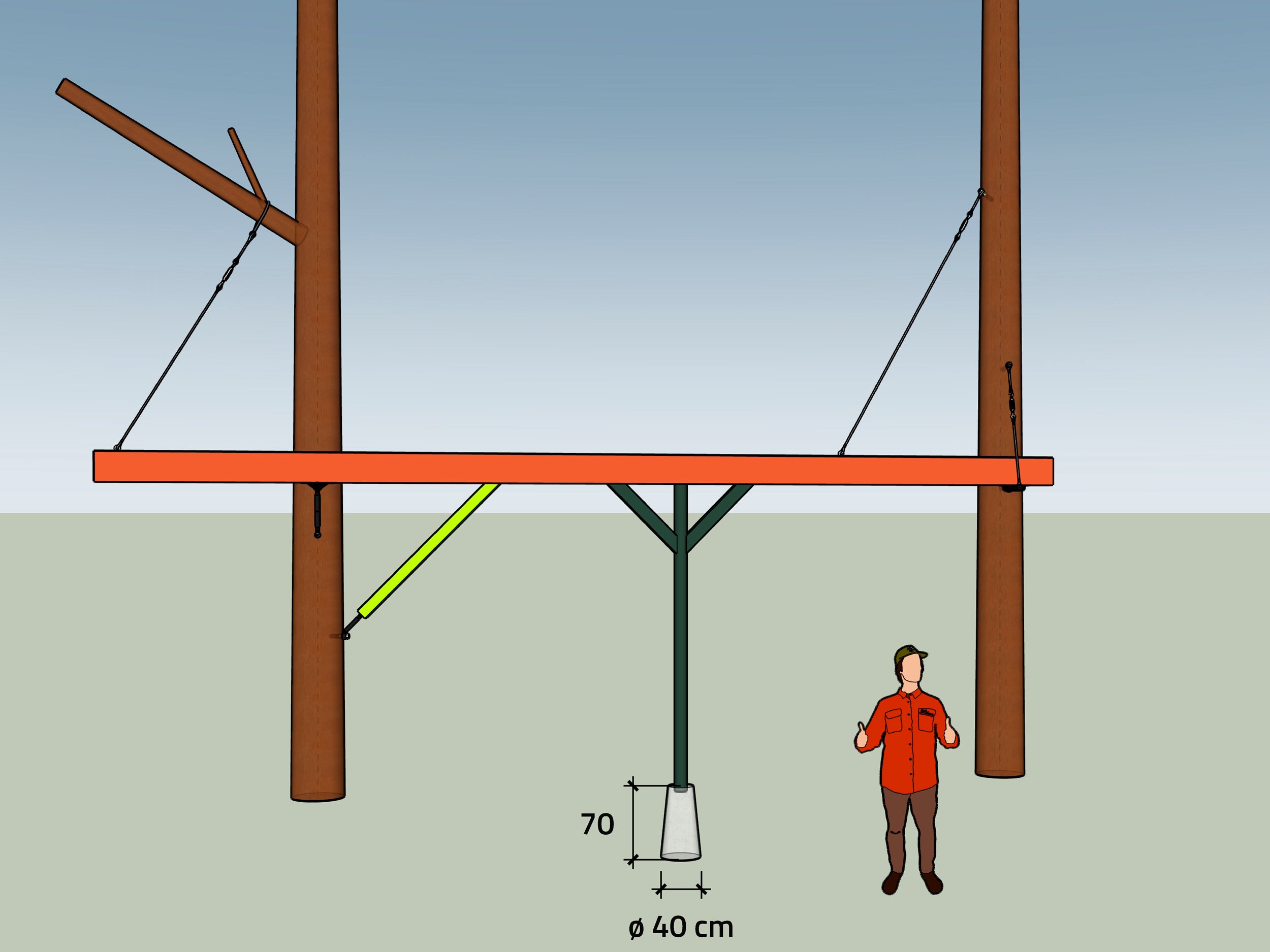

How to reinforce a beam that is too weak

Hang on a strong branch or fork in a tree

✔ Turnbuckle (M14 - M20)

✔ Steel cable (ø 6-10 mm)

✔ Ring nut + carriage bolt M12

Hanging with GTS tree bolts

✔ Turnbuckle (M14 - M20)

✔ Steel cable (ø 6-10 mm)

✔ Ring nut + carriage bolt M12

Concrete-encased support (wood or steel)

✔ Concrete footing approx. ø 40 x 70 cm

✔ Post shoe / support

✔ Wooden posts 9x9 - 14x14 cm

✔ Reinforced with struts

GTS+ Tree Bolt Reinforcement

The load capacity of the GTS Tree Bolts can be further increased if supplies are available:

✔ GTS+ Cable System (from above)

✔ GTS+ BackUp System (from below)

From a support distance of 4 m (13.1 ft), the wooden beams become very heavy > 30 kg. To get these beams into the tree, pulleys are required!

