You are here: Home / Service / Installation Instructions /

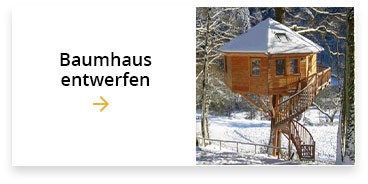

How to build a tree house:

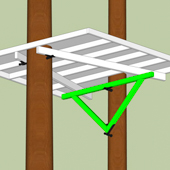

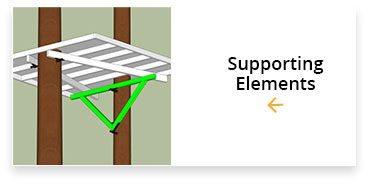

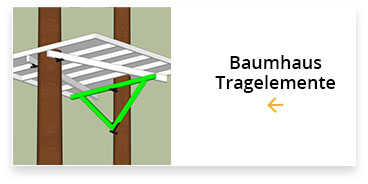

Assembly of a wooden tribeam construction

Basic principles and example pictures of tribeam construction can be found on the following pages:

Dimension of the wooden beams:

-

Beams made of KVH solid structural timber for outdoor use (larch, Douglas fir, cedar, …).

-

Width of the beams: 6 – 12 cm

-

Height of the beams: 8 – 20 cm

-

The beams are installed upright / on edge.

The exact dimensions of the beams are determined by:

- Load (light children’s playhouse or heavy insulated tree hotel?).

- The greater the load, the thicker the wooden beams must be.

- Dimension of the triangle: The larger the triangle, the thicker the beams must be.

- Position of the platform beams above (See pictures: “angled beams” or “doubled-up cross beam”).

Angled Beams

The individual platform beams are screwed to the upper triangle with an angle → the upper cross-beam of the triangle must be higher (e.g. 8 × 20 cm for a length of 4 m).

Doubled-up Cross-beam

The triangular cross-beam is “doubled up” with a continuous platform beam – the beams lying on top of each other must be bolted and/or glued with a force fit every 50 cm so that they form a static unit.

The cross-beam of the triangle can then be e.g. 10 × 10 cm, the platform beam above it 6 × 12 cm. The outer “free-floating platform beams” must be additionally secured with angle plates.

Size of the triangle:

- Vertical screw spacing 1.3 – 3 m

- The larger the triangle, the more stable.

- The more acute the lower triangle angle (V-Bracket), the more load is transferred vertically – good!

- Attention with very flat angle or wide cantilevered platform – here lower bolt is heavily loaded horizontally – GTS-tree connection less load-bearing – not good!

- If the triangle is very large (struts longer than 4 m), additional bracing should be installed so that the beams do not bend.

- Attention with strongly inclined trees and near the base of the trunk, here it is essential to build a dummy beforehand and check whether the triangle fits on the shaft of the GTS Screws!

- The GTS Screws should not be loaded too far on the outside in case of heavy weight (too large lever arm).

- Caution: The 2 parts of the “V-Bracket” must always be used together. NEVER fix individual struts with the individual parts, otherwise the steel plate may fail!!!!

Mounting the triangle

1. Find and check the exact position of the triangle in the tree:

Determine the desired position of the upper GTS screw in the tree and mark it e.g. with a wood screw.

Check the exact position of the screws / the triangle several times:

- Alignment of the triangle to the platform / to the other components.

- Exact height of screws incl. height of supports and wooden beams

- Does the triangle fit vertically and centrally at the desired position? The distance from wooden edge to tree should be approx. 10 – 15 cm. Watch out for: Bulges on the trunk, inclined tree, thick trunk base, thick branches, etc.

- If the tree trunk is inclined: Will the supports at the top and bottom still fit on the shaft of the tree screws / is there enough clearance?

Tip: Build a prototype from simple slats, then you can see immediately whether the triangle will fit in the desired position in the tree.

2. Assemble the triangle on the ground:

Once you have found the perfect position for the triangle, determine the exact dimensions.

Tip: In our experience, it is much easier to prefabricate the triangle construction on the ground.