4. Typical wood dimensions and measurements for treehouse construction

We will show you interactive examples of real treehouses that we have built with our carpentry company baumbaron. Simply click on the flashing dots to see which wood was used there.

Example - Treehouse exterior

Wooden stilts for treehouses

Wooden posts 12×12 cm (concreted in with post shoes). Additional struts ensure stability and reduce the buckling length.

Railing for platform

The railing must be at least 90 cm high. It is important that it is permanently and securely bolted to the platform. Uprights 7×7 cm, handrail: 7×9 cm, bars 2.5×4.5 cm

Floor joists

The floor joists are usually laid on the support structure and screwed firmly in place. Larch beams upright: 6×12 cm

3D-Tribeam

3D-Tribeams form a stable support structure for all sizes of platforms. Beam dimensions: 12×12 cm

Stair treads

Steps are subject to heavy wear and tear and require sturdy wooden planks with narrow growth rings: 4.5×20×100 cm

The most important thing is to protect wood from permanent moisture. Water must be able to drain away and wet wood should dry quickly.

Example - Treehouse interior

Ridge timber and rafters

Ridge timber 10×20 cm and rafters 7×10 cm are made of spruce. They form a beautiful contrast to the darker larch cladding above.

Purlin doubled

Since the purlins have a large span of 5 m (16.4 ft) and are heavily loaded by the roof, we screwed two beams (approx. 30 x 10 cm (11.8 in x 4 in)) together. This ensures that the sliding door always runs smoothly.

DIY sliding doors

The large sliding doors were reinforced with 12 mm OSB boards, with 2 cm larch panelling on the outside and 2 cm spruce panelling on the inside, plus used windows.

My mum

Approx. 160 cm tall and light as a feather. Ensures that there are always enough nuts in the treehouse.

Use different types of wood, surfaces or finishes to create contrasts – this will make your room appear larger and more vibrant!

5. The right wood screws (stainless steel vs. galvanised)

Of course, traditional joints such as tenons and lap joints look good and demonstrate genuine craftsmanship. But they are clearly inferior to modern wood screws in two respects: stability and efficiency.

Classic connections are often problematic, especially in non-buildable land (rural zones): water collects in joints and the wood begins to rot. In addition, notches unnecessarily weaken the cross-section of the beam.

Smooth joints with suitable wood screws are perfectly adequate for a treehouse or tiny house.