Screw the triangle together with the V-bracket / 45°-Diamond Bracket on the floor – a flat surface is advantageous. The wooden beams are screwed together smoothly, notches and carpenter’s joints are not necessary. We recommend 3 – 4 wood screws ø 6 – 8 mm, galvanised, staggered, for each joist connection.

Tip: The Static Support is usually not pre-assembled on the triangle, but mounted directly on the upper GTS screw! This makes it easier to assemble the triangle in the tree: you can place the assembled triangle on the upper screw more easily, move it and align it, especially with crooked trees.

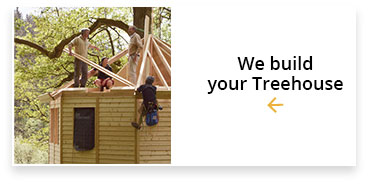

3. Assembly in the tree:

-

You have marked the exact position and alignment of the upper GTS.

-

You have prefabricated the triangle, neatly pinned it together and screwed on the lower bracket!

-

Now attach slings and ropes to the upper cross beam to lift the triangle into the tree.

-

Depending on the size of the triangle, other aids can make the work easier (pulley, slats, poles, carabiners, scaffolding, …).

Professional tip:

- Attach the triangle to two independent ropes on the left and right.

- Work in groups of at least three!

Step-by-step instructions:

- For the time being, only mount the upper GTS including the “Static Support” and Distance Rings. Be sure to grease the thread of the M30 nut beforehand, as you will often have to turn the nut down again later.

- Place the prefabricated triangular construction on the fixed bearing:

Now you still have a lot of room to move and you can move the upper crossbar freely!- Adjust the triangle horizontally and vertically with a spirit level.

Is the triangle centred at the bottom of the trunk –> position for the drill hole of the lower screw? - Make sure it is correctly aligned with the platform

- If necessary, move the whole triangle construction again a little on the “Static Support”.

- If everything is in order, fix the “Static Support” to the wooden beam with two small wood screws. The Static Support may have to be realigned later.

- Adjust the triangle horizontally and vertically with a spirit level.

- It is best to slide the necessary Distance Rings onto the upper screw now.

- Once everything is perfectly aligned, mark the lower screw hole of the “Bracket” and the exact position of the upper Static Support on the wooden beam (outline with a pencil).

- Swing the triangular construction aside and pre-drill the lower hole. VERY IMPORTANT: Make sure that both screw shafts point exactly in the same direction and are horizontal!!!

- Screw in the lower GTS and then loosen the nut with a jerk (be sure to grease the M30 thread beforehand!).

- Slide the entire structure onto the tree bolts (possibly with additional spacer rings).

- Check the perfect alignment of the triangle one last time.

- Fasten the nuts, the Static Support and all the remaining screws!

Other questions and solutions

Which GTS do I reinforce with “Strut GTS +” and “Cable Suspension”?

To make your triangle construction even more stable and load-bearing, you can reinforce the GTS. You can choose whether to reinforce the upper or lower bolt:

- Reinforcement only makes sense with the GTS Allstar.

- Reinforcement only makes sense with vertical loads.

The triangle cannot be pushed onto both screws at the same time!

- Probably the GTS screws are not perfectly screwed on top of each other and horizontally.

- Try to put the triangle on the shaft of the lower GTS first, and then bend / tap it onto the upper screw with a little force.

- It often helps to dismantle the fixed bearing completely.

Is the screw spacing of the GTS too large or too small?

- Too small: the Static Support hovers over the shaft -> simply shim it with a wooden block.

- Too big: Static Support does not fit on the shaft -> possibly let the Static Support into the cross beam (be careful not to go too far – stability of the beam must not be weakened!)

The beam is tilted too much to the front or back / the triangle hangs loosely in the air!?

- Make room for manoeuvre by reinforcing the top or bottom of the triangle with a wooden beam and doubling it up.

- You can then attach the Support to the extension, so that greater inclinations are possible.

- Sometimes a slight shift of the Static Support and turning of the Bracket helps.