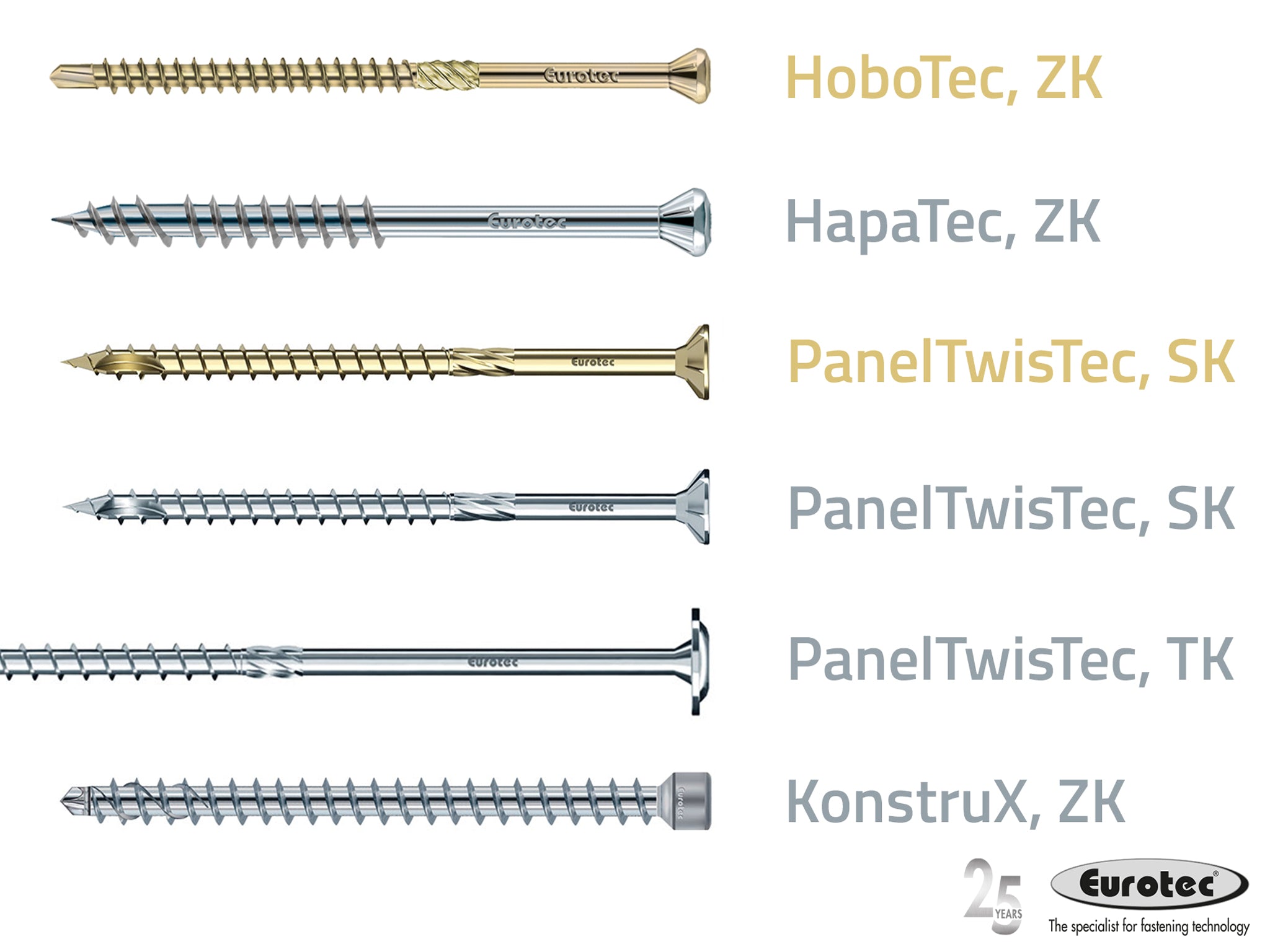

Stainless steel screws – for outdoor and damp areas

Wherever rain, splashing water or constant moisture are present, stainless steel is a must. It does not rust, is robust and still looks good even after years of use. Stainless steel A2 is sufficient for most applications. A4 is the better choice for highly acidic woods such as oak, acacia or cedar.

Unlike galvanised screws, which lose their protective coating as soon as they are screwed in and soon leave ugly rust marks, stainless steel stays clean – and so does the wood.

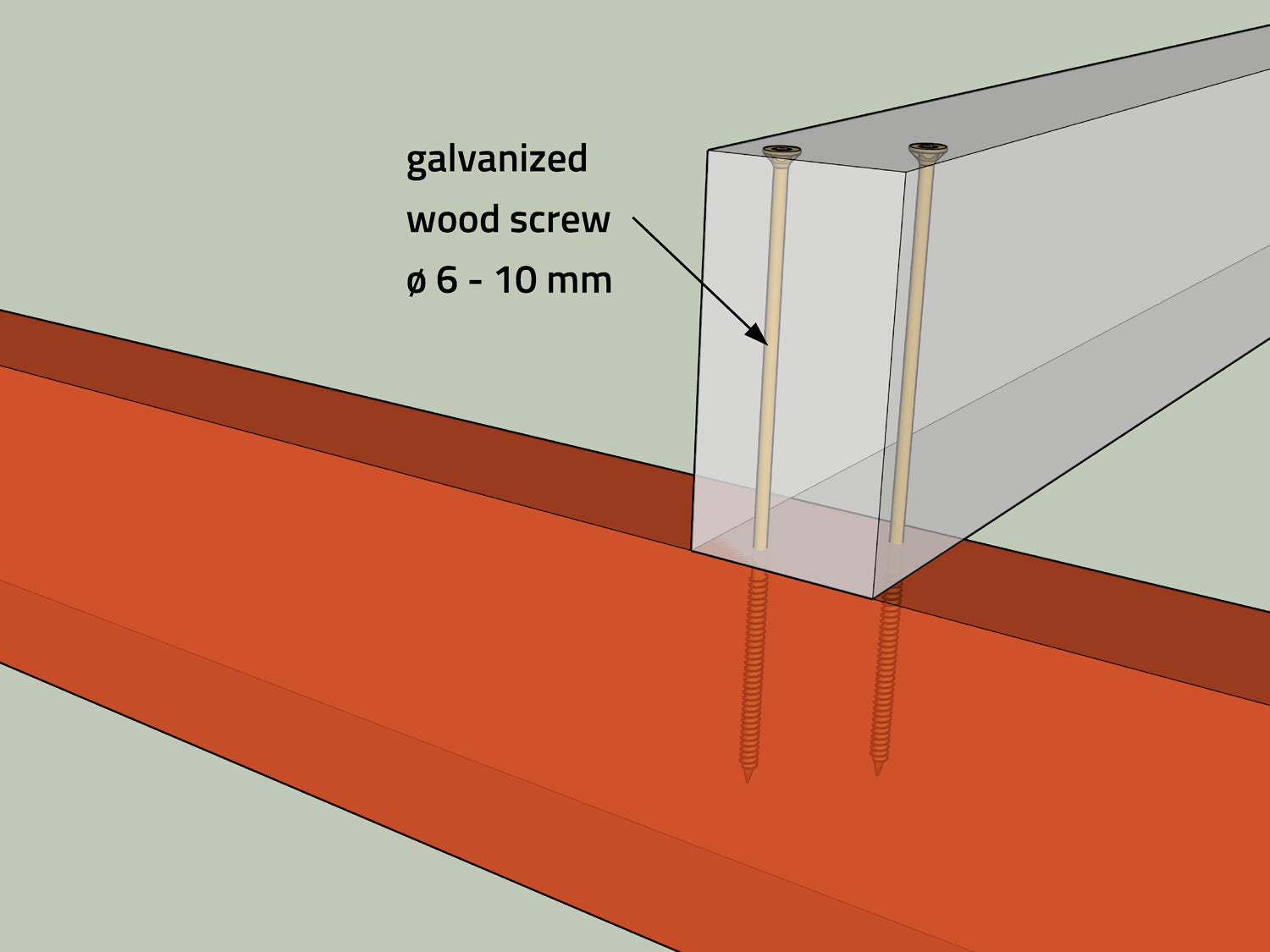

Galvanised screws – for interior use and floor joists

Galvanised screws are not only cheaper than stainless steel screws, they are also less brittle. For long screws measuring 140 mm or more, this is a real advantage, as they are less likely to break when screwed in.

That is why we deliberately use galvanised screws longer than 140 mm for the non-buildable land (rural zone) of the platform. This is a good technical and economic choice as long as the area remains predominantly dry.

However, anything shorter than 140 mm in the outdoor area should be made of stainless steel.

Stainless steel screws – for outdoor and damp areas

Wherever rain, splashing water or constant moisture are present, stainless steel is a must. It does not rust, is robust and still looks good even after years of use. Stainless steel A2 is sufficient for most applications. A4 is the better choice for highly acidic woods such as oak, acacia or cedar.

Unlike galvanised screws, which lose their protective coating as soon as they are screwed in and soon leave ugly rust marks, stainless steel stays clean – and so does the wood.

Galvanised screws – for interior use and floor joists

Galvanised screws are not only cheaper than stainless steel screws, they are also less brittle. For long screws measuring 140 mm or more, this is a real advantage, as they are less likely to break when screwed in.

That is why we deliberately use galvanised screws longer than 140 mm for the non-buildable land (rural zone) of the platform. This is a good technical and economic choice as long as the area remains predominantly dry.

However, anything shorter than 140 mm in the outdoor area should be made of stainless steel.

Wood Screw Kit – Treehouse Essentials

Ready to go – the perfect wood screw pack for Treehouse builders!

✔ The most important wood screws for indoor and outdoor use

✔ All common lengths and thicknesses included

✔ For support structures, platforms, terraces, walls, roofs, windows and much more.

✔ Modern Torx drive for effective work even in difficult situations

Traditional wood joints have had their day. Today, modern wood screws, high-quality glues and well-designed connection systems ensure maximum stability and efficiency.

5 professional tips for screw fastening

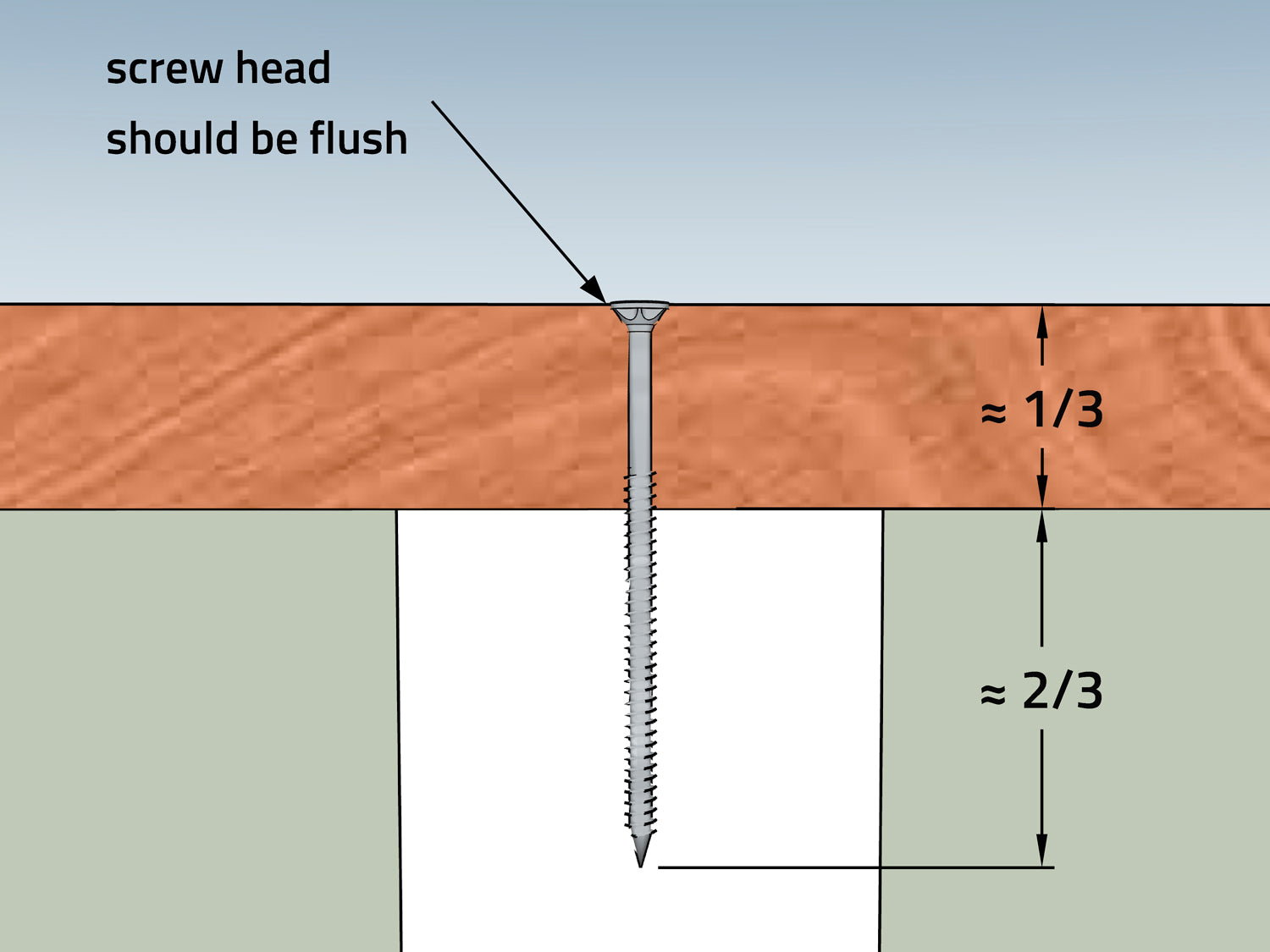

2/3 rule for screw length

- 1/3 is the thickness of the wooden part to be screwed.

- The screw should penetrate 2/3 deep into the other component.

The optimal screw length can usually be found using the 2/3 rule, e.g. 2.5 cm decking board ≈ approx. 7 cm screw length.

Securely screw floor joists in place

The 2/3 rule cannot always be followed for thick wooden beams. In this case, the screw should still be as long as possible:

- if the screws are too short, simply arrange several screws in a staggered pattern.

- Use galvanised screws for screw lengths over 140 mm.

When is it necessary to pre-drill?

- Screw very close to the edge (< 2 cm)

- From screw diameter ø 8 mm

- For hard and brittle wood (robinia, oak, beech, ash, etc.).

- When a neat appearance is required (facades, furniture, etc.)

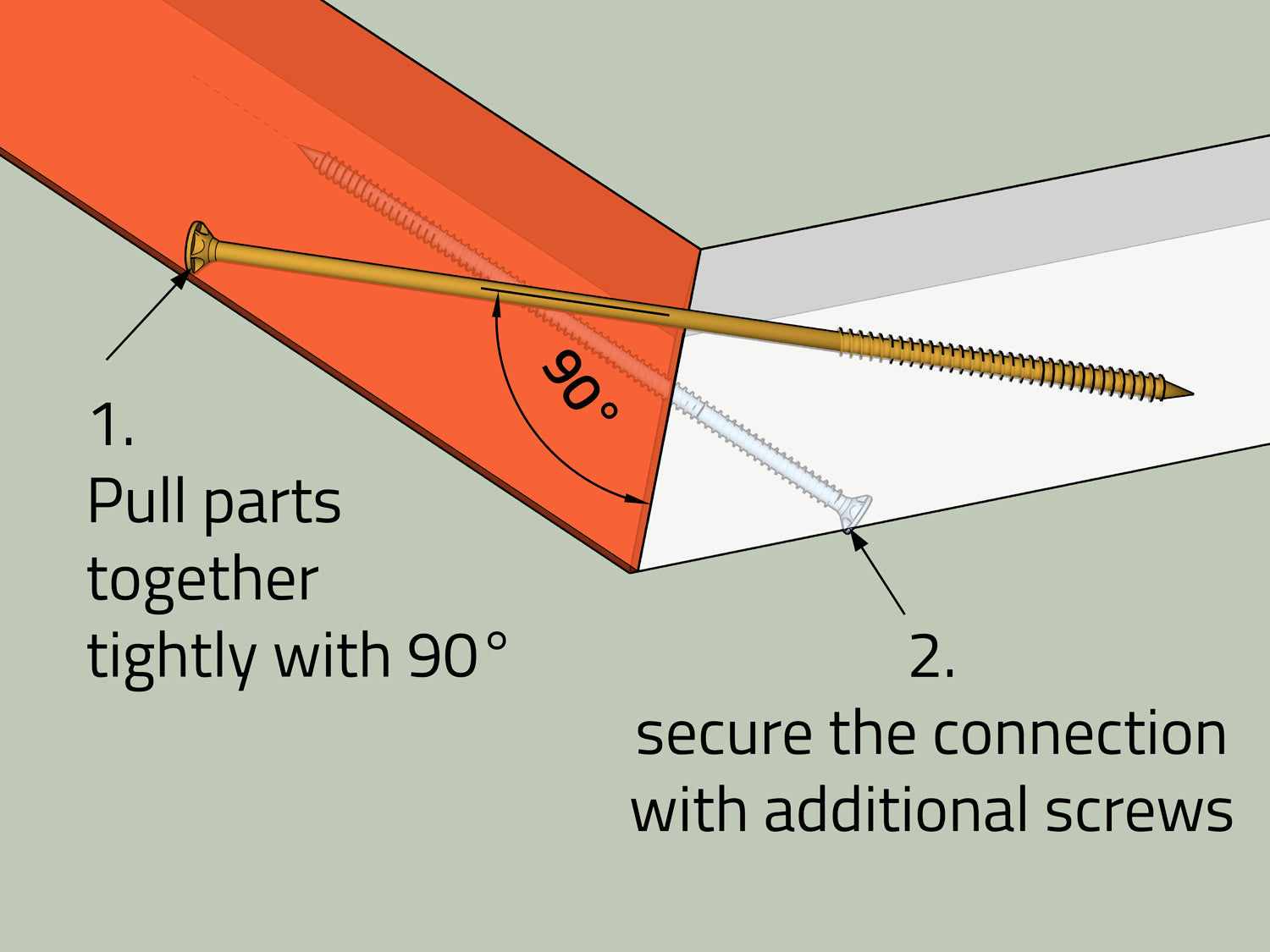

First plumb 90° - then secure!

1. The first screw (partial thread or flat head) always has the task of pressing the wooden parts together as tightly as possible. To prevent the wooden parts from slipping, screw at a 90° angle!

2. After pressing, secure the connection with additional screws (e.g. full thread).

100% TORX & quality

Only use TORX!!! Slotted and Phillips screws have no place on a construction site, especially when working overhead and in difficult places when building a treehouse. Please note: There are also significant differences in quality here, and it is always worth buying good brand-name products in larger quantities – the screws will last a lifetime and will still be there for your next project.